Unitary solid chlorine dioxide sustained-release generating agent and preparation method thereof

A technology of chlorine dioxide and generators, applied in botany equipment and methods, biocides, plant growth regulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

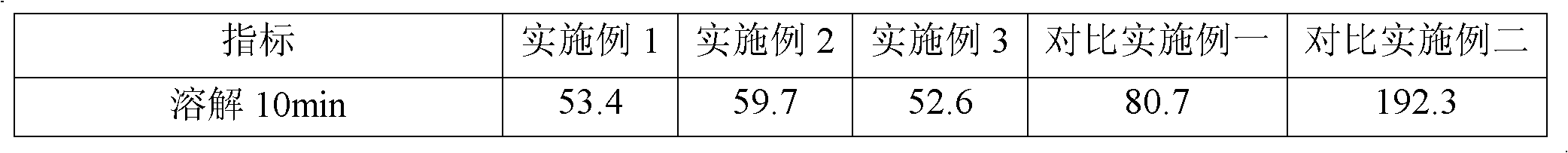

Examples

Embodiment 1

[0036]Under the condition that the ambient temperature is 17°C and the relative humidity is 35%, 20 kg of 100-mesh material is taken after sieving sodium chlorite, and dried at 80°C so that the water content is 0.43%; After sieving, take 25kg of 100-mesh material, dry at 80°C to make the water content 0.32%; take 0.5kg of 140-mesh material after sieving sodium chloride, and dry at 80°C to make the water content 0.43%. Dichloroisocyanuric acid After sodium sieving, take 0.5kg of 140-mesh material, dry at 80°C to make the water content 0.43%; take 0.5kg of 100-mesh material after sieving sodium hexametaphosphate, and dry at 80°C to make the water content 0.33%. After sieving sodium silicate, take 0.5kg of 100-mesh material, dry at 80°C to make the water content 0.47%; take 26.5kg of 100-mesh material after sieving sodium sulfate, and dry at 80°C to make the water content 0.32%; Take 5kg of 100-mesh material after sieving calcium chloride, and dry at 80°C to make the water conten...

Embodiment 2

[0039] Under the condition that the ambient temperature is 22°C and the relative humidity is 40%, take 23kg of 100-mesh material after sieving sodium chlorite, and dry at 80°C to make the water content 0.45%; After sieving, take 30kg of 100-mesh material, dry at 80°C to make the water content 0.32%; take 1kg of 140-mesh material after sieving sodium bromide, and dry it at 80°C to make the water content 0.22%. Take 1 kg of 140-mesh material, dry at 80°C to make the water content 0.05%; take 2 kg of 100-mesh material after sieving sodium pyrophosphate, and dry at 60°C to make the water content 0.48%; sieve sodium sulfate and take 100 mesh 13.5kg of material, dried at 60°C to make the water content 0.36%; 10kg of 100-mesh material was taken after sieving magnesium sulfate, and dried at 60°C to make the water content 0.10%; 100-mesh material was taken after sieving calcium stearate 15kg, dried at 80°C so that the water content is 0.14%; after sieving chitosan (degree of deacetylat...

Embodiment 3

[0042] Under the condition that the ambient temperature is 25°C and the relative humidity is 38%, 22 kg of 100-mesh material is taken after sieving sodium chlorite, and dried at 80°C so that the water content is 0.45%; After sieving, take 25.5kg of 100-mesh material, dry at 80°C to make the water content 0.34%; take 1kg of 140-mesh material after sieving sodium chloride, and dry at 80°C to make the water content 0.22%. Dichloroisocyanuric acid After sieving sodium hexametaphosphate, take 0.5kg of 140-mesh material, dry at 80°C to make the water content 0.34%; take 1kg of 100-mesh material after sieving sodium hexametaphosphate, dry at 80°C to make the water content 0.48%, and silicic acid After sodium sieving, take 0.5kg of 100-mesh material, dry at 80°C to make the water content 0.34%; take 15kg of 100-mesh material after sodium sulfate is sieved, dry at 80°C to make the water content 0.36%, and magnesium stearate After sieving, take 5kg of 100-mesh material, dry at 80°C to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com