Patents

Literature

30results about How to "No moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry charge type zinc air cell

InactiveCN1617383ASolve the technical problems of self-dischargeImprove performanceFuel and primary cellsZinc–air batteryZinc

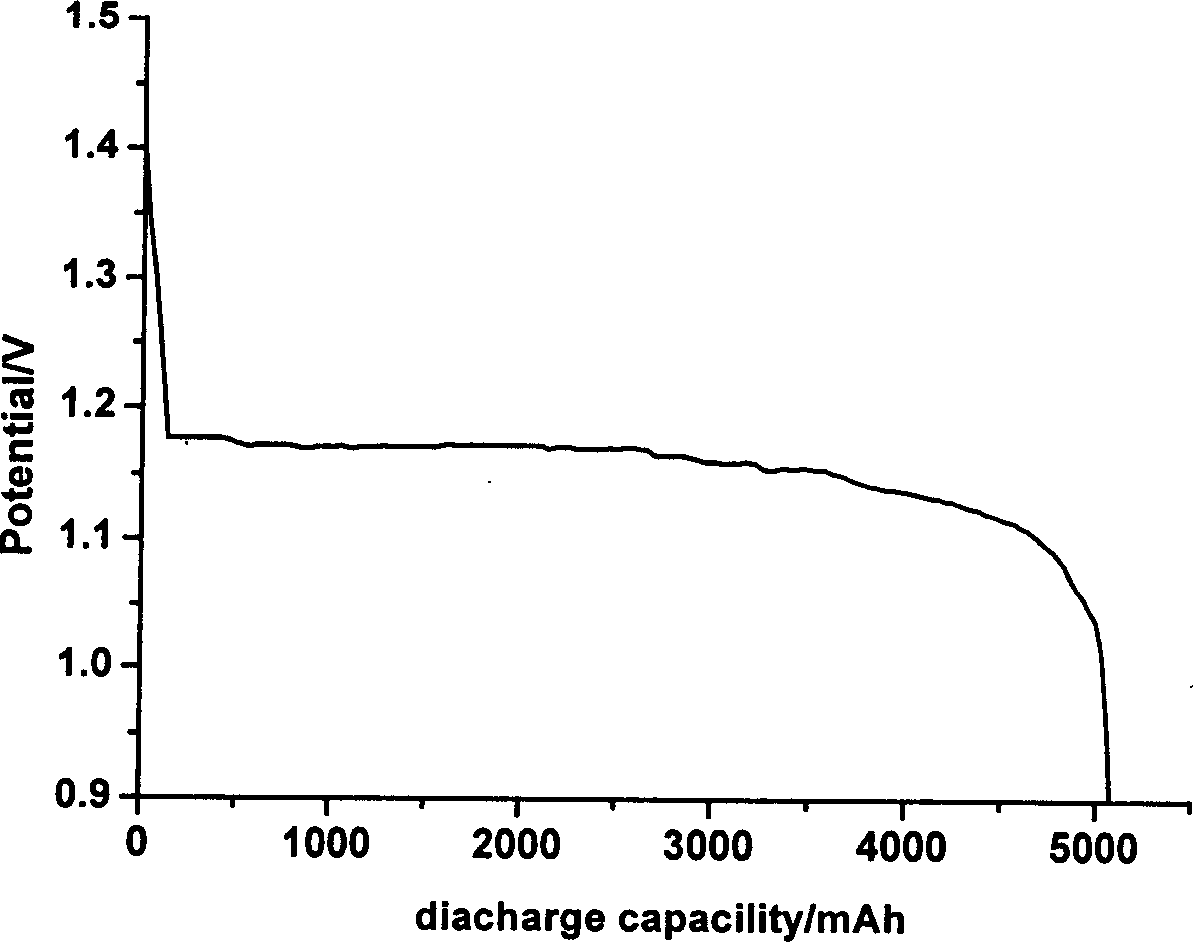

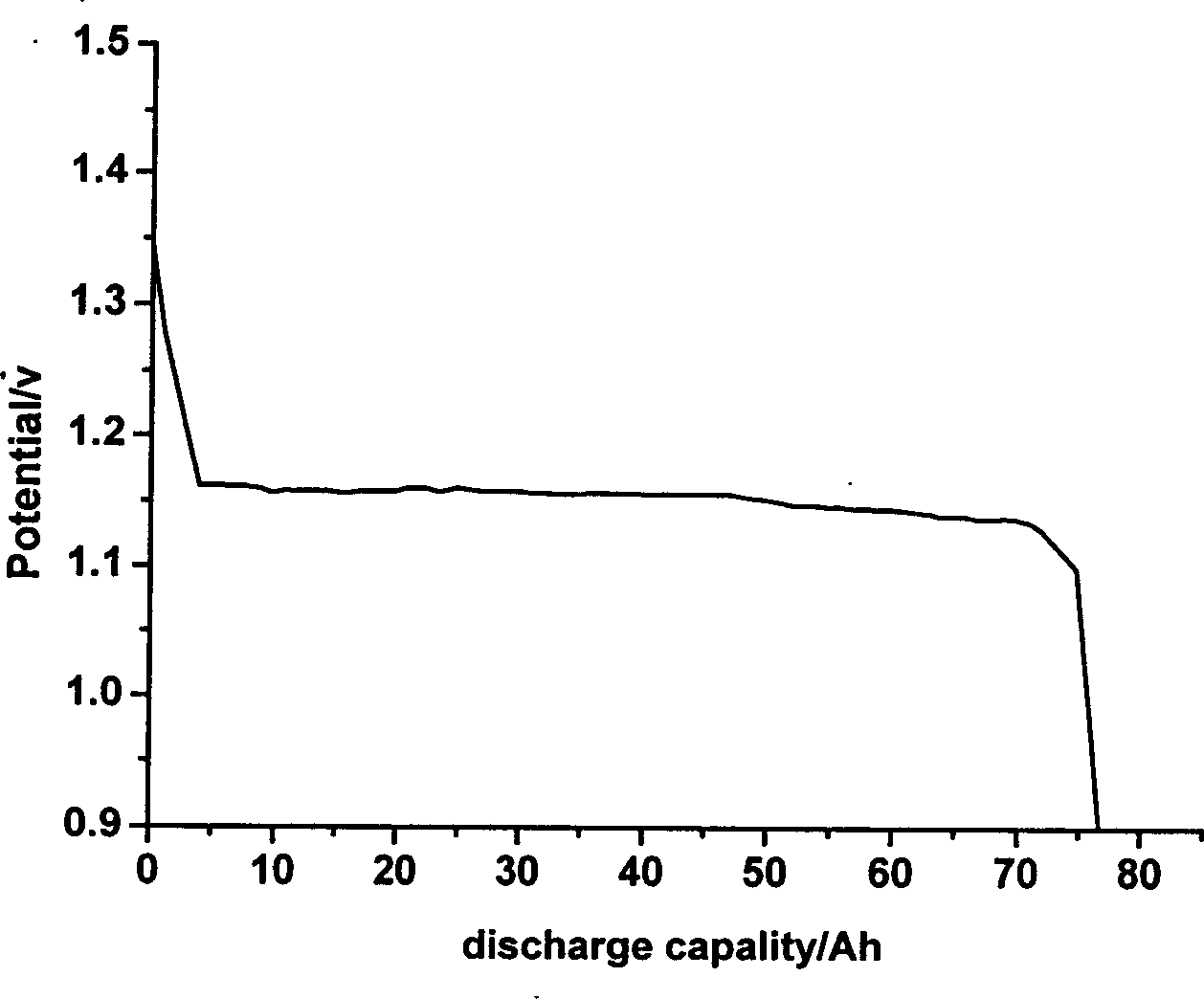

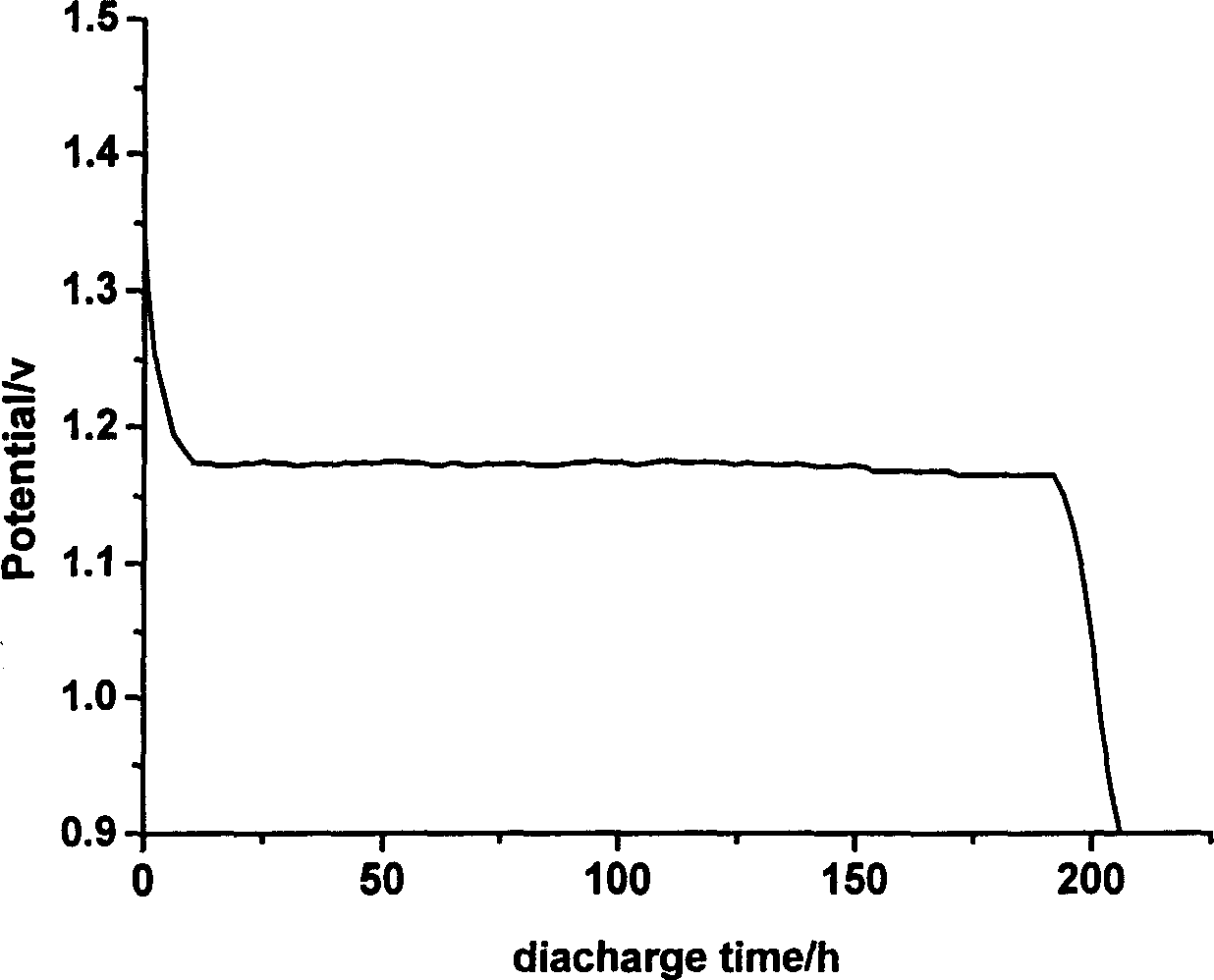

This invention relates to a dry charge Zn air battery including an electrolyte solution and an air diffusion electrode as the positive and a Zn electrode as the negative formed by dry-pressing active Zn powder at one run, the battery shell has an injection inlet for injecting electrolyte solution set at outside of the shell