Dry charge type zinc air cell

A zinc-air battery, electric type technology, applied in the direction of fuel cell half-cells and primary battery-type half-cells, etc., can solve the problems of battery leakage, water loss or moisture absorption, corrosion, etc., to prolong the service life, The production process is simplified and the production process is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 0.4gPbO, 0.2gIn 2 o 3 Mix with 20g of active zinc powder, and pass through a 200-mesh sieve after ball milling with a ball mill for 1 hour;

[0027] (2) Mix 0.412g of azodicarbonamide with the mixture in (1), add 0.4g of conductive carbon black and 0.4g of carboxymethyl cellulose (CMC), and stir and disperse evenly with a mixer;

[0028] (3) Pour the mixture in (2) into a mold covered with nickel foam, a conductive current collector, dry press it into a mold-shaped zinc electrode under a pressure of 15Mpa, and then heat it at 210°C for 25min to make pores The thermal decomposition of the agent creates pores for the zinc electrode.

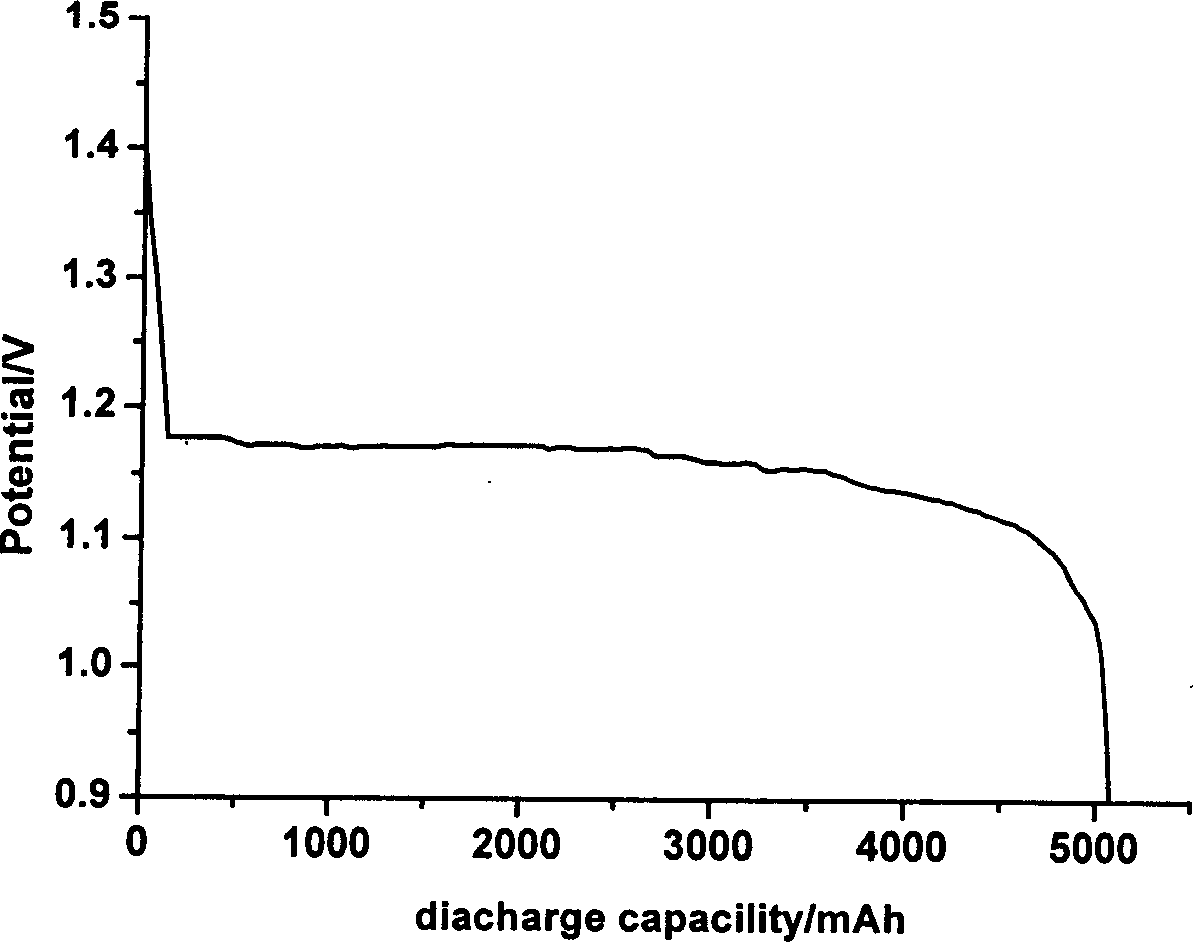

[0029] The obtained porous zinc electrode is used as the negative electrode, and the traditional air diffusion electrode is used as the positive electrode to assemble into an AA-type dry-charged zinc-air battery, and the battery shell is provided with an electrolyte solution injection port. When in use, inject 40% KOH electrolyte...

