Method for effectively improving 3D printing precision and strength of hollow part

A 3D printing, hollow part technology, applied in 3D object support structure, additive manufacturing, processing platform/substrate, etc., can solve the problems of printing accuracy and strength, support material cannot be recycled, moisture absorption and other problems, to simplify printing equipment Structure and function, the effect of reducing equipment development and printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

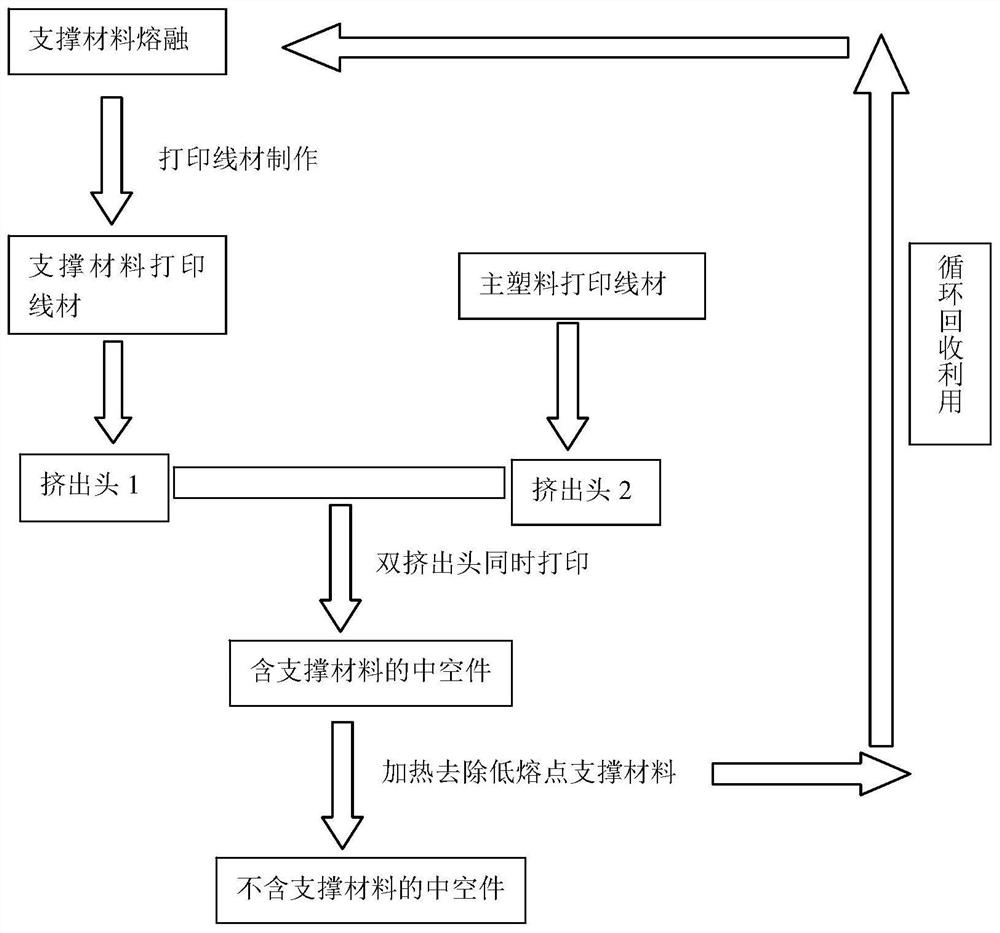

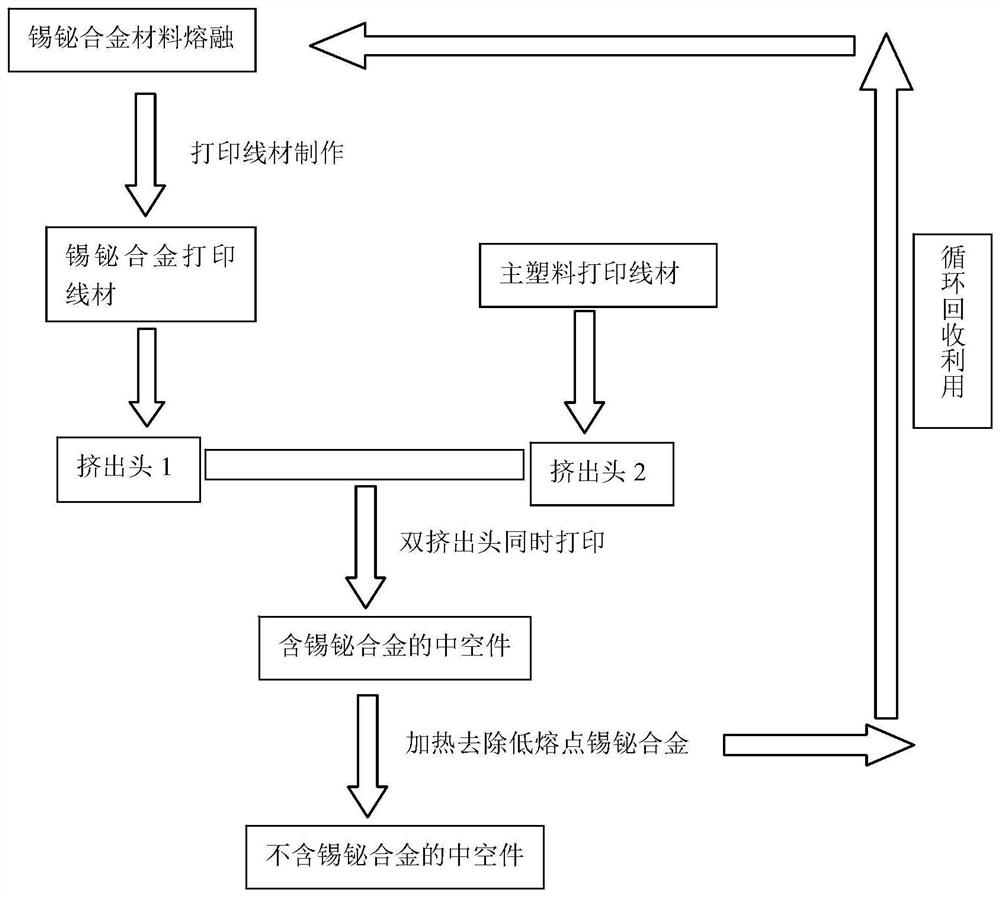

[0031] Reference manual attached figure 2 , a method for effectively improving the accuracy and strength of 3D printing of hollow parts, the steps are as follows:

[0032] S1: Select tin-bismuth alloy material as the basic material of the supporting structure, melt it, and form tin-bismuth alloy printing wire after processing;

[0033] S2: Use the dual extrusion heads to print the tin-bismuth alloy printing wire and the main plastic printing wire simultaneously, and print the hollow part synchronously, thereby forming a hollow part containing the tin-bismuth alloy;

[0034] S3: After the printing is completed, remove the tin-bismuth alloy material from the hollow part by boiling or heating in an oven;

[0035] S4: Recycling the above-mentioned tin-bismuth alloy material, the above-mentioned tin-bismuth alloy material can be recycled and melted again to make a printing wire for repeated use.

[0036] The supporting material of the present invention is tin-bismuth alloy with ...