to be injected when using, the porous Zn electrode is formed by mixing inhibitor and Zn powder in the quality proportion of 1-5:100, then to mix the pore-former and mixture in the quality ratio of 1-8:100 to be dry-pressed to Zn electrode under 10-20Mpa and heated for 5-40min under 80-300deg.C

Owner:SOUTH CHINA UNIV OF TECH

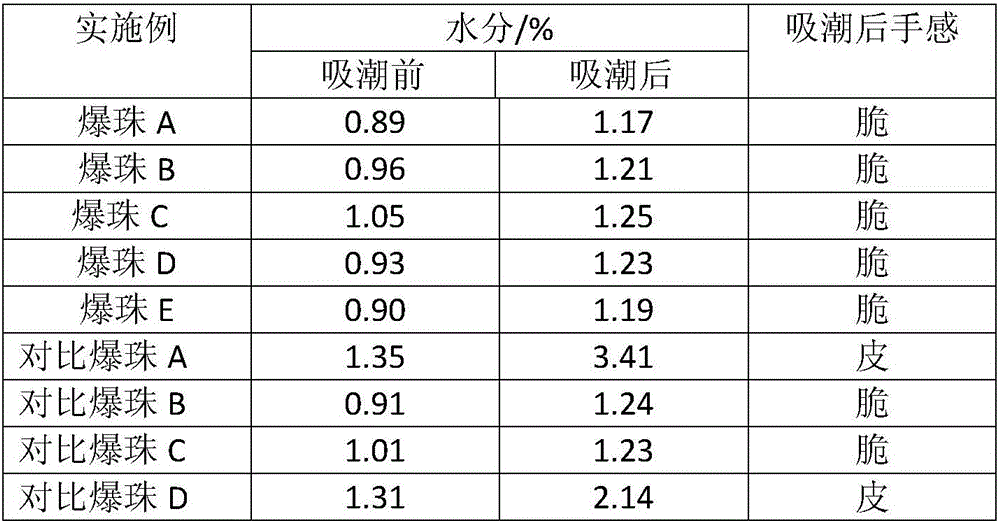

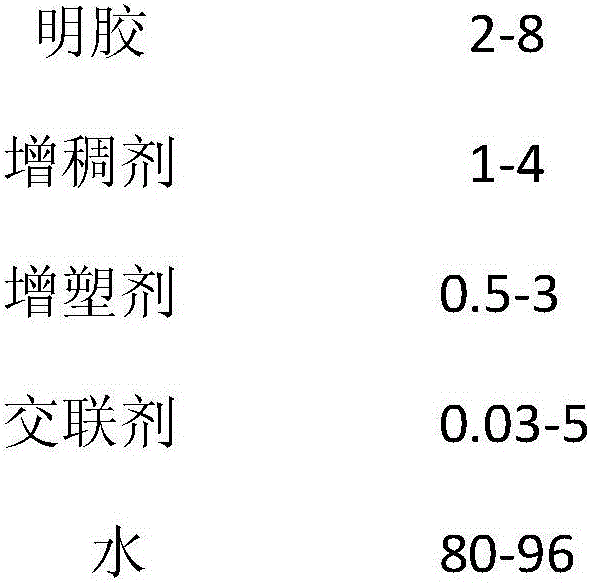

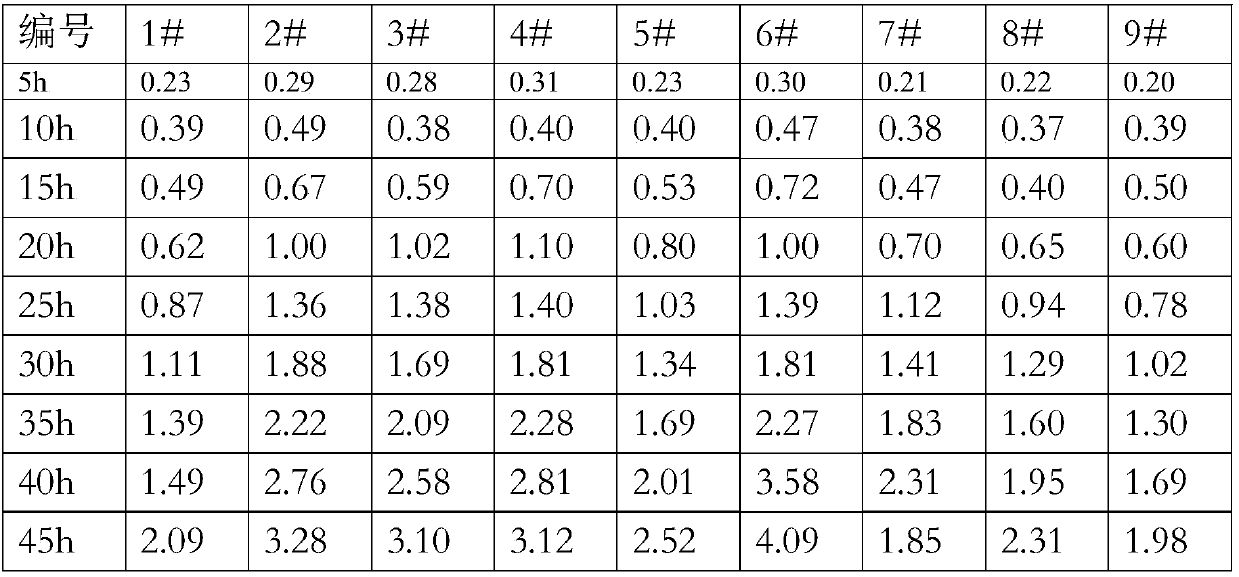

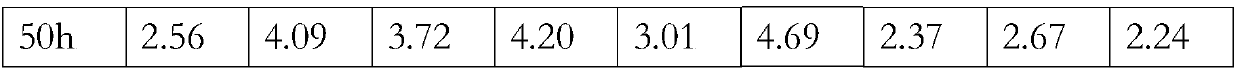

High-weatherability cigarette blasting bead rubber material and preparation method thereof

ActiveCN106497088AImprove performanceEquilibrium moisture content decreasedTobacco smoke filtersRubber materialWater baths

