Environment-friendly foaming fireproof plate and preparation method thereof

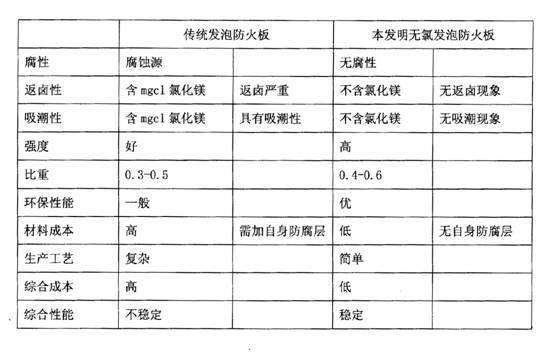

A fireproof board, an environmentally friendly technology, applied in the direction of chemical instruments and methods, manufacturing tools, ceramic products, etc., can solve problems such as unstable performance, unstable negative salt, and not durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0017] 1) Preparation of composition complex: first put 60kg of magnesium sulfate and 50kg of water into the container and stir well, then add the stirred liquid into 500kg of magnesium oxide and stir well, then add 20kg of phosphoric acid for stirring; after stirring evenly, add 200kg of kaolin As a bonding fireproof filler, add 50kg of hydrogen peroxide at the end;

[0018] 2) Oxidative foaming of the composition complex prepared in step 1);

[0019] 3) After the oxidation and foaming is completed, according to the required specifications, put it into the mold and press it to shape, and add a glued glass fiber cloth and a batter layer with a thickness of 2mm on the surface;

[0020] 4) Finally, enter the mold for the second time and put it on the press to finalize the shape to get the finished product.

specific Embodiment 2

[0021] 1) Preparation of composition complex: first put 90kg of magnesium sulfate and 125kg of water into the container and stir well, then add the stirred liquid into 750kg of magnesium oxide and stir well, then add 25kg of phosphoric acid for stirring; after stirring evenly, add 350kg of kaolin As a bonding fireproof filler, add 125kg hydrogen peroxide at the end;

[0022] 2) Oxidative foaming of the composition complex prepared in step 1);

[0023] 3) After the oxidation and foaming is completed, according to the required specifications, put it into the mold and press it to shape, and add a glued glass fiber cloth and a batter layer with a thickness of 2mm on the surface;

[0024] 4) Finally, enter the mold for the second time and put it on the press to finalize the shape to get the finished product.

specific Embodiment 3

[0025] 1) Preparation of composition complex: First, put 120kg of magnesium sulfate and 200kg of water into the container and stir well, then add the stirred liquid into 1000kg of magnesium oxide and stir well, then add 30kg of phosphoric acid for stirring; after stirring evenly, add 500kg of kaolin As a bonding fireproof filler, add 200kg of hydrogen peroxide at the end;

[0026] 2) Oxidative foaming of the composition complex prepared in step 1);

[0027] 3) After the oxidation and foaming is completed, according to the required specifications, put it into the mold and press it to shape, and add a glued glass fiber cloth and a batter layer with a thickness of 2mm on the surface;

[0028] 4) Finally, enter the mold for the second time and put it on the press to finalize the shape to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com