Patents

Literature

45results about How to "Glue accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

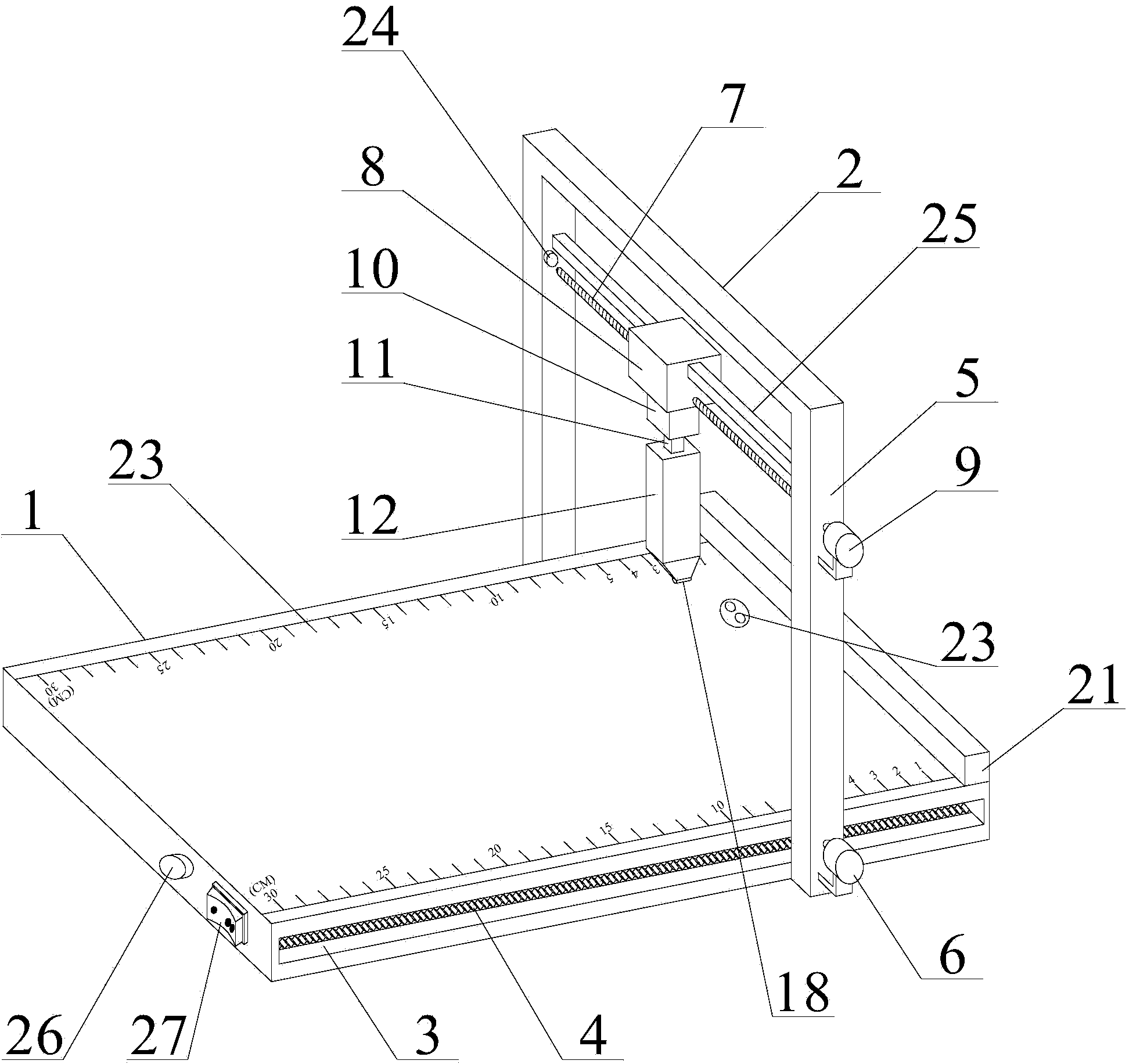

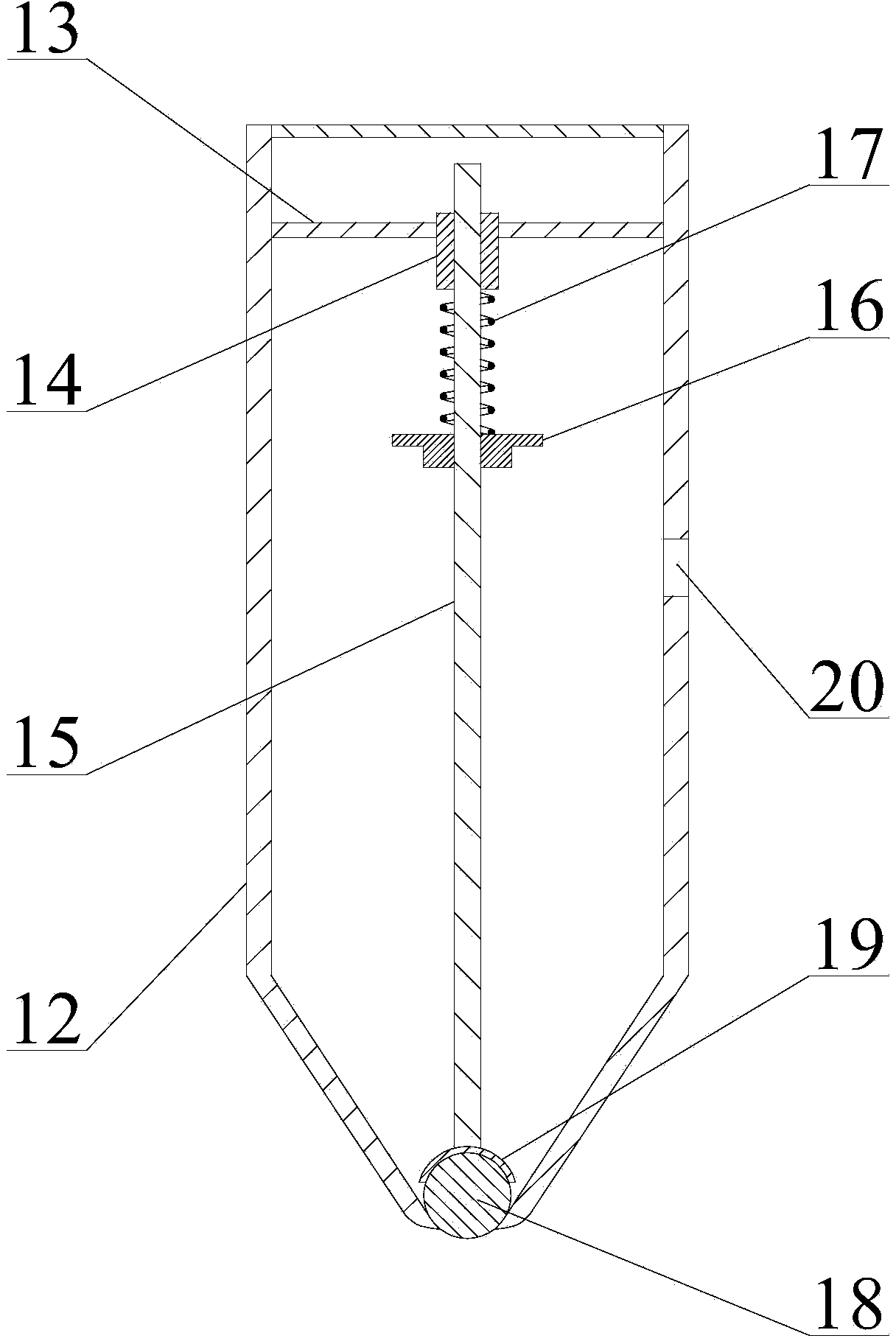

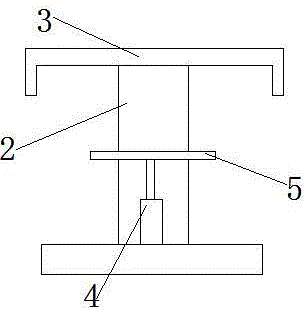

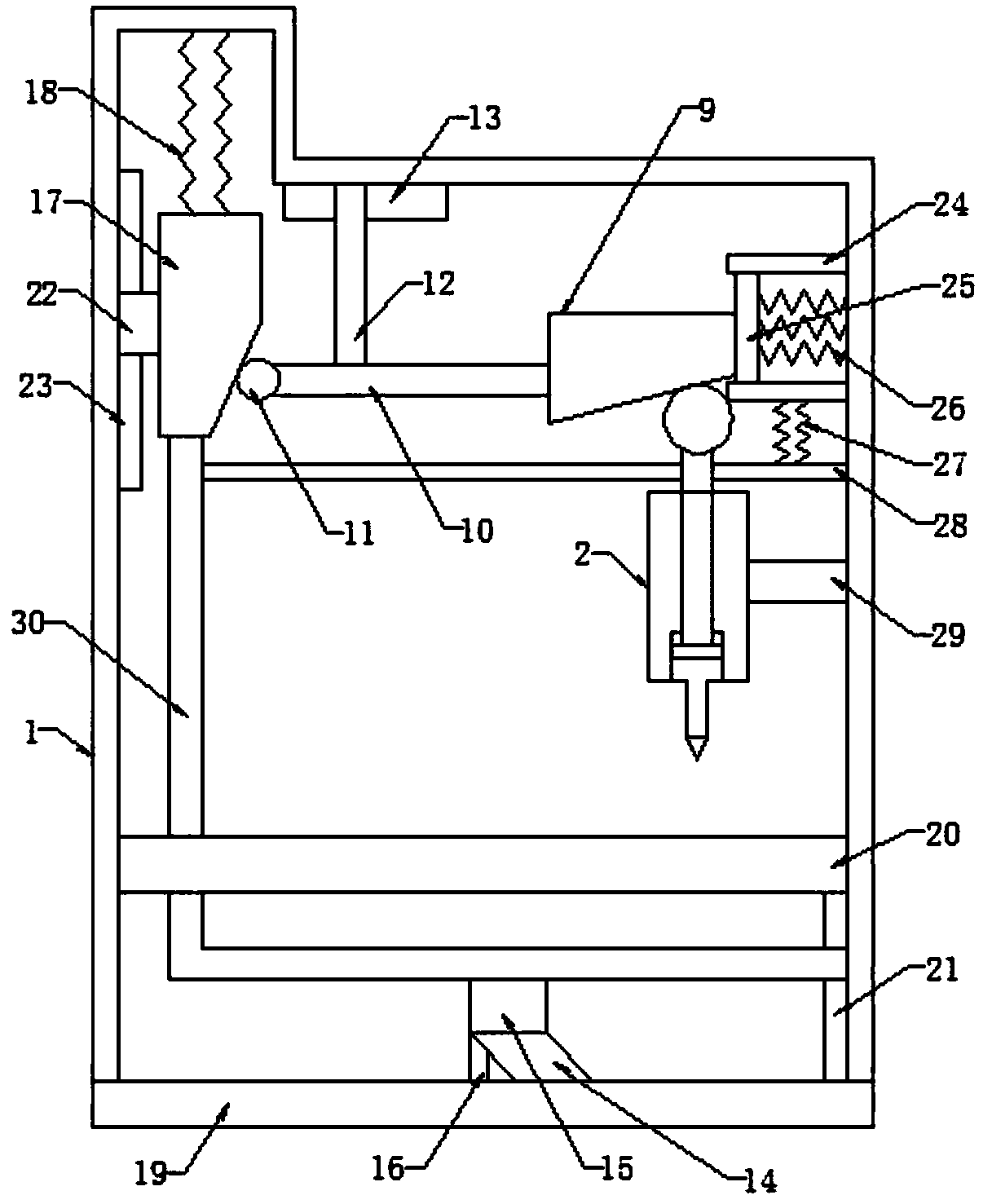

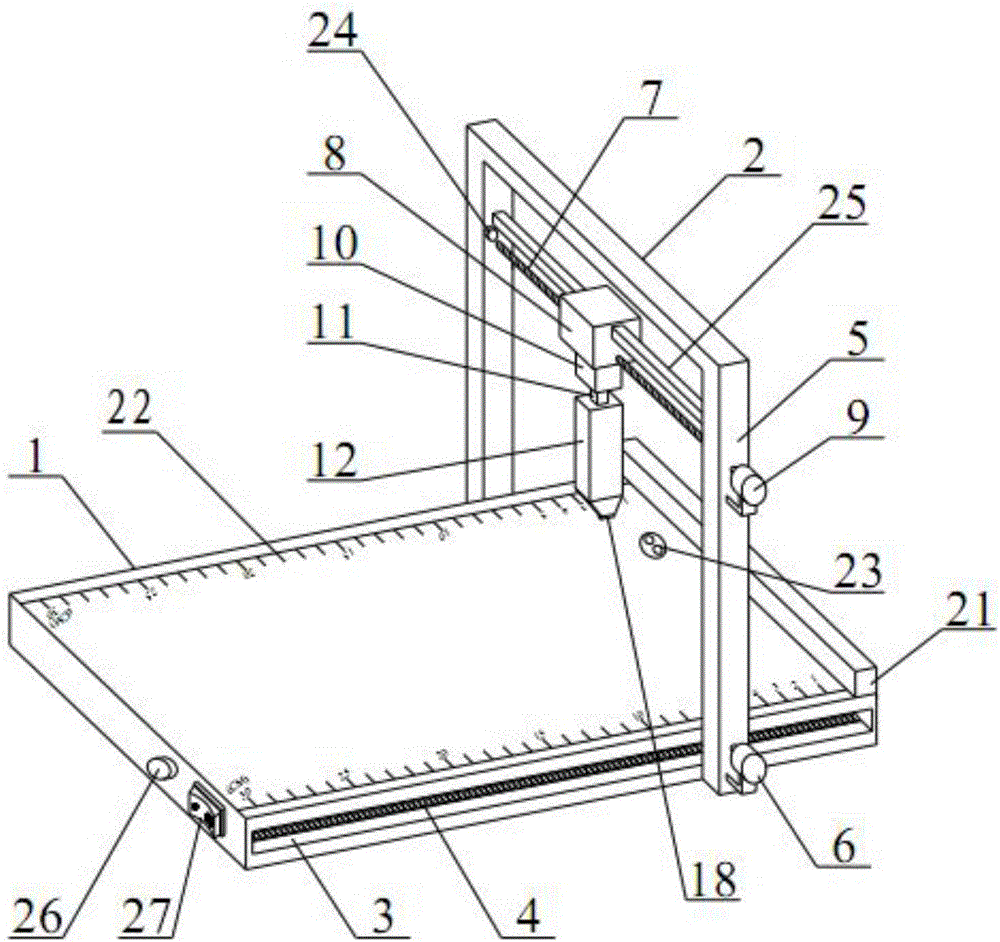

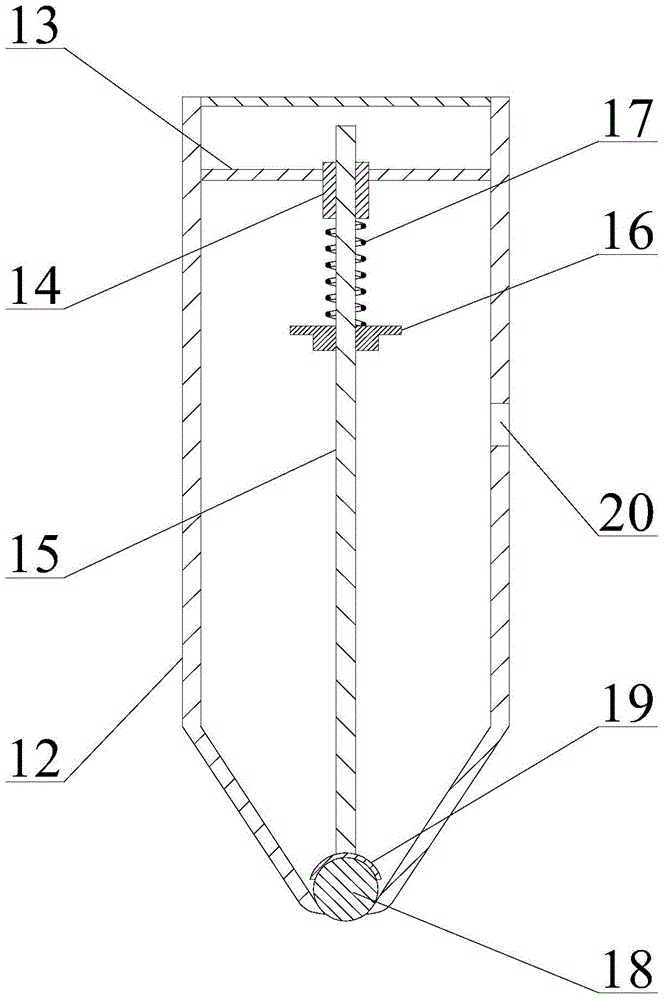

Small alternating current-direct current automatic glue spreader

InactiveCN103586163AAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machinePush pull

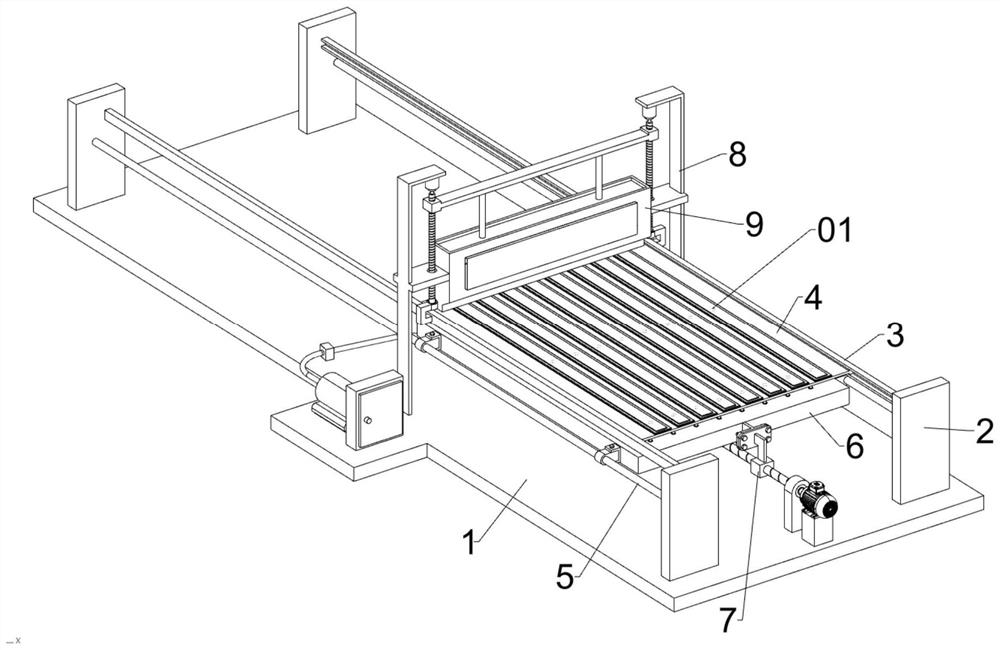

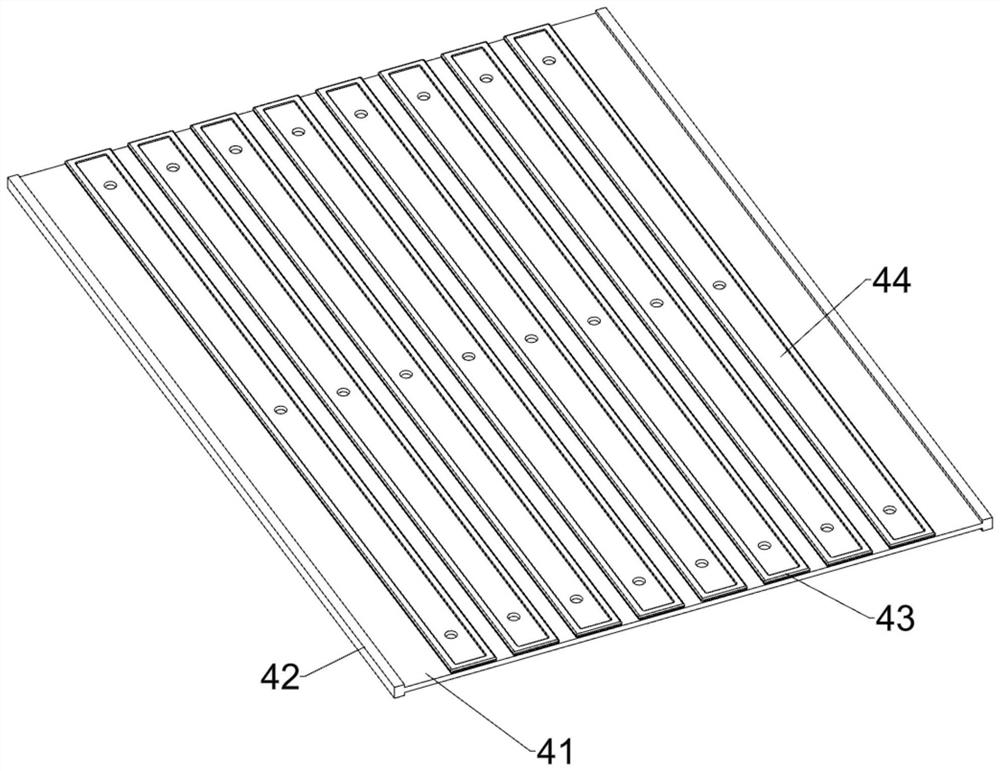

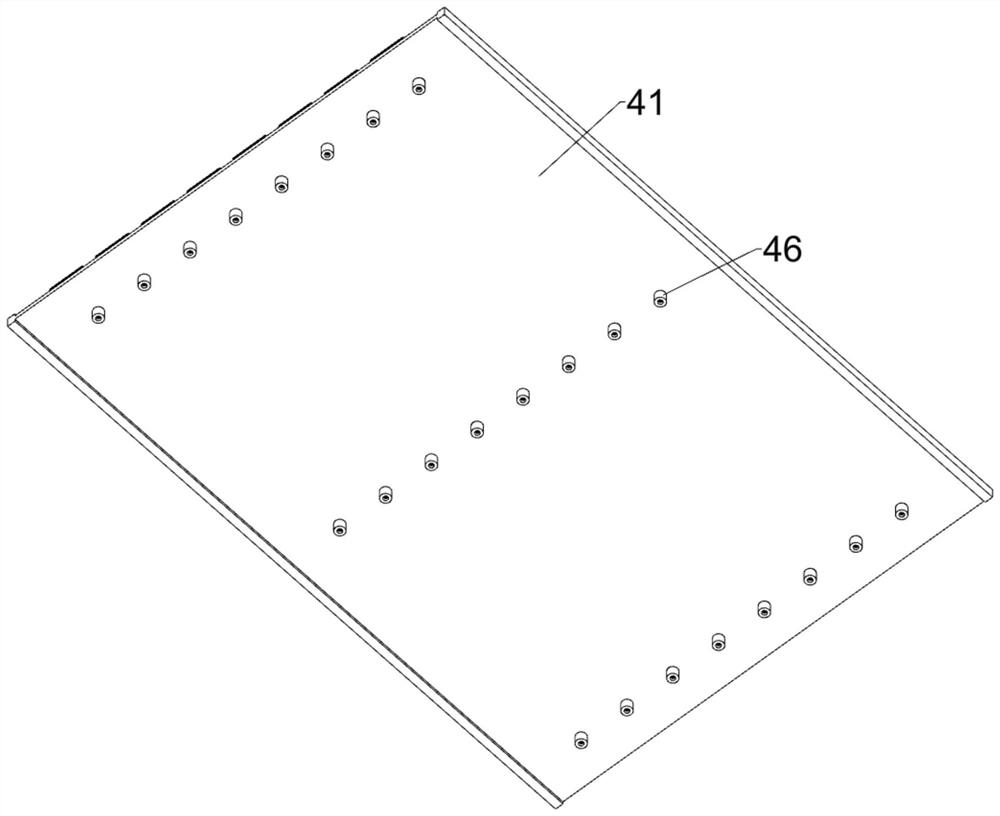

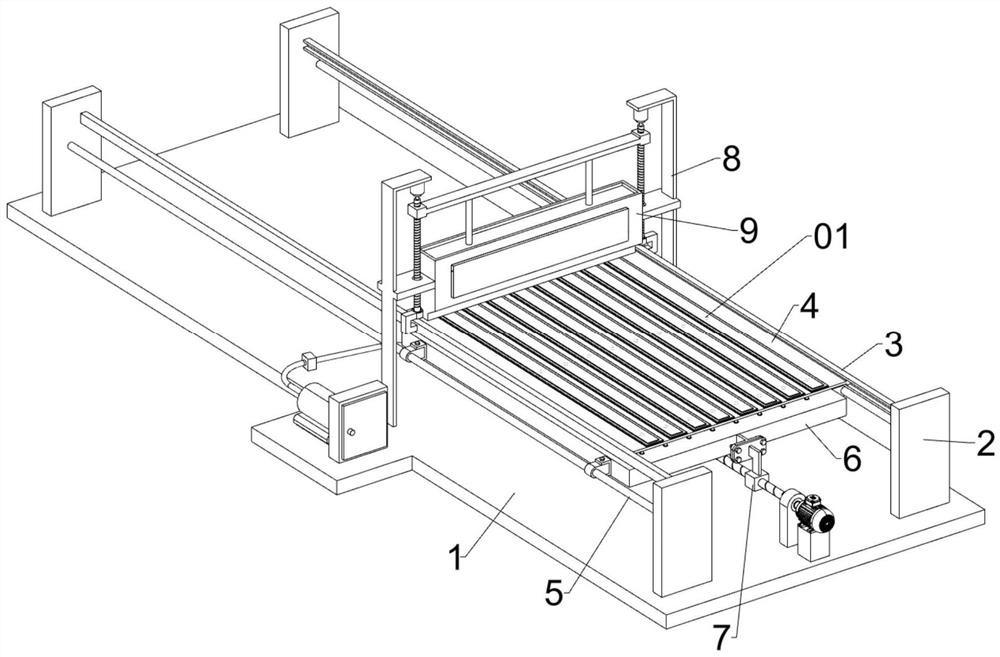

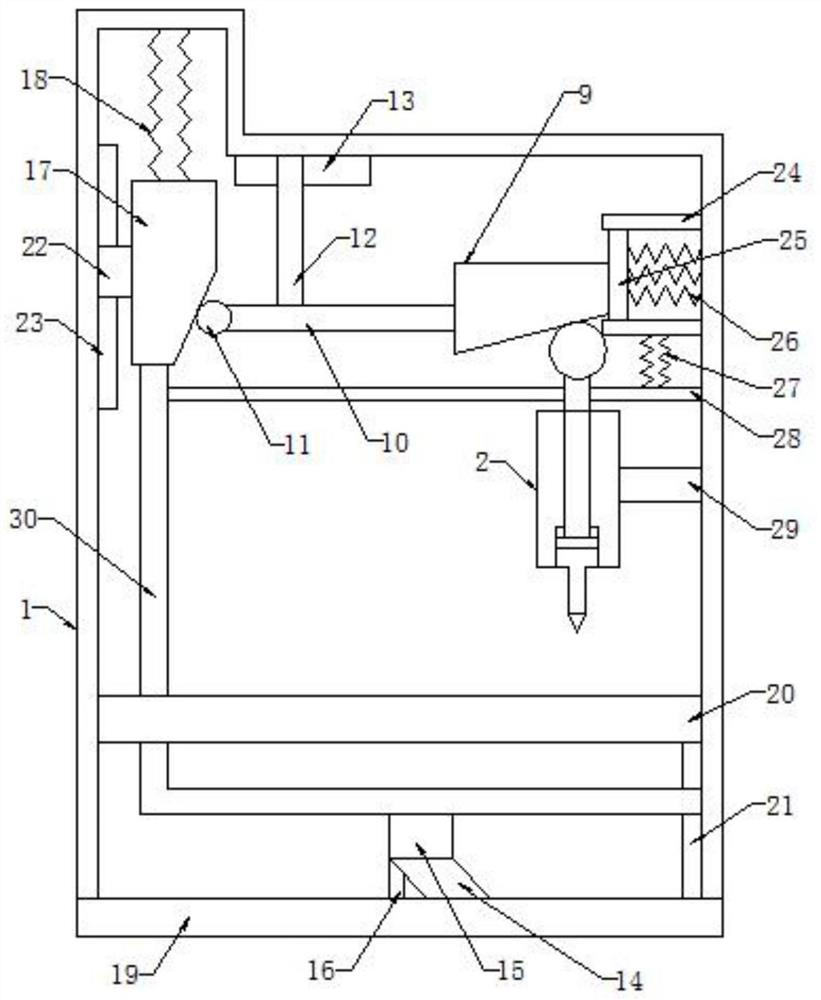

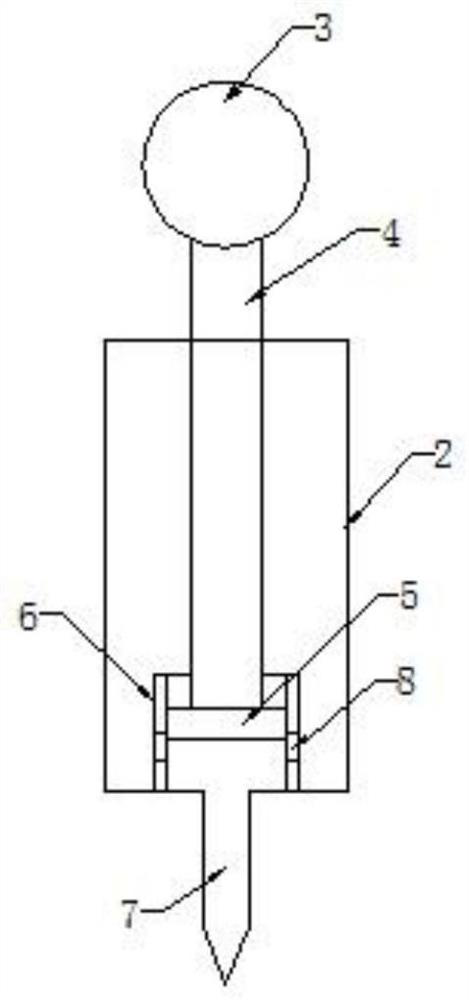

The invention discloses a small alternating current-direct current automatic glue spreader, and belongs to the field of office supplies. The glue spreader solves the problems that the manual glue spreading speed is low, the spreading is nonuniform, and adhesion is caused easily. Racks (4) are fixed in a cavity (3) of a bottom plate (1) of the glue spreader; gears meshed with the racks (4) are fixed on a cross rod of a gantry (2); a first motor (6) is fixed with one end of the cross rod; a screw rod (7) between two uprights (5) is sleeved with a slide block (8); a second motor (9) is fixed with one end of the screw rod (7); a push-pull electromagnet (10) is fixed below the slide block (8); a glue bottle (12) is fixed at the lower end of the push-pull electromagnet (10); the lower end of the glue bottle (12) is in an inverted trapezoid shape; a glue outlet is a strip-shaped port, and is closed by a cylindrical pressure head (18); and a pressure sheet (19) is fixed at the lower end of a threaded rod (15). The glue spreader has the advantages that the glue spreader is high in glue spreading speed, uniform in glue spreading, time-saving, labor-saving, and convenient to move and carry.