Embodiment 2

[0031] (1) Get 6gPbO, 3gCdO and 300g active zinc powder to mix, pass 50 mesh sieves with ball mill ball mill after 1 hour;

[0032] (2) Get 6.18g of azodicarbonamide and mix it with the mixture in (1), add 6g of conductive carbon black and 3g of carboxymethyl cellulose (CMC), 3g of polytetrafluoroethylene, stir and disperse evenly through a mixer;

[0033] (3) Pour the mixture in (2) into a mold covered with a conductive current collector nickel sheet, dry press it under a pressure of 20Mpa to form a mold-shaped zinc electrode, and then heat it at a temperature of 210°C for 25min to make pores The thermal decomposition of the agent creates pores for the zinc electrode.

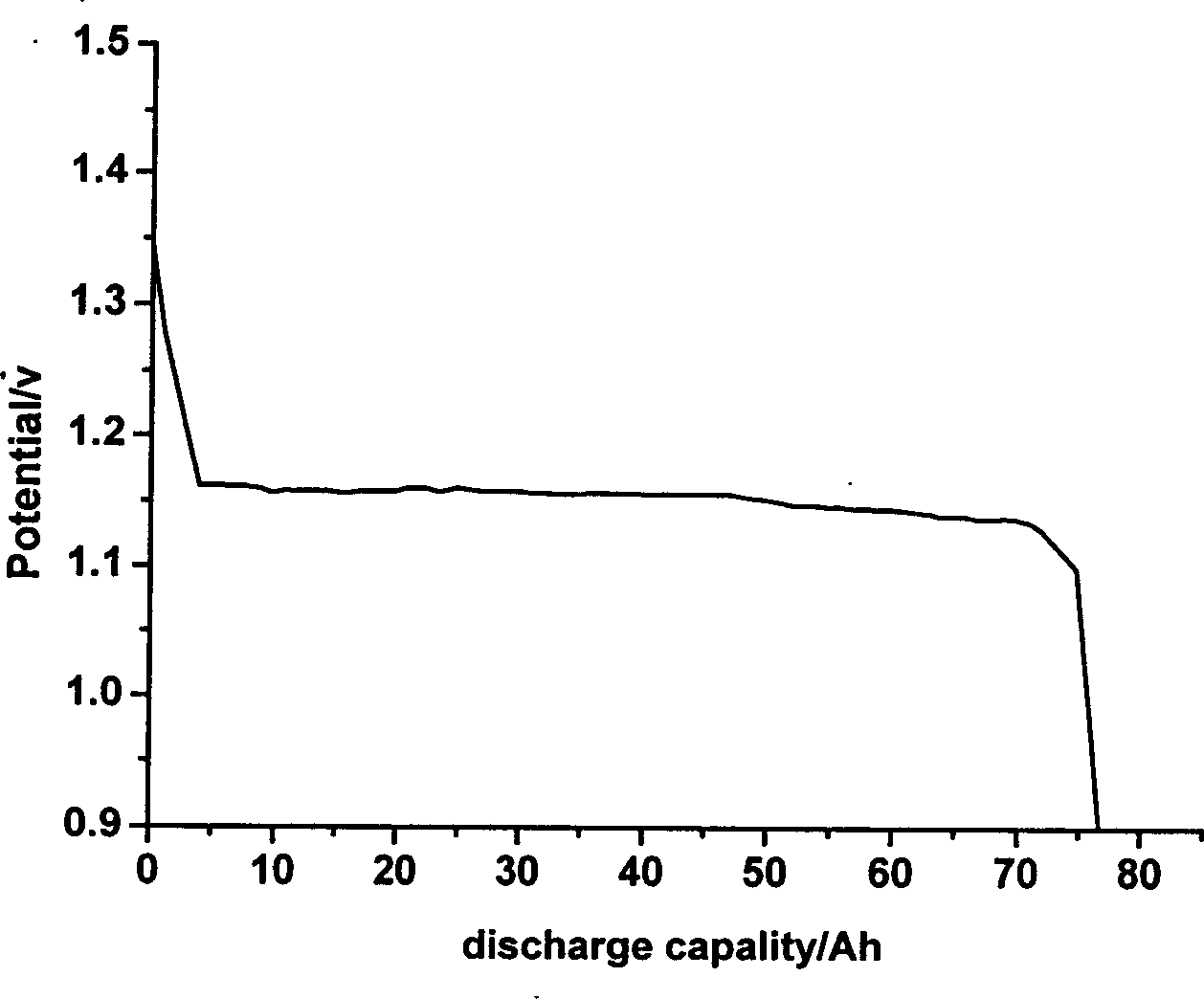

[0034] The obtained porous zinc electrode is used as the negative electrode, and the traditional air diffusion electrode is used as the positive electrode to assemble a square-shaped dry-charged zinc-air battery, and the battery shell is provided with an electrolyte solution injection port. When in use, inject ...

