Production method for ammoniated sulfur-based compound fertilizer by chemical synthesis

A technology for synthesizing ammoniated sulfur and production methods, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of not reaching 48% of total nutrients, low nitrogen utilization rate of compound fertilizers, and large decline in potassium content, reaching Easy to implement, improve the soil, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

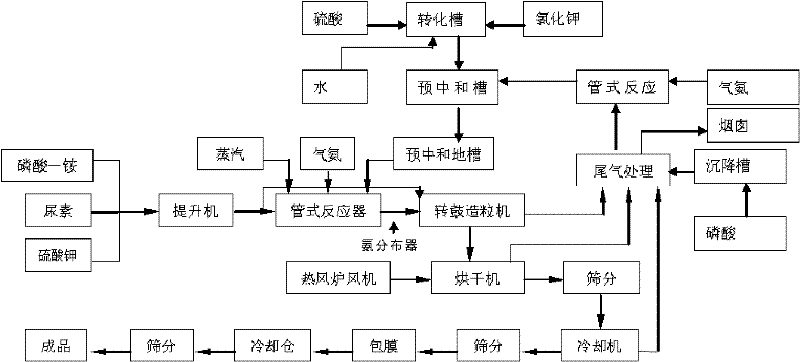

Image

Examples

Embodiment 1

[0018] The production method of the novel ammoniated sulfur-based compound fertilizer of this implementation is as follows:

[0019] (1) Phosphate P 2 o 5 Phosphoric acid with a concentration of 20.8% first enters the settling tank for sedimentation, the solid content of phosphoric acid is 1.5%, and then enters the tail gas of the compound fertilizer to absorb and neutralize the incomplete residual gas ammonia, and then enters the mixed acid tank for mixing with potassium bisulfate, sulfuric acid and chlorination Potassium is put into the potassium hydrogen conversion tank in proportion, the temperature of the conversion tank is 128°C, and the feeding amount is 3 tons of potassium chloride. At the same time, 0.4 cubic meters of water is added to the conversion tank to generate potassium bisulfate and enter the mixed acid tank, and the materials in the mixed acid tank The ratio is 1 ton of potassium chloride: 0.69 square sulfuric acid: 3.0 square phosphoric acid, then ventilat...

Embodiment 2

[0023] (1) Phosphate P 2 o 5 Phosphoric acid with a concentration of 20.3% first enters the settling tank for sedimentation, the solid content of phosphoric acid is 1.2%, and then enters the tail gas of the compound fertilizer to absorb and neutralize the incomplete residual gas ammonia, and then enters the mixed acid tank for mixing with potassium bisulfate, sulfuric acid and chlorination Potassium is put into the potassium hydrogen conversion tank in proportion, the temperature of the conversion tank is 136°C, and the feeding amount is 6 tons of potassium chloride. At the same time, 0.8 cubic meters of water is added to the conversion tank to generate potassium bisulfate and enter the mixed acid tank, and the materials in the mixed acid tank The ratio is 1 ton of potassium chloride: 0.69 square sulfuric acid: 3.1 square phosphoric acid, and then ammonia is ventilated into the mixed acid tank, and the pH value after neutralization is 0.8, and then it is transported to the tub...

Embodiment 3

[0027] (1) Phosphate P 2 o 5 Phosphoric acid with a concentration of 20.5% first enters the settling tank for sedimentation, the solid content of phosphoric acid is 2.0%, and then enters the tail gas of the compound fertilizer to absorb and neutralize the remaining incomplete gas ammonia, and then enters the mixed acid tank for mixing with potassium bisulfate, sulfuric acid and chlorination Potassium is fed into the potassium hydrogen conversion tank in proportion, the temperature of the conversion tank is 115°C, and the feeding amount is 5 tons of potassium chloride. At the same time, 0.6 cubic meters of water is added to the conversion tank to generate potassium bisulfate and enter the mixed acid tank. The ratio is 1 ton of potassium chloride: 0.69 square sulfuric acid: 3.05 square phosphoric acid, and then ammonia is ventilated into the mixed acid tank, and the pH value after neutralization is 0.9, and then it is transported to the tubular reactor by a pump, and the ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com