Owner:NORTHEAST GASOLINEEUM UNIV

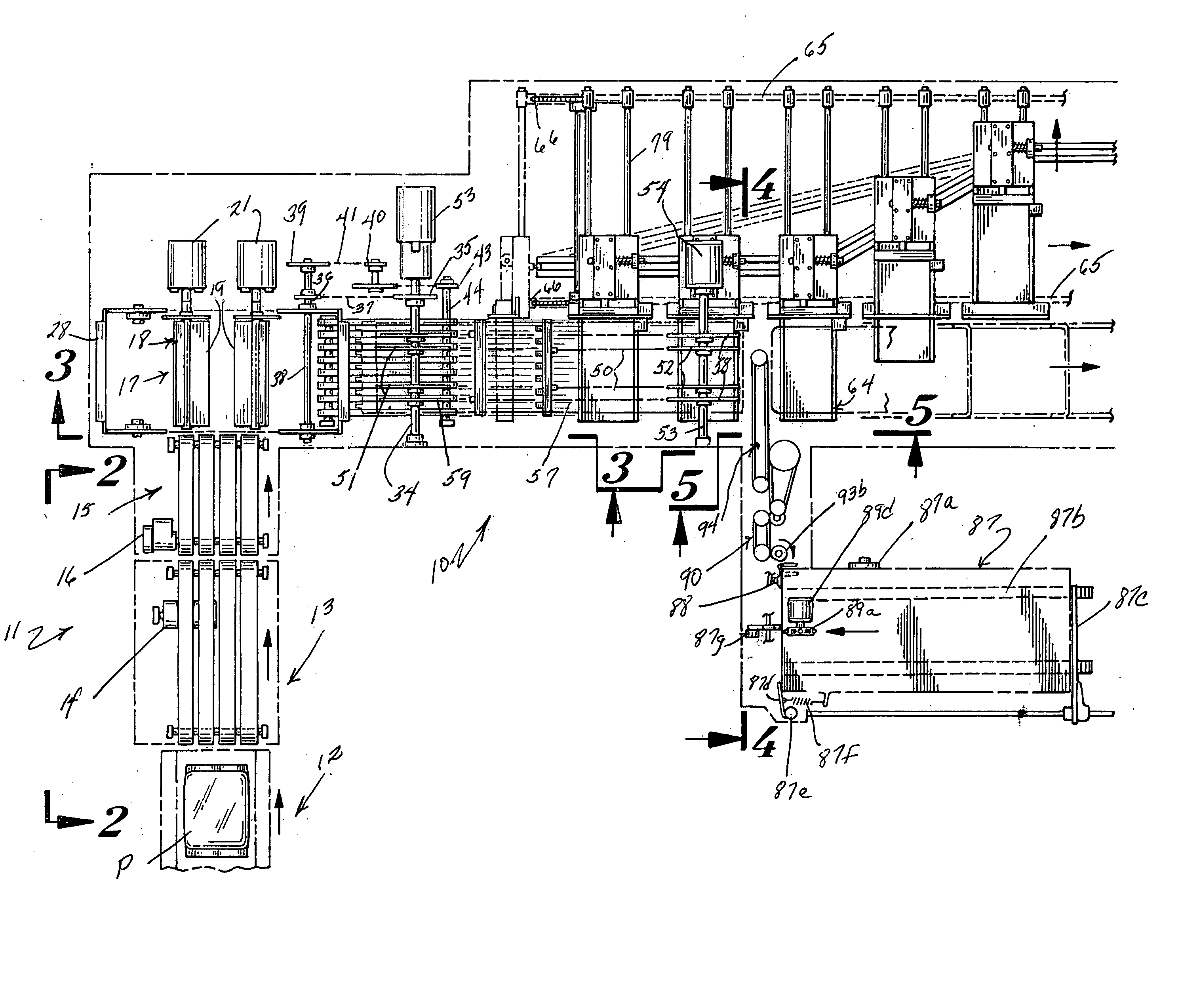

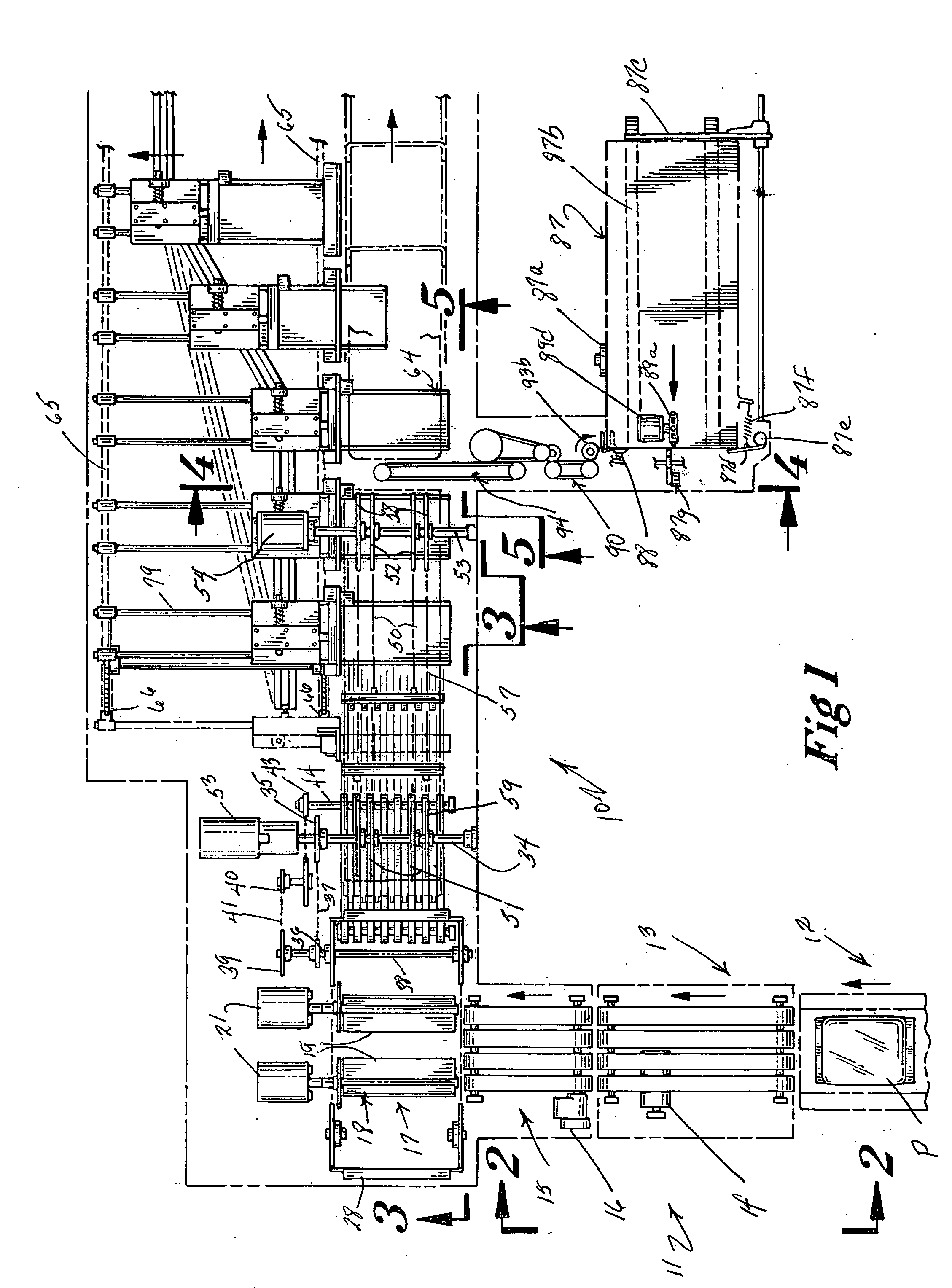

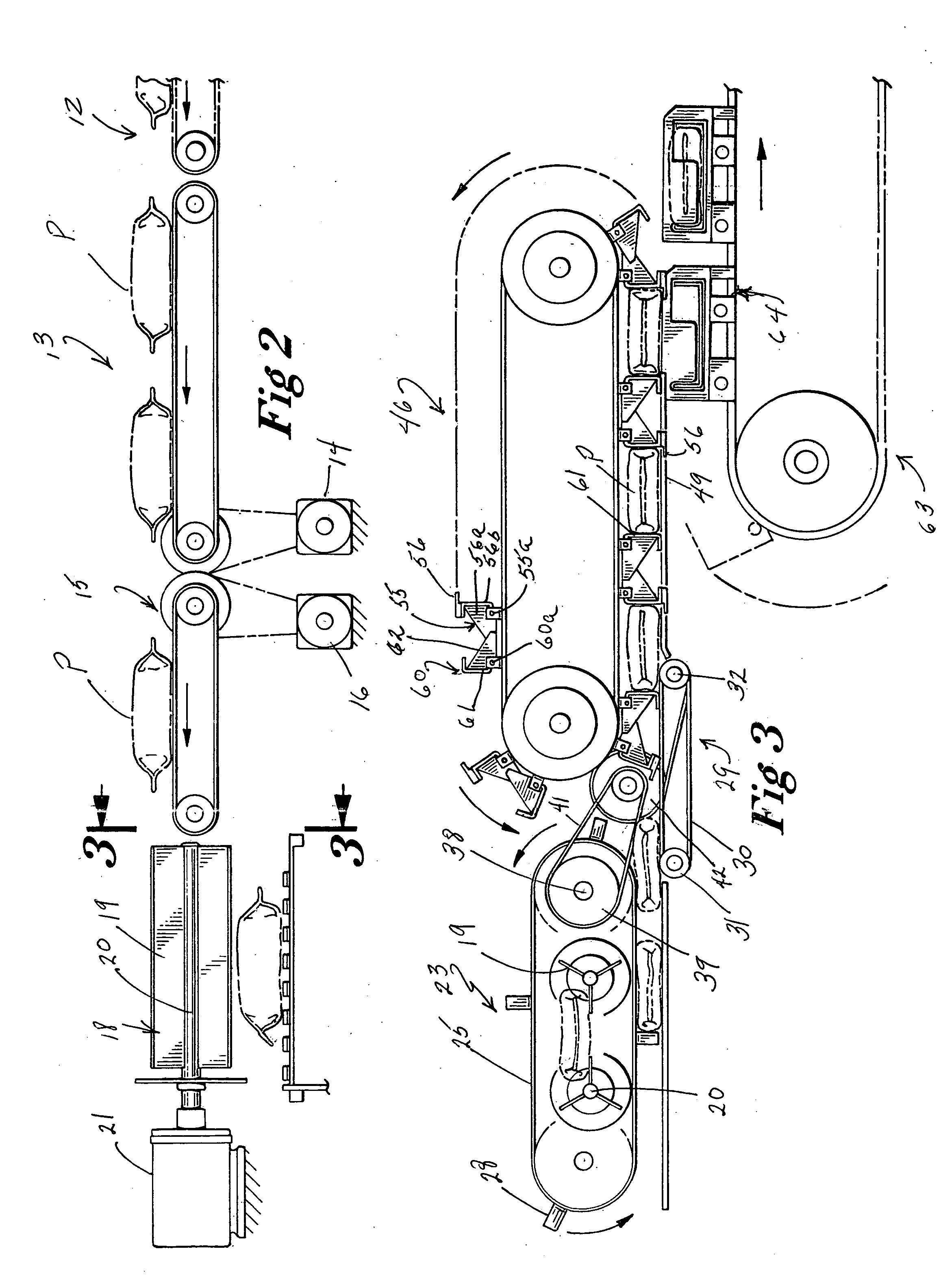

Wrap around carton packaging machine

InactiveUS20060037290A1Precise positioningGlue accurateWrapper folding/bending apparatusConveyor wrappingCompression deviceCarton

A packaging apparatus for wrapping a carton around a packaged product comprises a box mandrel conveyor including a plurality of mandrels which support the packaged product thereon. Packages are precisely fed to the mandrels of the box mandrel conveyor by a conditioning conveyor. Carton blanks are delivered to a conveying system for a carton magazine and are conveyed in vertical confronting relation to a mandrel. Each mandrel moves the carton blank against a large radius plows device thereby causing the carton blank to be folded around a mandrel containing a package. Folding and compression devices are provided for folding and compressing an end panel against a manufacturer's flap. Suitable flap closing means close the end flaps and upper and lower flaps after the mandrel is withdrawn from the carton.