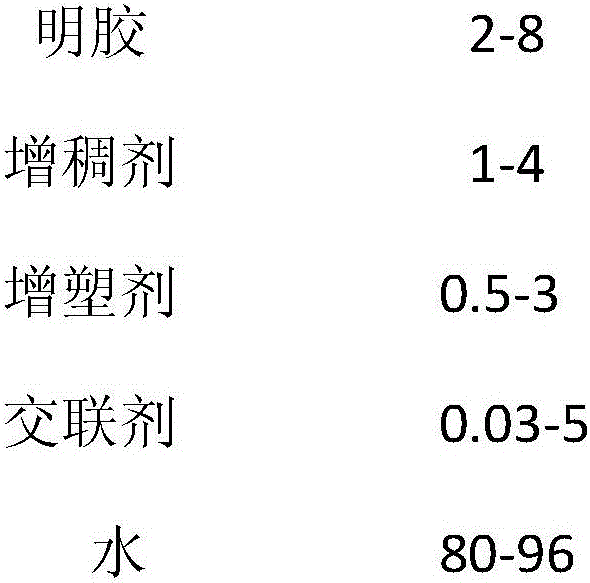

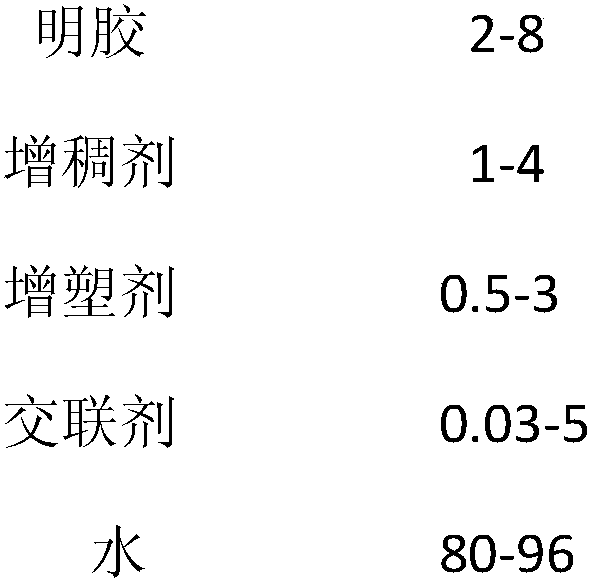

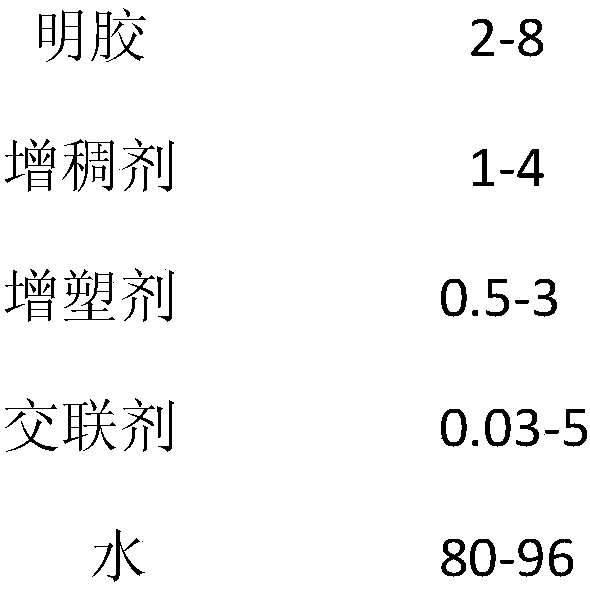

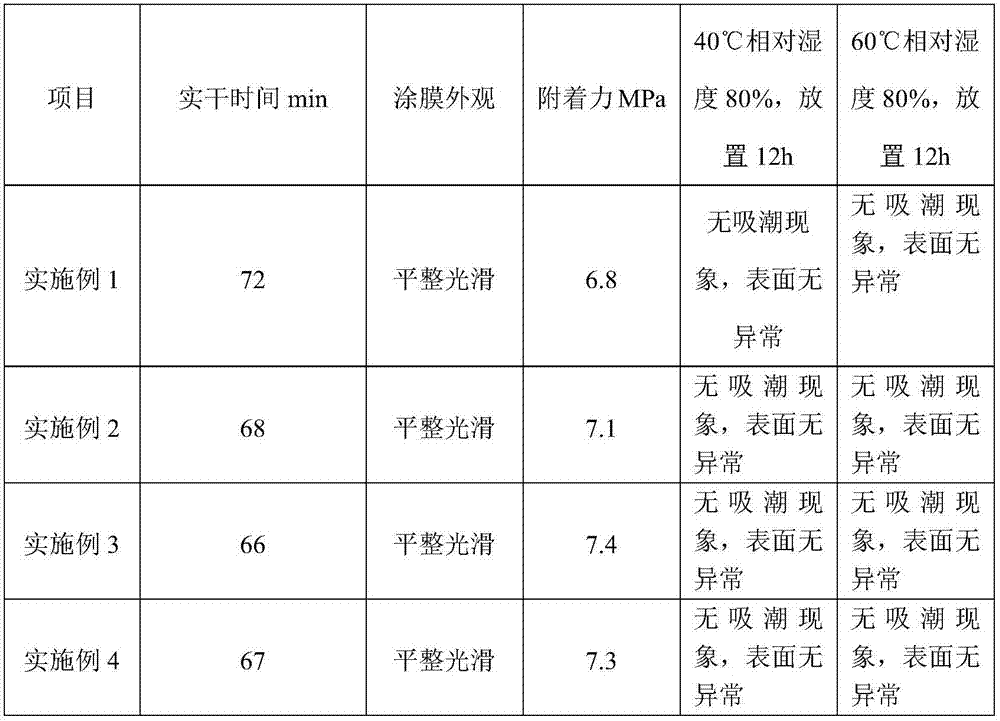

The invention provides a high-weatherability cigarette blasting bead rubber material and a preparation method thereof. The preparation method of the blasting bead rubber material includes the steps: mixing 1-4 parts of thickening agents and 80-96 parts of water by weight; heating mixture in a water bath to reach the temperature of 50-90 DEG C; stirring and dissolving the mixture into uniform solution and then adding 2-8 parts of gelatin and 0.5-3 parts of plasticizers; continuing heating and dissolving for 1-2 hours at the temperature of 50-70 DEG C; uniformly mixing the mixture and adding 0.03-5 parts of cross-linking agents; performing stirring reaction for 15 minutes to 1 hour; standing; filtering the mixture in a heat insulation state after foam floats and the filtrate is filtered to obtain the cigarette blasting bead rubber material. The cross-linking agents are added into a gelatin system, the performance of a gelatin film is improved by the cross-linking function of aldehydes for the gelatin, so that the equilibrium moisture content of blasting bead rubber is reduced, a blasting bead prepared from the rubber material is good in weatherability, and adaptability of the blasting bead to environmental temperature-humidity change in a high-humidity environment is improved.

Owner:HUBEI CHINA TOBACCO IND

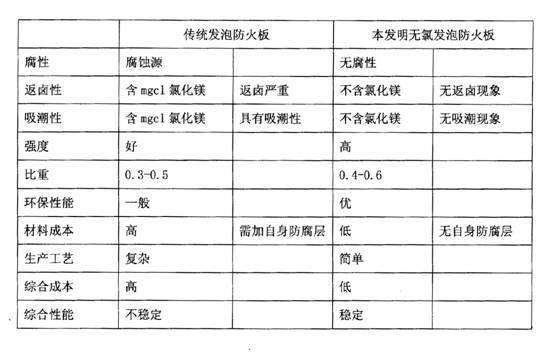

Environment-friendly foaming fireproof plate and preparation method thereof

InactiveCN101851111ANo corrosionNo reversionCeramic shaping apparatusWater-setting substance layered productGlass fiberPhosphoric acid

The invention relates to a non-corrosive environment-friendly foaming fireproof plate and a preparation method thereof. The non-corrosive environment-friendly foaming fireproof plate comprises the following materials in parts by weight: 500-1000 parts of magnesium oxide (MgO), 60-120 parts of magnesium sulfate (MgSO4), 200-500 parts of kaolin (Al2O3-2SiO2-2H2O), 20-30 parts of phosphoric acid (H3PO4), 50-200 parts of hydrogen peroxide (H2O2) and 50-200 parts of water (H2O5). The preparation method comprises the following steps: 1) preparing composite synthesis: firstly placing the magnesium sulfate and water into a container for fully stirring, then adding stirred liquid into magnesium oxide for fully stirring, and then adding little amount of magnesium sulfate for stirring; after stirring evenly, adding proper amount as bonding fireproof filler, and finally adding the hydrogen peroxide; 2) step 1) carrying out oxidation and foaming on the prepared composite synthesis; 3) entering a mold upper pressing machine for shaping according to needed specification after foaming, and adding sizing glass fiber cloth and a surface pulp layer with the thickness of 1-2mm are added on the surface; and 4) finally, entering the mold upper pressing machine for shaping again to obtain a finished product. The product of the invention does not contain magnesium chloride, has phenomena of no corrosion, no halogenide return and no moisture absorption, but also greatly reduces the cost, has no toxicity and pollution, is environment-friendly and has no harm to a human body.

Owner:雷震

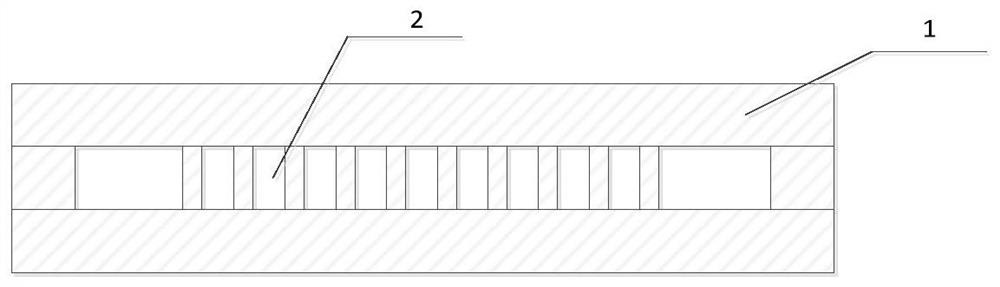

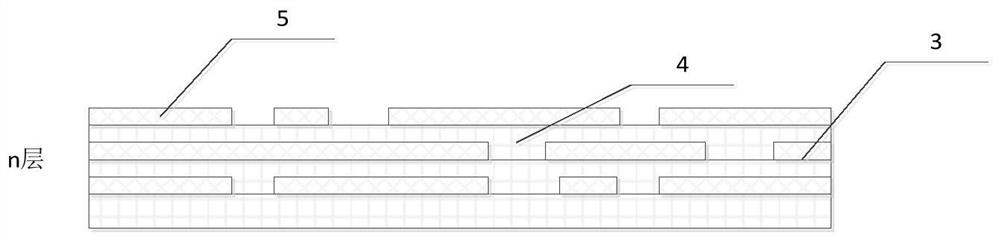

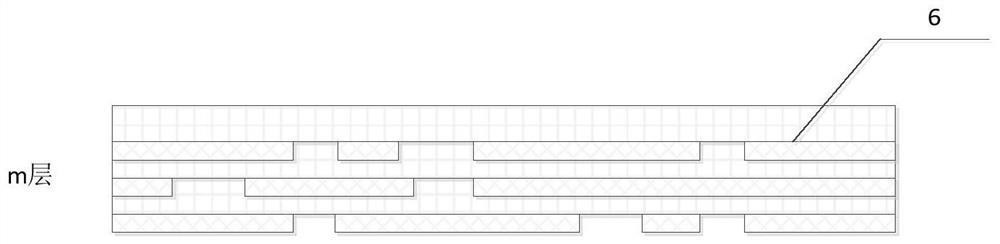

Printed circuit board with embedded micro-channels and preparation method of printed circuit board

ActiveCN113056087AAchieving Density CoolingImprove cooling effectPrinted circuit aspectsPrinted circuit manufactureHigh densityEngineering

