Efficient plywood gluing device

A gluing device and a technology for plywood, applied in the field of plywood, can solve the problems of unfavorable plywood forming quality, inability to dry quickly, and uneven gluing, etc., and achieve the effects of rapid drying, speeding up production efficiency, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

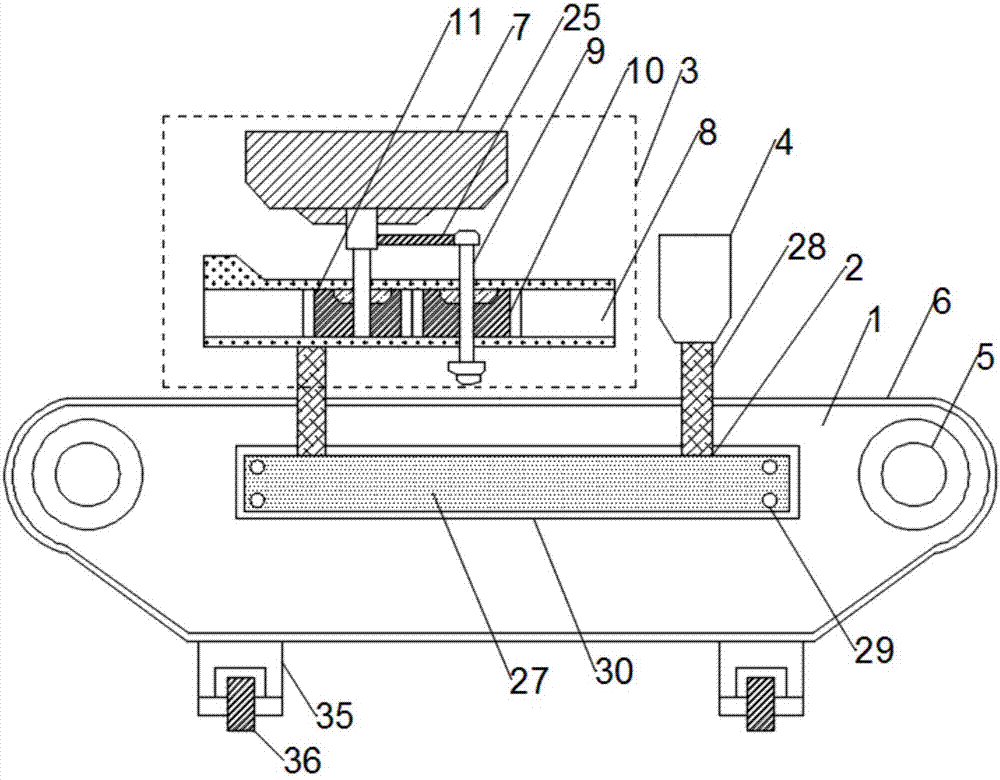

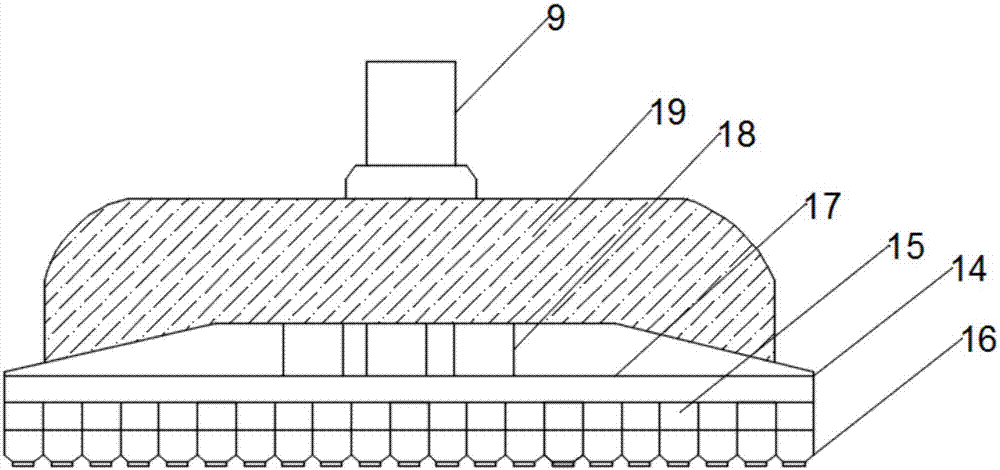

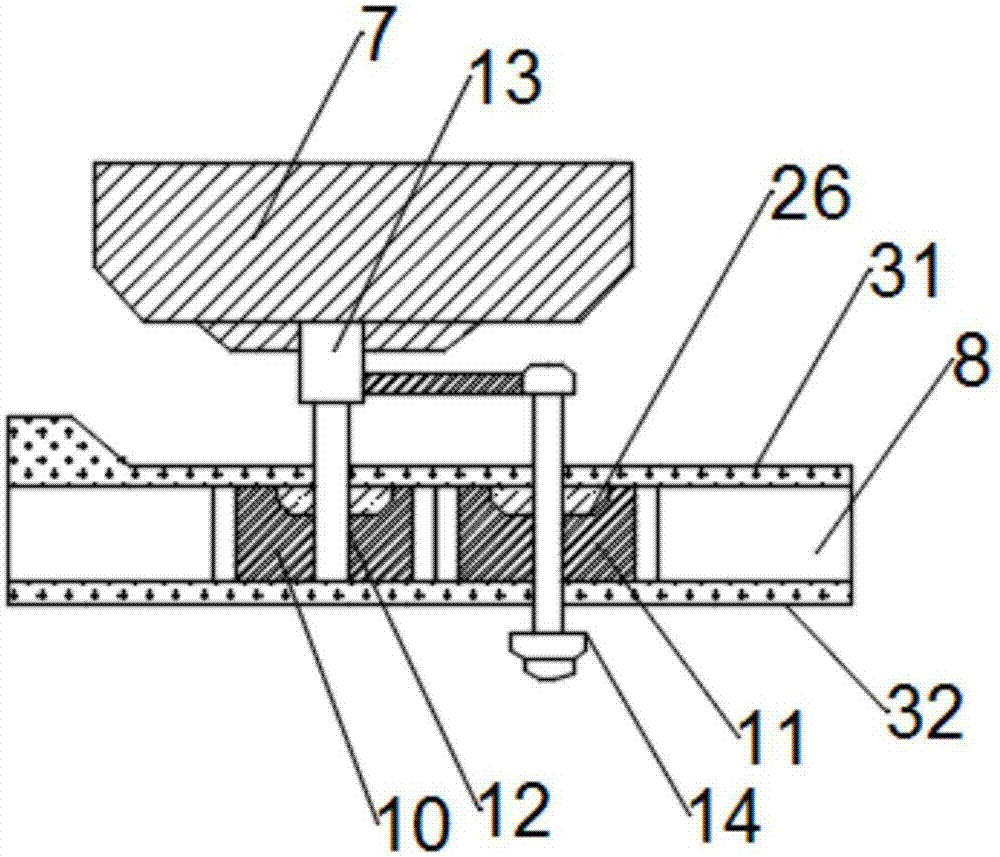

[0023] Such as Figure 1-5 As shown, the present invention provides a plywood high-efficiency gluing device, comprising a conveyor table 1, a mounting frame 2, a gluing device 3 and a drying device 4, the mounting frame 2 is fixedly installed on the side of the conveyor table 1, and the coating Both the glue device 3 and the drying device 4 are fixedly installed together through the mounting frame 2 and the transfer table 1, and the transfer table 1 is provided with a drive motor 5 inside, and the drive motor 5 drives the transfer plate 6 to rotate to realize the transfer and transportation. The gluing device 3 comprises a rotating motor 7, a support shell 8 and a screw 9, and the support shell 8 is provided with a first planetary gear 10 and a second planetary gear 11 inside, and between the first planetary gear 10 and the second planetary gear 11 The transmission shaft 12 is arranged at the inner center of the first planetary gear 10, and the other end of the transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com