A kind of popping pearl rubber material for high weather resistance cigarettes and its preparation method

A weather resistance, cigarette technology, applied in tobacco, application, e-liquid filter and other directions, can solve the problems of direct use of gelatin, easy water absorption swelling strength and elastic modulus, low gelatin strength and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

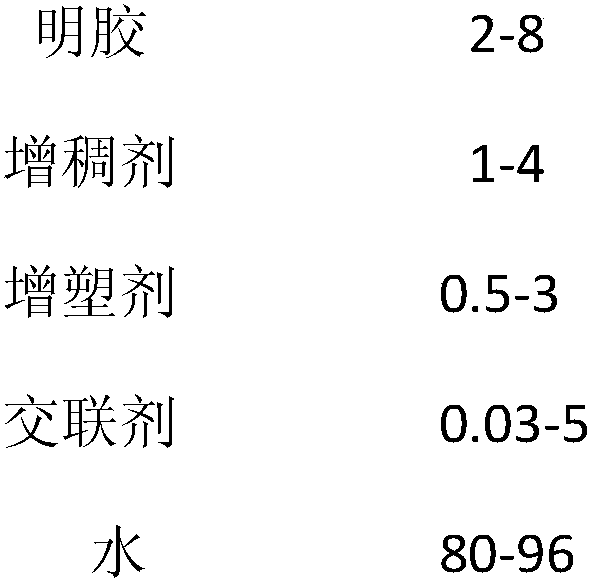

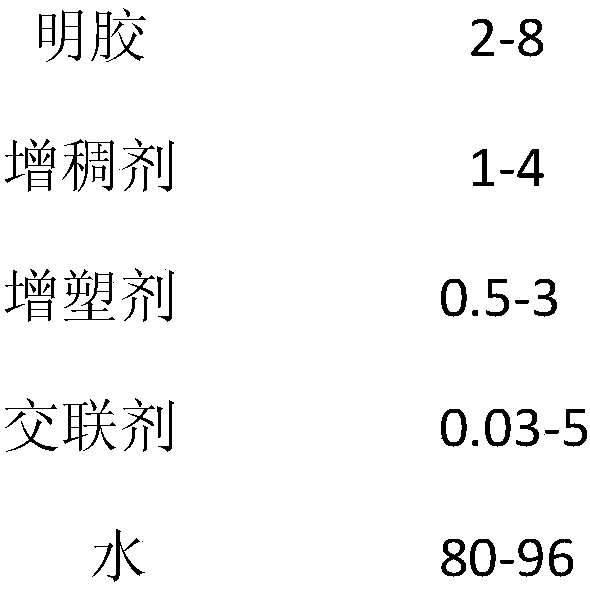

Method used

Image

Examples

Embodiment 1

[0019] Example 1, a high-weather-resistant cigarette popping rubber material is composed of the following components and raw materials in parts by weight: 5 parts of gelatin, 1.5 parts of carrageenan, 1 part of glycerin, 0.075 parts of glutaraldehyde, and 92 parts of water. The specific preparation method is as follows: first mix 1.5 parts of carrageenan with 92 parts of water, heat in a water bath to 65±5°C, stir and dissolve to form a homogeneous solution, then add gelatin and glycerin, heat to dissolve for 1-2 hours, and the heating temperature is 65±5°C , after mixing evenly, add 0.075 parts of glutaraldehyde, stir and react for 15 minutes, let it stand still, and pass through a 60-100 mesh screen under heat preservation after the foam floats up, and the obtained filtrate is the high-weather resistance cigarette popping rubber material.

[0020] Use the rubber material prepared in Example 1 to adopt the DWJSYJ-I type small capsule drop pilling machine to drop the quick-frie...

Embodiment 2

[0021] Example 2, a high-weather-resistant cigarette popping rubber material is composed of the following components and raw materials in parts by weight: 6 parts of gelatin, 2 parts of polyvinyl alcohol, 2 parts of polyethylene glycol, 5 parts of dialdehyde starch, 85 parts of water. The preparation method is as follows: first mix 2 parts of polyvinyl alcohol with 85 parts of water, heat in a water bath to 85±5°C, stir and dissolve to form a homogeneous solution, then add 6 parts of gelatin and 2 parts of polyethylene glycol, heat and dissolve for 1-2 hours, The heating temperature is 55±5°C, after mixing evenly, add 5 parts of dialdehyde starch and stir for 1 hour, let it stand still, after the foam floats up, pass through a 60-100 mesh screen under heat preservation, and the obtained filtrate is used for high weather resistance cigarettes Explosive bead rubber material.

[0022] The rubber material prepared in Example 2 is used to drop the quick-fried beads B in the DWJSYJ...

Embodiment 3

[0023] Example 3, a high-weather-resistant cigarette popping rubber material is composed of the following components and raw materials in parts by weight: 8 parts of gelatin, 3 parts of sodium alginate, 3 parts of sorbitol, 0.1 part of glyoxal, water 86 copies. The preparation method is as follows: first mix 3 parts of sodium alginate with 86 parts of water, heat in a water bath to 65±5°C, stir and dissolve to form a uniform solution, then add 8 parts of gelatin and 3 parts of sorbitol, heat to dissolve for 1-2 hours, and heat The temperature is 65±5°C. After mixing evenly, add 0.1 part of glyoxal and stir for 25 minutes, let it stand still, and pass through a 60-100 mesh screen under heat preservation after the foam floats up. The obtained filtrate is the high weather resistance cigarette explosive Bead rubber material.

[0024] Use the rubber material prepared in Example 3 to use the DWJSYJ-I type small capsule dropping pill machine to drip and produce the quick-fried beads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com