Anti-common cold capsule preparation method

A technology of capsules and relative density, which is applied in capsule delivery, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve the problems of powder moisture absorption, high temperature, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

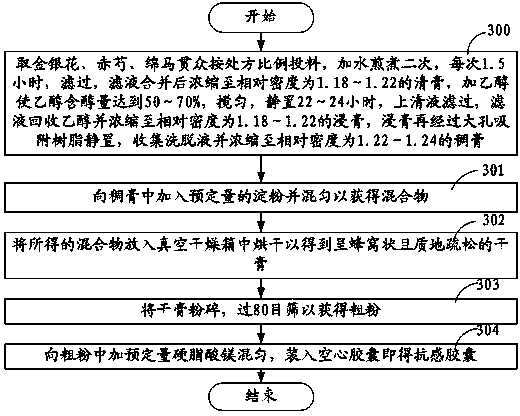

[0014] Please see figure 1 , which is a flow chart of the preparation method of the Kanggan capsule in a preferred embodiment, the preparation method of the Kanggan capsule comprises the following steps:

[0015] Step S300, taking honeysuckle, red peony root, and Mianma Guanzhong as ingredients according to the prescription ratio, adding water and decocting twice for 1.5 hours each time, filtering, and concentrating the filtrates to a clear paste at room temperature with a relative density of 1.18-1.22 , add ethanol to make the alcohol content of ethanol reach 50-70%, stir well and let stand for 22-24 hours to obtain the supernatant, and filter, recover ethanol from the filtrate, and concentrate to room temperature, relative density of 1.18-1.22 For the extract, for example, a double-effect concentrated evaporator can be used to recover ethanol in the filtrate and concentrate the filtrate, wherein the first-effect temperature of the double-effect concentrated evaporator is con...

Embodiment 1

[0023] Feed honeysuckle, red peony root, and Mianma Guanzhong according to the ratio of 3:3:1, add water to decoct twice, each time for 1.5 hours, filter, combine the filtrates and concentrate to a clear paste with a relative density of 1.18-1.22, add Ethanol makes the alcohol content of ethanol reach 50%. After stirring well, let it stand for 22-24 hours to obtain the supernatant, and filter it. The filtrate recovers ethanol and concentrates it to an extract with a relative density of 1.18-1.22. The extract passes through the large pores Collect the eluate after the adsorption resin is left to stand, and concentrate the eluate to a thick paste with a relative density of 1.22 to 1.24; add a predetermined amount of starch to the thick paste and mix well to obtain a mixture, and put the resulting mixture into vacuum drying Dry in the oven to obtain a honeycomb-shaped and loose dry paste. The thickness of the spreading plate is 1-3cm, the temperature is controlled at 60-80°C, the ...

Embodiment 2

[0025] Take honeysuckle, red peony root, and Mianma Guanzhong according to the ratio of 3:3:1, add water to decoct twice, each time for 1.5 hours, filter, combine the filtrates and concentrate to a clear paste with a relative density of 1.18-1.22, add Ethanol makes the alcohol content of ethanol reach 60%. After stirring well, let it stand for 22-24 hours to obtain the supernatant, and filter it. The filtrate recovers ethanol and concentrates it to an extract with a relative density of 1.18-1.22. The extract passes through the large pores The eluate is collected after the adsorption resin is left standing, and the eluate is concentrated to a thick paste with a relative density of 1.22 to 1.24; a predetermined amount of starch is added to the thick paste and mixed to obtain a mixture; the resulting mixture is placed in a vacuum Dry in a drying oven to obtain a honeycomb-shaped and loose dry paste. The thickness of the spreading plate is 1-3cm, the temperature is controlled at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com