Low-viscosity, baking-resisting and oil-free fruit jam with long shelf life and preparation method thereof

A baking-resistant, low-viscosity technology, applied in the field of fruit jam, can solve the problems of short shelf life of fruit jam, high blood pressure, high blood fat, easy color change, etc., to achieve attractive product color, improve moisture absorption, and fullness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

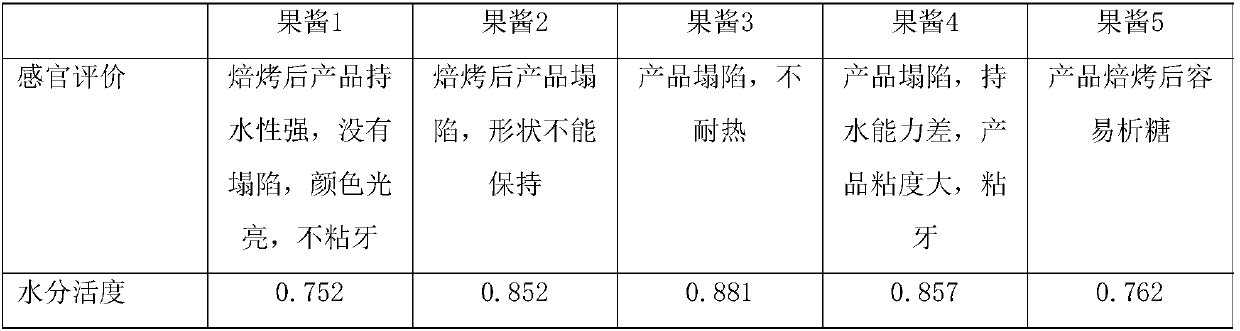

Examples

Embodiment 1

[0023] This embodiment mainly introduces the steps of utilizing the method to prepare strawberry jam for baking:

[0024] (1) Strawberries with a concentration of 30% are beaten, and the mass fraction is 0.01% anhydrous sodium sulfite and 0.08% sodium erythorbate;

[0025] (2) Then add wax gourd puree, which is obtained by enzymatically hydrolyzing wax gourd at 50°C for 3 hours with 0.01% amylase, removing seeds, pressing and filtering;

[0026] (3) Food colloid (0.25% pectin and 0.02% xanthan gum) is mixed with white granulated sugar, then added to the above-mentioned strawberry pulp and stirred evenly;

[0027] (4) 6% modified starch hydroxypropyl distarch phosphate was dissolved in 7% cold water and mixed evenly, then added to strawberry pulp, heated to 85°C, and gelatinized for 30 minutes;

[0028] (5) adding 21% glucose powder and 21% maltose syrup for heating, and evaporating excess moisture;

[0029] (6) Add 0.5% citric acid and 0.1% sodium citrate at last, and select...

Embodiment 2

[0031] This embodiment mainly introduces the steps of utilizing the method to prepare hawthorn jam for baking:

[0032] (1) Add 0.008% anhydrous sodium sulfite and 0.05% sodium erythorbate in the hawthorn with a concentration of 30%, and then beat;

[0033] (2) Wax gourd is treated with 0.015% amylase at 45° C. for 4 hours, and added to the hawthorn pulp in step (1) after deseeding, pressing and filtering;

[0034] (3) Add the solution after mixing uniformly with 4% oxidized hydroxypropyl starch and 5% cold water in the slurry;

[0035] (4) Add 0.6% citric acid to 25% white granulated sugar and heat at 101°C for 20 minutes to obtain invert syrup: white granulated sugar can be hydrolyzed and converted in high-temperature acidic environment; then mixed with 0.25% sodium alginate and 0.03 % xanthan gum is added to the slurry in step (3) after mixing, then heated to 80°C for gelatinization for 50min, and evaporates excess water,

[0036] (5) Add 0.05% sodium citrate and 0.09% pr...

Embodiment 3

[0038] This embodiment mainly introduces the steps of utilizing the method to prepare pineapple jam for baking:

[0039] (1) using 0.03% amylase to enzymatically treat wax gourd at 40° C. for 3 hours, then remove the seeds of wax gourd and squeeze to obtain sugar-free wax gourd puree;

[0040] (2) adding 40% pineapple pulp, adding mass fraction in the pineapple pulp is 0.005% anhydrous sodium sulfite and 0.01% sodium erythorbate;

[0041] (3) mix with 3% oxidized hydroxypropyl starch and 3% adipic acid cross-linked acetate waxy cornstarch and 7% cold water, evenly add in the slurry in step (2);

[0042] (4) Mix 5% white sugar and food colloid (0.3% sodium alginate and 0.15% sodium carboxymethylcellulose), add 10% maltose syrup, and heat to 90°C for gelatinization for 20 minutes;

[0043] (5) Then add 25% white granulated sugar, 20% glucose powder, 10% maltose syrup, and evaporate excess water;

[0044] (6) Finally, 0.6% of citric acid, 0.1% of sodium citrate and 0.09% of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com