The invention discloses a printed circuit board with embedded micro-channels. The printed circuit board comprises an embedded micro-channel metal core plate, wherein the top part of the embedded micro-channel metal core plate is provided with n wiring layers I, the bottom part of the embedded micro-channel metal core plate is provided with m wiring layers II, and the printed circuit board is provided with a liquid inlet and a liquid outlet which are communicated with the micro-channel. The structure has efficient heat dissipation capability, can realize transmission of high-density electrical signals, and meets the application requirements of high-density integrated high-power electronic devices.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Impregnating inorganic salt technology for anti-oxidation of carbon-graphite product

The invention relates to the field of preparation of carbon-graphite materials, and specifically discloses an impregnating inorganic salt technology for anti-oxidation of a carbon-graphite product. The technology comprises the following steps : (1) pressurizing and impregnating: (1.1) heating a product in a drying oven, putting the heated product in an impregnating barrel, and then putting the impregnating barrel together with the heated product in a stainless steel vacuum tank for vacuumizing; (1.2) introducing an impregnating solution a which is heated to a boiling state into an impregnatingvacuum tank under the condition of keeping a vacuum state, introducing air after the product is immerse in the impregnating solution, finally opening the vacuum tank and taking out the product and the impregnating barrel; (1.3) putting the product and the impregnating barrel in a lower bell jar of a hydraulic machine, and then sequentially sealing, pressurizing, maintaining pressure, relieving the pressure, pouring the impregnating solution and taking out the product; (2) curing the product; (3) carrying out secondary impregnation. Through the technology disclosed by the invention, the problem of high-temperature oxidation resistance of the carbon-graphite product can be solved, the situations that in the air of which the temperature is 650 DEG C, the anti-oxidation weight loss ratio is lower than 5 percent and the density increment rate is not smaller than 6 percent, and a treated material has no a moisture absorption phenomenon in the air.

Owner:ZIGONG DONGXIN CARBON CO LTD

Traditional Chinese medicine preparation for controlling pullorosis salmonellosis and preparation method thereof

InactiveCN103623134AUniform sizeSimple preparation processAntibacterial agentsAnimal feeding stuffBiotechnologySalmonella frintrop

The invention provides a traditional Chinese medicine preparation for controlling pullorosis salmonellosis. The traditional Chinese medicine preparation is characterized by being prepared from the following extracts in parts by weight: 3 to 5 parts of polygonum cuspidatum extract, 1 to 2 parts of fructus chebulae extract, and 1 to 2 parts of herba violae extract. The prepared traditional Chinese medicine compound particles are uniform in size, consistent in color and luster, and free of moisture adsorption, caking, deliquescence and other phenomena, meet the requirements of Chinese Pharmacopoeia, and are controllable in quality. The pharmacodynamics study shows that the traditional Chinese medicine preparation can be used for preventing and treating pullorosis salmonellosis.

Owner:SICHUAN AGRI UNIV

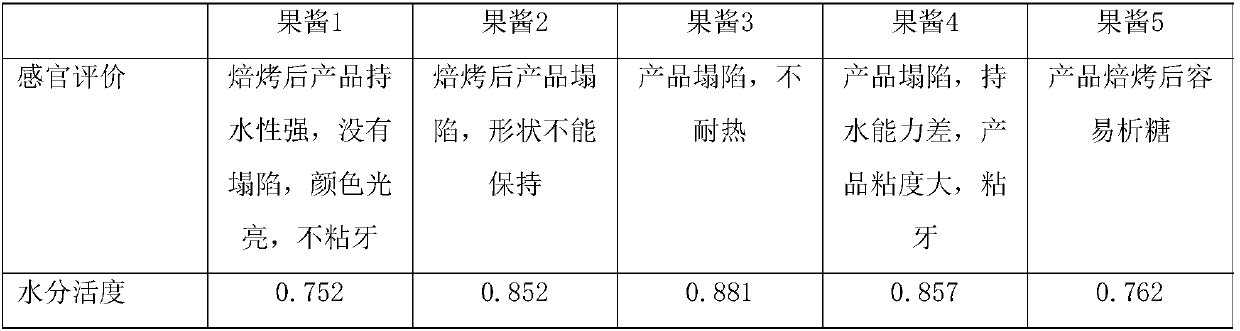

Low-viscosity, baking-resisting and oil-free fruit jam with long shelf life and preparation method thereof

The invention creatively provides low-viscosity, baking-resisting and oil-free fruit jam with long shelf life and a preparation method thereof. The fruit jam prepared by the method has the advantagesof high temperature resistance, relatively less water loss and no collapsing; the content of solid matters of finished-product jam is 60 percent to 70 percent and the water activity is 0.70 to 0.80; the fruit jam has a wet mouthfeel and is not stuck on teeth and nutrients and flavor can be ensured; and meanwhile, oil is not added, the fruit jam can be stored for a long period and has a more fine and smooth mouthfeel; and the fruit jam is suitable for more consumers to eat.

Owner:GREEN JUICE IND TIANJIN

Jasmine flower green bean cakes and production method thereof

InactiveCN106509645APure tasteLoose tasteFood preservationLipidic food ingredientsBiotechnologyVegetable oil

The invention discloses jasmine flower green bean cakes and a production method thereof. The jasmine flower green bean cakes are made from the following effective components and raw materials in parts by weight: 30-50 parts of vigna radiata, 10-20 parts of white granulated sugar, 5-8 parts of vegetable oil, 8-12 parts of trehalose, 2-5 parts of edible salt, 3-5 parts of potassium sorbate, 3-6 parts of sodium dehydroacetate, 3-7 parts of jasmine flower essential oil, 25-40 parts of fresh jasmine flower petals and 5-12 parts of purified water. The production method comprises the following steps of uniformly mixing the raw materials, and then performing compression molding through a filler molding machine so as to obtain the jasmine flower green bean cakes. Through the raw materials and the production method of the jasmine flower green bean cakes disclosed by the invention, the jasmine flower green bean cakes disclosed by the invention have unique flavor, can maintain specific flavor in a long time, and have the characteristics of being pure, loose, fragrant and soft in mouth feel; and the jasmine flower green bean cakes have full-bodied jasmine flower fragrance, so that the appetite can be greatly stimulated, when the jasmine flower green bean cakes are put into mouths, long aftertaste is generated, and the jasmine flower green bean cakes have the characteristics of being long in fresh keeping period, long in storage period and the like.

Owner:广西横县百利食品有限公司

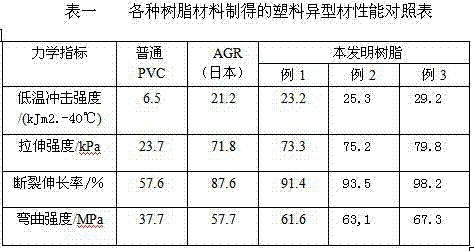

Preparation method and product of vinyl chloride, acrylate multi-copolymerized resin by mass polymerization process

The invention discloses a preparation method and a product of vinyl chloride, acrylate multi-copolymerized resin by mass polymerization process; a vinyl chloride pre-polymerized product is prepared firstly by a mass polymerization process, and the pre-polymerized product is copolymerized with two or more acrylates. The method has the characteristics of short time, high yield, easily-controllable polymerization degree, and low energy consumption; the process is simple, and the conditions are easy to control; the prepared product has the characteristics of low temperature resistance, corrosion resistance, overpressure resistance, high impact resistance, good rigidity, small linear expansion coefficient, and long service life, also has less electrolyte contents, high purity, good whiteness, uniform resin particles, good product transparency, and good plasticizing property, can substitute high-grade resin obtained by an ethene method, and is widely applicable to the production of high-end products.

Owner:NEIJIANG YUNTONG PLASTIC AUX

Method for preparing fireproof high-temperature resistant plate

InactiveCN107200998AHigh thermal decomposition temperatureImprove fire resistanceFlat articlesPolyethylene glycolMoisture absorption

The invention discloses a method for preparing a fireproof high-temperature resistant plate. The method comprises the following steps: uniformly mixing melamine, formaldehyde and water, adjusting the pH value of the system to be 9-9.7 by using sodium hydroxide, performing heating stirring, adding microcrystalline cellulose and cocamidopropyl betaine, adjusting the pH value of the system to 5-5.4 by using hydrochloric acid, adding castor oil and polyethylene glycol, stirring, and cooling so as to obtain pretreated microcrystalline cellulose; uniformly mixing phenolic aldehyde epoxy resin, polyamide resin, microencapsulated red phosphorus and ammonium polyphosphate, adding water and tartaric acid, uniformly stirring, further adding the pretreated microcrystalline cellulose, calcium sulfate, fumed silica, talcum powder and magnesium hydrate, uniformly mixing and stirring, performing pressing molding in a mold, and cooling to the room temperature, thereby obtaining the fireproof high-temperature resistant plate. The fireproof high-temperature resistant plate is good in compatibility, excellent in fire and high temperature resistance, excellent in water resistance and free of moisture absorption phenomenon.

Owner:安徽三义和能源科技有限公司

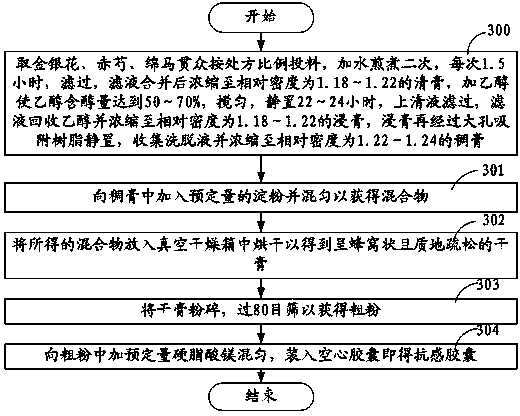

Anti-common cold capsule preparation method

InactiveCN103638122AReduce consumptionLoose textureCapsule deliveryRespiratory disorderMoisture absorptionEnergy source

The invention relates to an anti-common cold capsule preparation method, which comprises: taking honeysuckle, red peony root and dryopteris crassirhizoma, feeding the materials according to a certain ratio, adding water, decocting twice, filtering, mixing the filtrates, concentrating to obtain a clear paste with a relative density of 1.18-1.22, adding ethanol to achieve an ethanol alcohol content of 50-70%, uniformly stirring, standing to obtain a supernatant, filtering, recovering ethanol from the filtrate, concentrating to obtain an extract with a relative density of 1.18-1.22, standing the extract through a macroporous absorption resin, collecting the eluent, concentrating to obtain a thick paste with a relative density of 1.22-1.24, adding starch to the thick paste, uniformly mixing to obtain a mixture, placing the mixture into a vacuum dry box to dry to obtain a honeycomb dry paste with loose texture, crushing the dry paste, screening to obtain coarse powder, adding magnesium stearate to the coarse powder, uniformly mixing, and filling into a hollow capsule to obtain the anti-common cold capsule. According to the present invention, stability of the product can not be affected, energy source consumption can be reduced, the dried dry paste has the loose texture so as to be easily collected, crushed and screened, and no moisture absorption phenomenon is generated when filling the coarse powder into the hollow capsule.

