High-weatherability cigarette blasting bead rubber material and preparation method thereof

A weather resistance, cigarette technology, applied in the application, tobacco, smoke oil filter and other directions, can solve the problems of low gelatin strength, easy water absorption, swelling strength and elastic modulus, and high brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

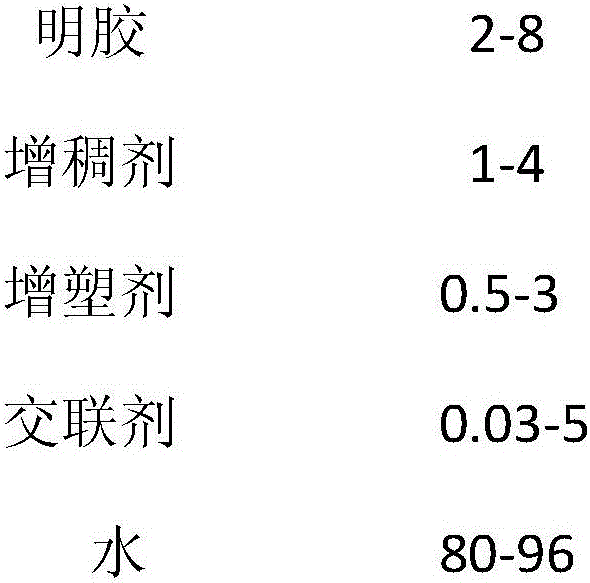

Method used

Image

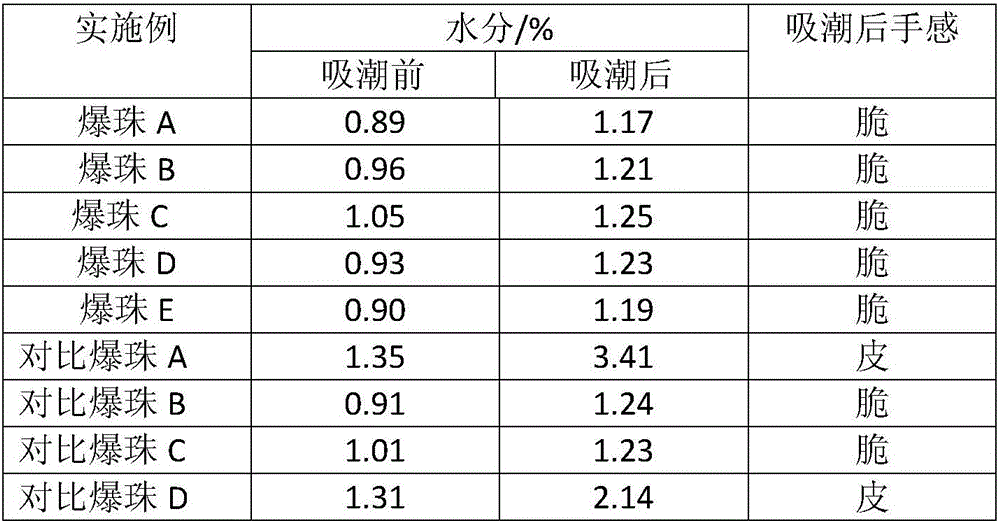

Examples

Embodiment 1

[0019] Example 1, a high-weather-resistant cigarette popping rubber material is composed of the following components and raw materials in parts by weight: 5 parts of gelatin, 1.5 parts of carrageenan, 1 part of glycerin, 0.075 parts of glutaraldehyde, and 92 parts of water. The specific preparation method is as follows: first mix 1.5 parts of carrageenan with 92 parts of water, heat in a water bath to 65±5°C, stir and dissolve to form a homogeneous solution, then add gelatin and glycerin, heat to dissolve for 1-2 hours, and the heating temperature is 65±5°C , after mixing evenly, add 0.075 parts of glutaraldehyde, stir and react for 15 minutes, let it stand still, and pass through a 60-100 mesh screen under heat preservation after the foam floats up, and the obtained filtrate is the high-weather resistance cigarette popping rubber material.

[0020] Use the rubber material prepared in Example 1 to adopt the DWJSYJ-I type small capsule drop pilling machine to drop the quick-frie...

Embodiment 2

[0021] Example 2, a high-weather-resistant cigarette popping rubber material is composed of the following components and raw materials in parts by weight: 6 parts of gelatin, 2 parts of polyvinyl alcohol, 2 parts of polyethylene glycol, 5 parts of dialdehyde starch, 85 parts of water. The preparation method is as follows: first mix 2 parts of polyvinyl alcohol with 85 parts of water, heat in a water bath to 85±5°C, stir and dissolve to form a homogeneous solution, then add 6 parts of gelatin and 2 parts of polyethylene glycol, heat and dissolve for 1-2 hours, The heating temperature is 55±5°C, after mixing evenly, add 5 parts of dialdehyde starch and stir for 1 hour, let it stand still, after the foam floats up, pass through a 60-100 mesh screen under heat preservation, and the obtained filtrate is used for high weather resistance cigarettes Explosive bead rubber material.

[0022] The rubber material prepared in Example 2 is used to drop the quick-fried beads B in the DWJSYJ...

Embodiment 3

[0023] Example 3, a high-weather-resistant cigarette popping rubber material is composed of the following components and raw materials in parts by weight: 8 parts of gelatin, 3 parts of sodium alginate, 3 parts of sorbitol, 0.1 part of glyoxal, water 86 copies. The preparation method is as follows: first mix 3 parts of sodium alginate with 86 parts of water, heat in a water bath to 65±5°C, stir and dissolve to form a uniform solution, then add 8 parts of gelatin and 3 parts of sorbitol, heat to dissolve for 1-2 hours, and heat The temperature is 65±5°C. After mixing evenly, add 0.1 part of glyoxal and stir for 25 minutes, let it stand still, and pass through a 60-100 mesh screen under heat preservation after the foam floats up. The obtained filtrate is the high weather resistance cigarette explosive Bead rubber material.

[0024] Use the rubber material prepared in Example 3 to use the DWJSYJ-I type small capsule dropping pill machine to drip and produce the quick-fried beads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com