Embodiment 3

[0036] (1) Get 0.1gPbO, 0.05gCdO and 5g active zinc powder to mix, pass 300 mesh sieves after ball milling 1 hour with ball mill;

[0037] (2) Mix 0.103g of azodicarbonamide with the mixture in (1), add 0.1g of conductive carbon black and 0.1g of carboxymethyl cellulose (CMC), and stir and disperse evenly with a mixer;

[0038] (3) Pour the mixture in (2) into a mold covered with a conductive current collector nickel mesh, dry press it into a mold-shaped zinc electrode under a pressure of 15Mpa, and then heat it at a temperature of 210°C for 20min to make pores The thermal decomposition of the agent creates pores for the zinc electrode.

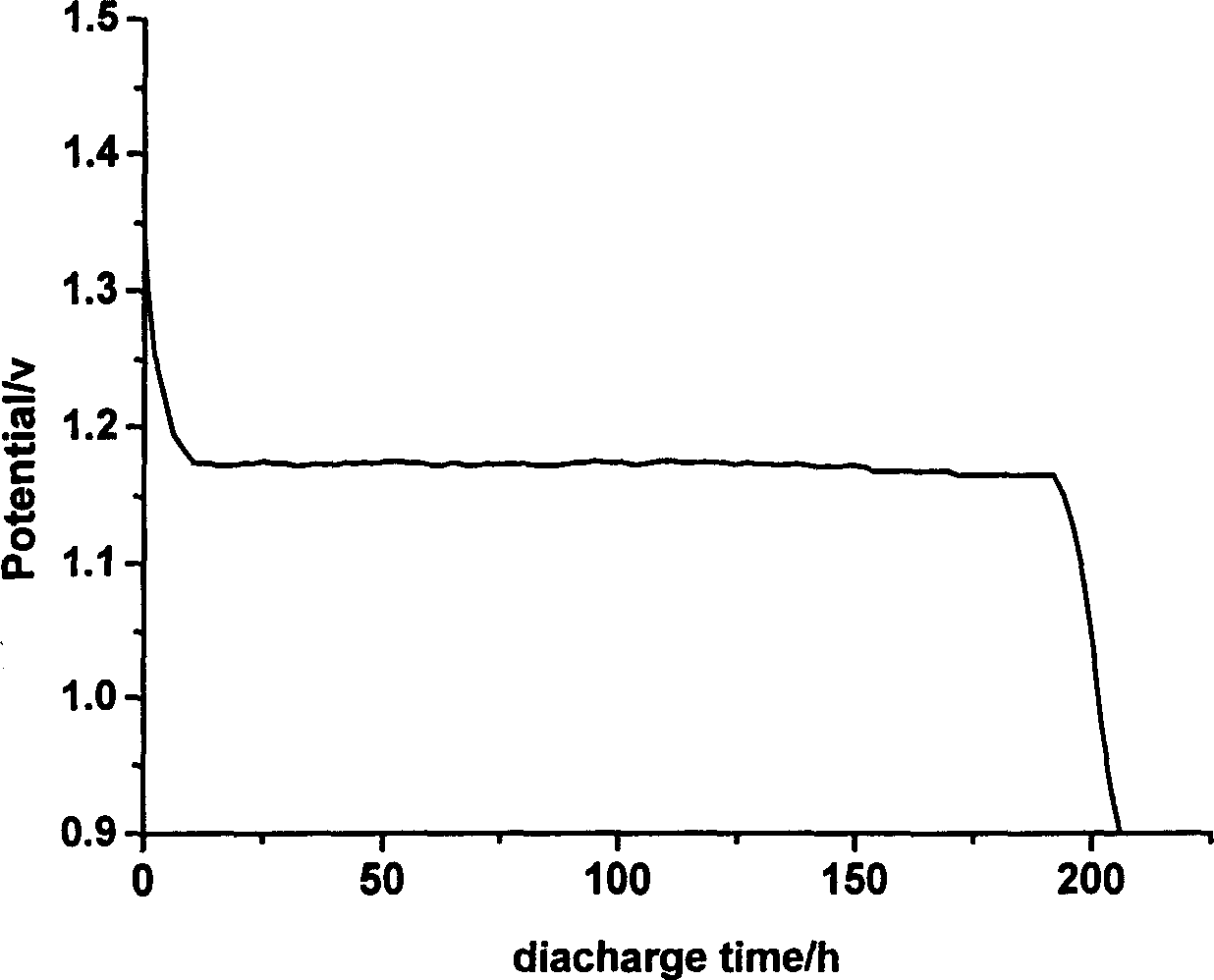

[0039] The obtained porous zinc electrode is used as the negative electrode, and the traditional air diffusion electrode is used as the positive electrode to assemble an A675 button-type dry-charged zinc-air battery, and the battery case has an electrolyte solution injection port. When in use, inject 40% KOH electrolyte solution through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com