Owner:NINGXIA DUOWEI PHARMA

Crystalline mixture solid containing maltitol and preparation therefor

InactiveUS6863737B2Eliminate the problemImprove solubilitySugar derivativesSugar productsSolubilityMaltitol

A crystalline mixture solid containing maltitol having an oil absorptivity of 0.1 to 6.9 wt % and a bulk density of 0.60 to 0.75 g / cc when it is ground and classified to ensure that at least 70 wt % of the obtained particles should have a particle size of 16 to 50 mesh and a process for producing a crystalline mixture solid containing maltitol, comprising introducing air bubbles into a maltitol aqueous solution. According to this process, a crystalline mixture solid containing maltitol having high solubility and almost no moisture absorption is produced at a high work efficiency and a low cost in a short period of time.

Owner:UENO FINE CHEM IND LTD

Jasmine flower cakes and production method thereof

The invention discloses jasmine flower cakes and a production method thereof. The jasmine flower cakes are prepared from the following effective components and raw materials in parts by weight: 25 to 40 parts of flour, 30 to 50 parts of mung beans, 10 to 20 parts of white granulated sugar, 5 to 8 parts of plant oil, 8 to 12 parts of trehalose, 2 to 5 parts of edible salt, 3 to 5 parts of potassium sorbate, 3 to 6 parts of sodium dehydroacetate, 3 to 7 parts of jasmine flower essence, 25 to 40 parts of fresh jasmine flower petals and 5 to 10 parts of cheese. A product is obtained by uniformly mixing the raw materials and pressing the raw materials through a sandwich forming machine. By the adoption of the raw materials and the production method, the product disclosed by the invention has unique flavor, and the unique flavor can be retained for a relatively long time; the product has the characteristics of pure taste, looseness, fragrance, appetizing and softness; by the mellow jasmine fragrance, great appetite can be stimulated; the jasmine flower cakes have good aftertaste after being chewed in mouth and are long in freshness retaining period and long in storage period.

Owner:广西横县百利食品有限公司

Gastric dissolve type tablet containing olanzapine and preparation method for gastric dissolve type tablet

InactiveCN106176656ADissolution rate is fastImprove preparation qualityOrganic active ingredientsNervous disorderMoisture absorptionSorbitan

The invention relates to the technical field of pharmaceutical preparations, in particular to a gastric dissolve type tablet containing olanzapine and a preparation method for the gastric dissolve type tablet. The gastric dissolve type tablet containing olanzapine comprises the following components in parts by weight: 10-20 parts of olanzapine, 20-30 parts of hydroxypropyl-beta-cyclodextrin, 10-30 parts of microcrystalline cellulose, 3-5 parts of croscarmellose sodium, 8-12 parts of pregelatinized starch, 6-10 parts of sorbitan fatty acid ester, 5-8 parts of magnesium hydroxide, 3-6 parts of xylitol, 3-5 parts of sodium alginate, 2-4 parts of tapioca starch, 1-3 parts of kaolin, 3-5 parts of a lubricant and 2-6 parts of a coating material. The gastric dissolve type tablet, prepared according to the preparation method, is high in dissolving-out speed, the preparation is stable in quality, no remarkable moisture absorption phenomenon is generated when the gastric dissolve type tablet is placed for a long time, a wet granulation step is omitted through tabletting by adopting a direct compression method, the gastric dissolve type tablet has the outstanding advantages of saving time, saving energy, being simple in technology, and being less in working procedures, the stability of the tablet is beneficial for being enhanced, and the gastric dissolve type tablet is suitable for being widely popularized and applied.

Owner:合肥美利康医药技术股份有限公司

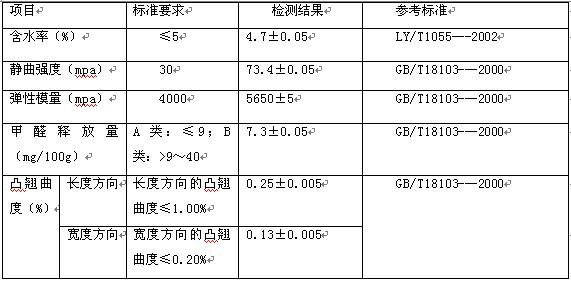

Preparation method for anti-flaming bamboo floor

InactiveCN102493624AGood physical propertiesPerformance is not affectedFlooringEngineeringHigh pressure

The invention relates to the field of bamboo floor processing, in particular to a preparation method for an anti-flaming bamboo floor. The preparation method for the anti-flaming bamboo floor is realized by the following technical scheme that the preparation method for the anti-flaming bamboo floor comprises the following steps: (1) cutting off and hacking an original bamboo, and sawing to obtain a green blank plate; (2) carrying out carbonized treatment, putting a bamboo chip into a high-pressure processing tank, introducing high-pressure saturated vapor into the tank, improving pressure to 0.2-0.3MPa, keeping warm and pressure for 3-4 hours, finally releasing pressure, and bleaching water to take out after pressure is released; (3) drying to cause the moisture content of the blank plate to be regulated to 5-8%; (4) anti-flaming treatment: adopting a vacuum pressurizing and impregnating method, wherein the vacuum degree is 80-87kPa, the vacuum time is 1.5-2 hours, the impregnating pressure is 0.5-0.6MPa, and the impregnating time is 2-3 hours; and (5) carrying out hot pressure at the hot pressing temperature of 120-150 DEG C and the pressure of 2.5-3MPa for 15-20 minutes. The bamboo floor prepared with the method not only has a good favorable physical performance but also has a good anti-flaming effect.

Owner:朱江福

Compound fertilizer containing various forms of nitrogen, and preparation method thereof

InactiveCN111018627AVarious formsMeet the problem of easy moisture absorptionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceNutrition

The invention relates to a compound fertilizer containing various forms of nitrogen, and a preparation method thereof. According to the invention, the contained nitrogen comes from urea and a fertilizer containing nitrate nitrogen, the surfaces of the granular urea and the granular fertilizer containing nitrate nitrogen are coated with a layer of a separant containing medium trace elements under the action of a binder, a mixture containing a phosphate fertilizer and a potash fertilizer is wrapped with the binder, and a mass part ratio of the granular urea to the granular fertilizer containingnitrate nitrogen to the separant to the mixture of the phosphate fertilizer and the potash fertilizer is 100:(20-200):(15-55):(60-140); and the compound fertilizer containing various forms of nitrogencan provide urea nitrogen, nitrate nitrogen and other forms of nitrogen at the same time, is reasonable and diversified in nutrient form compatibility, meets the requirements of plants on different nutrition elements and forms, solves the technical problems that urea nitrogen and nitrate nitrogen cannot be mixed and coexist, the moisture absorption point is low and the process cannot be achievedin the compound fertilizer industry for a long time, and meets the agricultural requirements and the process requirements of industrial production.

Owner:ZHENGZHOU UNIV

Ready-to-use vitamin standard substance and preparation method, use method and storage stabilizer thereof

PendingCN111707512AAvoid degradationStable structurePreparing sample for investigationFreeze-dryingProcess engineering

The invention discloses a high-stability ready-to-use vitamin standard substance and a preparation method, a use method and a storage stabilizer thereof. The preparation method comprises the followingsteps of (1) diluting a vitamin standard stock solution by using a storage stabilizer to obtain a vitamin standard working solution,(2) performing sterilization and standard substance concentration conformity verification on the vitamin standard working solution,(3) fixing the vitamin standard mixed solution with the required concentration in a container by adopting a vacuum freeze drying technology, wherein the vitamin standard mixed solution with the required concentration is obtained by diluting the vitamin standard working solution in the step (2) to a series of gradient concentration standard solutions by using a storage stabilizer, and (4) packaging and storing. According to the preparation method of the ready-to-use vitamin standard substance, not only is the long-term storage stability of the low-concentration standard substance improved, but also the prepared vitamin standard substance is rehydrated and dissolved immediately after being used and operated, and the tedious preparation process of a standard solution is omitted.

Owner:深圳市瑞赛生物技术有限公司

Preparation method of intumescent flame retardant

The invention discloses a preparation method of an intumescent flame retardant, and belongs to the technical field of synthesis of flame retardants. Firstly, trihydroxy methyl-hexane and tea saponin are esterified, an esterified product is then esterified with phenyl trichloromethane, finally, the product and ammonium polyphosphate are subjected to esterification reaction to obtain the intumescent flame retardant, the tea saponin contains -OH and -COOH which can react with -OH in the trihydroxy methyl-hexane of a carbon source, and can further react with -NH4+ in the ammonium polyphosphate, the phenyl trichloromethane not only can react with -OH, but also can react with -NH4+, single compounds which have clear structures are difficultly produced among molecules by reaction in a one-to-one correspondence manner, more possibly, components are cross-linked with one another among the molecules and are condensed into cross-linked polymers which have three-dimensional structures, and the polymer flame retardant is well compatible to a high polymer material. The intumescent flame retardant has the features of high efficiency, low toxicity, zero smoke and the like, and is a novel flame retardant which meets the requirement of environmental protection.