Owner:SMITH BRENTON L

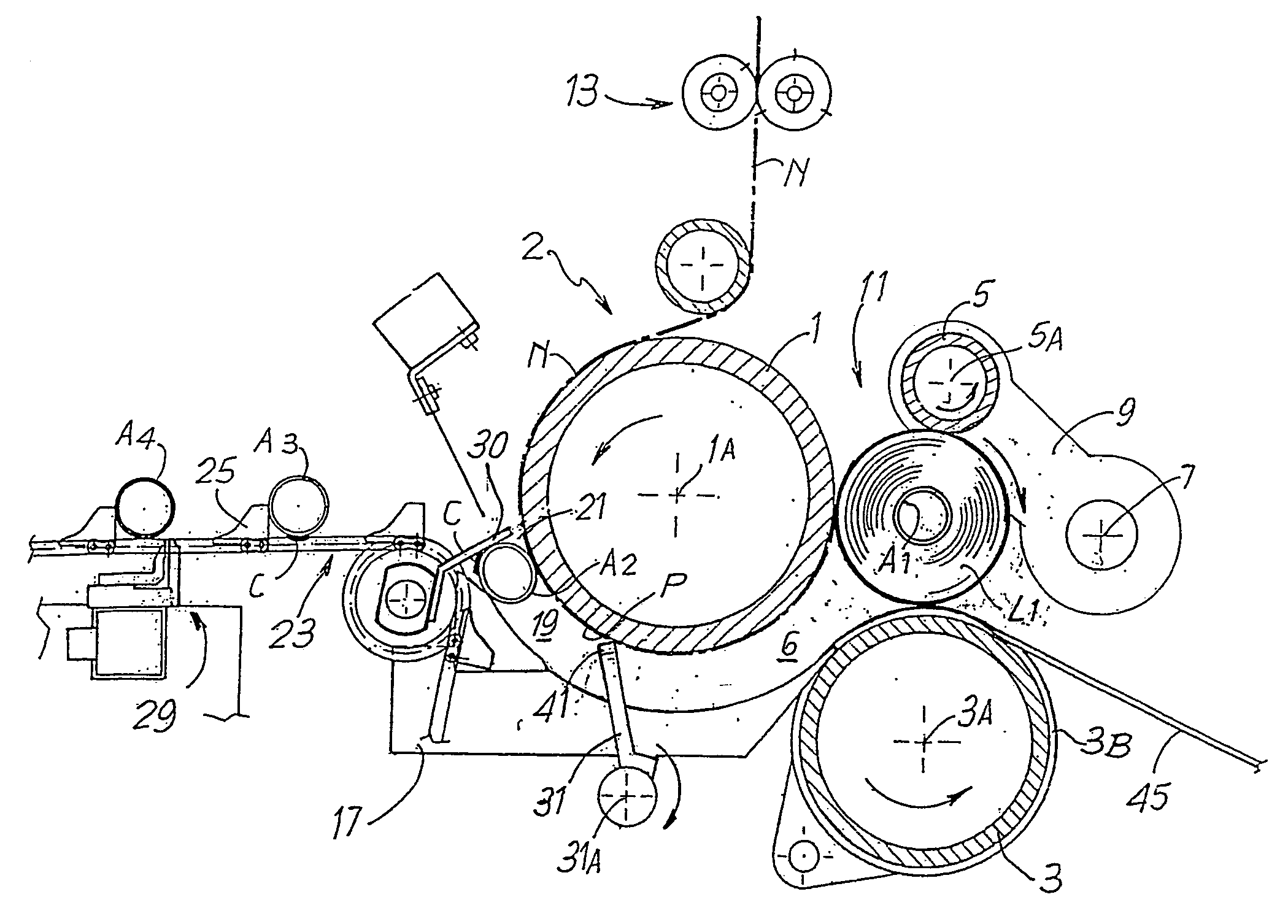

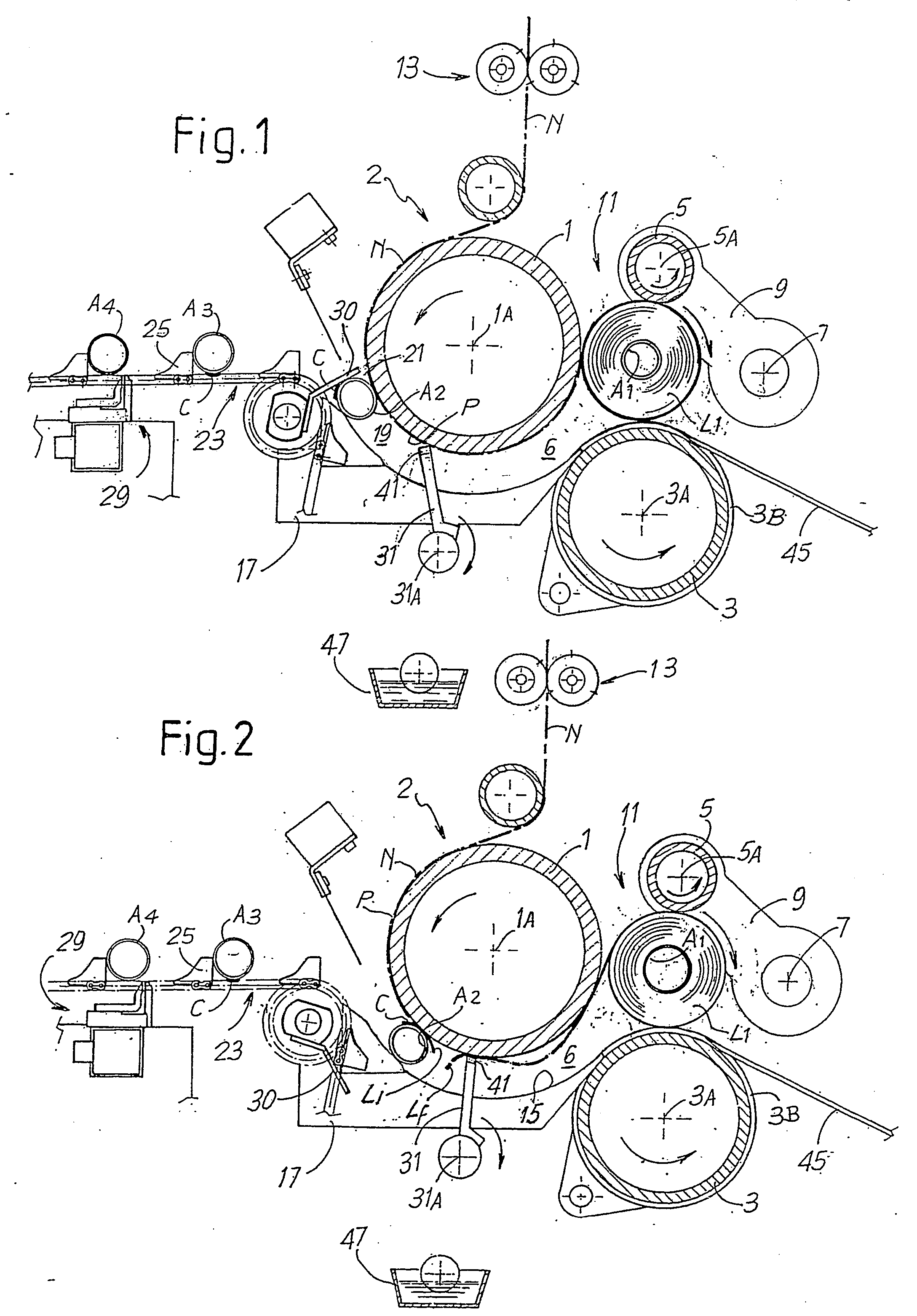

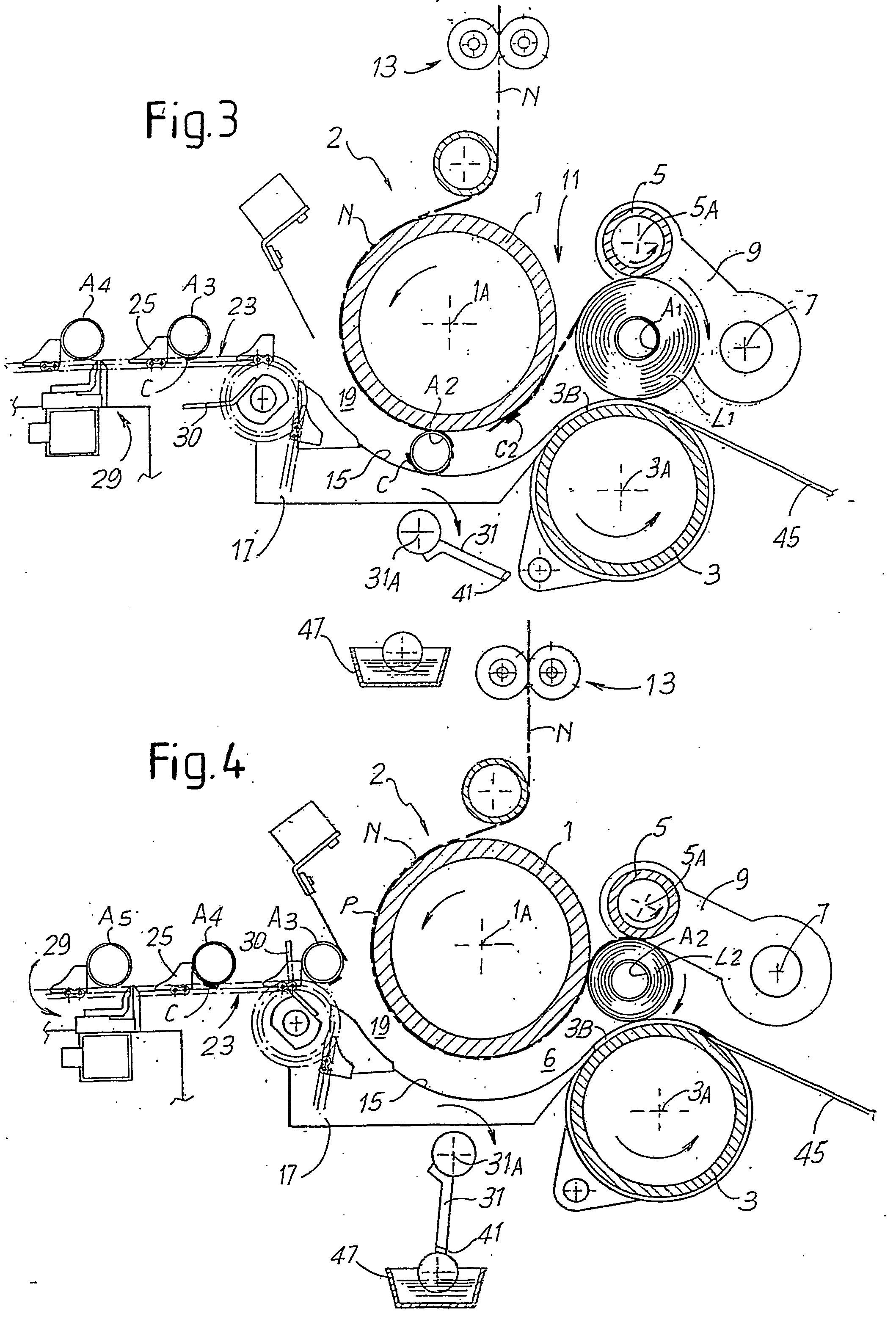

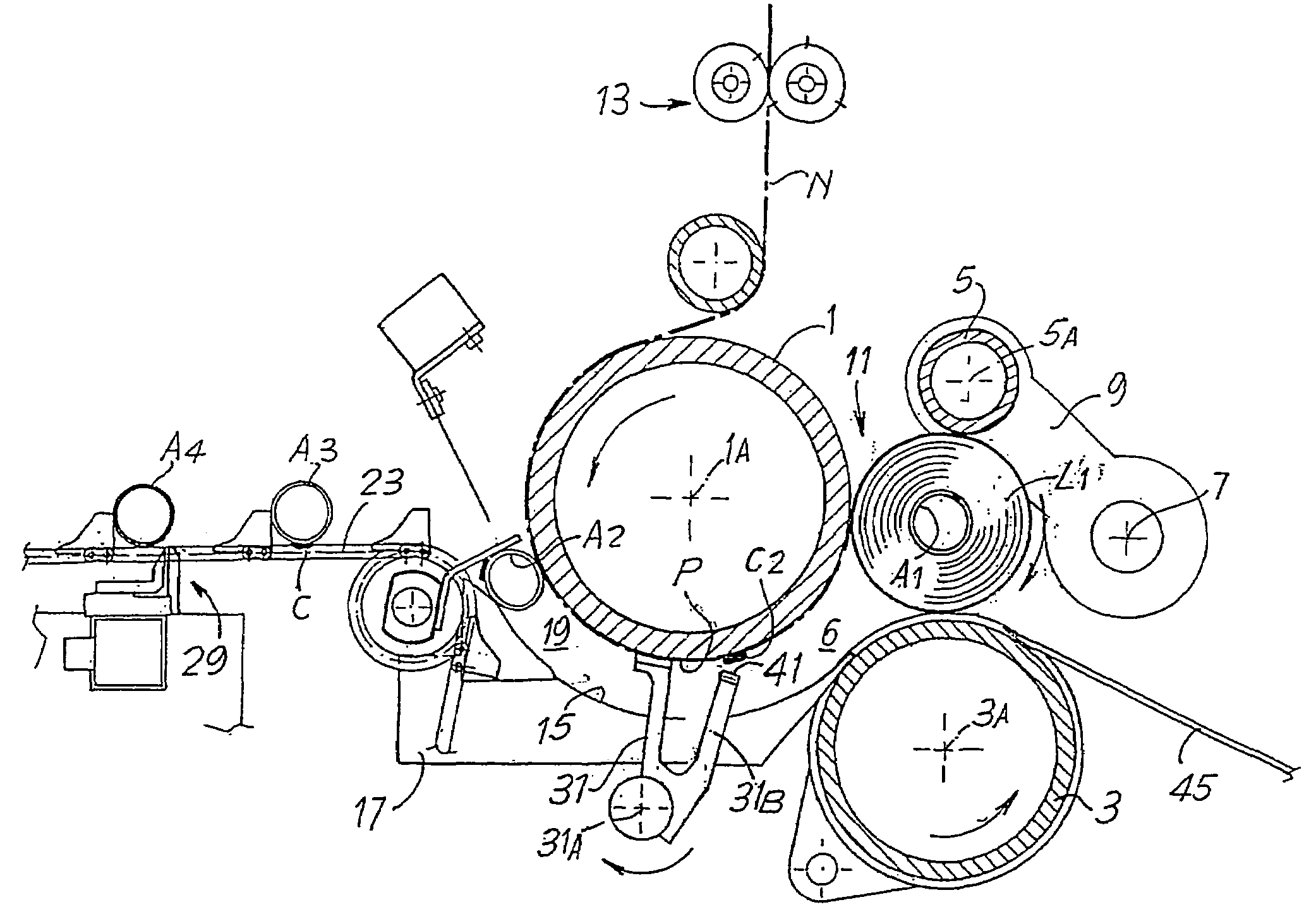

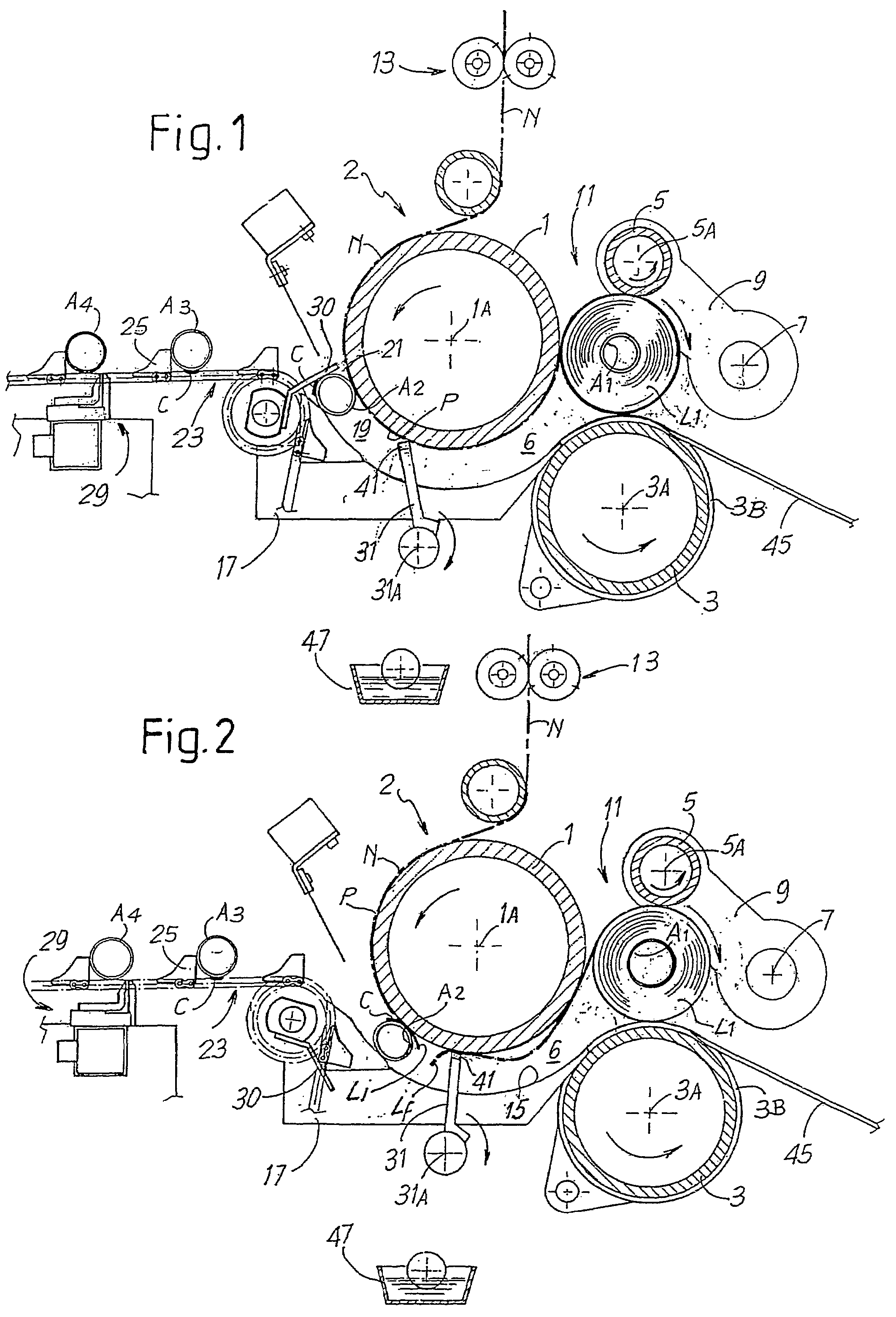

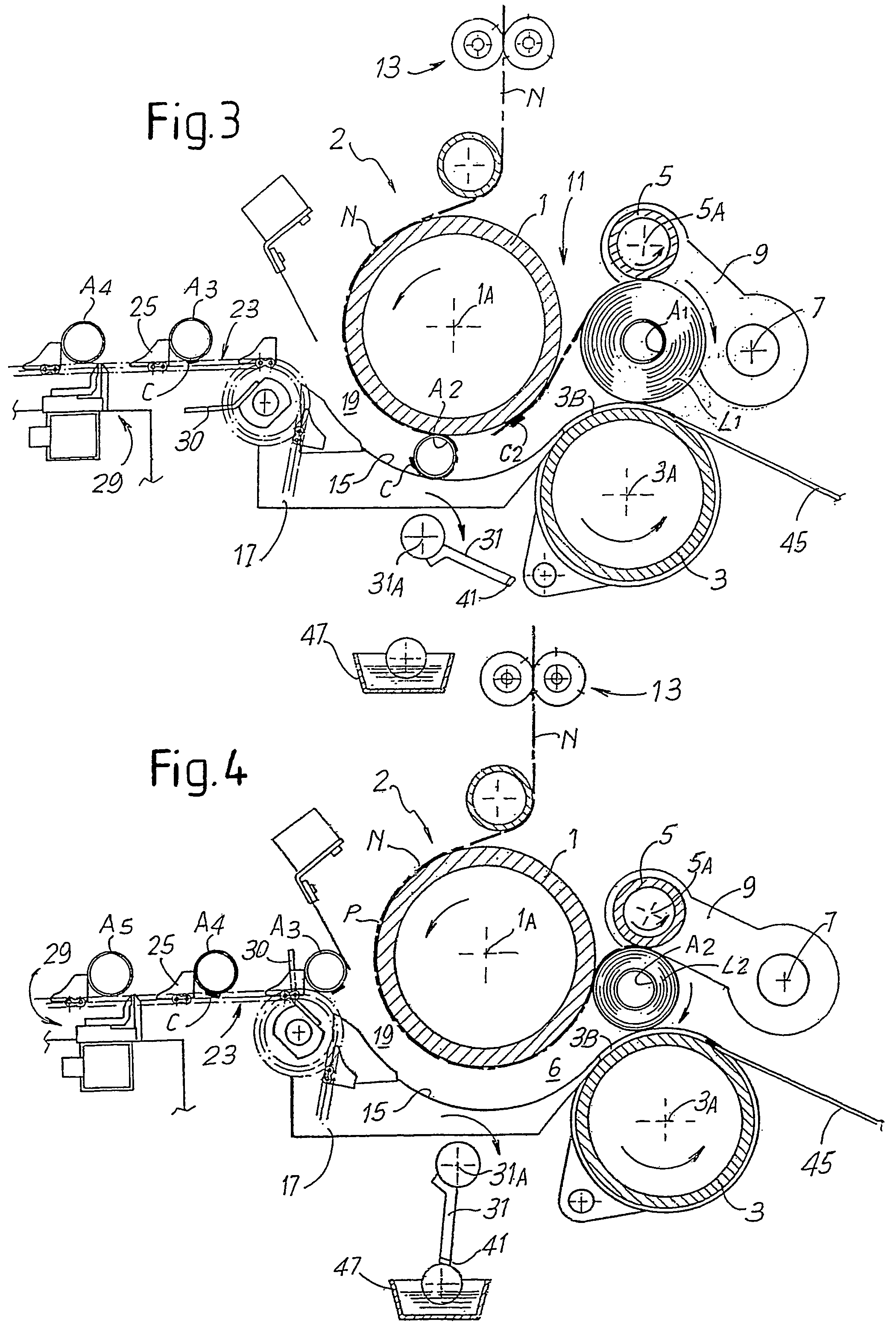

Rewinding machine with gluing device to glue the final edge of the log formed and relative winding method

InactiveUS20060076450A1Glue accurateImprove performanceArticle deliveryWebs handlingEngineeringConductor Coil

The rewinding machine comprises: winding elements (1, 3, 5) to wind the web material (N) and form the logs (L1, L2); at least a first glue dispenser (31B) to apply a first glue (C2) to a portion of said web material, in proximity to a severing line, along which the web material is severed upon termination of winding a log. The first glue dispenser comprises a mechanical element (31B) that touches the web material (N) upon termination of winding each log (L1, L2), to transfer the first glue to the web material (N).

Owner:FABIO PERINI SPA

Rewinding machine with gluing device to glue the final edge of the log formed and relative winding method

InactiveUS7523884B2Glue accurateImprove performanceArticle deliveryWebs handlingEngineeringConductor Coil

The rewinding machine comprises: winding elements (1, 3, 5) to wind the web material (N) and form the logs (L1, L2); at least a first glue dispenser (31B) to apply a first glue (C2) to a portion of said web material, in proximity to a severing line, along which the web material is severed upon termination of winding a log. The first glue dispenser comprises a mechanical element (31B) that touches the web material (N) upon termination of winding each log (L1, L2), to transfer the first glue to the web material (N).

