Moisture-proof paint and preparation method thereof

A moisture-proof coating and epoxy resin technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problem of moisture removal and achieve good adsorption performance and good moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

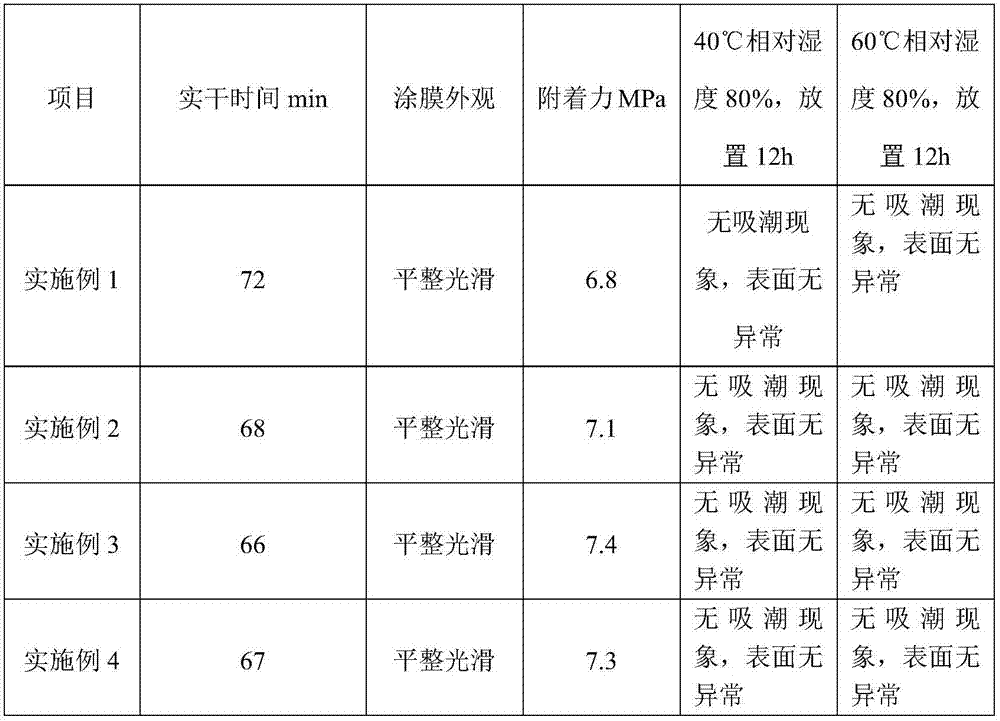

Examples

Embodiment 1

[0017] A moisture-proof coating comprising the following components in terms of weight components: 3 parts of bisphenol A epoxy resin, 2 parts of propylene glycol polyoxypropylene ether, 1 part of chlorinated paraffin, 1 part of barium sulfate, 2 parts of silica sol, and bentonite 2 parts, 1 part of stearic acid, 3 parts of polyacrylamide, 2 parts of ethylene-vinyl acetate copolymer, 1 part of plasticizer di-n-octyl phthalate, 0.5 part of emulsified silicone oil defoamer, 10 parts of surfactant 0.5 part of sodium dialkylbenzene sulfonate, 40 parts of solvent ethyl acetate.

[0018] The above-mentioned preparation method of moisture-proof coating includes the following steps:

[0019] Step 1. Put the epoxy resin, chlorinated paraffin, barium sulfate, and bentonite in a mixer and stir and mix to obtain a mixture one;

[0020] Step 2. Place the mixture one in the reaction kettle, add polyacrylamide, defoamer, ethylene-vinyl acetate copolymer and plasticizer, and heat up to 70°C under t...

Embodiment 2

[0023] A moisture-proof coating comprising the following components by weight: 4 parts of bisphenol A epoxy resin, 2 parts of propylene glycol polyoxypropylene ether, 2 parts of chlorinated paraffin, 1 part of barium sulfate, 3 parts of silica sol, and bentonite 3 parts, 2 parts of stearic acid, 3 parts of polyacrylamide, 3 parts of ethylene-vinyl acetate copolymer, 1 part of plasticizer di-n-octyl phthalate, 0.6 part of emulsified silicone oil defoamer, 10 parts of surfactant 0.6 parts of sodium dialkylbenzene sulfonate, 43 parts of solvent ethyl acetate.

[0024] The above-mentioned preparation method of moisture-proof coating includes the following steps:

[0025] Step 1. Put the epoxy resin, chlorinated paraffin, barium sulfate, and bentonite in a mixer and stir and mix to obtain a mixture one;

[0026] Step 2. Place the mixture one in the reaction kettle, add polyacrylamide, defoamer, ethylene-vinyl acetate copolymer and plasticizer, and heat up to 73°C under the protection of ...

Embodiment 3

[0029] A moisture-proof coating comprising the following components in terms of weight components: 6 parts of bisphenol A epoxy resin, 3 parts of propylene glycol polyoxypropylene ether, 2 parts of chlorinated paraffin, 2 parts of barium sulfate, 4 parts of silica sol, and bentonite 6 parts, 3 parts of stearic acid, 4 parts of polyacrylamide, 3 parts of ethylene-vinyl acetate copolymer, 2 parts of plasticizer di-n-octyl phthalate, 0.8 parts of emulsified silicone oil defoamer, 10 parts of surfactant 0.7 parts of sodium dialkylbenzene sulfonate, 46 parts of solvent ethyl acetate.

[0030] The above-mentioned preparation method of moisture-proof coating includes the following steps:

[0031] Step 1. Put the epoxy resin, chlorinated paraffin, barium sulfate, and bentonite in a mixer and stir and mix to obtain a mixture one;

[0032] Step 2. Place the mixture one in the reactor, add polyacrylamide, defoamer, ethylene-vinyl acetate copolymer and plasticizer, and heat up to 78°C under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com