Owner:SHAOXING GOLD SUN TEXTILE CO LTD

Olanzapine gastric-dissolved type tablet

InactiveCN107898765AShorten the production cycleImprove finished product qualityOrganic active ingredientsNervous disorderMoisture absorptionCroscarmellose sodium

The invention provides an olanzapine gastric-dissolved type tablet, which is prepared from the following raw materials: olanzapine, xylitol, microcrystalline cellulose, polyoxyethylene sorbitan fattyacid ester, magnesium stearate, croscarmellose sodium, magnesium hydrate and pregelatinized starch. Compared with the prior art, the olanzapine gastric-dissolved type tablet provided by the inventionhas the following beneficial effects of short production period, stable finished product quality, and no moisture absorption phenomenon occurred when being placed in air for a long time.

Owner:GUANGDONG YIMING PHARMA

A kind of popping pearl rubber material for high weather resistance cigarettes and its preparation method

ActiveCN106497088BImprove performanceEquilibrium moisture content decreasedTobacco smoke filtersWater bathsCross-link

Owner:HUBEI CHINA TOBACCO IND

Moisture-proof paint and preparation method thereof

InactiveCN107365546AImprove adsorption capacityImprove moisture resistanceEpoxy resin coatingsEpoxySolvent

The invention discloses a moisture-proof paint and a preparation method thereof. The paint comprises the following components: an epoxy resin, propylene glycol polyoxypropylene ether, chlorinated paraffin, barium sulfate, silica sol, bentonite, stearic acid, polyacrylamide, an ethylene-vinyl acetate copolymer, a plasticizer, a defoaming agent, a surfactant and a solvent. The preparation method comprises the following steps: putting the epoxy resin, chlorinated paraffin, barium sulfate and bentonite in a stirrer, and performing stirring and mixing to obtain a mixture 1; putting the mixture 1 into a reaction kettle, adding the polyacrylamide, defoaming agent, ethylene-vinyl acetate copolymer and plasticizer, performing heating under inert gas protective conditions and performing holding for some time to obtain a mixture 2; and finally, adding the propylene glycol polyoxypropylene ether, silica sol, stearic acid, surfactant and solvent into the mixture 2, and performing mixing to obtain the moisture-proof paint. The moisture-proof paint disclosed by the invention has favorable adsorbability and moisture proofness.

Owner:江苏达克罗涂装技术有限公司

A kind of tf series paper tube base paper and its preparation process

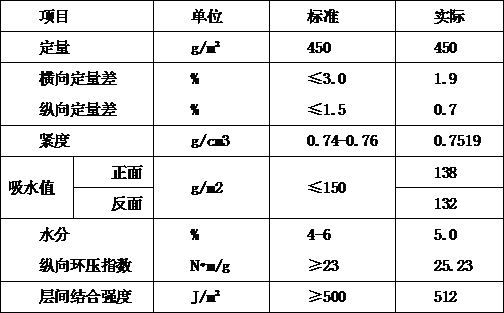

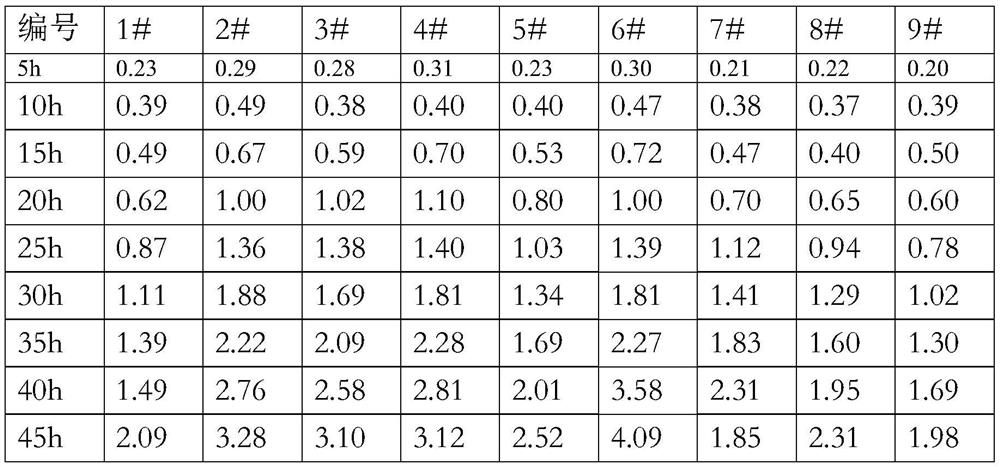

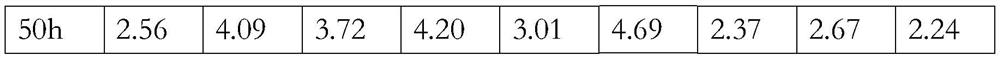

ActiveCN110258155BSlow down moisture absorptionNo moisture absorptionNon-fibrous pulp additionSpecial paperPapermakingProcess engineering

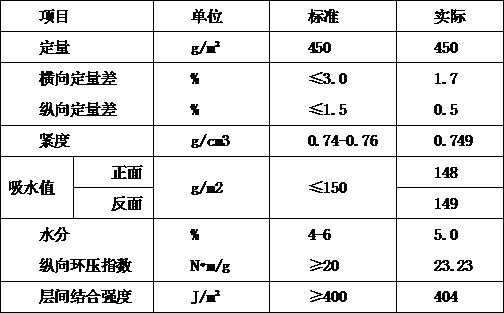

The invention discloses TF series paper tube base paper and a preparation process thereof, and mainly relates to the technical field of papermaking, and the paper is divided into two levels of TF400 and TF500. The paper has the following technical indexes: the quantification is 450 g / m<2>, the transverse quantification allowable error range is + / -3.0%, the longitudinal quantification allowable error is + / -1.5%, the tightness is 0.74 to 0.76 g / cm<3>; the longitudinal ring crush index of TF400 is larger than or equal to 20 N*m / g, the interlayer bonding strength is larger than or equal to 400 J / m<2>, the longitudinal ring crush index of TF500 is larger than or equal to 23 N*m / g, the interlayer bonding strength is larger than or equal to 500 J / m<2>, the water absorption value (60s) is smaller than or equal to 150 g / m<2>, and the finished paper moisture content is 4-6%. The manufacturing process of the paper tube base paper comprises the steps of performing pulping, papermaking and rewinding to obtain the paper tube base paper, and then packaging the finished paper. Pulping is carried out in the pulping process, and starch in pulp is added in the paper forming process. The invention has the advantages of low cost, low water content, low possibility of moisture absorption, high glue absorption speed, high pipe forming pressure, short drying time and the like.

Owner:ZHONGTIAN PAPER

Crystalline Mixture Solid Containing Maltitol and Preparation Therefor

InactiveUS20030188739A1Improve solubilityNo moisture absorptionSugar derivativesSugar productsSolubilityMaltitol

A crystalline mixture solid containing maltitol having an oil absorptivity of 0.1 to 6.9 wt % and a bulk density of 0.60 to 0.75 g / cc when it is ground and classified to ensure that at least 70 wt % of the obtained particles should have a particle size of 16 to 50 mesh and a process for producing a crystalline mixture solid containing maltitol, comprising introducing air bubbles into a maltitol aqueous solution. According to this process, a crystalline mixture solid containing maltitol having high solubility and almost no moisture absorption is produced at a high work efficiency and a low cost in a short period of time.

Owner:UENO FINE CHEM IND LTD

Inorganic salt impregnation process for anti-oxidation of carbon graphite products

ActiveCN109534854BSolve the problem of high temperature anti-oxidationNo moisture absorptionInorganic saltsCarbon graphite

The invention relates to the field of preparation of carbon graphite materials, in particular to a process of impregnating an inorganic salt for oxidation resistance of carbon graphite products. The process includes steps 1) pressurized impregnation, heating the product in an oven, putting the heated product into the impregnation barrel, and then putting the impregnation barrel together into a stainless steel vacuum tank to extract the vacuum; 1.2) under the condition of maintaining vacuum, Introduce the impregnation liquid a heated to boiling state into the impregnation vacuum tank; after the impregnation liquid submerges the product, let in the air, and finally open the vacuum tank, take out the product and the impregnation barrel; 1.3) Put the product and the impregnation barrel into the lower bell jar of the hydraulic press , and then sequentially perform sealing, adding air pressure, maintaining pressure, releasing pressure, pouring out the impregnation solution, and taking out the product; 2) curing the product; 3) secondary impregnation. Through this process, the problem of high-temperature oxidation resistance of carbon graphite products is solved, and the anti-oxidation weight loss rate is 5% lower in the air at 650°C, the density increase rate is ≮6%, and the treated material has no moisture absorption in the air.

Owner:ZIGONG DONGXIN CARBON CO LTD

Iron and manganese complex for promoting polyhalogenated organic dehalogenation and detoxification in soil

ActiveCN101053689BGood chemical stabilityNo moisture absorptionChemical protectionManganeseSelf purification

The invention discloses a ferro manganese complexes for advancing the multi-halogenating organism dehalogenation detoxifcation, which is composed of a metallic element and a ligand, with the mol ratio 1:1 to 1:9. The metallic element is iron, manganese or the ferro manganese mixture, while the ligand is an organic ligand or an abio-ligand. The ferro manganese complexes can be applied to advance the dehalogenation detoxifcation of the contamination such as multi-halogenating organism etc, and accelerate the harness of the organic pollutant in the electron rubbish pollution place; meanwhile thenatural self-purification capacity of the soil is fully utilized and exerted, by the exogenous matter adjustment, the processing power of the environmental pollutant on the soil is advanced, which has high applying foreground.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Processing method of pleurotus eryngii enzyme byproduct meal replacement powder

ActiveCN112544962ASave energyEasy to shapeFood shapingFood processesBiotechnologySODIUM METAPHOSPHATE

The invention belongs to the technical field of food processing, and particularly relates to a processing method of pleurotus eryngii enzyme byproduct meal replacement powder. The method comprises thefollowing steps: (1) preparing a pleurotus eryngii enzyme solid product; (2) preparing solid product dry powder; and (3) adding oat flour, millet flour, konjac powder, soybean flour, sodium hexametaphosphate, xylitol and edible essence to the pleurotus eryngii enzyme solid product dry powder, and performing uniform mixing so as to obtain the solid product meal replacement powder. The method is simple in process, convenient to operate, high in fermentation speed and easy to implement and popularize, the additional value and resource utilization efficiency of the produced pleurotus eryngii areimproved, waste-free full-effect high-additional-value comprehensive utilization is achieved, the pleurotus eryngii enzyme solid product dry powder is made into the meal replacement powder, dispersionstability is good, water retention capacity is high, and the meal replacement powder is pasty after being brewed. The meal replacement powder has the effects of reducing blood fat, reducing cholesterol, promoting gastrointestinal digestion, enhancing body immunity, preventing cardiovascular diseases and the like.