Owner:FABIO PERINI SPA

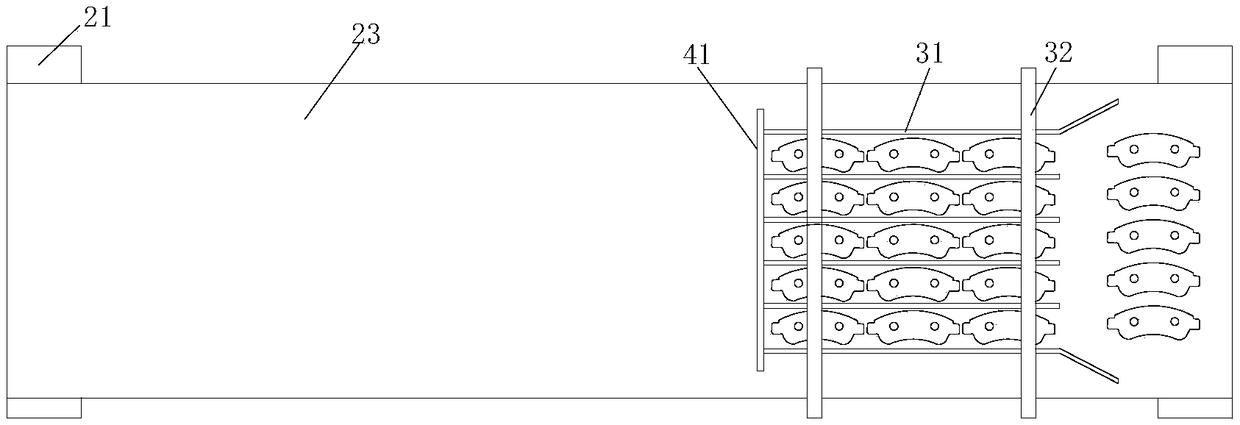

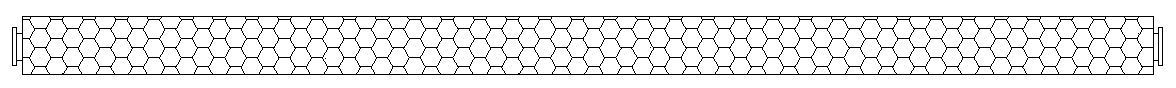

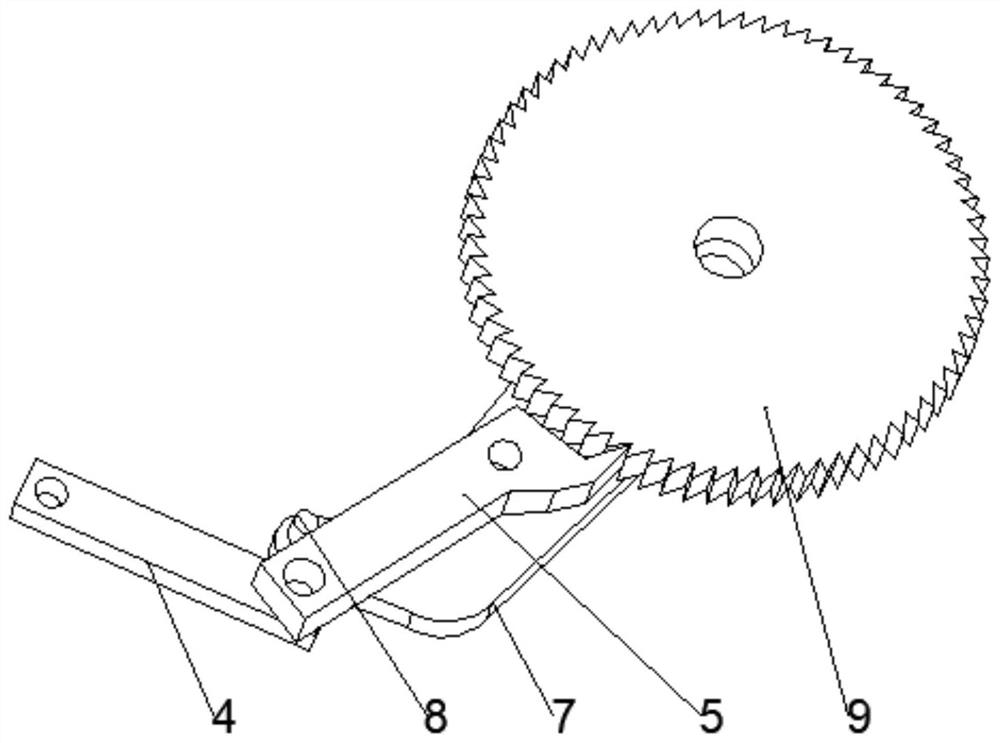

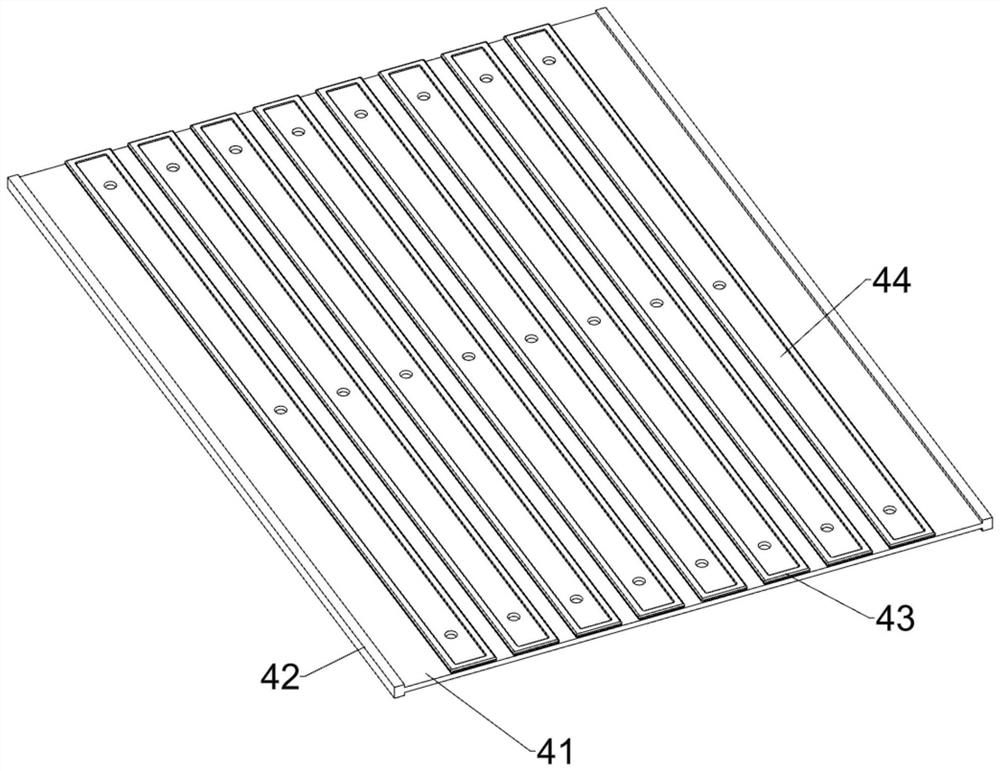

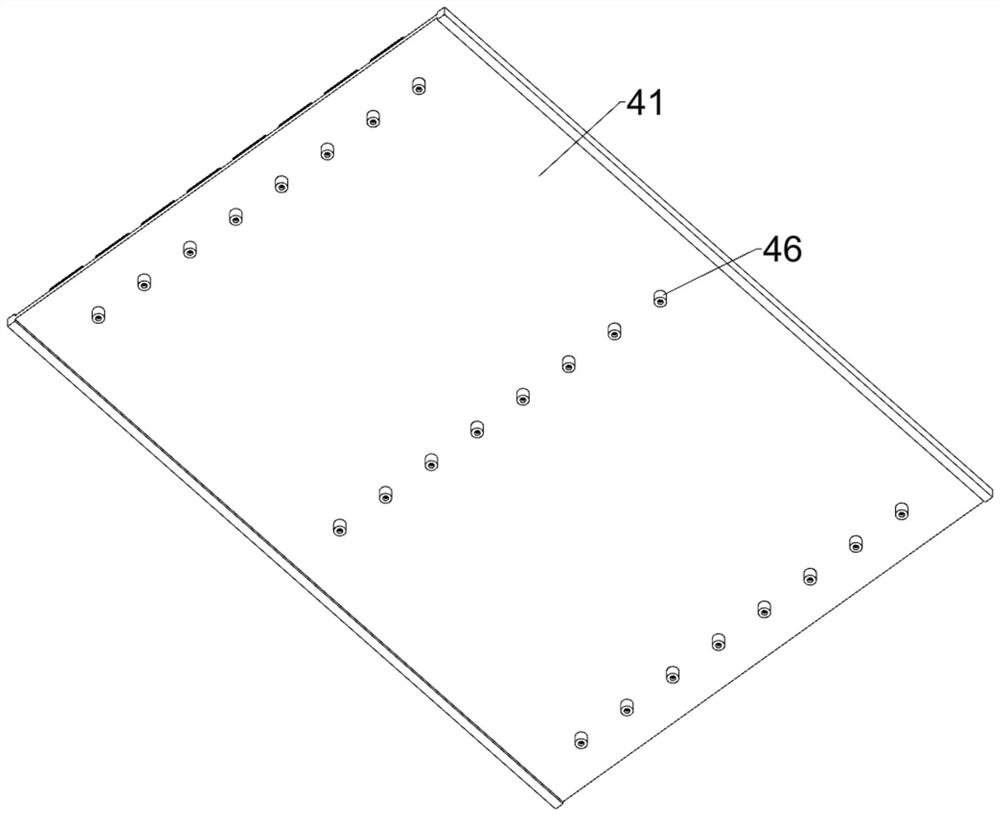

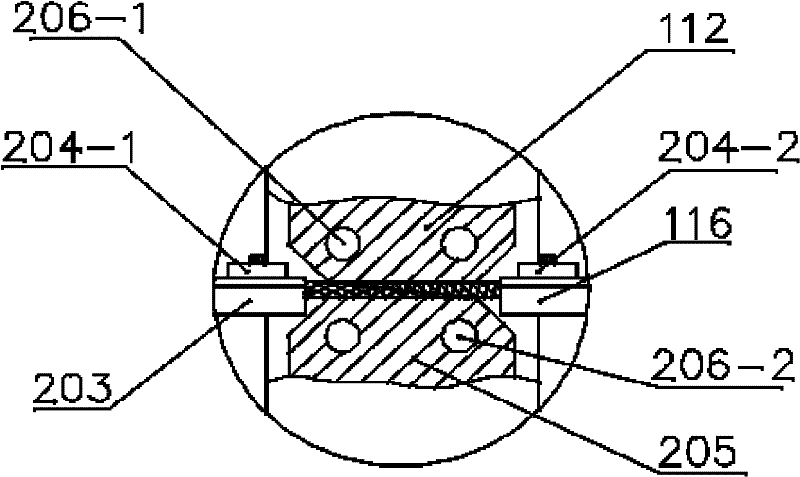

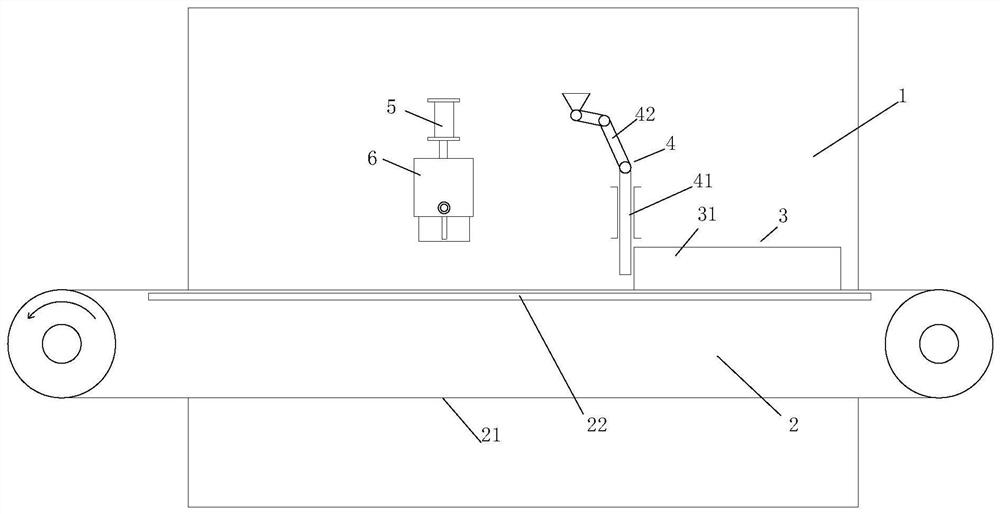

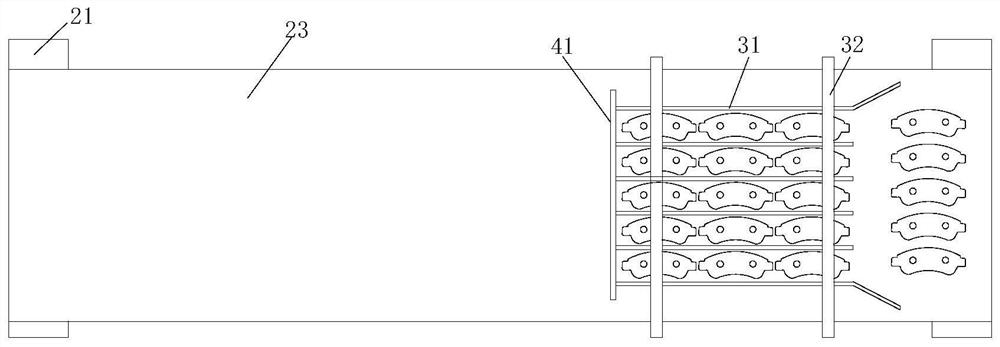

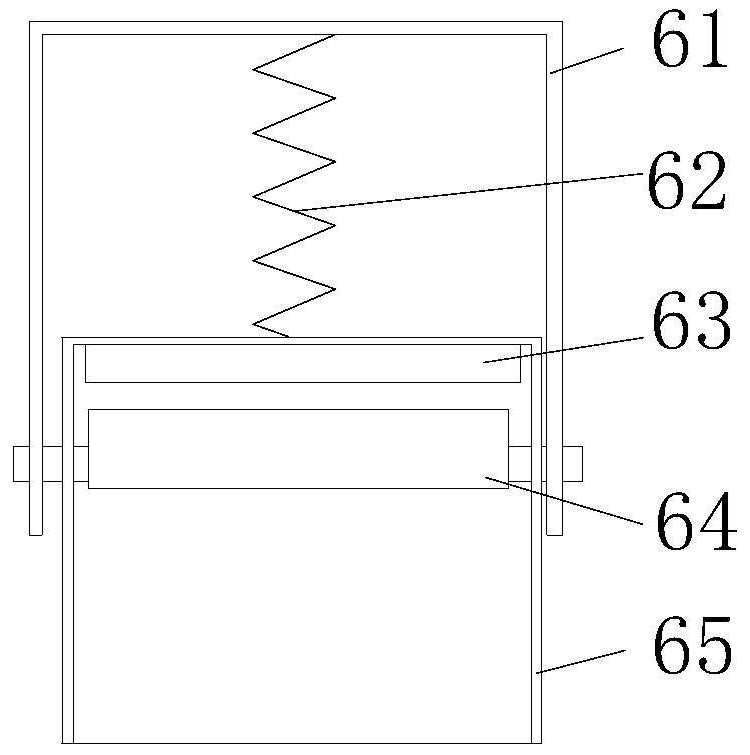

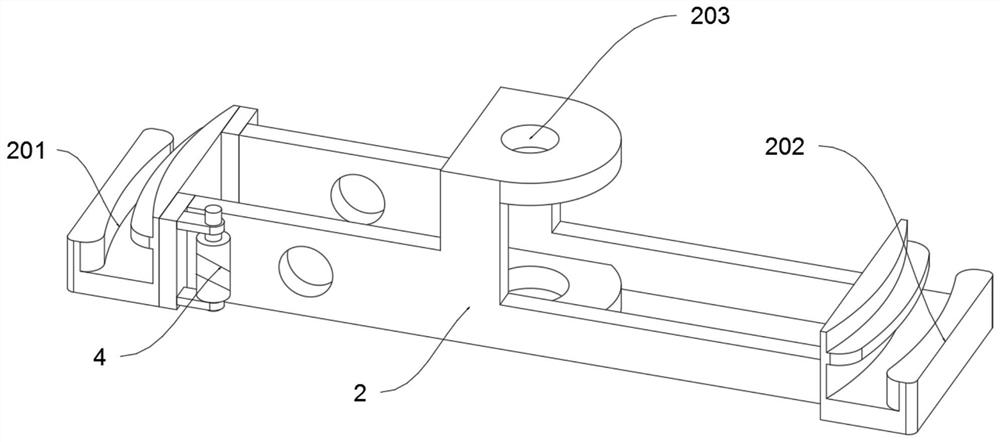

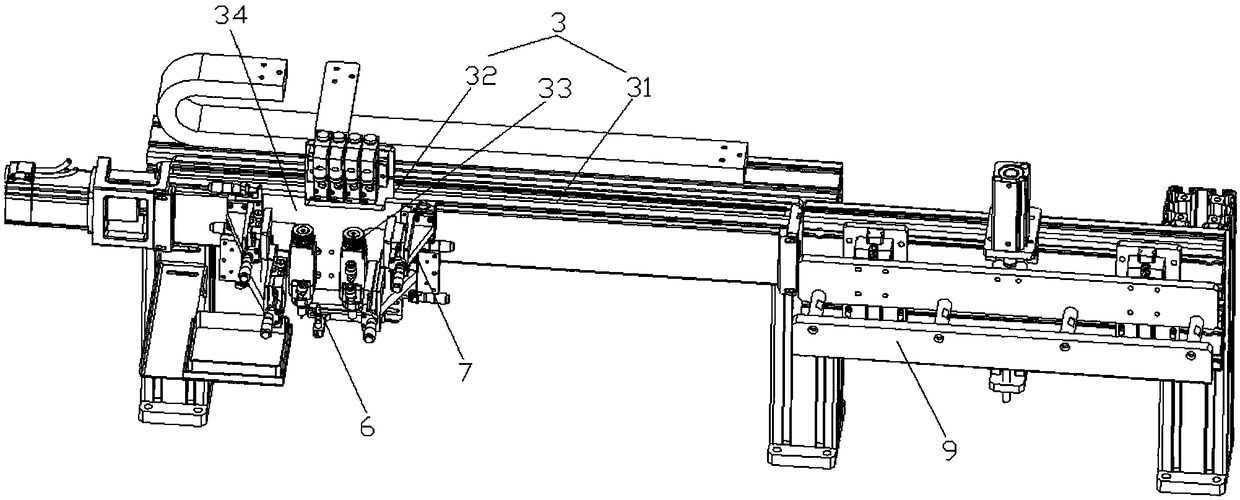

Gluing device for steel backings for brake pad

ActiveCN108654915AAchieve rotationIncrease productivityLiquid surface applicatorsCoatingsEngineeringBrake pad

The invention discloses a gluing device for steel backings for a brake pad. The gluing device comprises a rack, a conveying mechanism, a guide plate mechanism and a gluing mechanism. The steel backings machined in a previous process are conveyed to the gluing device through the conveying mechanism, flow line production is realized, and production efficiency is improved. The guide plate mechanism can sort the steel backings arranged disorderly on a conveying belt so that the steel backings can be arranged linearly and regularly. A printing plate on a gluing assembly is provided with printing areas, the shapes of the printing areas are matched with that of the steel backings, when the printing areas perform gluing on the steel backings, only the printing areas of the printing plate are in contact with the upper surfaces of the steel backings, the portions, being not in need of gluing, of the steel backings are not in contact with the printing areas on a roller brush, the situation that the places, being not in need of gluing, of the steel backings are stained with glue, so that product scrap is caused can be prevented, and meanwhile glue can also be saved.

Owner:ANHUI GUIDA AUTO PARTS

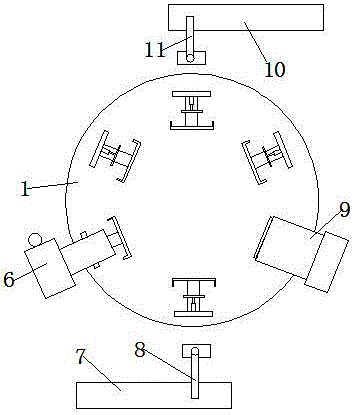

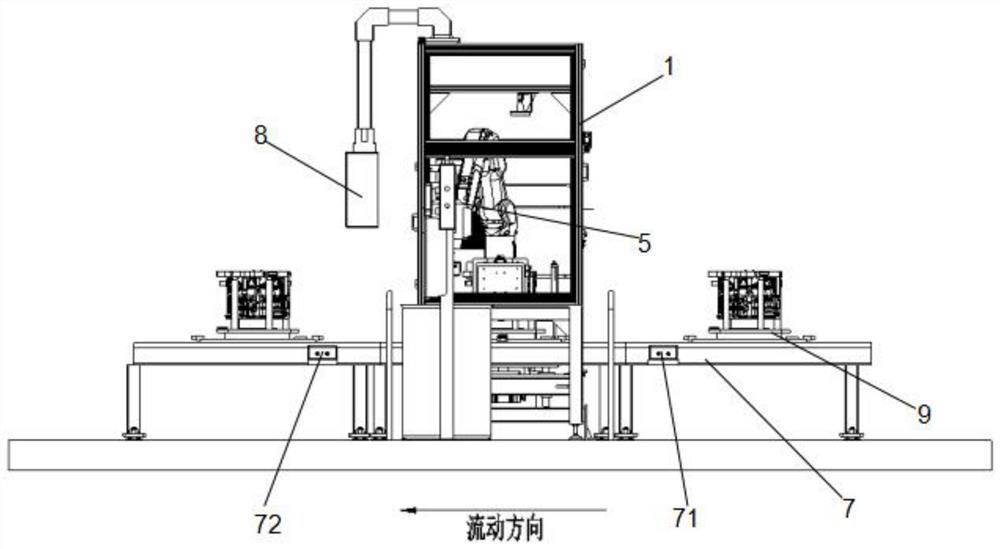

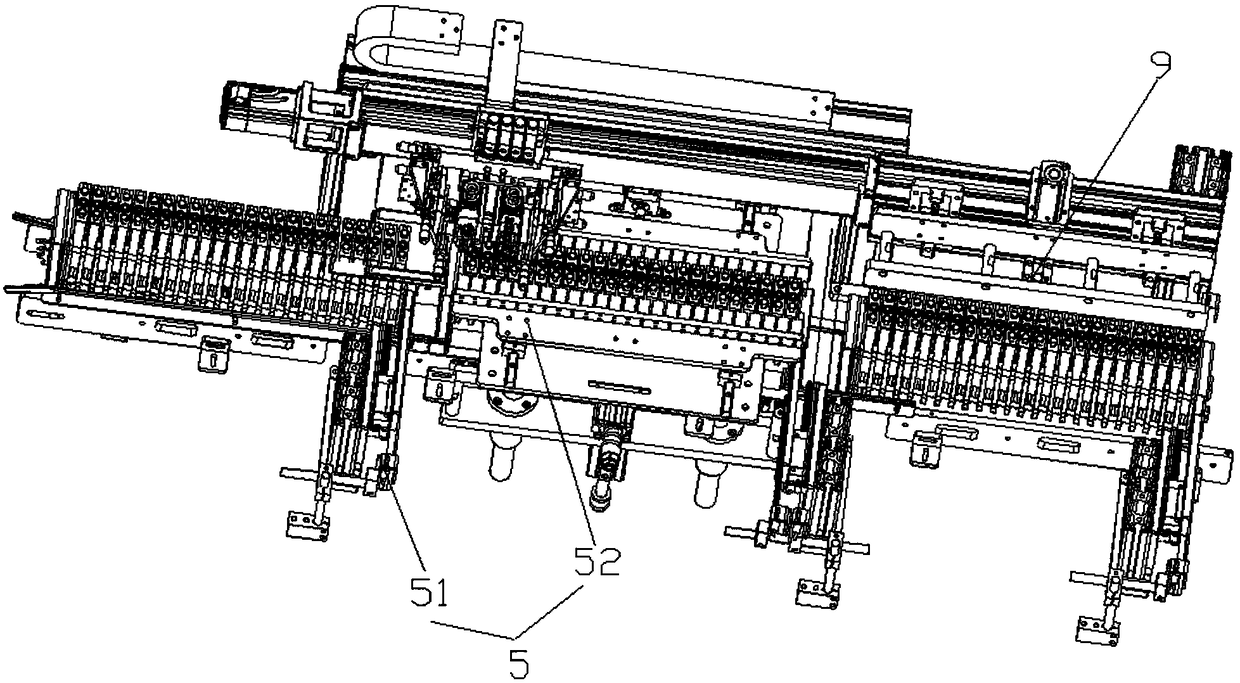

Vehicle lamp gluing and lamination device

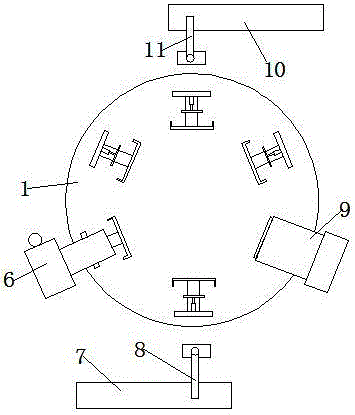

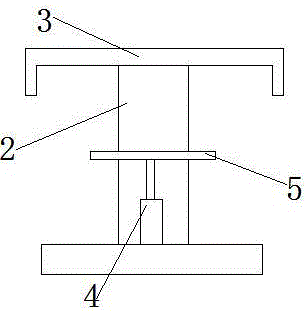

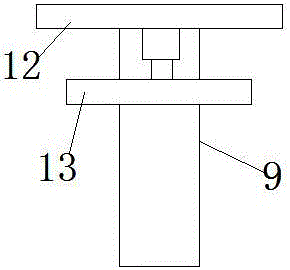

InactiveCN106513261AReduce labor intensitySimple structureLiquid surface applicatorsCoatingsUltimate tensile strengthManipulator

The invention discloses a vehicle lamp gluing and lamination device. The vehicle lamp gluing and lamination device comprises a rotating worktable; multiple fixing devices are arranged on the rotating worktable; the fixing devices include fixed bases; front side baffle plates are arranged on the front sides of the upper ends of the fixed bases; back side fixed plates are arranged on the back sides of the upper ends of the fixed bases; automatic push rods are arranged on the back side fixed plates; movable baffle plates are arranged at the front ends of the automatic push rods; a gluing device is arranged on the right side of a selection fitting worktable; a loading conveying belt is arranged on the back side of the rotating worktable; a loading manipulator is arranged between the loading conveying belt and the rotating worktable; a lamination device is arranged on the side edge of the rotating worktable on the back side of the loading manipulator; an unloading conveying belt is arranged on the side edge of the rotating worktable on the back side of the pressing device; and an unloading manipulator is arranged between the unloading conveying belt and the rotating worktable. The vehicle lamp gluing and lamination device is simple in structure and reasonable in design, can guarantee uniform gluing and precise lamination position, is high in automation degree, effectively relieves the labor intensity of workers, and improves the production efficiency.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

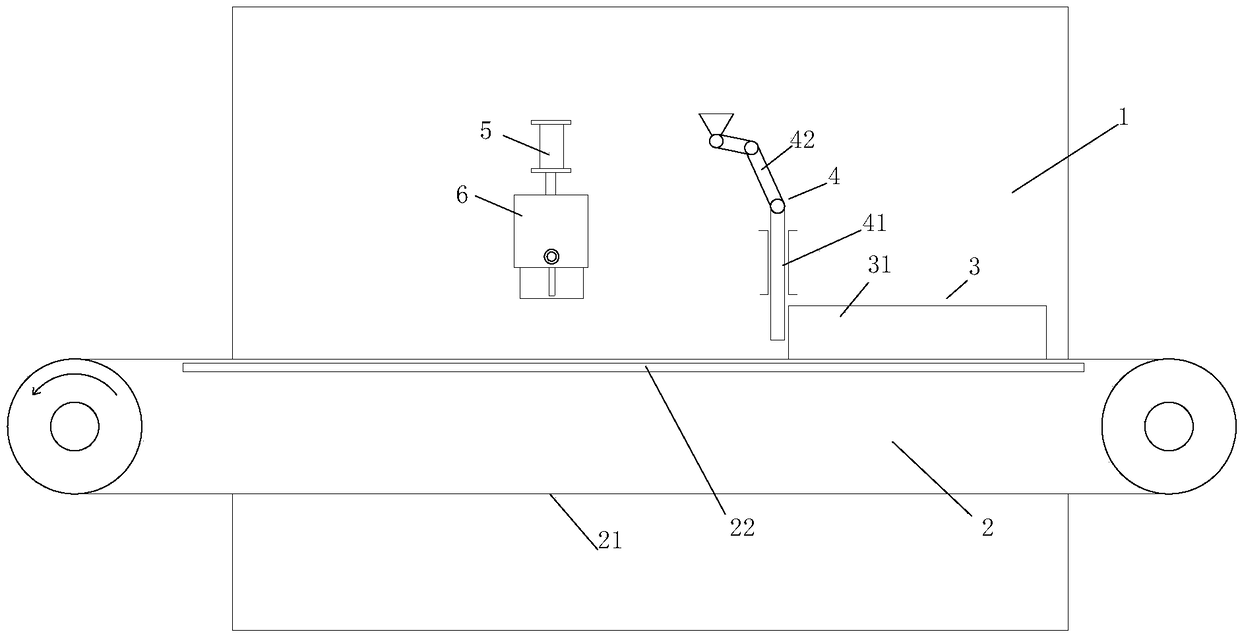

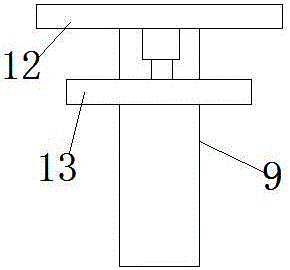

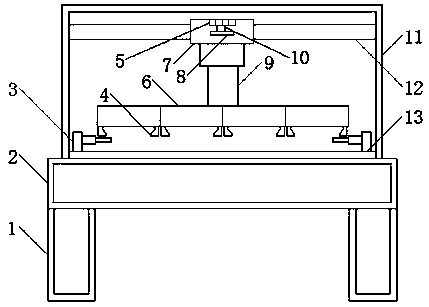

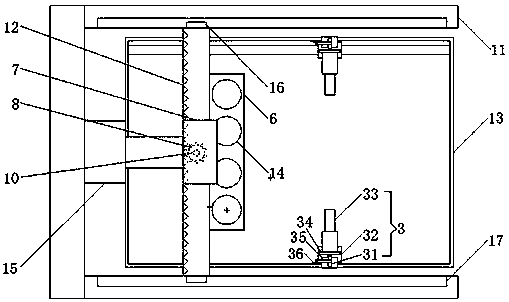

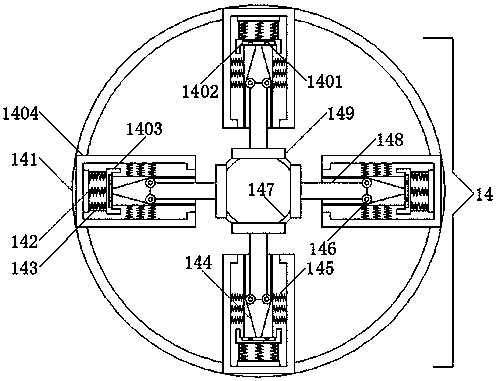

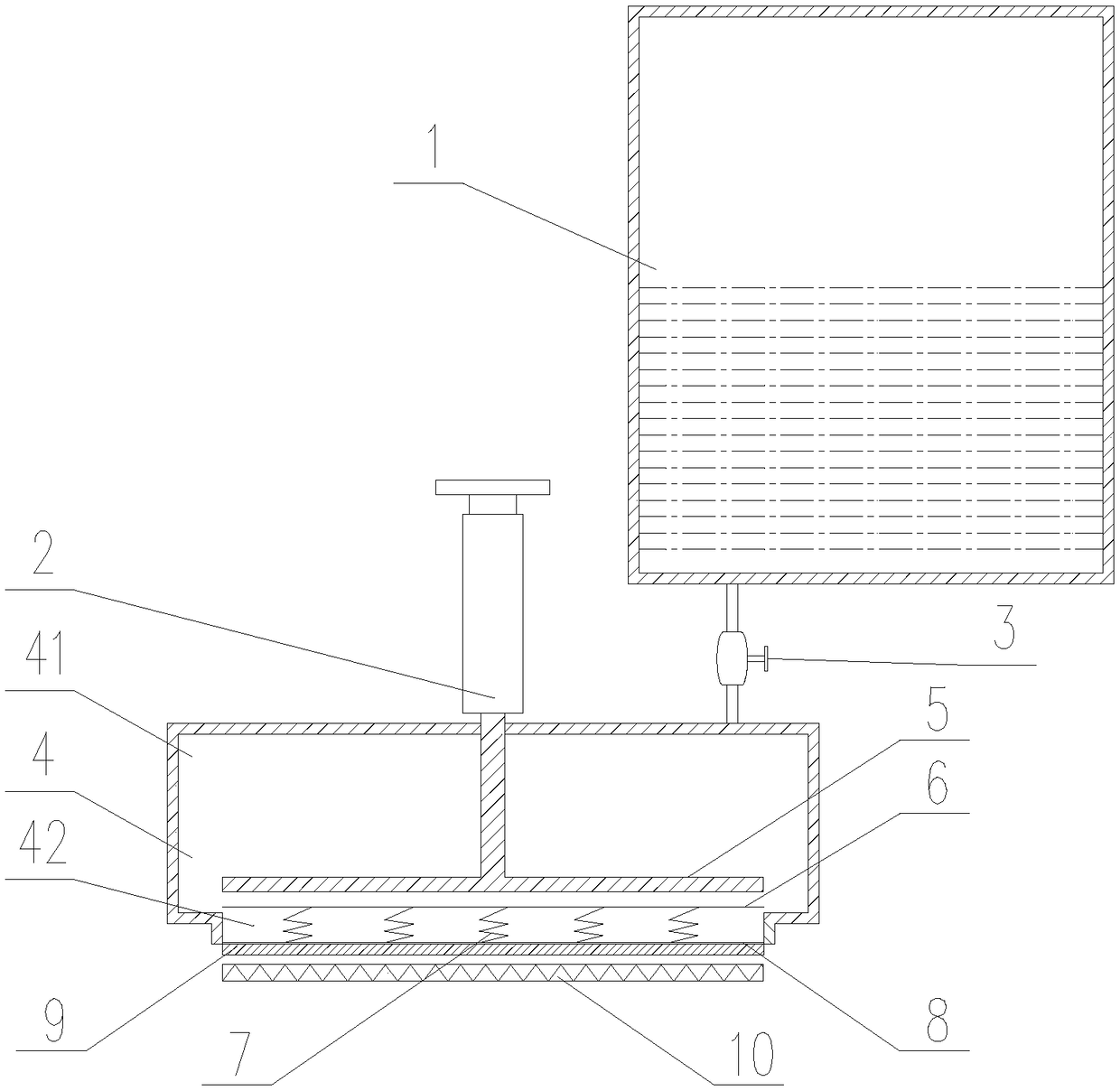

Glue coating machine for machining glued products and glue coating method

ActiveCN107930999AShorten the timeImprove work efficiencyLiquid surface applicatorsCoatingsSoftware engineeringCoating

The invention discloses a glue coating machine for machining glued products and a glue coating method in the technical field of glue coating machines. The glue coating machine comprises support legs;a worktable is arranged at the tops of the support legs; a fixed bracket is arranged at the top of the worktable; an electric extension rod is arranged at the upper end of the fixed bracket; the otherend of the electric extension rod is connected with a movable rod; a movable box is arranged on the outer wall of the movable rod; a hydraulic extension rod is arranged at the bottom of the movable box; a fixed table is arranged at the bottom of the hydraulic extension rod; limiting devices are uniformly arranged on the fixed table; cooling devices are uniformly arranged at the top of the fixed table; a glue coating table is arranged at the top of the worktable; pressing devices are arranged on the left and right sides of the glue coating table; and objects are fixed on the glue coating table, so that the gluing accuracy is guaranteed, replacement of the fixed table is not needed any more, a lot of time is saved, glue cannot slide off, the objects are protected from being damaged, and theyield is improved.

Owner:温岭市第二绝缘材料厂

Gluing and pressing device for automobile lamps

InactiveCN106493541AReduce labor intensitySimple structureLiquid surface applicatorsMaterial gluingEngineeringConveyor belt

The invention discloses a gluing and pressing device for automobile lamps. The gluing and pressing device comprises a rotating workbench. A plurality of fixing devices are arranged on the rotating workbench. Each fixing device comprises a fixing base. A front side baffle is arranged on the front side of the upper end of each fixing base, and a rear side fixing plate is arranged on the rear side of the upper end of each fixing base. Each rear side fixing plate is provided with an automatic push rod. The front end of each automatic push rod is provided with a movable baffle. A gluing device is arranged at the right side of the rotating workbench. A feeding conveyor belt is arranged on the rear side of the rotating workbench, and a feeding mechanical arm is arranged between the feeding conveyor belt and the rotating workbench. A pressing device is arranged on the side edge of the rotating workbench and located on the rear side of the feeding mechanical arm. A discharging conveyor belt is arranged on the side edge of the rotating workbench and located on the rear side of the pressing device, and a discharging mechanical arm is arranged between the discharging conveyor belt and the rotating workbench. The gluing and pressing device is simple in structure and reasonable in design, gluing evenness can be guaranteed, the pressing position is accurate, the degree of automation is high, labor intensity of workers is effectively relieved, and production efficiency is improved.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

