Production method of potassium dihydrogen phosphate

A technology of potassium dihydrogen phosphate and its production method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc. It can solve the problems of high production cost, expensive raw materials, excessive chloride ion content, etc., so as to reduce equipment investment and reduce production Cost, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

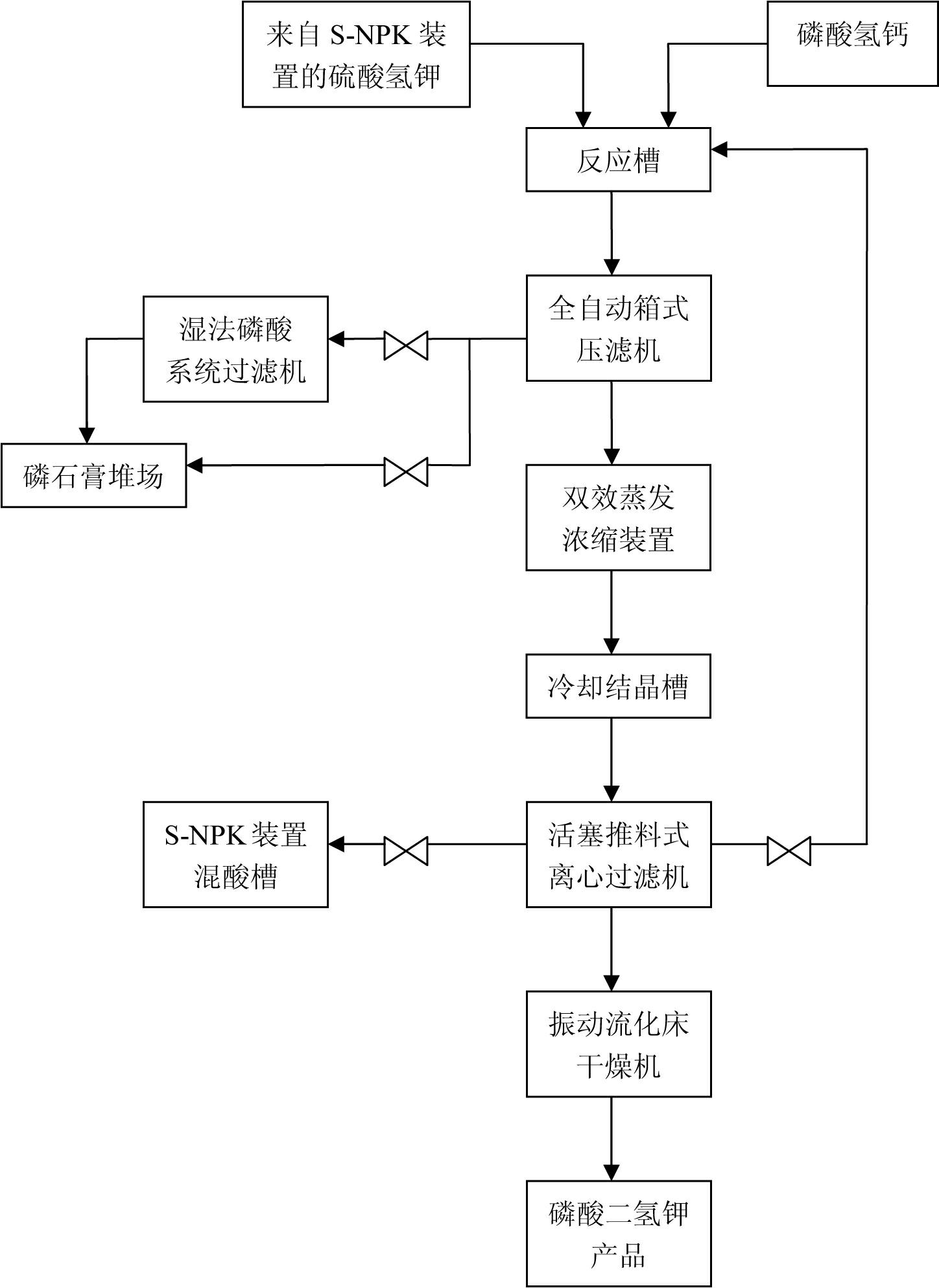

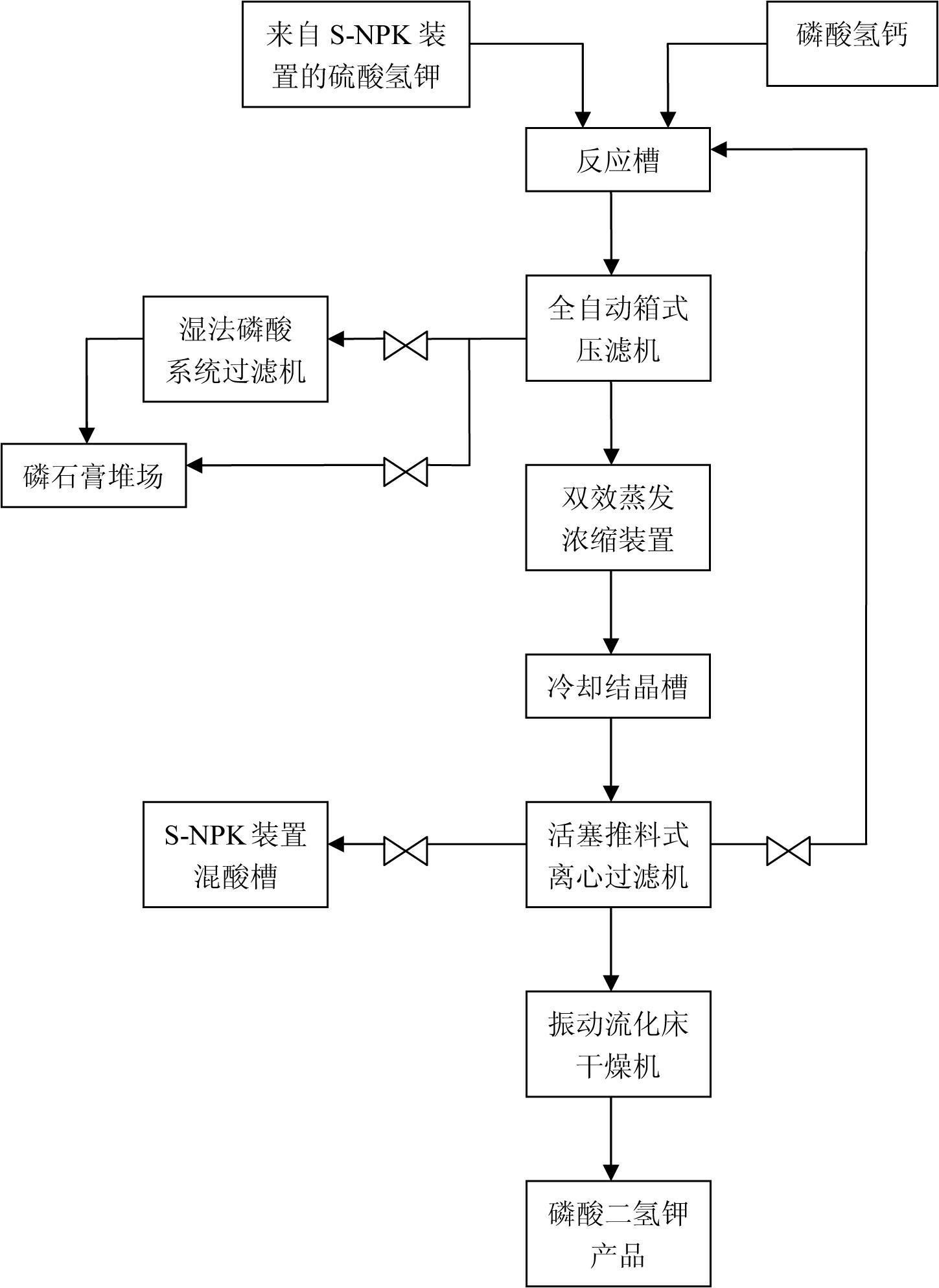

Image

Examples

Embodiment 1

[0019] Take out part of the potassium bisulfate solution in the potassium bisulfate section of the high-concentration sulfur-based compound fertilizer production process (S-NPK device) and add it to the potassium dihydrogen phosphate reaction tank, and then add the potassium bisulfate solution with a molar ratio of 1 to the reaction tank. : 1 ~ 1: 1.05 powdered calcium hydrogen phosphate, react for 6 hours under the condition of full stirring, the reaction temperature is 70 ~ 85 ℃, the slurry after the reaction is filtered by a fully automatic box filter press, and the filter residue is sent to the wet After being filtered by the French phosphoric acid system filter, it is sent to the phosphogypsum storage yard or directly to the storage yard for storage. The filtrate is potassium dihydrogen phosphate solution, which is sent to the evaporation concentration device for concentration; the concentrated supersaturated solution enters the cooling crystallization tank for cooling and ...

Embodiment 2

