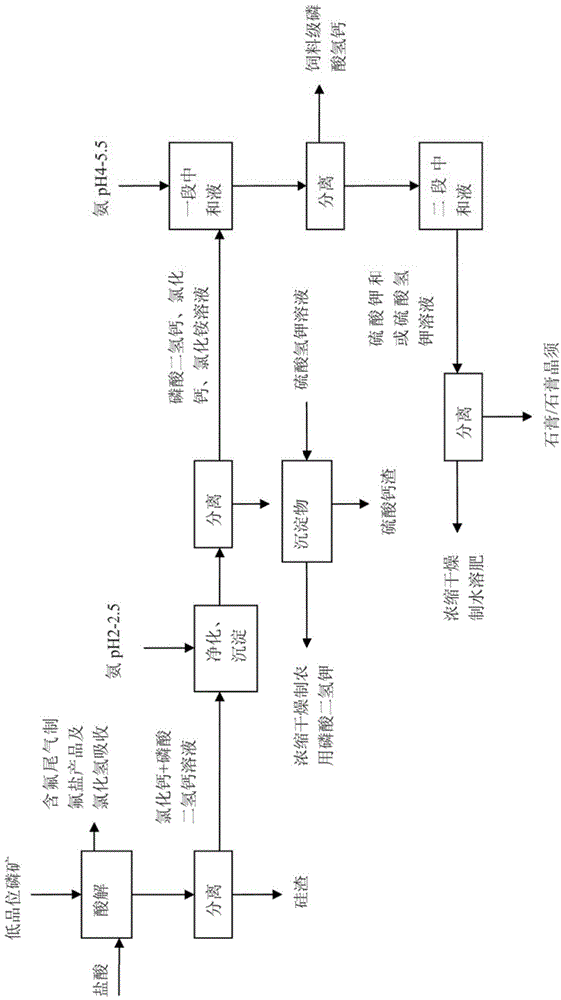

Method of combined production of multiple phosphates and phosphate fertilizer from low grade phosphate ore

A low-grade, phosphate technology, applied in the fields of phosphate, chemical instruments and methods, phosphorus oxyacids, etc., can solve the problems of long and complicated production process, not considering environmental pollution, difficult to realize industrial production, etc. The technology is simple and easy to implement, the production process technology is simplified, and the effect of improving the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments.

[0026] The phosphate rock powder used in the present invention is produced in Susong County, Anhui Province, and the main components are shown in the following table:

[0027] P 2 o 5 %

Mg0

Fe 2 o 3

al 2 o 3

CaO

16.37

0.28

1.36

7.11

22.12

17.38

1.86

1.60

5.53

28.78

21.31

1.16

3.08

3.77

40.72

[0028] The steps that the present invention adopts are as follows:

[0029] (1) Phosphate rock extraction. The phosphate rock powder is decomposed under the condition of 50-80 DEG C by using hydrochloric acid with a concentration of 10%-25% by weight, and the pH value of the extraction end point is controlled at 1.0-1.5. Filter and separate the silicon slag that cannot be hydrolyzed by acid to obtain an extract containing calcium dihydrogen phosphate and calcium chloride. The fluorine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com