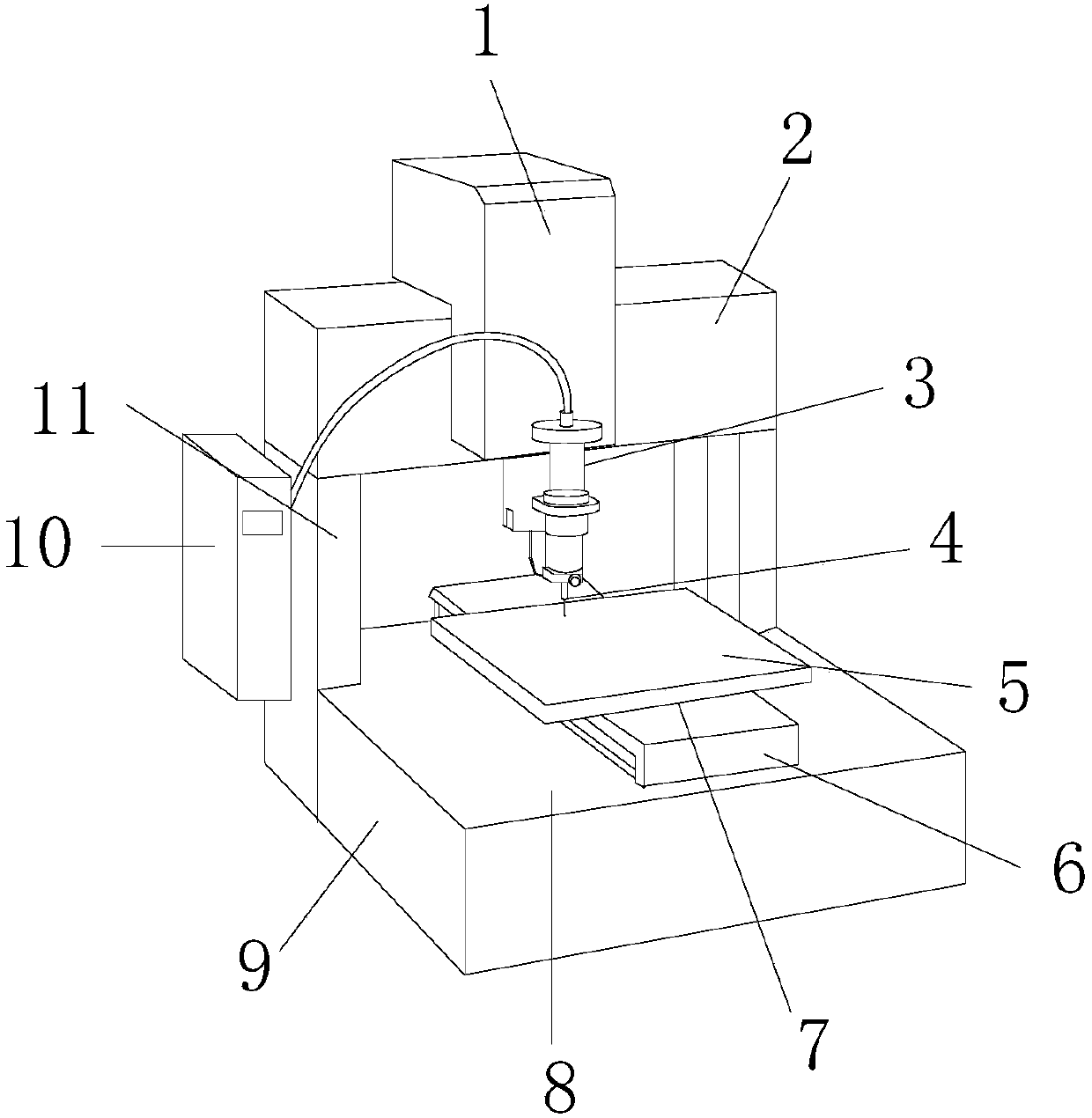

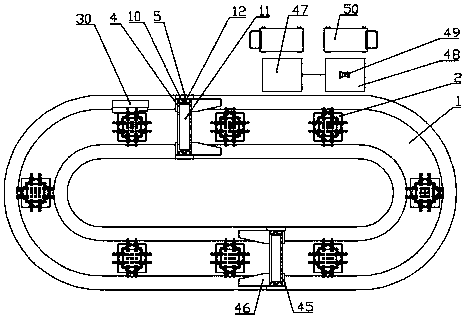

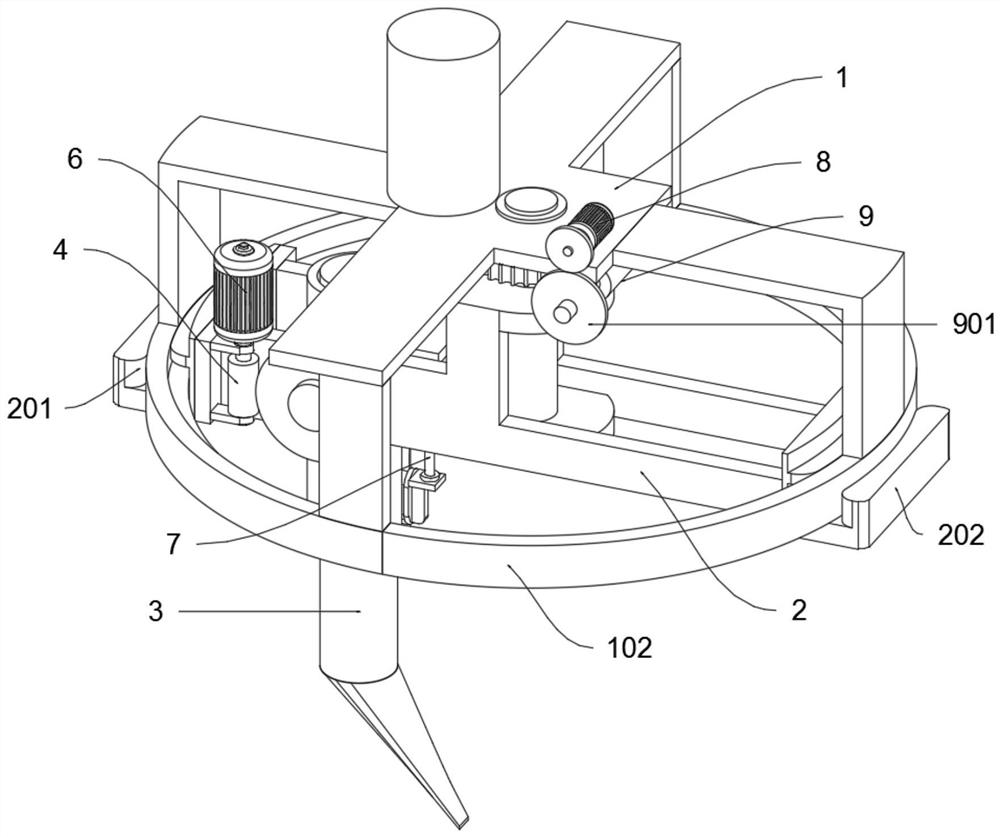

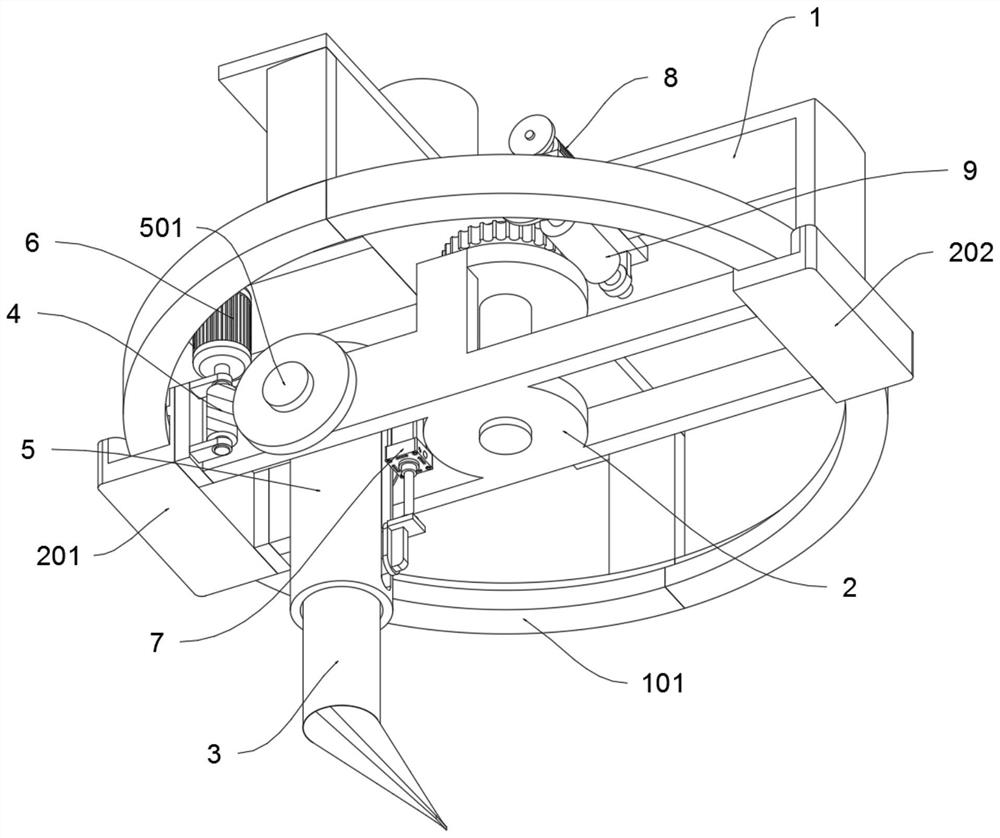

Automatic gluing machine used for automobile luggage rack

InactiveCN107774516APositioning balancePrecise positioningLiquid surface applicatorsCoatingsCircular discElectric machinery

The invention discloses an automatic gluing machine used for an automobile luggage rack. The structure of the automatic gluing machine comprises a gluing stroke moving shaft, a sliding rail rest, a glue storage bottle, a gluing valve head, a workpiece fixing rack, a bottom slide rail, a multi-station rotary positioning mechanism, a working table, a fixed base, a gluing controller and a rack, wherein the fixed base is of a square structure, the top end of the fixed base and the working table are of an integrated structure, and the left and right ends of the rear end of the working table are fixedly connected with and vertical to the rack. According to the invention, a driving motor is used for driving a rotating disk to rotate and driving a workpiece on the workpiece fixing rack to rotate to generate gluing tracks in multiple directions, so as to enlarge the gluing scope, and thus realizing uniform gluing of the product; and under the actions of an offset rod and a magnetic block, the workpiece can be located in a center position more easily and be positioned precisely, and deviation and displacement can be reduced; and an elastic plate can reduce vibration when the workpiece is machined, so as to increase gluing stability, increase the working efficiency and improve the product machining quality.

Owner:金陈敏

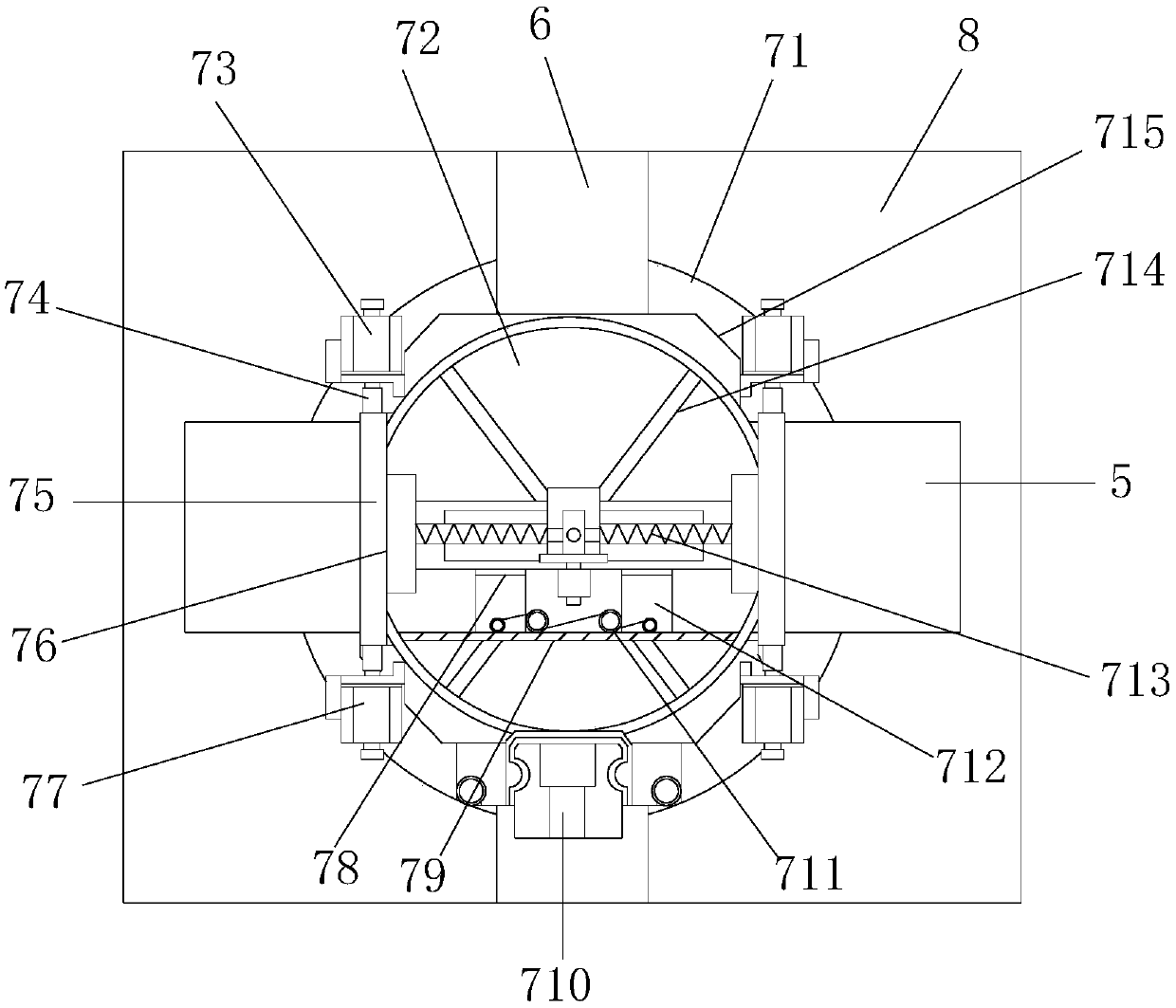

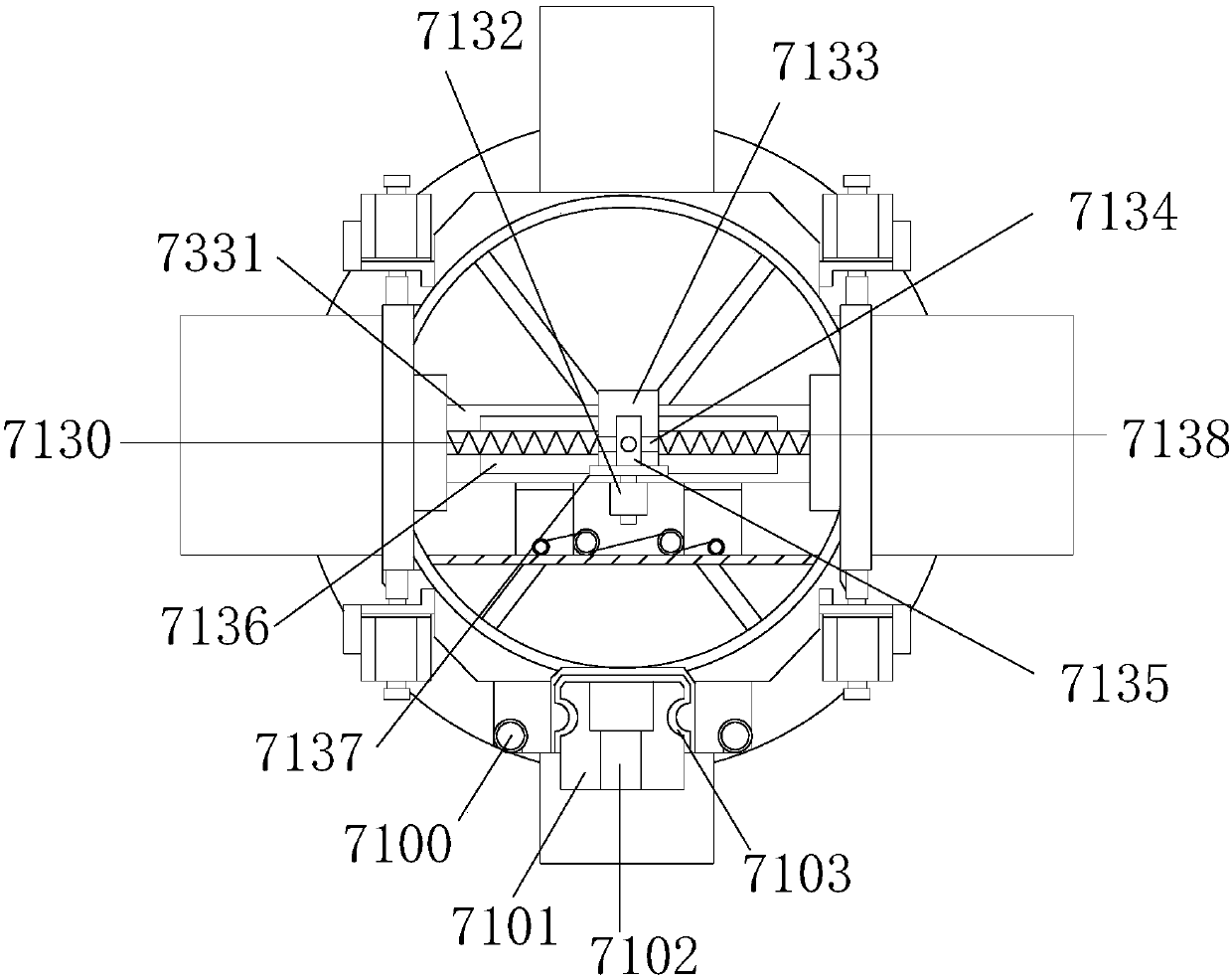

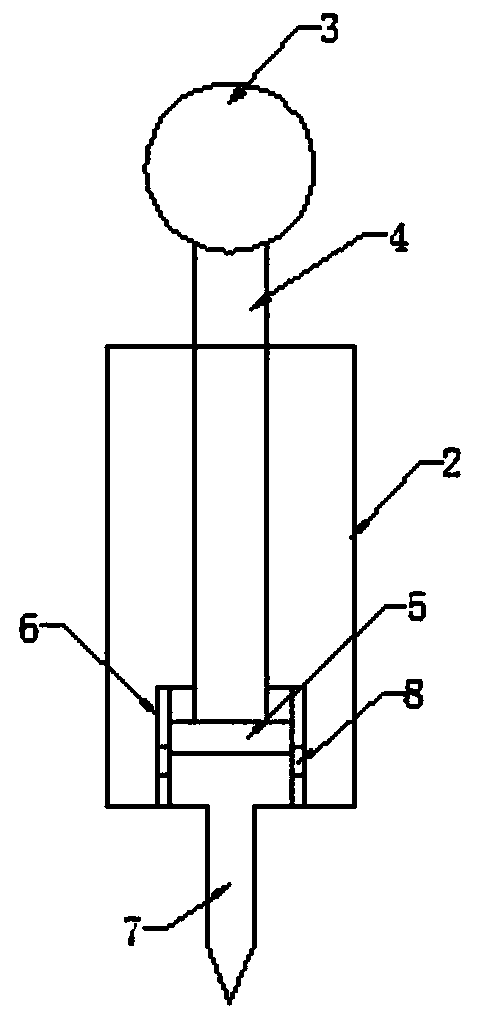

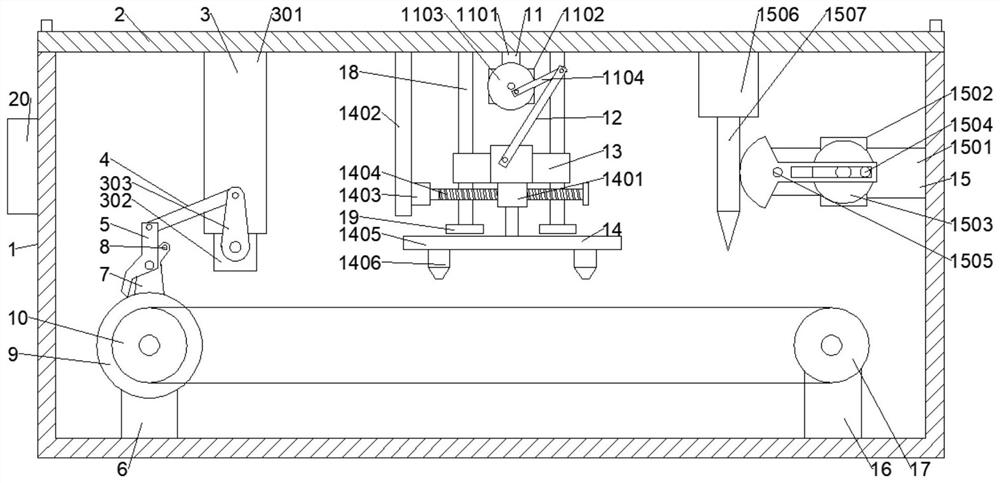

Automatic glue injecting device for LED lamp production

ActiveCN111203367AImprove work efficiencySmooth rotationLiquid surface applicatorsCoatingsEngineeringLED lamp

The invention discloses an automatic glue injecting device for LED lamp production, and relates to the technical field of LED lamp devices. The device mainly solves the problems of inconvenience during LED lamp production, inconvenience for glue injecting through glue injecting needle cylinders and over-low working efficiency. The device mainly comprises a rotating conveying belt, and a limiting mechanism, a pushing mechanism, a feeding and discharging mechanism, an automatic glue injecting mechanism and a rotating mechanism are arranged on the rotating conveying belt. According to the device,LED lamp containing trays are placed on fixing tables, the rotating conveying belt drives the LED lamp containing trays to pass through the positions below the glue injecting needle cylinders and drives winding wheels to rotate, a lifting plate is pulled downwards through connecting wires, glue in the glue injecting needle cylinders is guided to the LED lamp containing trays through glue injecting heads, and glue injecting is carried out; and when the fixing tables move, the LED lamp containing trays can be driven to rotate through meshing of strip-shaped racks and annular racks, and when theLED lamp containing trays pass through the glue injecting needle cylinders again, glue injecting is carried out in another direction. The device has the beneficial effects that glue injecting can berapidly carried out, and the working efficiency is improved.

Owner:ZHEJIANG HAIHONG IND PROD DESIGN CO LTD

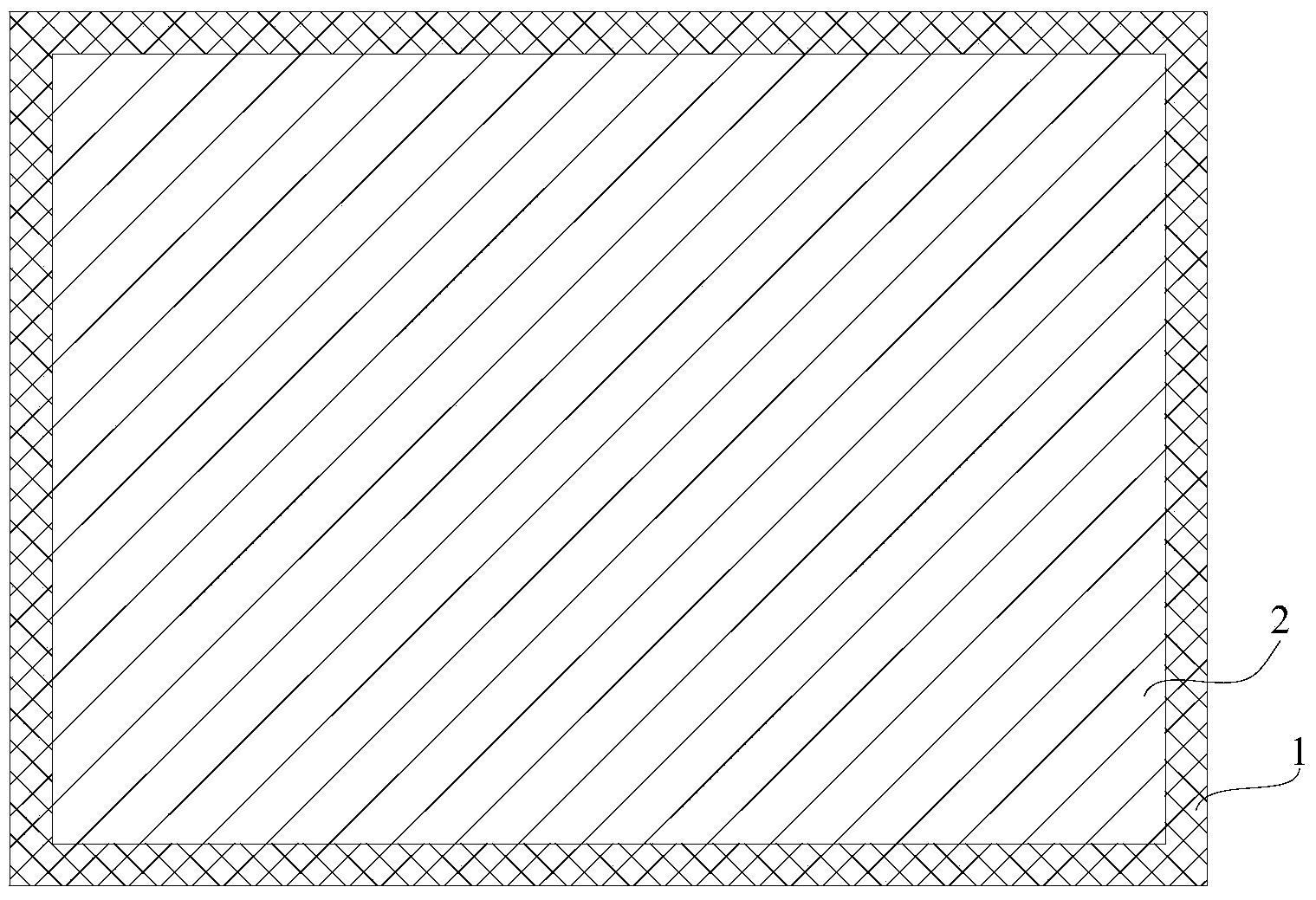

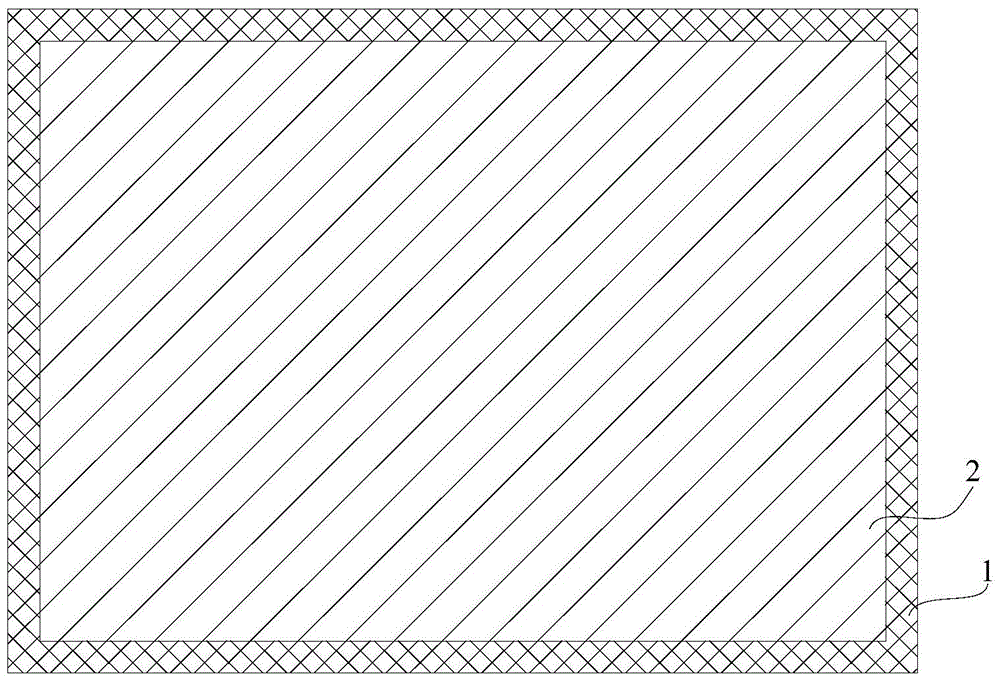

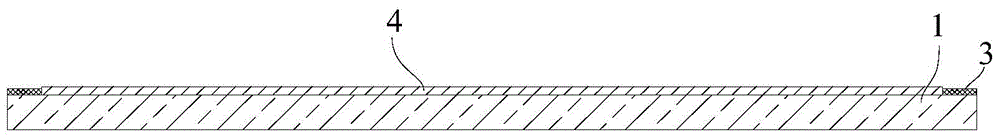

Bonding method

ActiveCN104004458AGlue accurateHigh speedAdhesive processes with adhesive heatingChemistrySilicone Gels

The invention discloses a bonding method comprising the following steps of firstly, enclosing on a to-be-glued surface of a first to-be-bonded part by using a high-temperature-resistant adhesive tape to form a closed bonding region; secondly, coating silicone gel to the bonding region to form an adhesive layer with uniform thickness in the bonding region, and enabling the thickness of the adhesive layer to be larger than the thickness of the high-temperature-resistant adhesive tape; thirdly, heating the adhesive layer to solidify a gel solution on the adhesive layer to obtain a solidified adhesive layer; and fourthly, tearing the high-temperature-resistant adhesive tape, and then, bonding a second to-be-bonded part with the first to-be-bonded part. According to the invention, the to-be-glued surface of the first to-be-bonded part is enclosed by using the high-temperature-resistant adhesive tape to form the closed bonding region, so that the adhesive coating range is limited, and furthermore, gel is accurately and rapidly coated.

