Processing technology of anti-scratch wear-resistant 5G high-precision photoelectric integrated circuit board

A technology of optoelectronic integration and processing technology, which is applied in circuit substrate materials, printed circuit components, non-polymer adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

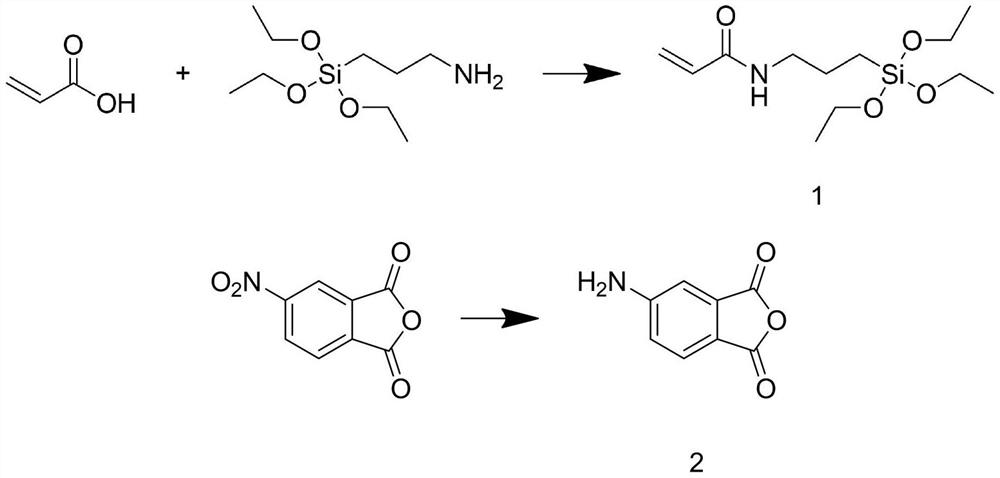

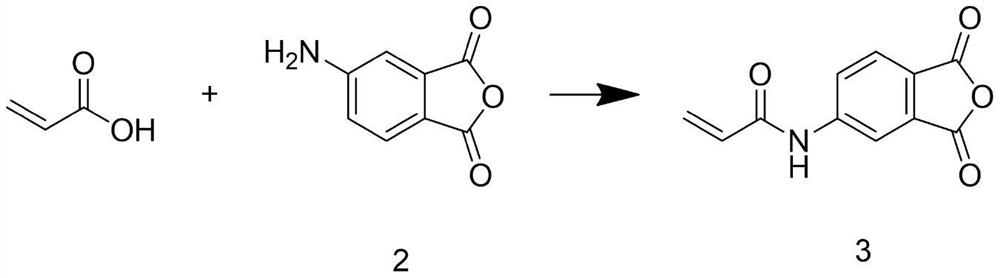

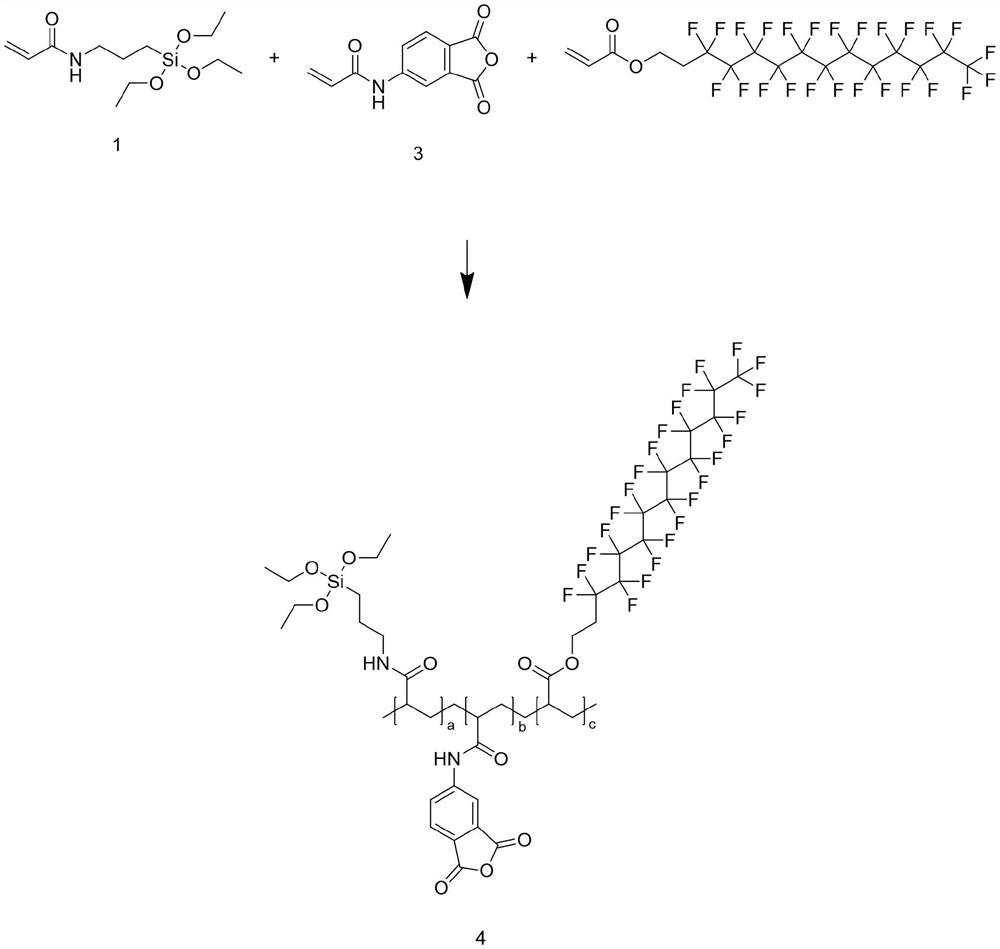

Method used

Image

Examples

Embodiment 1

[0039] A scratch-resistant and wear-resistant 5G high-precision optoelectronic integrated circuit board processing technology, specifically including the following steps:

[0040] Step S1: Disperse the modified epoxy resin and silicon carbide in deionized water, stir at a speed of 150r / min, and a temperature of 60°C, add sodium hydroxide, react for 1h, and distill off the deionized water , to prepare glue;

[0041]Step S2: Mix alumina, silicon dioxide, calcium zirconate, potassium carbonate, and methanol, add them into a ball mill, and perform ball milling and mixing. After ball milling for 20 minutes, add adhesive liquid and modified curing agent, and continue ball milling until the mixture is uniform. The mixed material is obtained, put the mixed material into a mold, and press-molded at a temperature of 110°C to obtain a substrate, and integrate electronic components on the substrate to obtain a scratch-resistant and wear-resistant 5G high-precision optoelectronic integrate...

Embodiment 2

[0050] A scratch-resistant and wear-resistant 5G high-precision optoelectronic integrated circuit board processing technology, specifically including the following steps:

