Glue filling device and glue filling method thereof

A technology of glue filling and glue parts, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., which can solve the problems of reducing the operating life of the glue filling device and the deformation of the guide column, and achieves accurate positioning and stable transportation , the effect of safe glue filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be emphasized that the following implementations are only exemplary and not intended to limit the scope and application of the present invention.

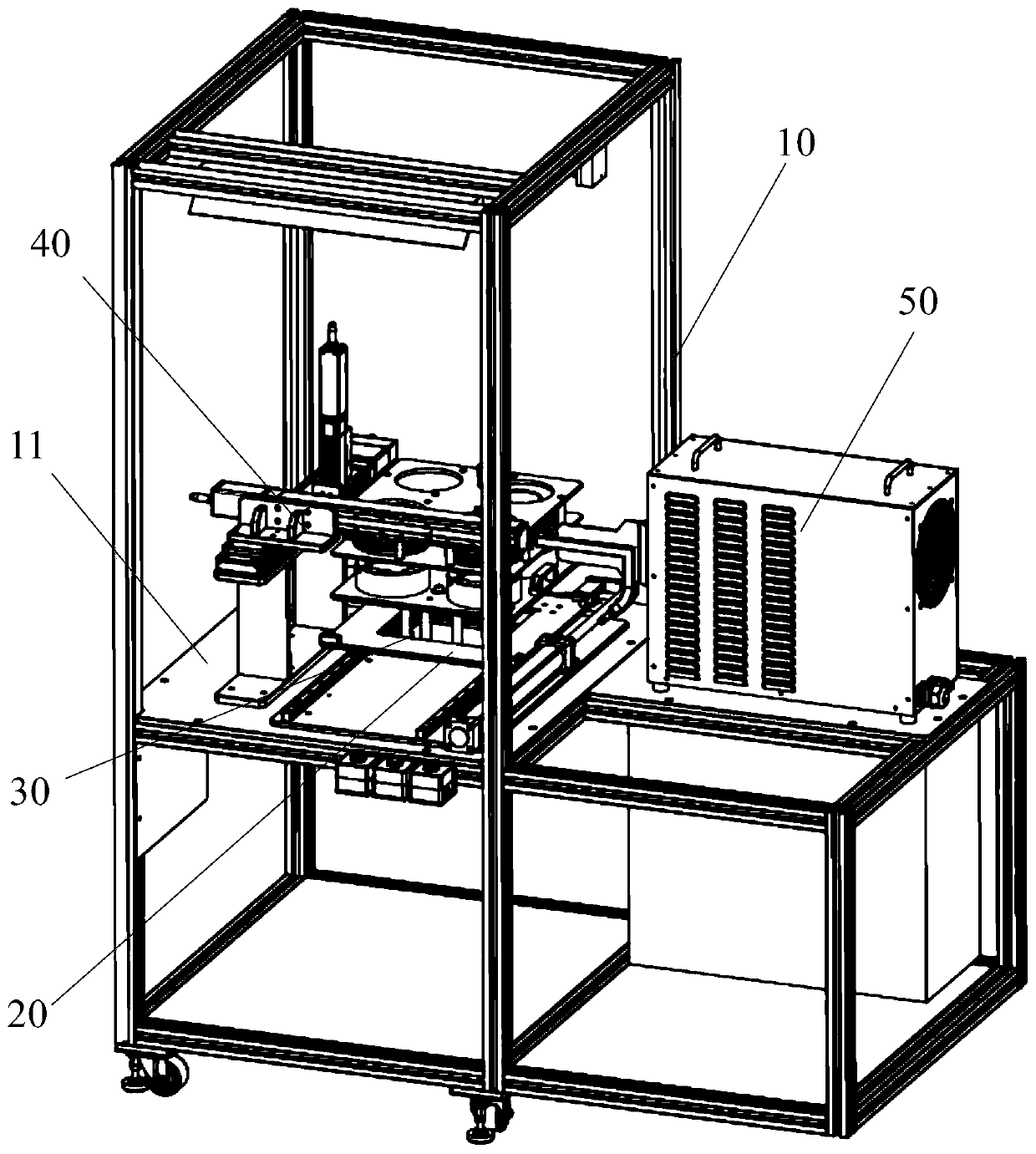

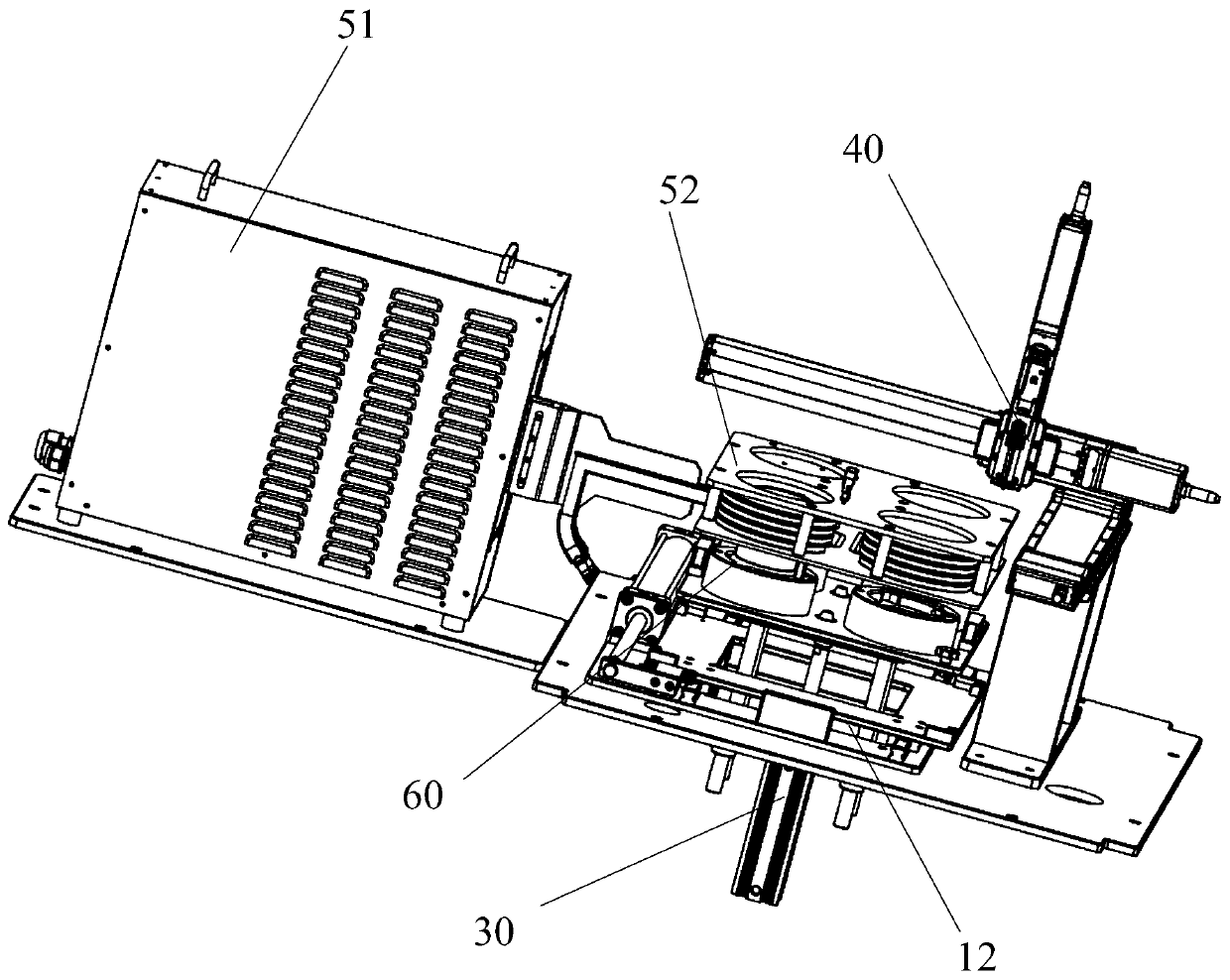

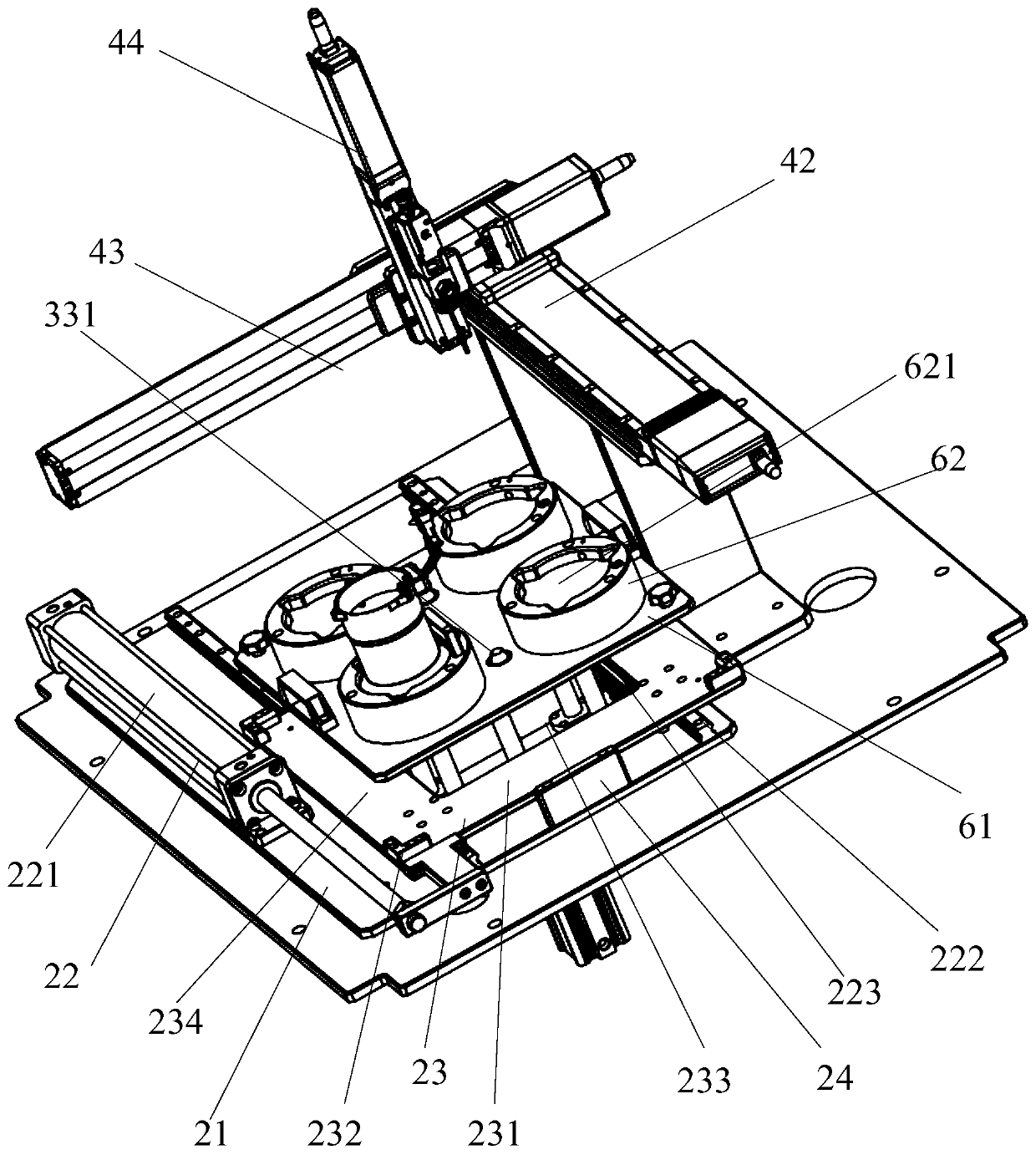

[0032] See Figure 1 to Figure 7 , the present invention is a glue filling device, which includes a fixed frame 10 with a base plate 11, a horizontal push mechanism 20 mounted on the base plate 11, a push mechanism 30 mounted on the base plate 11, and a glue filling device mounted on the base plate 11. The mechanism 40 , the heating mechanism 50 located above the horizontal pushing mechanism 20 , and the positioning mechanism 60 accommodated in the horizontal pushing mechanism 20 .

[0033] The fixing frame 10 is a frame structure, and the substrate 11 is fixed on the fixing frame 10 horizontally. The substrate 11 has a receiving hole 12 extending through its upper and lower surfaces.

[0034] The lateral pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com