Owner:SUZHOU TONGLI PHOTOELECTRIC CO LTD

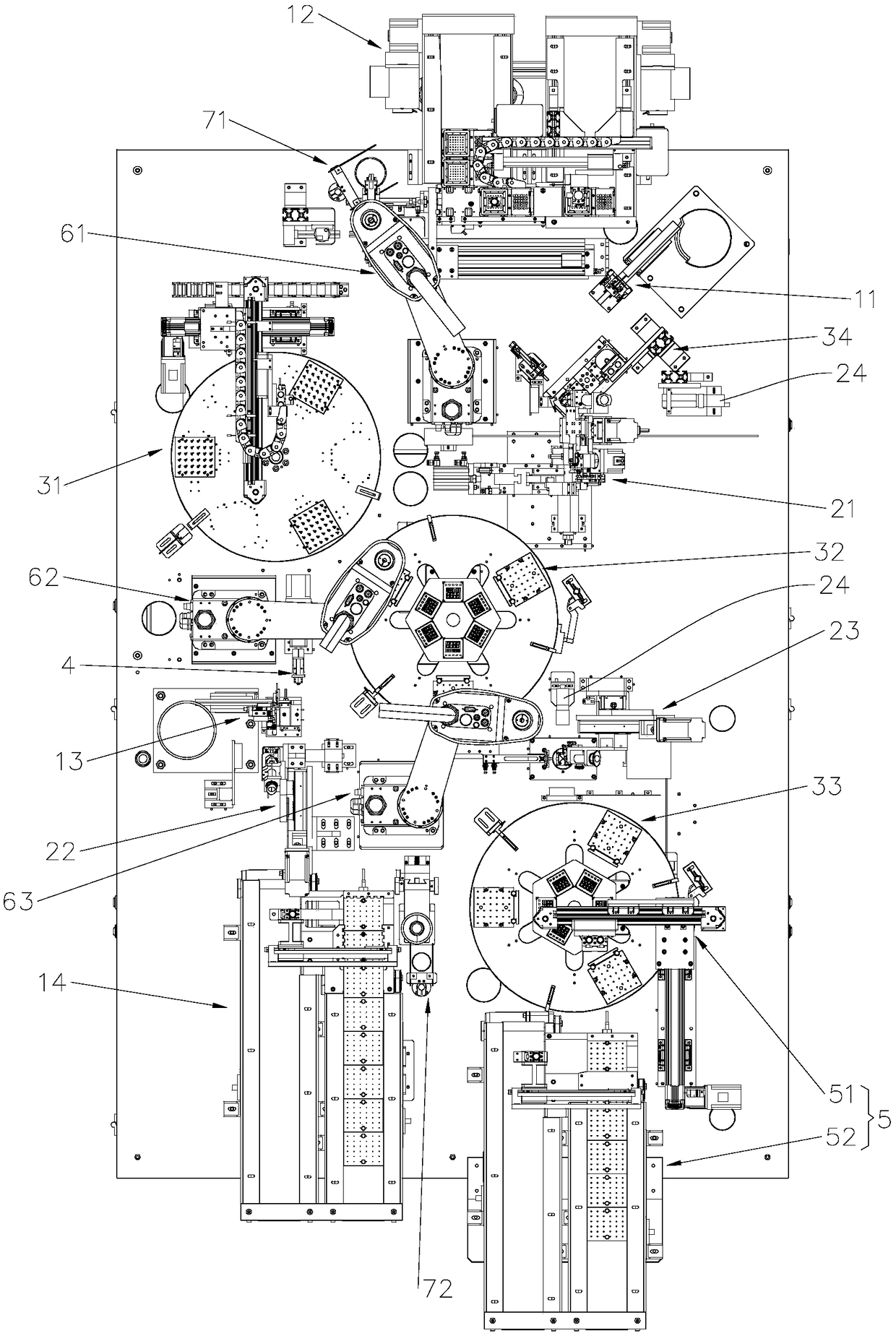

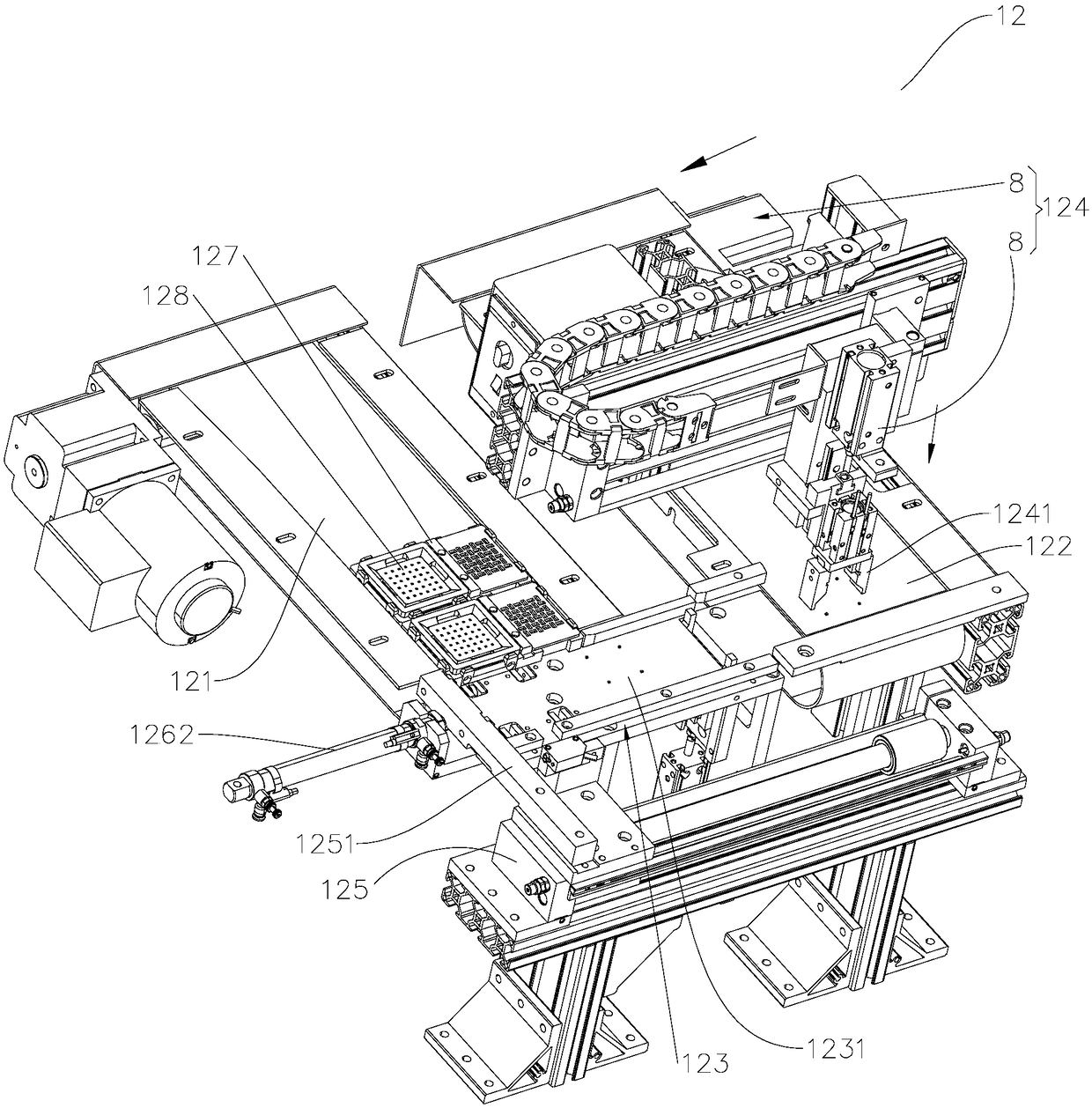

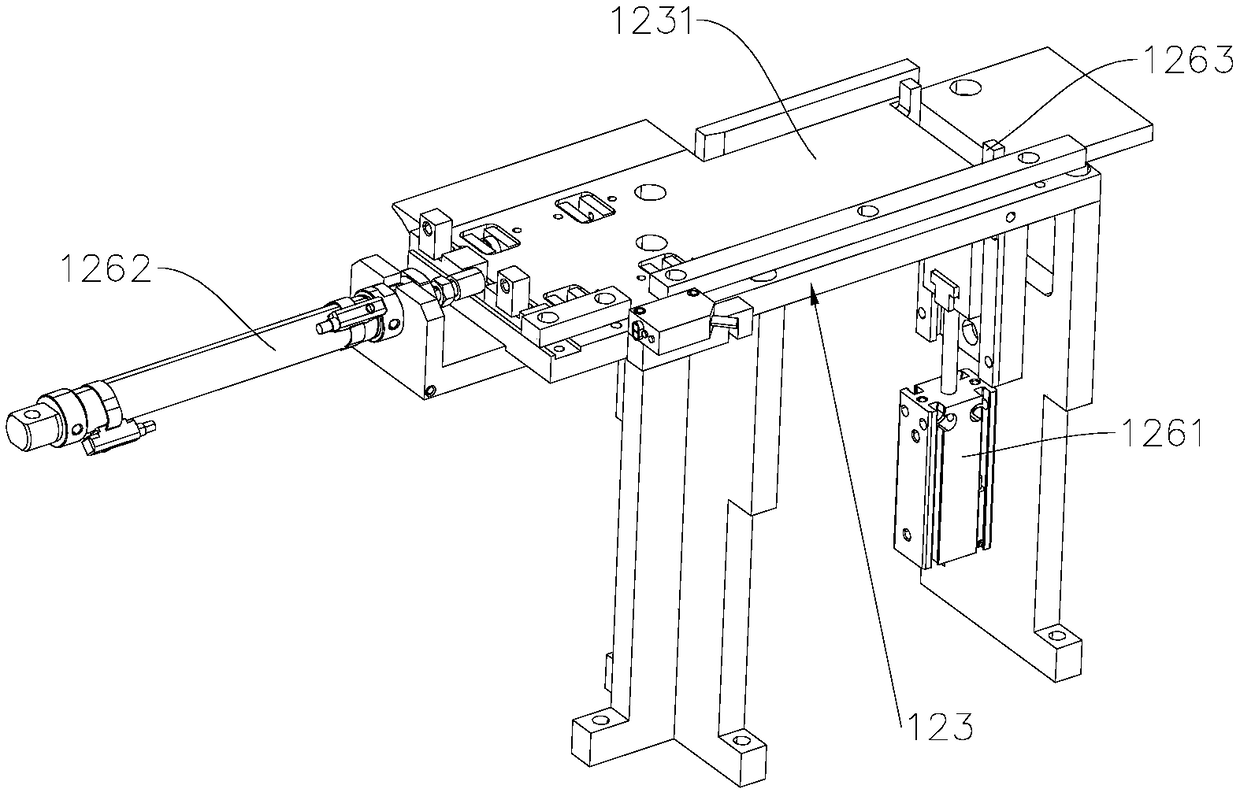

Fiber-optic head assembly production line

PendingCN109445038APrecise alignmentIncrease productivityLiquid surface applicatorsMaterial gluingProduction lineFiber

The invention discloses a fiber-optic head assembly production line for assembling a light-transmitting sheet, a mounting cap, a casing and a cylinder. The fiber-optic head assembly production line comprises a mounting cap feeding device, a light-transmitting sheet feeding device, a housing feeding device, a cylinder feeding device, a first dispensing device, a second dispensing device, a third dispensing device, a first solidification device, a second solidification device, a third solidification device, a first displacement device, a second displacement device, a third displacement device, aturn-over device and a discharging device. The mounting cap feeding device, the light-transmitting sheet feeding device, the housing feeding device and the cylinder feeding device are respectively used for conveying the mounting cap, the light-transmitting sheet, the casing and the cylinder. Through the above structure, the automated assembly of the fiber-optic head can be completed, the production efficiency can be improved, the components can be accurately aligned, the glue can be accurately applied, and the assembly precision and the finished product quality can be improved.

Owner:GUANGDONG SHUOTAI INTELLIGENT EQUIP

Electronic component gluing device

ActiveCN109647662AReduce industrial pressureReduce manufacturing costLiquid surface applicatorsCoatingsEngineeringCuneus

The invention discloses an electronic component gluing device. A device body is included and internally provided with a gluing mechanism, a pressing mechanism and a pedaling mechanism. The gluing mechanism comprises a gluing barrel, an extrusion ball valve and a piston connected with the extrusion ball valve through an extrusion shaft. The pressing mechanism comprises a pressing wedge block, a push shaft, a pushing ball valve, a connecting shaft fixedly arranged on the push shaft, and a sliding rod which is in sliding connection with the connecting shaft. The pedaling mechanism comprises a pedal plate, a pull ring, an elastic shaft, an L-shaped downward sliding rod fixedly connected with the pull ring, a downward sliding wedge block arranged on the top of the L-shaped downward sliding rod,and an elastic piece elastically connected with the downward sliding wedge block, wherein the pull ring and the elastic shaft are arranged on the upper side and the lower side of the pedal plate. Through the gluing mechanism, the pressing mechanism and the pedaling mechanism arranged in the device body, the hands and the feet of operators can act at the same time, the gluing work can be finishedwithout cooperation of multiple people, the operation efficiency is improved, and the enterprise production cost is reduced.

Owner:徐州蓝联诚制造有限公司

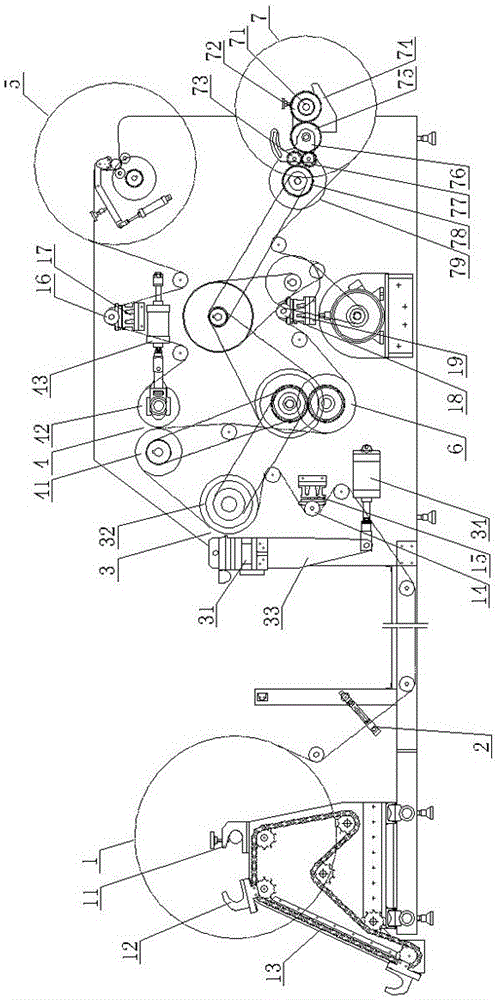

Butyl rubber coating machine

ActiveCN105946334AChange the squeegee angleGlue accurateControlling laminationLaminationMagnetic powderTension control

The invention discloses a butyl rubber coating machine which comprises first and second unreeling mechanisms, an automatic skew adjustment mechanism, a rubber scraping and coating mechanism, a compounding mechanism, a cooling forming mechanism and a rolling-up mechanism, and is characterized in that a first discharge material of the first unreeling mechanism enters the compounding mechanism after passing through the automatic skew adjustment mechanism, a first tension control roller and the rubber scraping and coating mechanism; a second discharge material of the second unreeling mechanism enters the compounding mechanism after passing through a second tension control roller; a compound material compounded by the compounding mechanism enters the rolling-up mechanism after passing through the cooling forming mechanism and a third tension control roller; the first, second and third tension control rollers are respectively arranged on first, second and third tension sensors; the first tension sensor is electrically connected with a first magnetic powder brake of the first unreeling mechanism; the second tension sensor is electrically connected with a second magnetic powder brake of the second unreeling mechanism; and the third tension sensor is electrically connected with a third magnetic powder brake of the rolling-up mechanism. The butyl rubber coating machine can be applicable to coating of poor materials of high-viscosity runners, such as butyl rubber, is good in coating quality, and can improve the production efficiency.