Embodiment 2

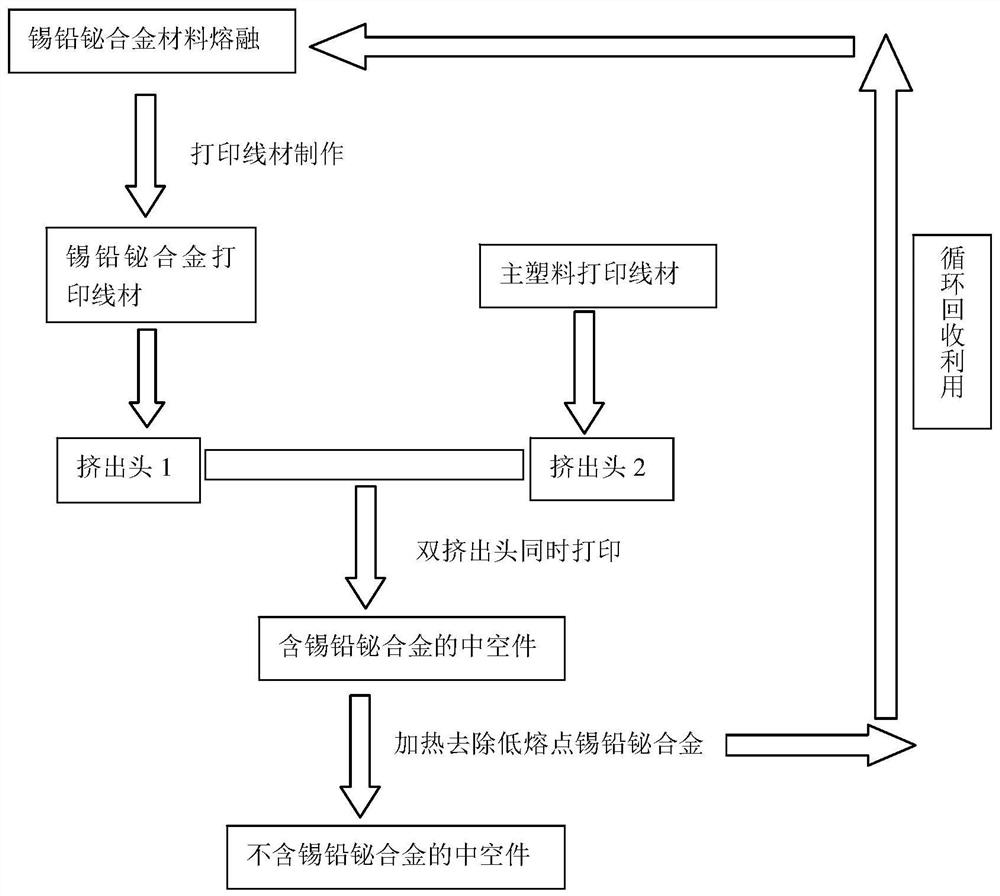

[0038] Reference manual attached image 3 , a method for effectively improving the accuracy and strength of 3D printing of hollow parts, the steps are as follows:

[0039] S1: Select tin-lead-bismuth alloy material as the basic material of the supporting structure, melt it, and form tin-lead-bismuth alloy printing wire after processing;

[0040] S2: Use the dual extrusion heads to print the tin-lead-bismuth alloy printing wire and the main plastic printing wire simultaneously, and print the hollow part synchronously, and then form the hollow part containing the tin-lead-bismuth alloy;

[0041] S3: After the printing is completed, remove the tin-lead-bismuth alloy material from the hollow part by boiling water or heating in an oven;

[0042] S4: Recycling the above-mentioned tin-lead-bismuth alloy material, the above-mentioned tin-lead-bismuth alloy material can be recycled and melted again to make a printing wire for repeated use.

[0043] The supporting material of the pres...

Embodiment 3

[0045] Reference manual attached Figure 4 , a method for effectively improving the accuracy and strength of 3D printing of hollow parts, the steps are as follows:

[0046] S1: Select the lead-bismuth alloy material as the basic material of the supporting structure, melt it, and form the lead-bismuth alloy printing wire after processing;

[0047] S2: Use the dual extrusion heads to simultaneously and separately print the lead-bismuth alloy printing wire and the main plastic printing wire, and print the hollow part synchronously, thereby forming a hollow part containing the lead-bismuth alloy;

[0048] S3: After the printing is completed, remove the lead-bismuth alloy material from the hollow part by boiling water or heating in an oven;

[0049] S4: Recycling the above-mentioned lead-bismuth alloy material, the above-mentioned lead-bismuth alloy material can be recycled and melted again to make a printing wire for reuse.

[0050] The support material of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com