Owner:QINGDAO AGRI UNIV

Weak alkaline instant cooking kitchenware builder and preparation method thereof

InactiveCN109266449AExtended service lifeNo damageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAcetic acidSodium metasilicate

The invention discloses a weak alkaline instant cooking kitchenware builder and a preparation method thereof. The weak alkaline instant cooking kitchenware builder includes, by mass percentage, 58-60%of sodium metasilicate pentahydrate, 32-34% of sodium carbonate, 3-5% of sodium gluconate, 0.5-1.0% of ethylenediamine tetraacetic acid tetrasodium salt and 2-4% of sodium dodecyl benzene sulfonate.The preparation method includes first placing the weighed sodium carbonate having passed through a filter sieve into a stirring tank for stirring; adding the sodium metasilicate pentahydrate and the sodium gluconate having passed through the filter sieve, and stirring for 3 min; adding the ethylenediamine tetraacetic acid tetrasodium salt passing through the filter sieve, and stirring for 3 min; finally adding the sodium dodecyl benzene sulfonate having passing through the filter sieve, and stirring for 2 min.

Owner:DALIAN SANDAAOKE CHEM

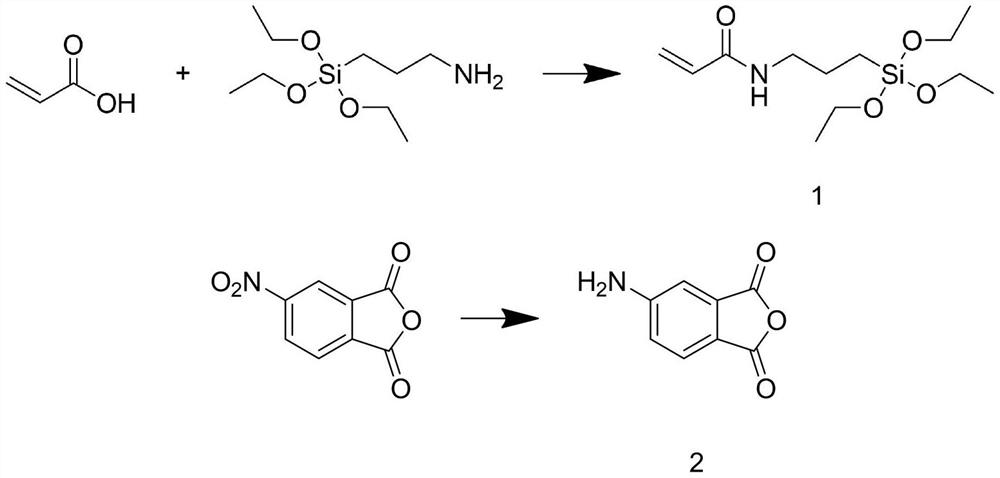

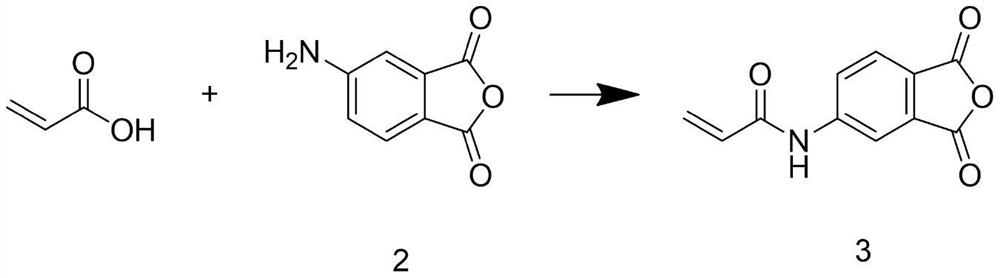

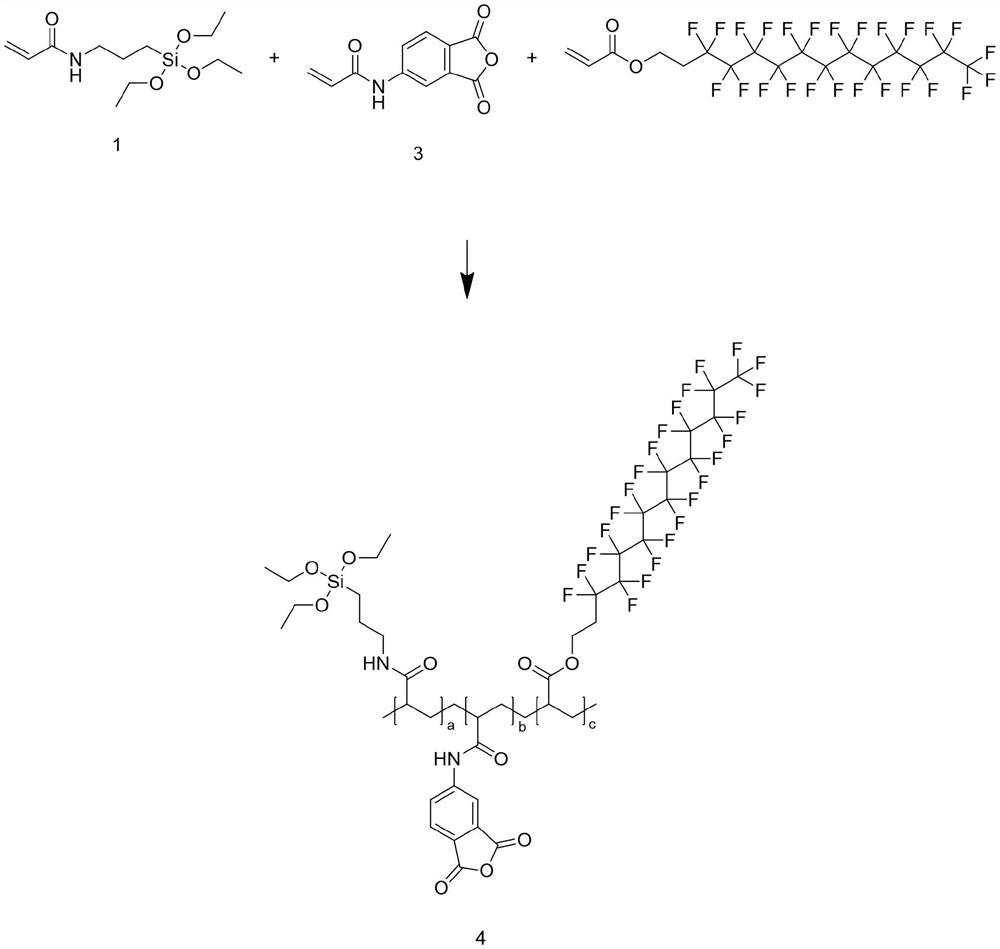

Processing technology of anti-scratch wear-resistant 5G high-precision photoelectric integrated circuit board

PendingCN114449747ANo moisture absorptionGood anti-scratch and wear-resistant effectNon-macromolecular adhesive additivesEpoxy resin adhesivesSide chainFirming agent

The invention discloses a processing technology of an anti-scratch wear-resistant 5G high-precision photoelectric integrated circuit board, which comprises the following steps: dispersing modified epoxy resin and silicon carbide in deionized water, stirring, adding sodium hydroxide, reacting, distilling to remove the deionized water to obtain adhesive liquid, and drying to obtain the anti-scratch wear-resistant 5G high-precision photoelectric integrated circuit board. Aluminum oxide, silicon dioxide, calcium zirconate, potassium carbonate, methyl alcohol, glue liquid and a modified curing agent are mixed and subjected to compression molding, a substrate is prepared, then electronic elements are integrated on the substrate, the integrated circuit board is prepared, a side chain of the modified epoxy resin contains long-chain fluoroalkane, the prepared integrated circuit board does not have the moisture absorption phenomenon, and the service life of the integrated circuit board is prolonged. Meanwhile, aerobic silane of a side chain is hydrolyzed to generate silanol which is grafted with active hydroxyl on the surface of the silicon carbide, so that the silicon carbide is uniformly dispersed in the adhesive liquid, the wear resistance of the adhesive liquid is improved, and the wear resistance effect of the integrated circuit board is further improved.

Owner:江苏智纬电子科技有限公司

A kind of preparation method of intumescent flame retardant

The invention discloses a preparation method of an intumescent flame retardant, and belongs to the technical field of synthesis of flame retardants. Firstly, trihydroxy methyl-hexane and tea saponin are esterified, an esterified product is then esterified with phenyl trichloromethane, finally, the product and ammonium polyphosphate are subjected to esterification reaction to obtain the intumescent flame retardant, the tea saponin contains -OH and -COOH which can react with -OH in the trihydroxy methyl-hexane of a carbon source, and can further react with -NH4+ in the ammonium polyphosphate, the phenyl trichloromethane not only can react with -OH, but also can react with -NH4+, single compounds which have clear structures are difficultly produced among molecules by reaction in a one-to-one correspondence manner, more possibly, components are cross-linked with one another among the molecules and are condensed into cross-linked polymers which have three-dimensional structures, and the polymer flame retardant is well compatible to a high polymer material. The intumescent flame retardant has the features of high efficiency, low toxicity, zero smoke and the like, and is a novel flame retardant which meets the requirement of environmental protection.