Owner:RUIAN JIAYUAN MACHINERY

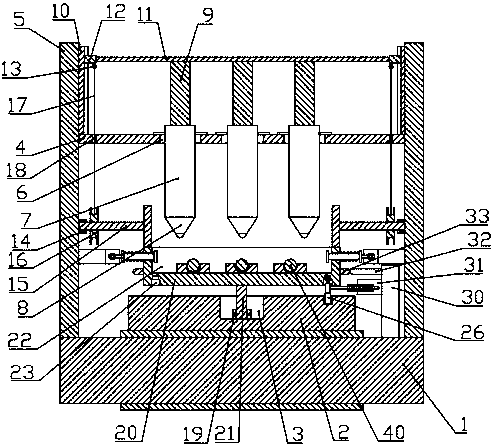

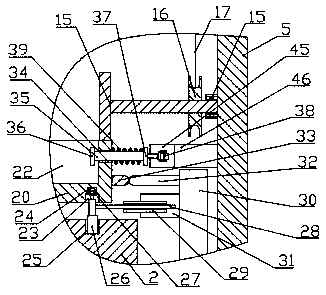

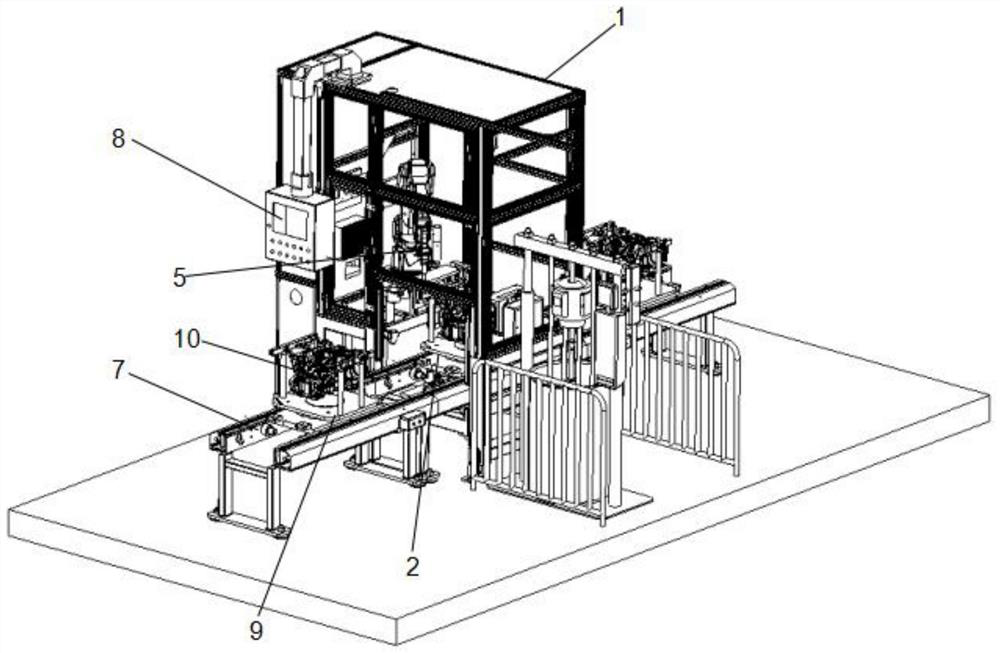

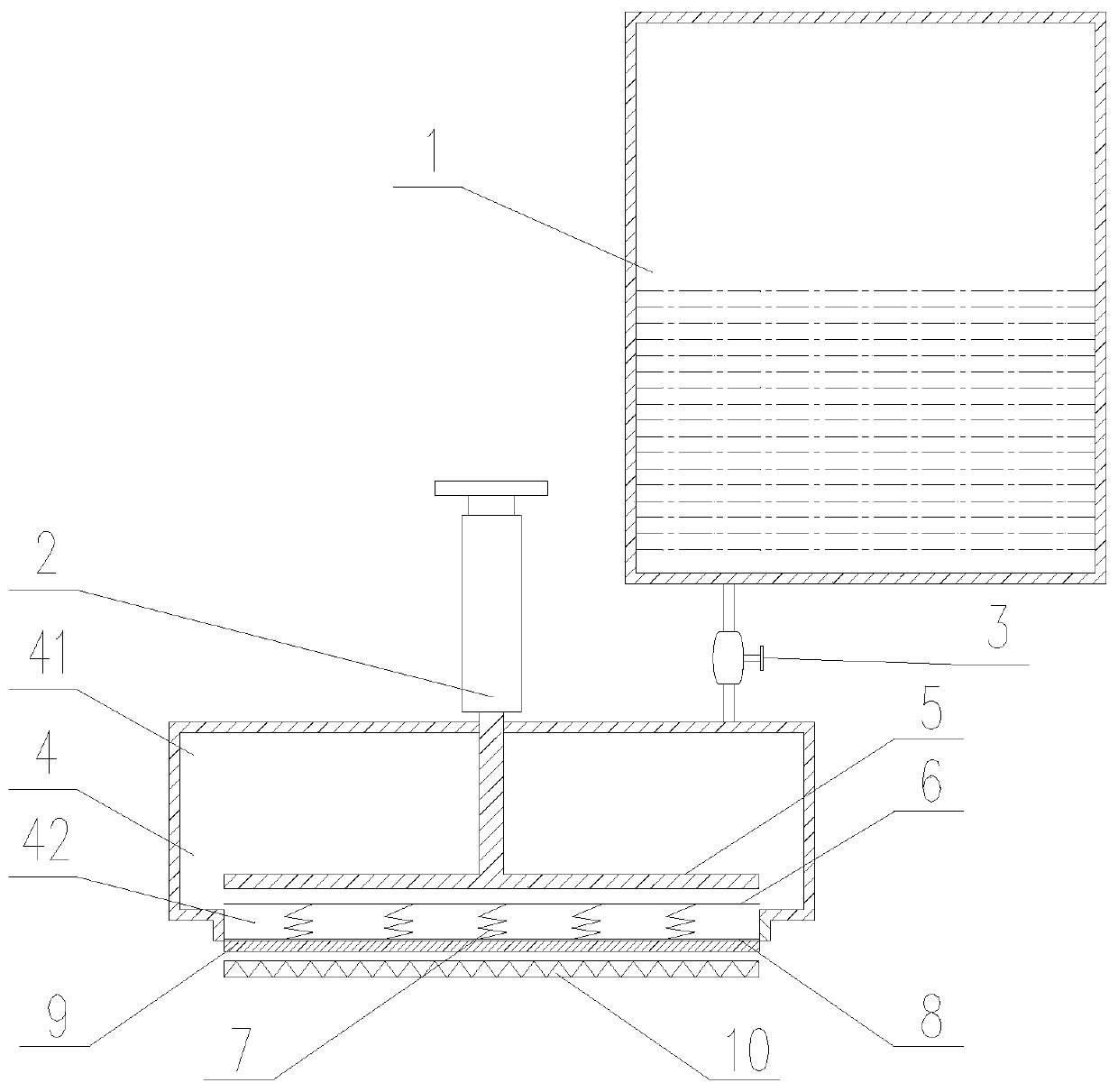

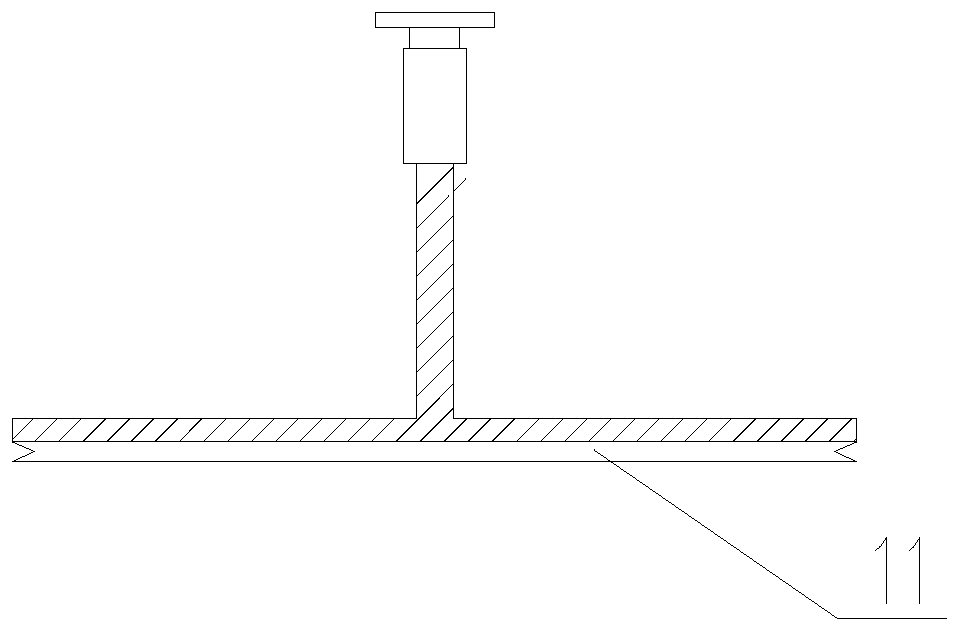

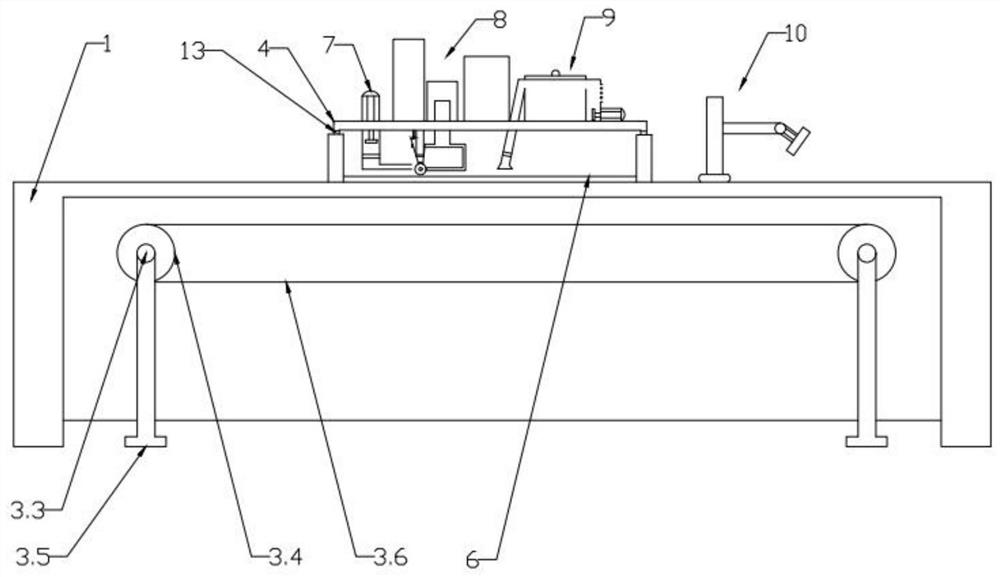

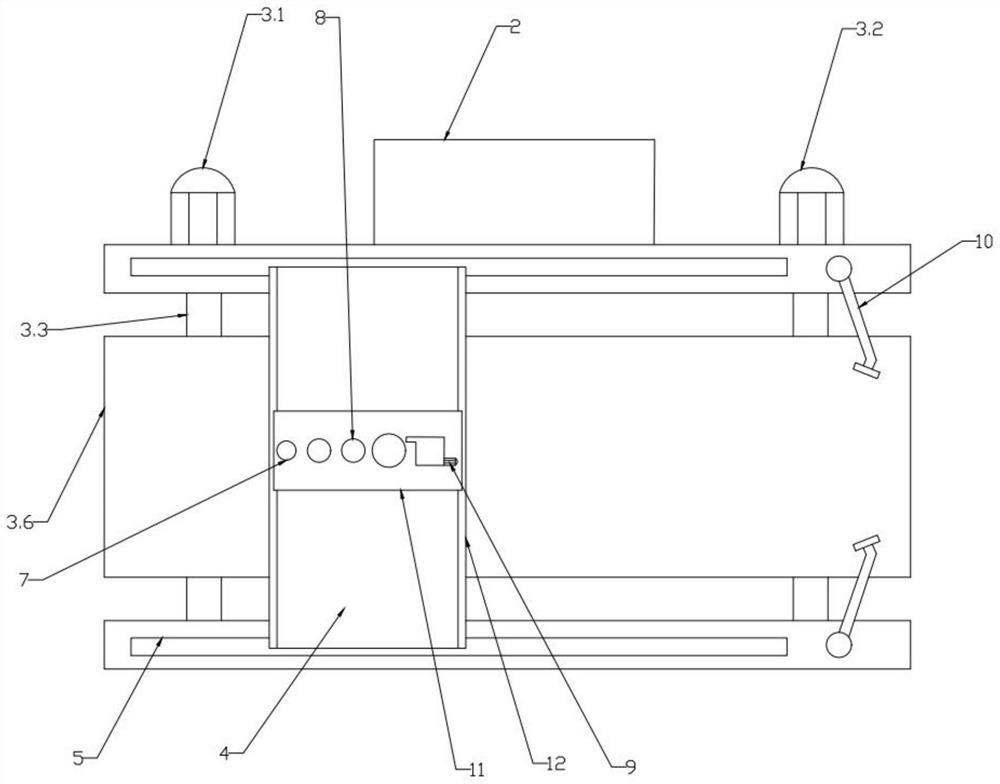

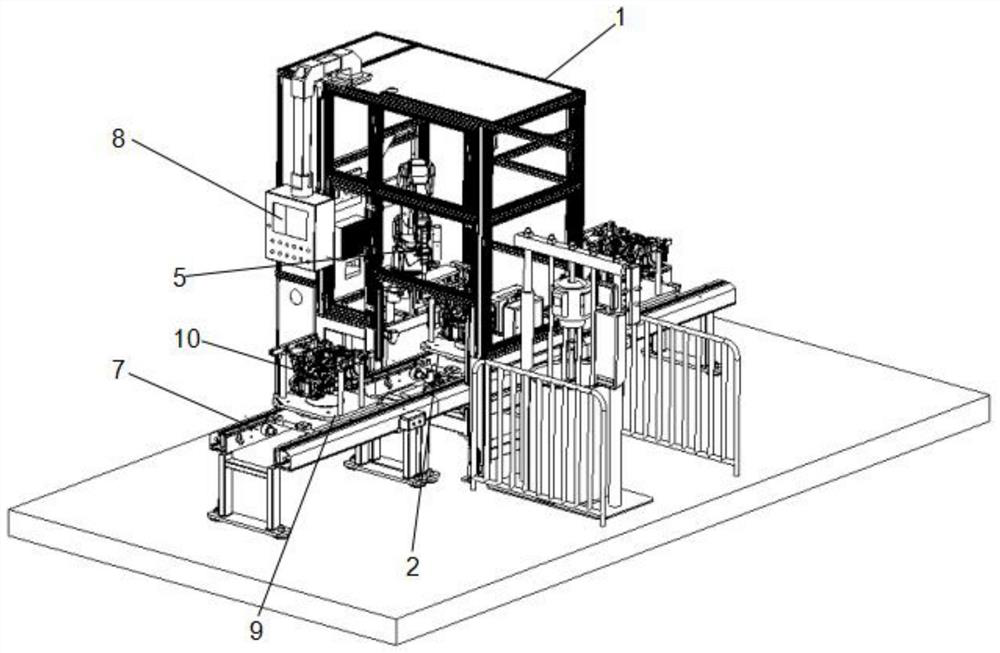

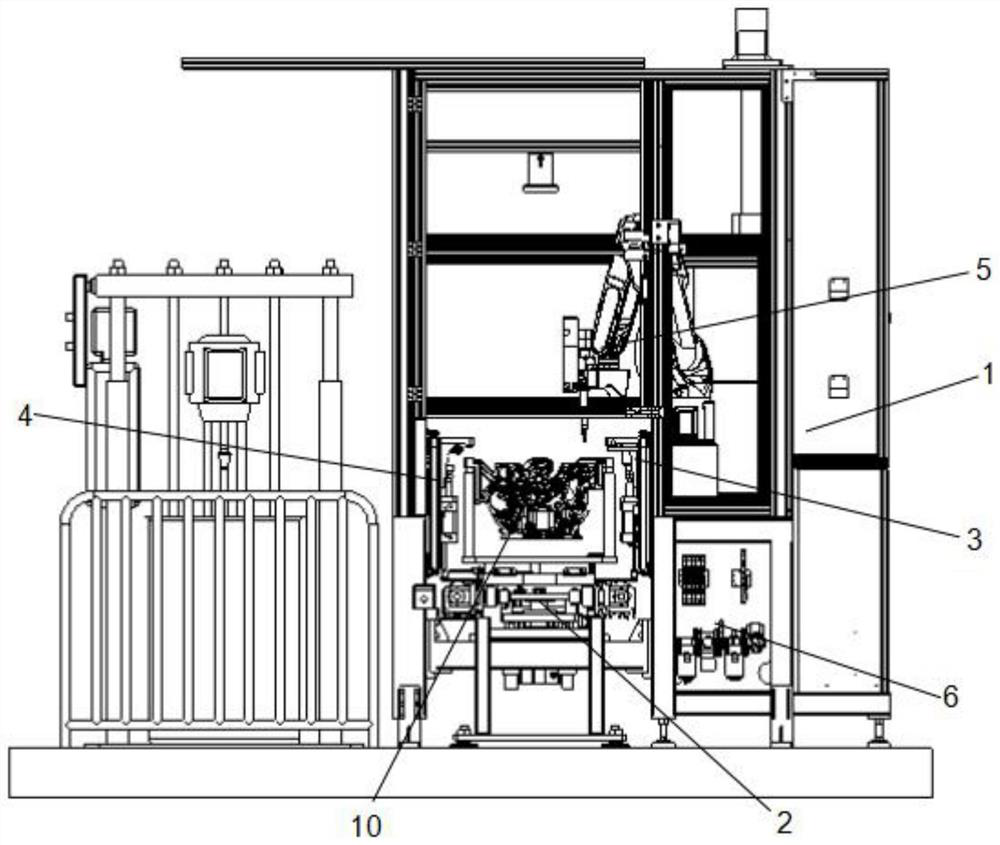

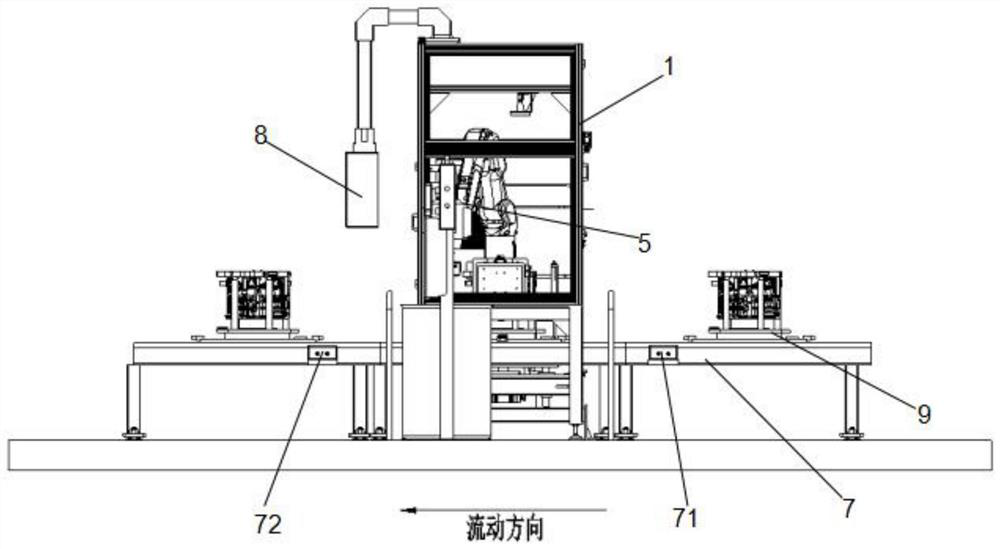

Oil pan gumming machine

ActiveCN111822250ACompact structureHigh degree of automationLiquid surface applicatorsCoatingsEngineeringMachine

The invention provides an oil pan gumming machine. The oil pan gumming machine comprises a protective machine frame, guide rails are installed on the front side of the protective machine frame, a feeding slide seat is installed on the guide rails, and a workpiece is placed on the feeding slide seat. The oil pan gumming machine further comprises a lifting positioning mechanism which is installed onthe front side of the protective machine frame and located on the lower portions of the guide rails, a gumming mechanism installed on the protective machine frame, a main plug pin mechanism which isinstalled on the protective machine frame and located on the lower portion of the gumming mechanism, an auxiliary plug pin mechanism which is installed on the guide rails and transversely arranged with the main plug pin mechanism side by side in a spaced mode oppositely, and a workpiece recognition sensor is fixed to the auxiliary plug pin mechanism. The oil pan gumming machine is compact in structure and high in automation degree, through automatic cooperation of the feeding slide seat, the lifting positioning mechanism, the main plug pin mechanism, the auxiliary plug pin mechanism and the gumming mechanism, full-automatic continuous feeding, precise positioning, accurate gumming, gumming visual detection and automatic discharging of an engine oil pan can be achieved, the whole working efficiency is high, and the gumming quality is good.

Owner:GUANGZHOU BOYAN ELECTROMECHANICAL EQUIP IND

Glue supply device for corrugated carton gluer

ActiveCN108749109BEliminate folding and bonding misalignmentPrecise Control of UniformityPaper-makingBox making operationsCartonEngineering

The invention discloses a glue supply device of a carton sticking machine of a corrugated paper box, and belongs to the technical field of carton sticking machines. The glue supply device of the carton sticking machine of the corrugated paper box comprises a glue supply device, a glue coating device and an extrusion plate, wherein an air cylinder is arranged between the extrusion plate and the glue supply device, the glue coating device comprises a first cavity and a second cavity, wherein the first cavity can be used for containing an extruding plate, and the second cavity is just capable ofcontaining the second cavity of the extruding plate; a second balance plate is arranged on one side, opposite to the extrusion plate, of the glue coating device, the second balance plate is in slidingconnection with the glue coating device, and one side, far away from the extrusion plate, of the second balance plate is provided with a glue coating head. According to the device, the glue amount ofglue coating is accurately controlled by controlling the movement process of the air cylinder, meanwhile, the position of the gluing position and the uniformity of the gluing are accurately controlled through the second balance plate and the gluing device, so that the position precision and the gluing quality of the gluing can be improved; and meanwhile, the device is simple in structure, low incost and cleaning can be conveniently carried out.

Owner:襄阳申谦包装有限公司

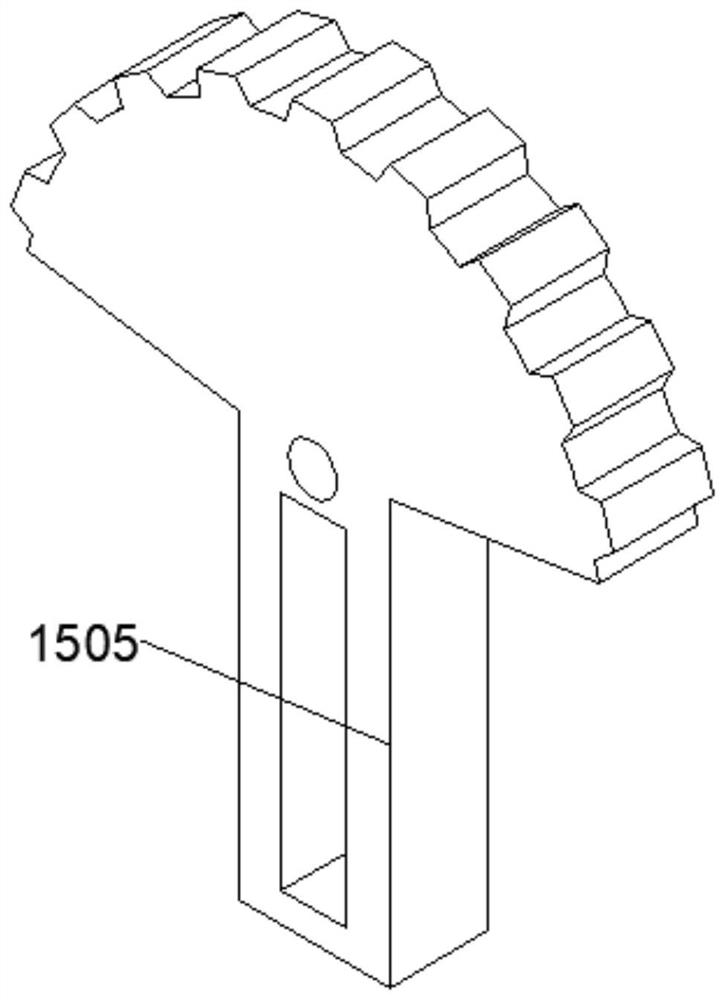

Packaging film gluing device

PendingCN112474186AFlexible height adjustmentNovel structureLiquid surface applicatorsCoatingsRatchetElectrical and Electronics engineering

The invention discloses a packaging film gluing device, and relates to a film processing device. The packaging film gluing device comprises a main box, a sealing cover is fixedly connected to the upper portion of the main box, a first driving mechanism is fixedly connected to the lower portion of the left side of the sealing cover, the first driving mechanism is rotationally connected with a firstswing rod, the first swing rod is rotationally connected with a pawl, a first vertical plate is fixedly connected to the lower portion of the left side of the main box, a special-shaped plate rotationally connected with the middle of the pawl is fixedly connected to the upper portion of the first vertical plate, a blocking column is fixedly connected to the upper portion of the right side of thespecial-shaped plate, the middle of the first vertical plate is rotationally connected with a ratchet wheel matched with the pawl, the front side of the ratchet wheel is fixedly connected with a winding roller, a second driving mechanism is fixedly connected to the lower portion of the middle of the sealing cover, and the second driving mechanism is rotationally connected with a second swing rod.The ratchet wheel and pawl structure is arranged, the winding roller can be intermittently driven to rotate, and therefore a film can be intermittently wound, and better gluing is achieved in cooperation with a gluing mechanism; and a first rotating disc drives a second rotating rod to rotate, and then a connecting frame is driven by the second swing rod to slide up and down.

Owner:佛山市捷信来包装材料有限公司

Glue supply device of carton sticking machine of corrugated paper box

ActiveCN108749109AEliminate folding and bonding misalignmentPrecise Control of UniformityBox making operationsPaper-makingCartonEngineering

The invention discloses a glue supply device of a carton sticking machine of a corrugated paper box, and belongs to the technical field of carton sticking machines. The glue supply device of the carton sticking machine of the corrugated paper box comprises a glue supply device, a glue coating device and an extrusion plate, wherein an air cylinder is arranged between the extrusion plate and the glue supply device, the glue coating device comprises a first cavity and a second cavity, wherein the first cavity can be used for containing an extruding plate, and the second cavity is just capable ofcontaining the second cavity of the extruding plate; a second balance plate is arranged on one side, opposite to the extrusion plate, of the glue coating device, the second balance plate is in slidingconnection with the glue coating device, and one side, far away from the extrusion plate, of the second balance plate is provided with a glue coating head. According to the device, the glue amount ofglue coating is accurately controlled by controlling the movement process of the air cylinder, meanwhile, the position of the gluing position and the uniformity of the gluing are accurately controlled through the second balance plate and the gluing device, so that the position precision and the gluing quality of the gluing can be improved; and meanwhile, the device is simple in structure, low incost and cleaning can be conveniently carried out.

Owner:襄阳申谦包装有限公司

Positioning gluing device for gluing machine

InactiveCN112774925AEnsure safetyGuaranteed cleanlinessLiquid surface applicatorsCleaning using gasesElectric machineryDust control

The invention discloses a positioning gluing device for a gluing machine. The positioning gluing device comprises a main machine table, a conveying device is rotationally arranged below the main machine table, a first sliding groove is formed in the position, close to the front side edge and the rear side edge, of the upper face of the main machine table, a first sliding plate is arranged on the first sliding groove in a sliding mode, and a first sliding strip is integrally formed below the first sliding plate. A storage battery is fixedly arranged on the outer side wall of the rear face of the main machine table through a bolt. Second sliding grooves are formed in two sides of the first sliding plate. A second sliding plate is arranged on the second sliding grooves in a sliding manner, a sliding strip II is integrally formed below the second sliding plate, a heating device is fixedly arranged on one side of the upper face of the second sliding plate through a bolt, and a gluing device is fixedly arranged at the middle position of the second sliding plate. A secondary dust removal device is fixedly arranged on the other side of the second sliding plate through bolts, and a primary dust removal device is rotationally arranged on one side of the main machine table and located over a second motor. The positioning gluing device for the gluing machine has the beneficial effects that positioning can be achieved, gluing is even, glue leakage is avoided, and multi-structure combined work is achieved.

Owner:常州苏橡橡塑制品有限公司

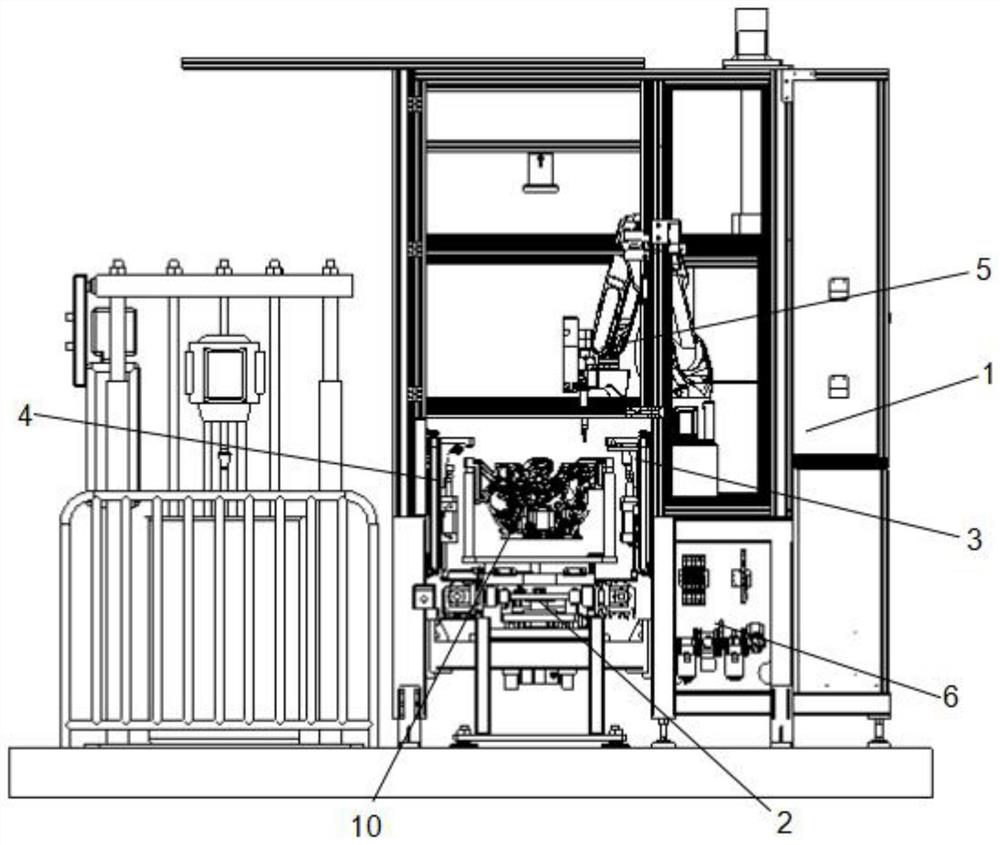

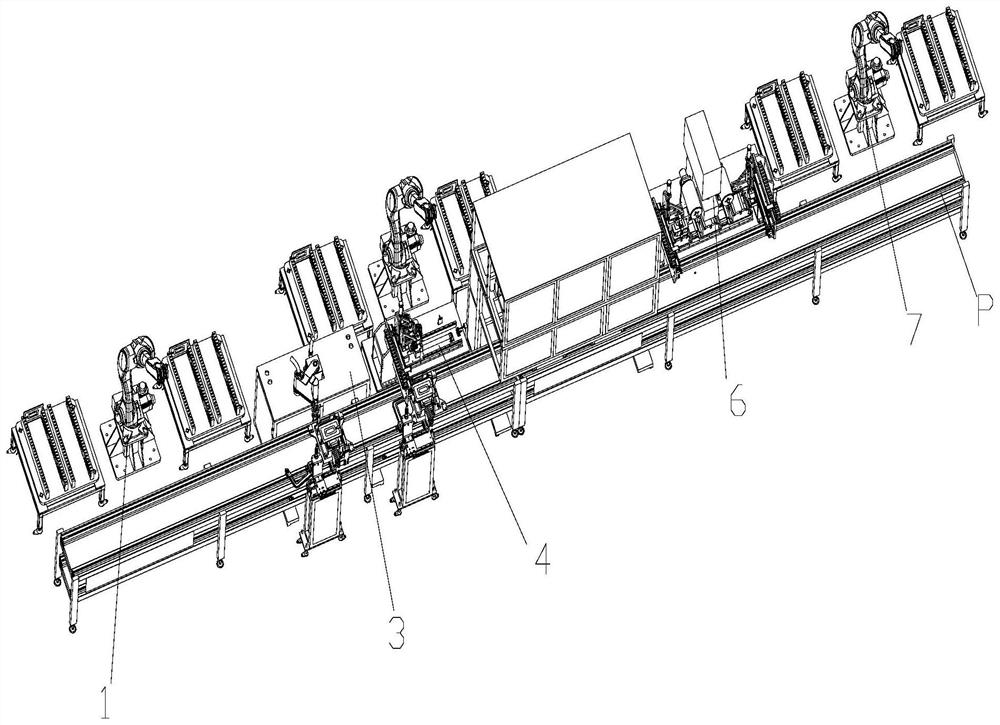

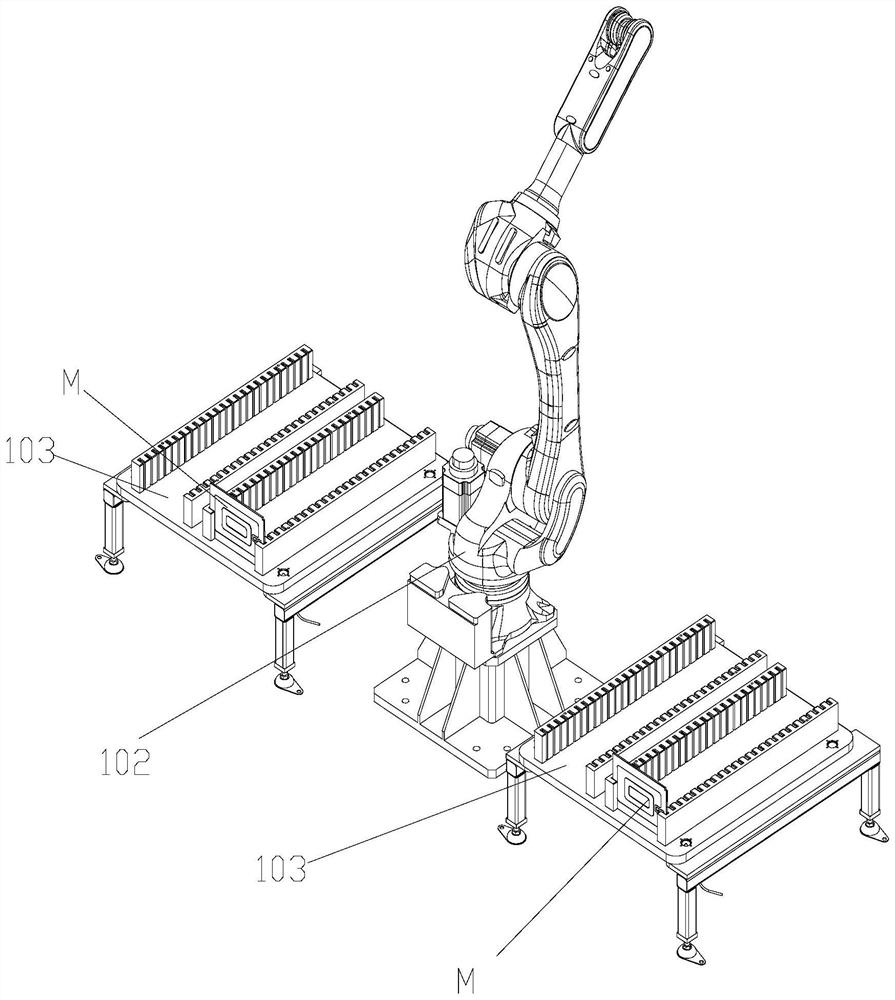

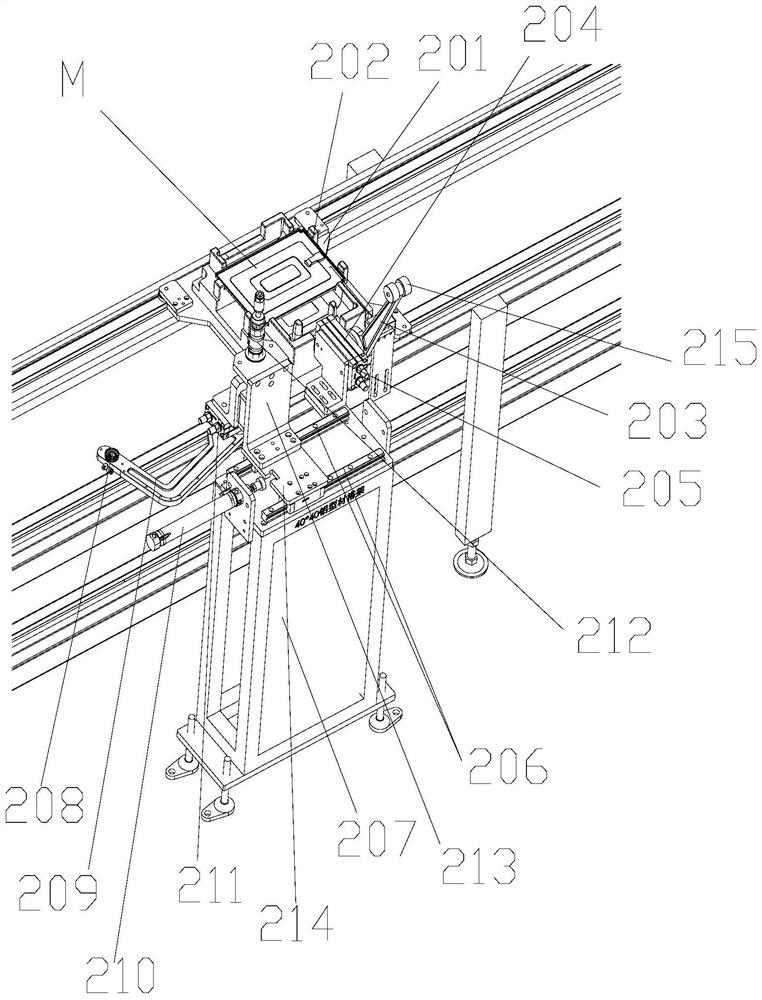

Ultrasonic welding automatic production line

PendingCN112222597AIncrease productivityReduce manufacturing costNon-electric welding apparatusProduction lineUltrasonic welding

The invention belongs to the technical field of automatic production, and particularly relates to an ultrasonic welding automatic production line. The ultrasonic welding automatic production line comprises a conveying mechanism, the conveying mechanism is provided with an accompanying tool plate, a robot feeding mechanism used for grabbing a first accessory and placing the first accessory on the accompanying tool plate, an automatic quantitative dispensing mechanism used for dispensing glue on the first accessory, a feeding assembly mechanism used for feeding a second accessory to the positionabove the first accessory to form an assembly and an ultrasonic welding mechanism used for carrying out ultrasonic welding on the assembly are arranged beside the conveying mechanism. According to the ultrasonic welding automatic production line, manual production is replaced with production of the production line, the production efficiency is improved, and the production cost is reduced.