[0051] Step S1: Disperse the modified epoxy resin and silicon carbide in deionized water, stir at a speed of 180r / min and a temperature of 65°C, add sodium hydroxide, react for 1.3h, and distill to remove deionization water to make the viscous liquid;

[0052] Step S2: Mix alumina, silicon dioxide, calcium zirconate, potassium carbonate, and methanol, add them into a ball mill, and perform ball milling and mixing. After ball milling for 25 minutes, add adhesive liquid and modified curing agent, and continue ball milling until the mixture is uniform. The mixed material is obtained, put the mixed material into a mold, and press-molded at a temperature of 115°C to obtain a substrate, and integrate electronic components on the substrate to obtain a scratch-resistant and wear-resistant 5G high-precision optoelec...

Embodiment 3

[0061] A scratch-resistant and wear-resistant 5G high-precision optoelectronic integrated circuit board processing technology, specifically including the following steps:

[0062] Step S1: Disperse the modified epoxy resin and silicon carbide in deionized water, stir at a speed of 200r / min and a temperature of 70°C, add sodium hydroxide, react for 1.5h, and distill to remove deionization water to make the viscous liquid;

[0063] Step S2: Mix alumina, silicon dioxide, calcium zirconate, potassium carbonate, and methanol, add them to a ball mill, and perform ball milling and mixing. After ball milling for 30 minutes, add adhesive liquid and modified curing agent, and continue ball milling until the mixture is uniform. The mixed material is obtained, put the mixed material into a mold, and press-molded at a temperature of 120°C to obtain a substrate, and integrate electronic components on the substrate to obtain a scratch-resistant and wear-resistant 5G high-precision optoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com