Preparation method and product of vinyl chloride, acrylate multi-copolymerized resin by mass polymerization process

A technology of acrylate and vinyl chloride, applied in the fields of acrylate copolymer resin and vinyl chloride, which can solve the problems of insufficient purity and gel performance, lack of thermal stability and whiteness, and excessive use of additives, etc., to achieve industrialization The effects of promotion, small linear expansion coefficient, and easy control of polymerization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

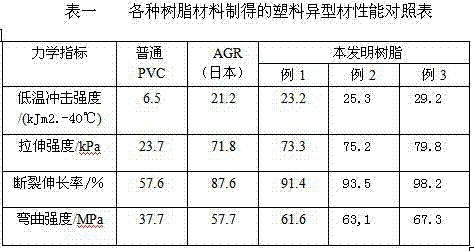

Examples

Embodiment 1

[0028] 1. Raw materials: commercially available 5% (wt%) acrylate monomer (composed of methyl acrylate and butyl acrylate in a mass ratio of 2:1), 95% (wt%) vinyl chloride monomer.

[0029] 2. Initiator: Di(2-ethyl)hexyl peroxydicarbonate and cumyl peroxyneodecanoate are compounded at a mass ratio of 1:2, the total mass of the initiator is 0.02% of the mass of the raw material, and the reaction During the process, the real-time dynamic mass fraction of the initiator in the system is controlled to be no more than 0.05%.

[0030] 3. Put 10% (wt%) raw material weight of vinyl chloride monomer and an initiator equivalent to 0.1% of the mass of the fed monomer into the pre-polymerization kettle, and stir at high speed, 40-43°C and 0.40-0.65Mpa pressure conditions Under the reaction, the prepolymerization product of vinyl chloride (VCM) is generated. When the weight-average degree of polymerization of the prepolymerization product reaches 10%, the VCM prepolymerization product is tr...

Embodiment 2

[0032] Repeat embodiment 1 step, difference is:

[0033] Raw material composition: commercially available 15% (wt%) acrylate monomer (such as ethyl acrylate and isooctyl acrylate at a mass ratio of 1:3), 85% (wt%) vinyl chloride monomer.

[0034] Initiator composition: Di(2-ethyl)hexyl peroxydicarbonate and cumyl peroxyneodecanoate are compounded at a mass ratio of 1:1, the total mass of the initiator is 0.08% of the mass of the raw material, the reaction process , the real-time dynamic mass fraction of the control initiator in the system is not greater than 0.05%.

[0035] During the reaction, keep the pressure in the polymerization tank at 0.70-0.75Mpa and the temperature at 60-63°C.

[0036] The measured weight-average degree of polymerization of acrylate is about 93%, the average molecular weight of the product is about 1100, the number-average molecular weight is about 48000, the whiteness is 81, and the gelation temperature is 77°C.

Embodiment 3

[0038] Repeat embodiment 1 step, difference is:

[0039] Composition of raw materials: 25% (wt%) commercially available acrylate monomer (composed of butyl acrylate, isooctyl acrylate, etc., nonyl acrylate in a weight ratio of 1:1:3), 75% (wt%) Vinyl chloride monomer.

[0040] Initiator composition: Di(2-ethyl)hexyl peroxydicarbonate and cumyl peroxyneodecanoate are compounded at a mass ratio of 2:1, the total mass of the initiator is 0.04% of the mass of the raw material, the reaction process , the real-time dynamic mass fraction of the control initiator in the system is not more than 0.05%.

[0041] During the reaction, keep the pressure in the polymerization tank at 0.58-0.72Mpa and the temperature at 68-70°C.

[0042] The measured weight-average degree of polymerization of acrylate is about 90%, the average molecular weight of the product is about 1100, the number-average molecular weight is about 44000, the whiteness of the product is 81, and the gelation temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com