Owner:智昌科技集团股份有限公司

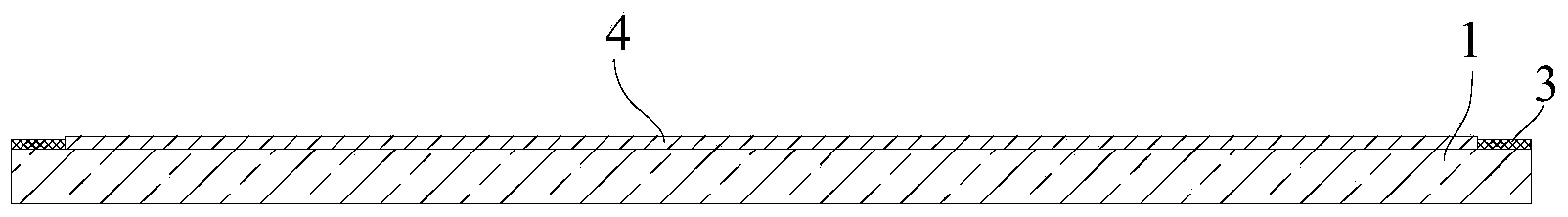

Precise gluing device for corrosive aluminum foil

ActiveCN112403843AUniform thickness and smoothReduce dosageLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention relates to a gluing device, in particular to a precise gluing device for corrosive aluminum foil. The precise gluing device for the corrosive aluminum foil comprises a base, guide railsand guide columns, a placing portion is slidably arranged among the guide rails, a positioning portion is slidably arranged among the guide columns, and the aluminum foil is evenly placed on the positioning portion at intervals. Second screw rods rotate, so that second nut blocks drive a pressing plate to move downwards slowly at a constant speed, a piston plate extrudes the glue in a glue containing box downwards slowly in the glue containing box, and the flowing speeds of the glue flowing out of nozzles are the same, so that the glue is uniformly and slowly extruded on the surface of the aluminum foil which moves downwards at a constant speed, and the glue on the surface of the aluminum foil is uniform in thickness and smooth; and when the glue flows out of the nozzles, the glue is extruded towards the middle of trapezoidal grooves due to the flow guide effect of inclined planes on the two sides of each trapezoidal groove, so that the phenomenon of non-uniform gluing on the surface of the aluminum foil due to bubbles generated when the glue flows out of the trapezoidal grooves can be prevented.

Owner:JIANGXI WANNIAN QUNXING ELECTRONICS

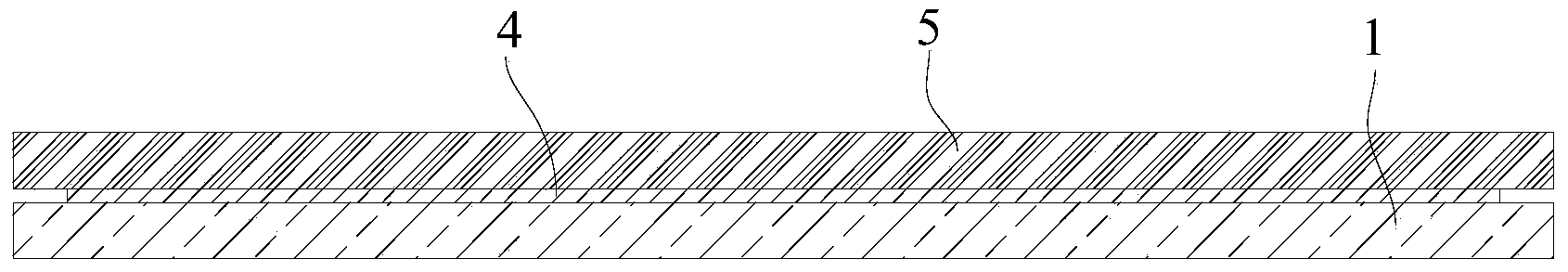

A precise gluing device for corroded aluminum foil

ActiveCN112403843BUniform thickness and smoothPrevent uneven glue applicationLiquid surface applicatorsCoatingsMetallurgyAdhesive glue

The invention relates to a gluing device, in particular to a precise gluing device for corroding aluminum foil. A precise gluing device for corroding aluminum foil comprises a base, a guide rail and a guide post, a placement part is slidably arranged between the guide rails, a positioning part is slidably arranged between the guide posts, and the aluminum foil is evenly spaced on the positioning part. The second screw rod rotates, so that the second nut block drives the pressure plate to move downward at a constant speed and slowly, and the piston plate gently squeezes the glue in the glue box downward, and the flow rate out of the nozzle is the same, so that the The glue is evenly and gently squeezed on the surface of the aluminum foil moving at a constant speed below, so that the thickness of the glue on the surface of the aluminum foil is uniform and smooth. When the glue flows out of the nozzle, the glue will be squeezed into the middle of the trapezoidal groove due to the diversion effect of the slopes on both sides of the trapezoidal groove. This can prevent bubbles from appearing when the glue flows out of the trapezoidal groove, which may cause uneven coating on the surface of the aluminum foil.

Owner:JIANGXI WANNIAN QUNXING ELECTRONICS

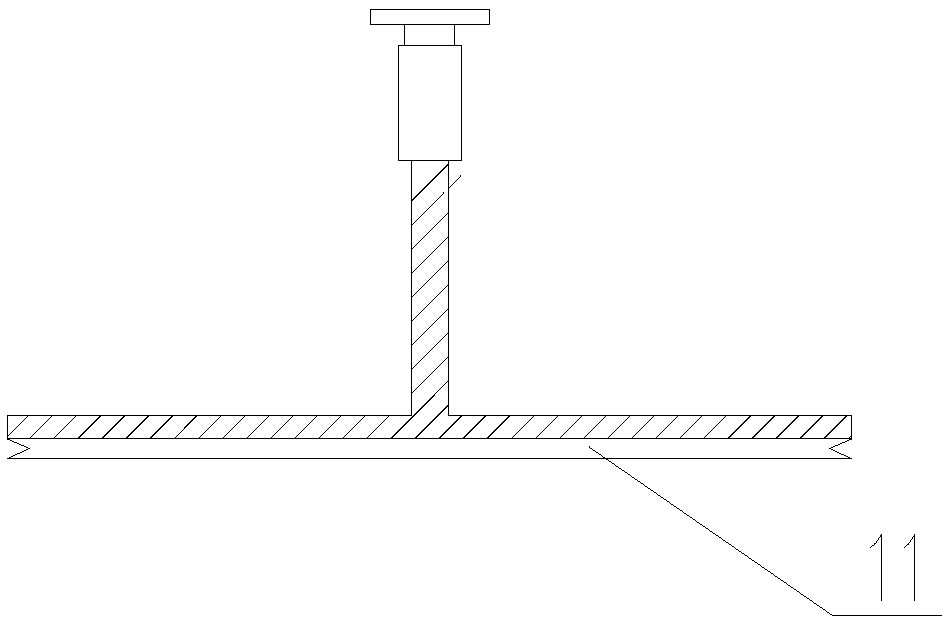

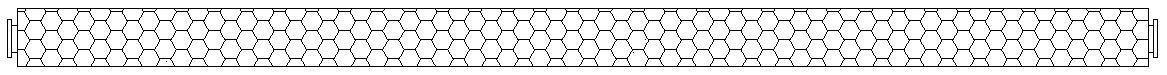

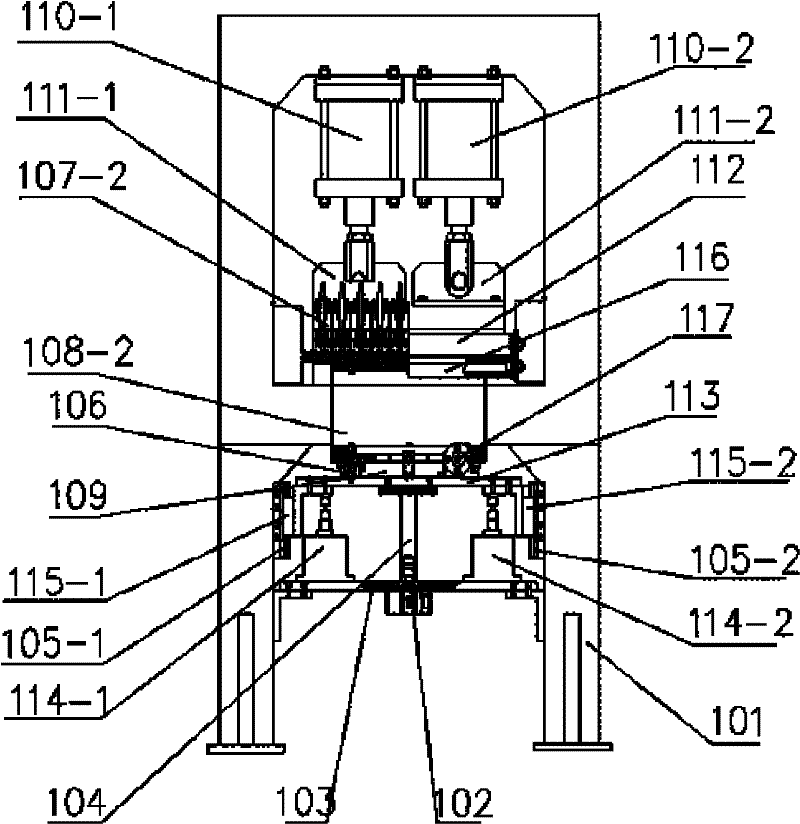

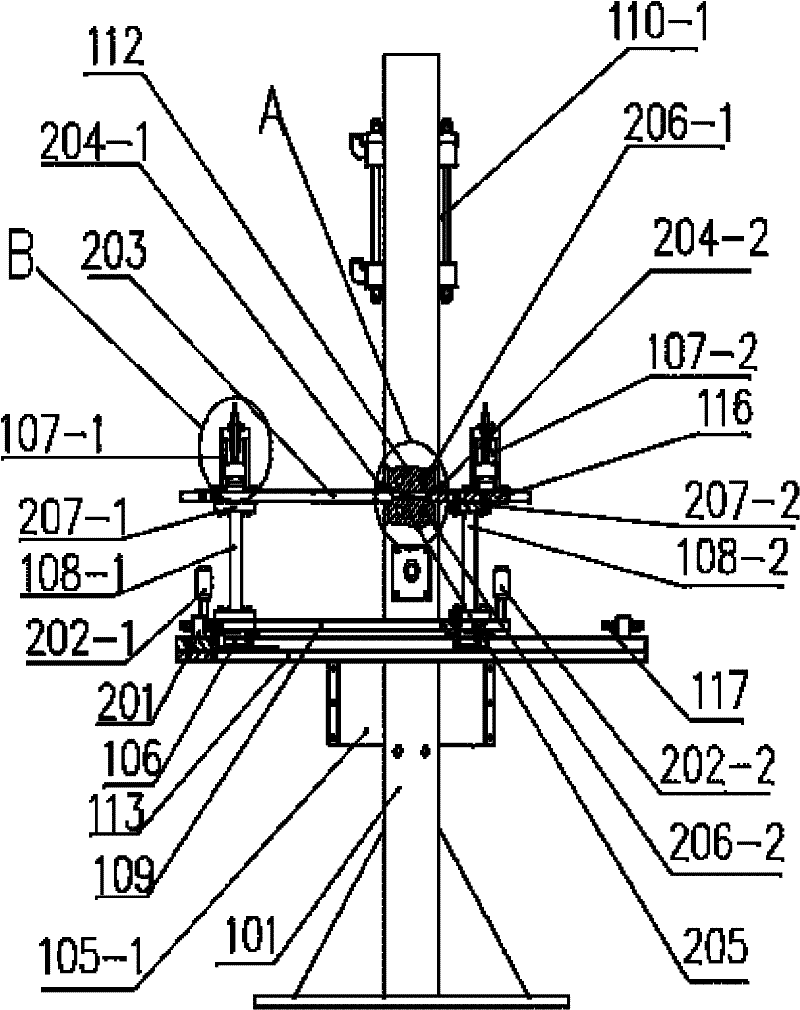

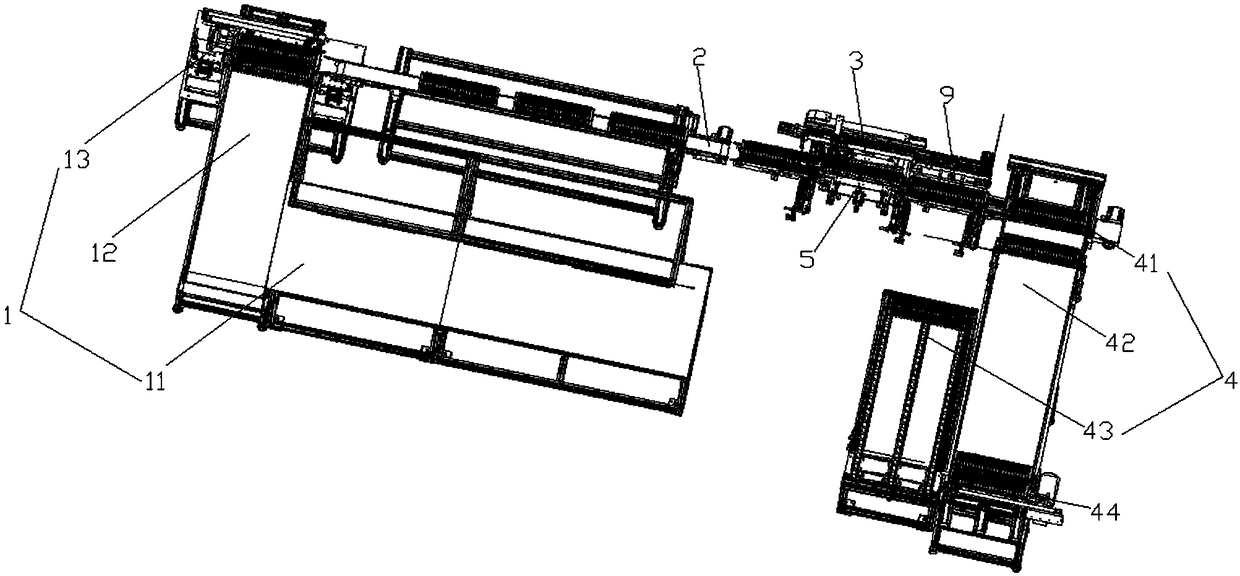

Bamboo batten hot-pressing extension machine

InactiveCN101774192BGlue accurateAccurate positioning of lapsPlywood pressesVeneer pressesEngineeringOil pressure

The invention discloses a bamboo batten hot-pressing extension machine, which comprises a stand. A lifting cylinder supporting plate is arranged at the lower part of the stand; a lifting cylinder is arranged in the middle of the lifting cylinder supporting plate and connected with a push rod; bracket buffers are arranged at two ends of the lifting cylinder supporting plate; positioning guide rails are arranged on two sides of the stand and provided with substrates which are provided with feeding guide rails; movable plates are arranged on the feeding guide rails; push handles are arranged at two ends of the movable plates; a positioner is arranged at one end of each substrate; an oil pressure buffer is arranged at the other end of each substrate; the movable plates are provided with brackets; front slotted plates and rear slotted plates are arranged on the brackets; bamboo batten press plates are respectively arranged at one end of each front slotted plate and one end of each rear slotted plate; compressing devices are respectively arranged at the other ends of e each front slotted plate and each rear slotted plate; upper hot-pressing plates and lower hot-pressing plates are respectively arranged in the middle of the brackets; and compressing cylinders are arranged on the brackets and connected with the upper hot-pressing plates through lugs. The invention has good crimping quality, high production efficiency and low production cost and is particularly suitable for crimping bamboo battens with the width of 3-12mmm and the thickness of 1.5-5mm.

Owner:戴若夫

A gluing device for steel backing for brake pads

ActiveCN108654915BAchieve rotationIncrease productivityLiquid surface applicatorsCoatingsAdhesive glueBrake pad

The invention discloses a gluing device for steel backings for a brake pad. The gluing device comprises a rack, a conveying mechanism, a guide plate mechanism and a gluing mechanism. The steel backings machined in a previous process are conveyed to the gluing device through the conveying mechanism, flow line production is realized, and production efficiency is improved. The guide plate mechanism can sort the steel backings arranged disorderly on a conveying belt so that the steel backings can be arranged linearly and regularly. A printing plate on a gluing assembly is provided with printing areas, the shapes of the printing areas are matched with that of the steel backings, when the printing areas perform gluing on the steel backings, only the printing areas of the printing plate are in contact with the upper surfaces of the steel backings, the portions, being not in need of gluing, of the steel backings are not in contact with the printing areas on a roller brush, the situation that the places, being not in need of gluing, of the steel backings are stained with glue, so that product scrap is caused can be prevented, and meanwhile glue can also be saved.

Owner:ANHUI GUIDA AUTO PARTS

A glue coating device for electronic components

ActiveCN109647662BReduce industrial pressureReduce manufacturing costLiquid surface applicatorsCoatingsElectronic componentPiston

The invention discloses an electronic component gluing device. A device body is included and internally provided with a gluing mechanism, a pressing mechanism and a pedaling mechanism. The gluing mechanism comprises a gluing barrel, an extrusion ball valve and a piston connected with the extrusion ball valve through an extrusion shaft. The pressing mechanism comprises a pressing wedge block, a push shaft, a pushing ball valve, a connecting shaft fixedly arranged on the push shaft, and a sliding rod which is in sliding connection with the connecting shaft. The pedaling mechanism comprises a pedal plate, a pull ring, an elastic shaft, an L-shaped downward sliding rod fixedly connected with the pull ring, a downward sliding wedge block arranged on the top of the L-shaped downward sliding rod,and an elastic piece elastically connected with the downward sliding wedge block, wherein the pull ring and the elastic shaft are arranged on the upper side and the lower side of the pedal plate. Through the gluing mechanism, the pressing mechanism and the pedaling mechanism arranged in the device body, the hands and the feet of operators can act at the same time, the gluing work can be finishedwithout cooperation of multiple people, the operation efficiency is improved, and the enterprise production cost is reduced.

Owner:徐州蓝联诚制造有限公司

Automatic efficient gluing equipment for electronic components

InactiveCN112893010APlay the role of supporting the rotating frameRealize regulationLiquid surface applicatorsCoatingsInterference fitElectronic component

The invention provides automatic efficient gluing equipment for electronic components. The equipment comprises an upper connecting frame, a gluing head, a lower worm, a telescopic cylinder, a lower driving part, a telescopic driving part, an upper driving part and an upper worm. A movable rotating rod of the upper connecting frame is fixedly connected into a middle fixing hole of a rotating frame in an interference fit mode, and the two ends of the rotating frame are connected to an annular support of the upper connecting frame in a sliding mode. The two ends of the lower worm are rotatably connected to the inner side of the rotating frame through bearings. The two sides of the upper end of a telescopic cylinder are rotatably connected to the left side of the rotating frame through bearings, and a side worm gear of the telescopic cylinder is engaged with the lower worm. The gluing head is rotatably connected to the interior of the telescopic cylinder. The lower driving part is arranged above the rotating frame, and an output shaft of the lower driving part is fixedly connected to the upper end of a shaft of the lower worm. The inclination angle of the lower end of the gluing head can be changed by adjusting the angle of the side worm gear, so that the gluing head is easier to get close to the connecting end of the electronic elements with inner pins, and the pins of the electronic elements are further accurately glued.

Owner:青岛蔷薇优品电子商务有限公司

A kind of oil pan glue coating machine

ActiveCN111822250BCompact structureHigh degree of automationLiquid surface applicatorsCoatingsVisual inspectionStructural engineering

Owner:GUANGZHOU BOYAN ELECTROMECHANICAL EQUIP IND

AC and DC dual-purpose small automatic glue coating machine

InactiveCN103586163BAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machineryPush pull

AC and DC dual-purpose small automatic glue applicator. It belongs to the field of office supplies. It solves the problems of slow manual glue application, uneven coating and easy adhesion. A rack (4) is fixed in the cavity (3) of the bottom plate (1) of the gluing machine, a gear meshing with the rack (4) is fixed on the cross bar of the door frame (2), and the first motor (6 ) is fixed with one end of the crossbar; the lead screw (7) between the two columns (5) is covered with a slider (8), and the second motor (9) is fixed with one end of the lead screw (7); the lower part of the slider (8) A push-pull electromagnet (10) is fixed, and a rubber bottle (12) is fixed at the lower end of the push-pull electromagnet (10). The glue port is closed by a cylindrical pressure head (18); the lower end of the threaded rod (15) is fixed with a pressure piece (19). The invention has the advantages of fast glue application speed, uniform glue application, time saving and labor saving, and convenient movement and portability.

Owner:NORTHEAST GASOLINEEUM UNIV

Fitting method

ActiveCN104004458BGlue accurateHigh speedAdhesive processes with adhesive heatingSilicone GelsMetallurgy

The pasting method comprises the following steps: the first step: enclosing the surface of the first part to be pasted with high-temperature-resistant adhesive tape to form a closed pasting area; the second step: applying silicone gel to the pasting area area to form a uniform thickness adhesive layer in the sticking area, and make the thickness of the adhesive layer greater than the thickness of the high temperature resistant tape; the third step: heating the adhesive layer so that the The glue in the adhesive layer is cured to obtain a cured adhesive layer; the fourth step: tearing off the high temperature resistant tape, and then attaching the second part to be bonded to the first part to be bonded. In the present invention, the surface to be glued of the first component to be pasted is surrounded by a high-temperature-resistant adhesive tape to form a closed pasting area to limit the scope of glue application, so that the glue application is accurate and fast.

Owner:SUZHOU TONGLI PHOTOELECTRIC CO LTD

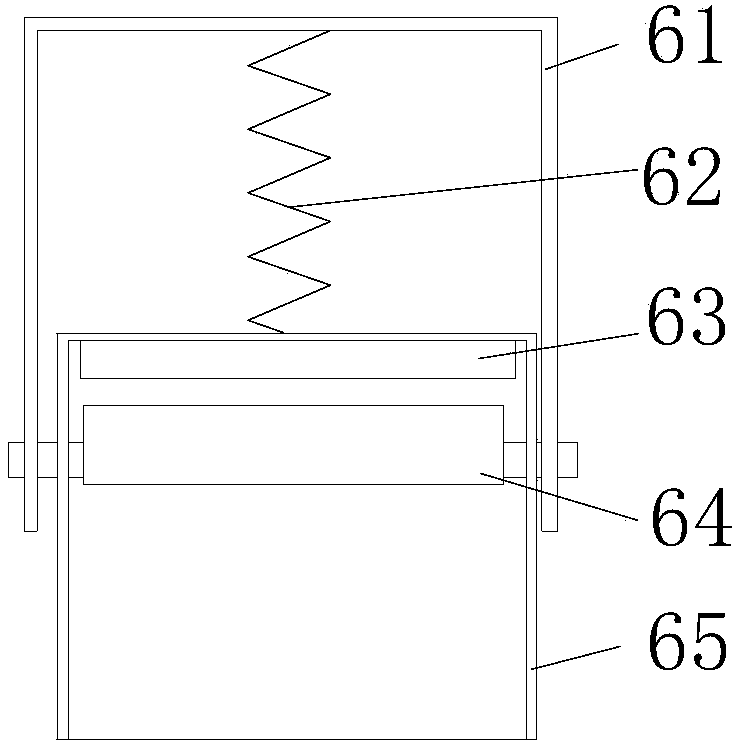

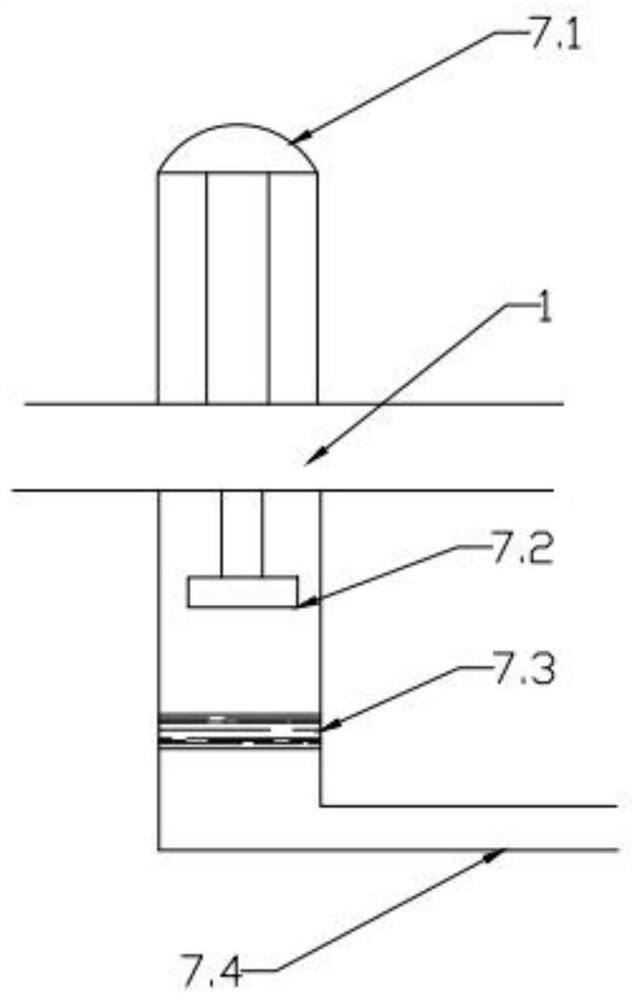

Cover cap gluing device of battery pack

PendingCN108126868APrecise positioningGlue accurateLiquid surface applicatorsCell lids/coversEngineeringPiston rod

The invention discloses a cover cap gluing device of a battery pack. The cover cap gluing device comprises a feeding mechanism, a transmission mechanism and a discharging mechanism, wherein a cover cap gluing mechanism used for gluing a battery cover cap is arranged above the transmission mechanism. The cover cap gluing mechanism comprises an electric sliding table, a lifting air cylinder and a nozzle valve, wherein the lifting air cylinder is fixed on a sliding block of the electric sliding table, the nozzle valve is fixed at one end of a piston rod of the lifting air cylinder and is used forspraying glue to the cover cap, and a positioning mechanism used for positioning the battery pack is arranged below the cover cap gluing mechanism. The positioning mechanism comprises a blocking plate and a clamping mechanism, wherein the blocking plate is used for blocking the battery pack from running on the transmission mechanism, the clamping mechanism is used for fixing the two sides of a battery in the battery pack, the battery pack is positioned, and the battery cover cap is glued, so that the battery of the battery pack is protected. One end of a piston rod of the lifting air cylinderis connected with a mounting plate, the nozzle valve and the lifting air cylinder are connected through the mounting plate, and the mounting plate is provided with a three-axis manual displacement platform used for finely adjusting the nozzle valve, so that the precise positioning of gluing is carried out.

Owner:苏州市晴空自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com