[0021] Take out part of the potassium bisulfate solution in the potassium bisulfate section of the high-concentration sulfur-based compound fertilizer production process (S-NPK device) and add it to the potassium dihydrogen phosphate reaction tank, and then add the potassium bisulfate solution with a molar ratio of 1 to the reaction tank. : 1 ~ 1: 1.05 powdered calcium hydrogen phosphate, react for 3 hours under the condition of full stirring, the reaction temperature is 80 ~ 90 ℃, the slurry after the reaction is filtered by a fully automatic box filter press, and the filter residue is sent to the wet After being filtered by the French phosphoric acid system filter, it is sent to the phosphogypsum storage yard or directly to the storage yard for storage. The filtrate is potassium dihydrogen phosphate solution, which is sent to the evaporation concentration device for concentration; the concentrated supersaturated solution enters the cooling crystallization tank for cooling and ...

Embodiment 3

[0023] Take out part of the potassium bisulfate solution in the potassium bisulfate section of the high-concentration sulfur-based compound fertilizer production process (S-NPK device) and add it to the potassium dihydrogen phosphate reaction tank, and then add the potassium bisulfate solution with a molar ratio of 1 to the reaction tank. : 1 powdered calcium hydrogen phosphate, react for 5 hours under the condition of full stirring, the reaction temperature is 80-85°C, the slurry after the reaction is filtered by a fully automatic box-type filter press, and the filter residue is sent to the wet-process phosphoric acid system for filtration After being filtered by the machine, it is sent to the phosphogypsum storage yard or directly to the storage yard for storage. The filtrate is potassium dihydrogen phosphate solution, which is sent to the evaporation and concentration device for concentration; the concentrated supersaturated solution enters the cooling crystallization tank fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com