Processing method of pleurotus eryngii enzyme byproduct meal replacement powder

A processing method and technology of Pleurotus eryngii, applied in the field of food processing, can solve the problems of high-value and full-efficiency utilization of Pleurotus eryngii solid raw materials, improper resource handling, waste and environmental protection, and achieve full-efficiency high value-added comprehensive utilization and operation Convenience, enhanced effect of hypoglycemic and weight loss effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

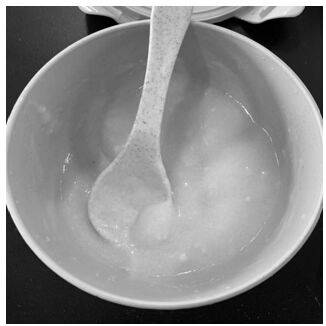

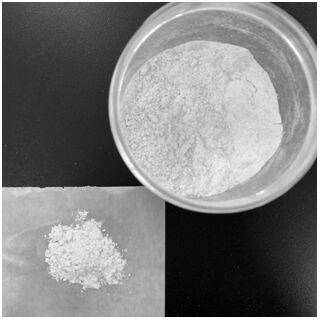

Image

Examples

Embodiment 1

[0025] (1) Soak the cut Pleurotus eryngii (small pieces of about 0.5cm) in a sodium bicarbonate solution with a mass fraction of 10%, soak for 5 minutes, take out the freeze-thaw treatment, and then use citric acid with a mass concentration of 15% The solution is soaked and rinsed twice, and the raw materials are put into the fermenter according to the weight ratio of sugar: material: water = 1:3:10, and the capacity accounts for three-fifths of the container;

[0026] (2) Take the activated and centrifuged lactic acid bacteria sludge, adjust to OD with sterile saline 600 =0.6, according to the ratio of Leuconostoc enterococcus:Lactobacillus plantarum=2:1, inoculate 5% of the mixed bacterial solution, place it at room temperature for enhanced fermentation, stir once a day, and filter it with gauze after 7 days to obtain Pleurotus eryngii enzyme solid product;

[0027] (3) Put the obtained solid product in an ultra-low temperature refrigerator for pre-freeze-drying, and then p...

Embodiment 2

[0030] (1) Soak the cut Pleurotus eryngii (small pieces of about 0.5cm) in a sodium bicarbonate solution with a mass fraction of 10%, soak for 5 minutes, take out the freeze-thaw treatment, and then use citric acid with a mass concentration of 15% The solution is soaked and rinsed twice, and the raw materials are put into the fermenter according to the weight ratio of sugar: material: water = 1:3:10, and the capacity accounts for three-fifths of the container;

[0031] (2) Take the activated and centrifuged lactic acid bacteria sludge, adjust it to OD600=0.6 with sterile saline, inoculate 5% of the mixed bacteria solution according to the ratio of Leuconostoc enterococci:Lactobacillus plantarum=2:1, and place in Intensive fermentation at room temperature. Stir once a day, ferment for 7 days and filter with gauze to obtain the solid product of Pleurotus eryngii enzyme.

[0032] (3) The obtained solid product is pre-lyophilized in an ultra-low temperature refrigerator, and then...

Embodiment 3

[0035] (1) Soak the cut Pleurotus eryngii (small pieces of about 0.5cm) in a sodium bicarbonate solution with a mass fraction of 10%, soak for 5 minutes, take out the freeze-thaw treatment, and then use citric acid with a mass concentration of 15% The solution is soaked and rinsed twice, and the raw materials are put into the fermenter according to the weight ratio of sugar: material: water = 1:3:10, and the capacity accounts for three-fifths of the container;

[0036] (2) Take the activated and centrifuged lactic acid bacteria sludge, adjust it to OD600=0.6 with sterile saline, inoculate 5% of the mixed bacterial solution according to the ratio of Leuconostoc enterococci:Lactobacillus plantarum=2:1, and place in Intensive fermentation at room temperature. Stir once a day, ferment for 7 days and filter with gauze to obtain the solid product of Pleurotus eryngii enzyme.

[0037] (3) The obtained solid product is pre-lyophilized in an ultra-low temperature refrigerator, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com