Ready-to-use vitamin standard substance and preparation method, use method and storage stabilizer thereof

A technology with stable storage and vitamins, which is applied in the field of preparation of vitamin standard products, can solve the problems of easy loss in the weighing process, easy degradation in the storage process, cumbersome preparation process, etc., and achieve the effect of firm structure, improved stability, and not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

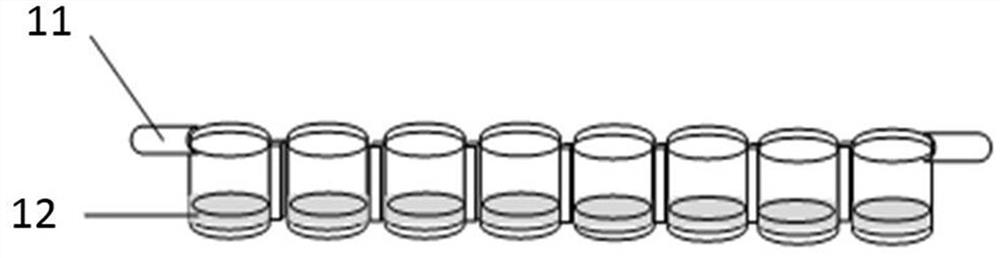

[0031] Example 1. Ready-to-Use Vitamin B12 Slat Standards

[0032] The content of vitamin B12 in food is very small, generally in the range of 2-10μg / 100g. In the national standard, ATCC 7830 is used to quantitatively measure the specificity and high sensitivity of vitamin B12. The sensitivity of this method reaches 0.001ng / ml. The vitamin B12 standard is also a lower concentration.

[0033] The vitamin B12 powder standard substance described in this example was purchased from Supelco 47869 with a purity of 99.2%.

[0034] A preparation method of highly stable ready-to-use vitamin B12 slat-type standard substance, which is prepared through the following steps:

[0035] (10) Preparation of vitamin B12 standard stock solution and storage stabilizer;

[0036] (11) Use the storage stabilizer prepared in the above step (10) to fully mix and dilute the vitamin B12 standard stock solution prepared in the above step (10) to obtain the vitamin B12 standard working solution;

[0037]...

Embodiment 2

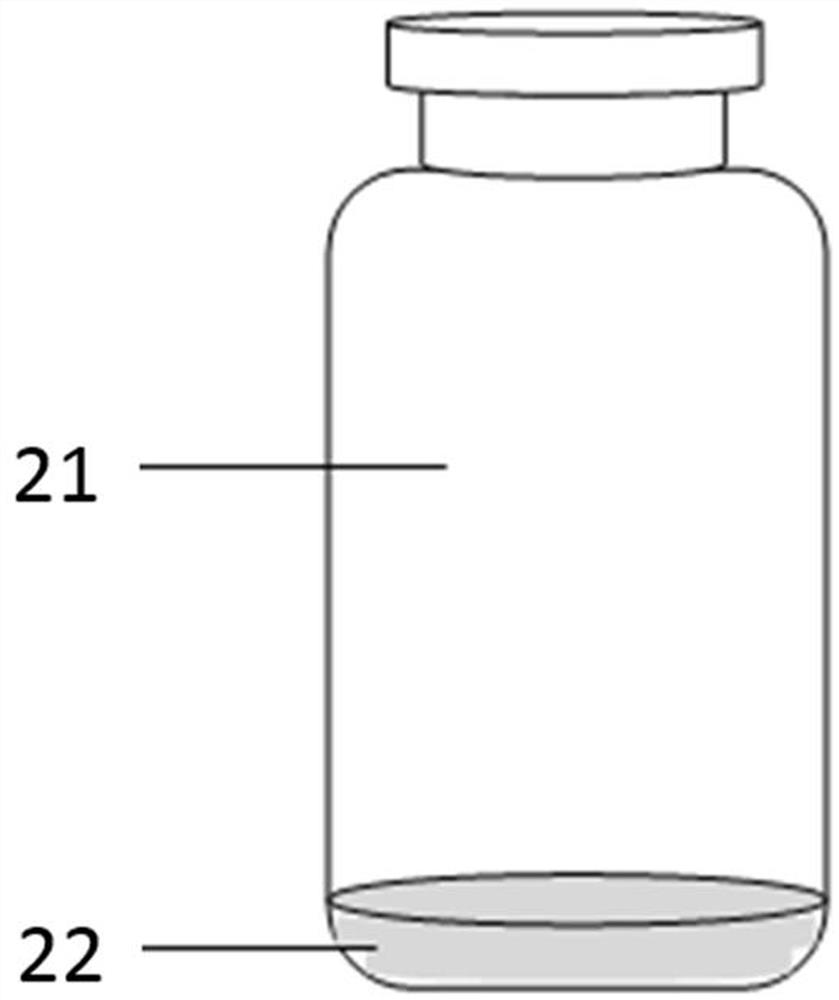

[0047] Example 2. Ready-to-use Biotin Bottled Standards

[0048] The biotin powder standard substance described in this example was purchased from Supelco 47868 with a purity of 98%.

[0049] A preparation method of high-stability ready-to-use biotin bottled standard substance, which is prepared through the following steps:

[0050] (20) Preparation of biotin standard stock solution and storage stabilizer;

[0051] (21) Use the storage stabilizer prepared in the above step (20) to fully mix and dilute the biotin standard stock solution prepared in the above step (20) to obtain a biotin standard working solution;

[0052] (22) Sterilize the biotin standard working solution and verify the concentration compliance;

[0053] (23) Use vacuum freeze-drying technology to fix the biotin standard mixture with the required concentration in the container, such as figure 2 shown; the required concentration of biotin standard mixture refers to the use of storage stabilizers to dilute t...

example 3

[0062] Example 3. Ready-to-use folic acid centrifuge tube standards

[0063] The folic acid powder standard substance described in this example was purchased from Supelco 47866 with a purity of 98.5%.

[0064] A preparation method of high-stability ready-to-use folic acid standard substance, which is prepared through the following steps:

[0065] (30) Prepare folic acid standard stock solution and prepare storage stabilizer;

[0066] (31) Use the storage stabilizer prepared in the above step (30) to fully mix and dilute the folic acid standard stock solution prepared in the above step (30) to obtain the folic acid standard working solution;

[0067] (32) Sterilize the folic acid standard working solution and verify its concentration compliance;

[0068] (33) Use vacuum freeze-drying technology to fix the folic acid standard mixture of the required concentration in the container; the folic acid standard mixture of the required concentration refers to diluting the folic acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com