Owner:SHAOXING GOLD SUN TEXTILE CO LTD

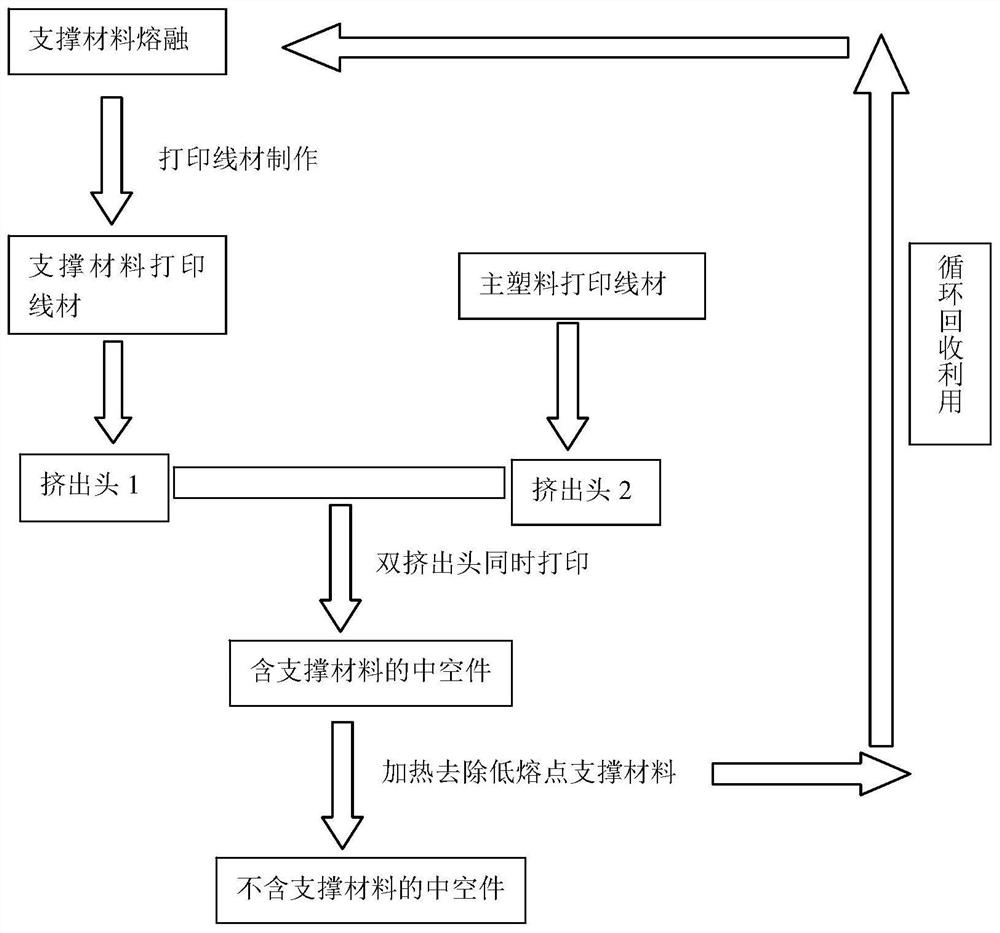

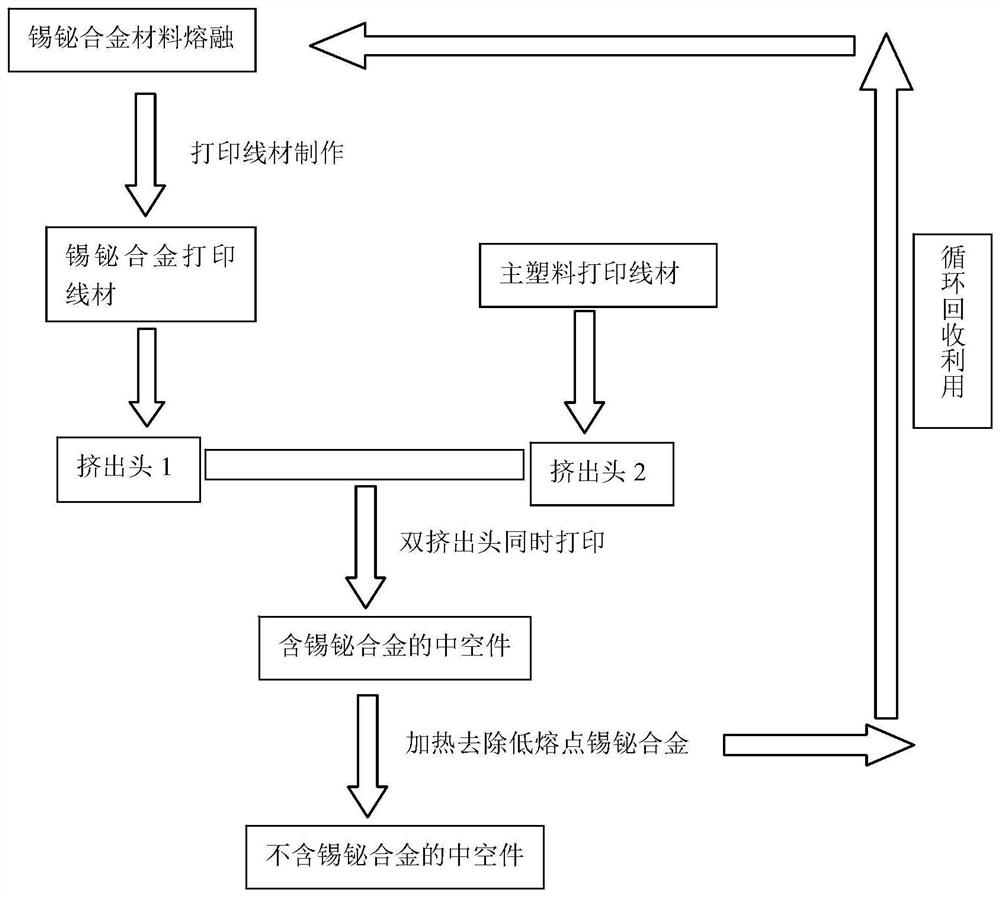

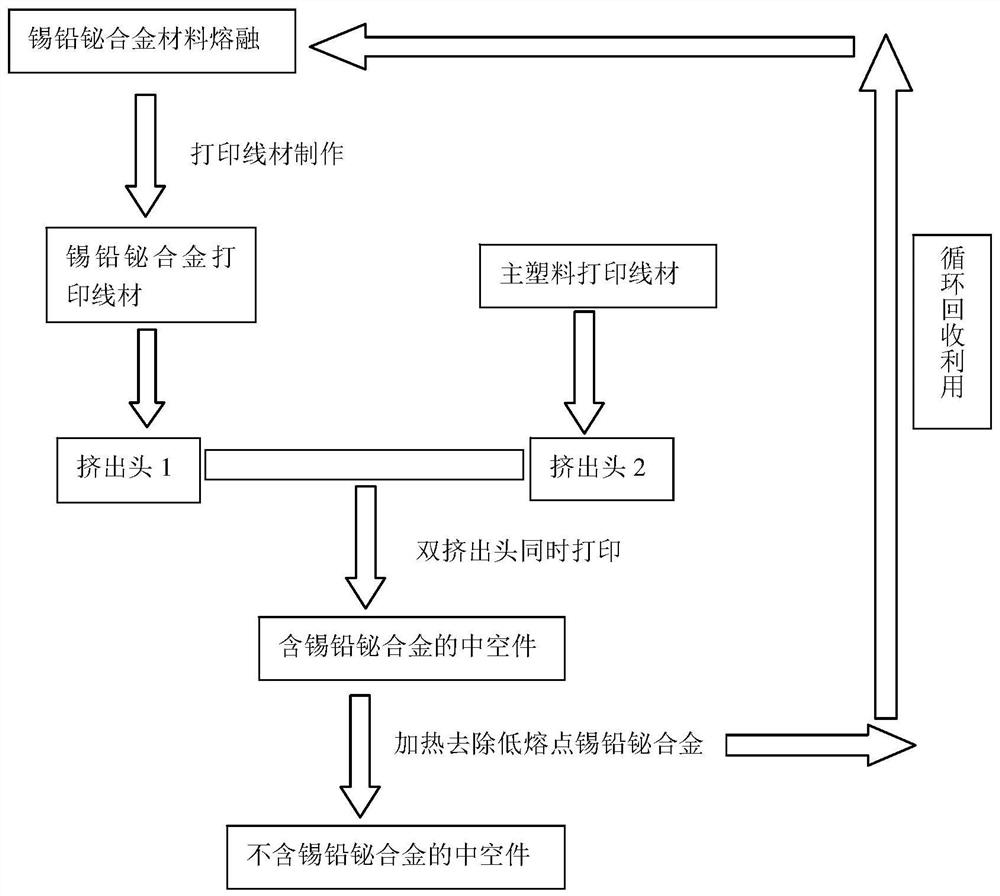

Method for effectively improving 3D printing precision and strength of hollow part

PendingCN111873410ASimplify the structure and function of printing equipmentReduce equipment development and printing costsManufacturing platforms/substratesManufacturing recyclingIndustrial engineeringAlloy

The invention discloses a method for effectively improving 3D printing precision and strength of a hollow part. The method comprises the following steps: selecting a low-melting-point metal or alloy material as a base material of a support structure to form a support material printing wire; a supporting material and a main plastic material are printed at the same time, the hollow part is printed synchronously, and the hollow part containing the supporting material is formed; after printing is completed, the supporting material is removed; and the supporting material is recycled. According to the method, the selected supporting material is low-melting-point metal or alloy, so that when the supporting material of the low-melting-point metal or alloy is removed, the supporting material cannotbe mutually dissolved with water to generate wastewater to pollute the environment, meanwhile, water absorption and dampness are avoided, and the problems that in the printing process, due to tape casting, unstable feeding, serious part leftover materials and the like are caused and influence the precision (especially the interior of a product) and the strength of the product are solved; and in addition, the structure and functions of printing equipment can be simplified, and the equipment research and development and printing cost can be effectively reduced.

Owner:XIAMEN RUNNER IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com