Patents

Literature

45results about How to "Positioning balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

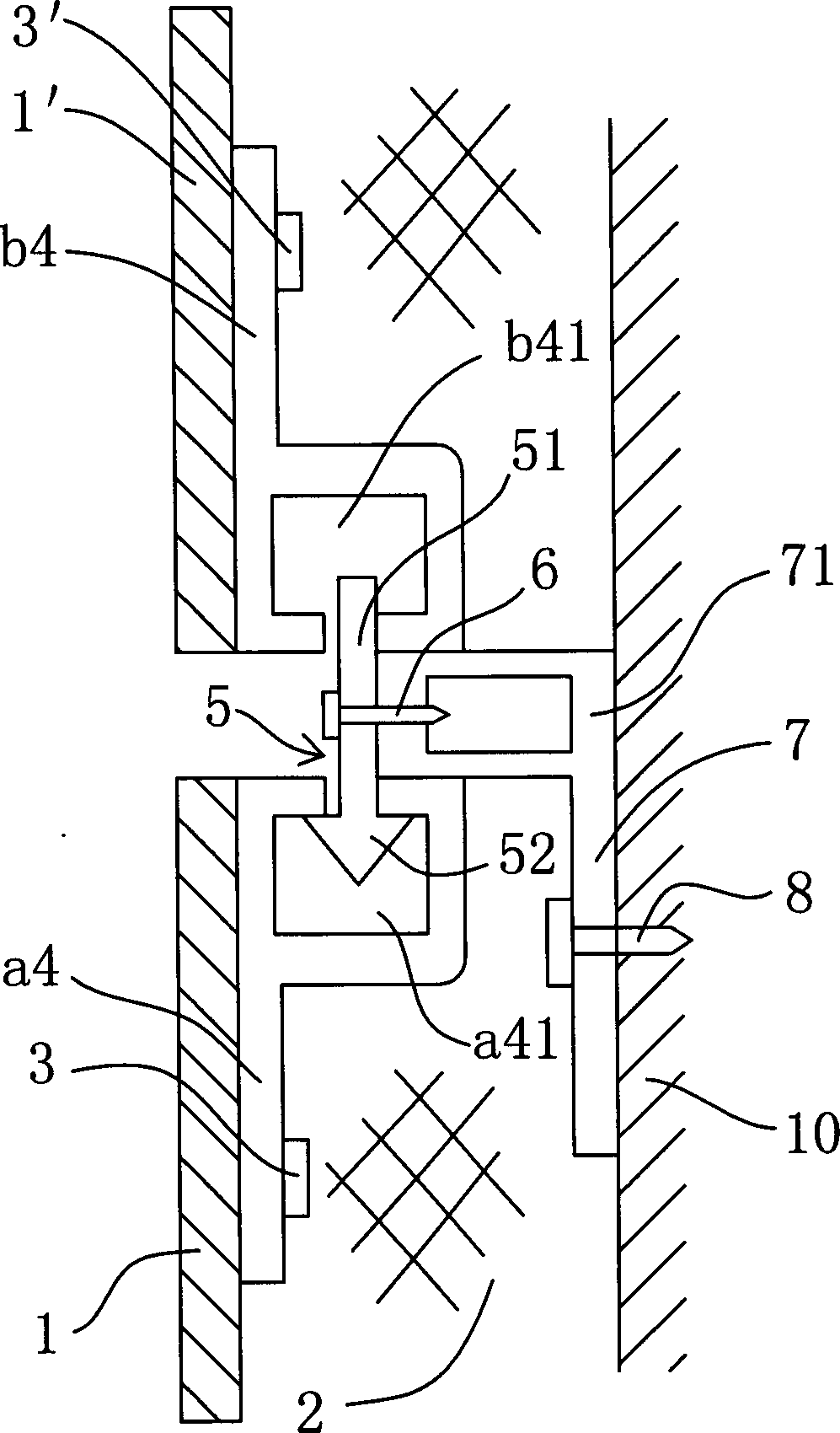

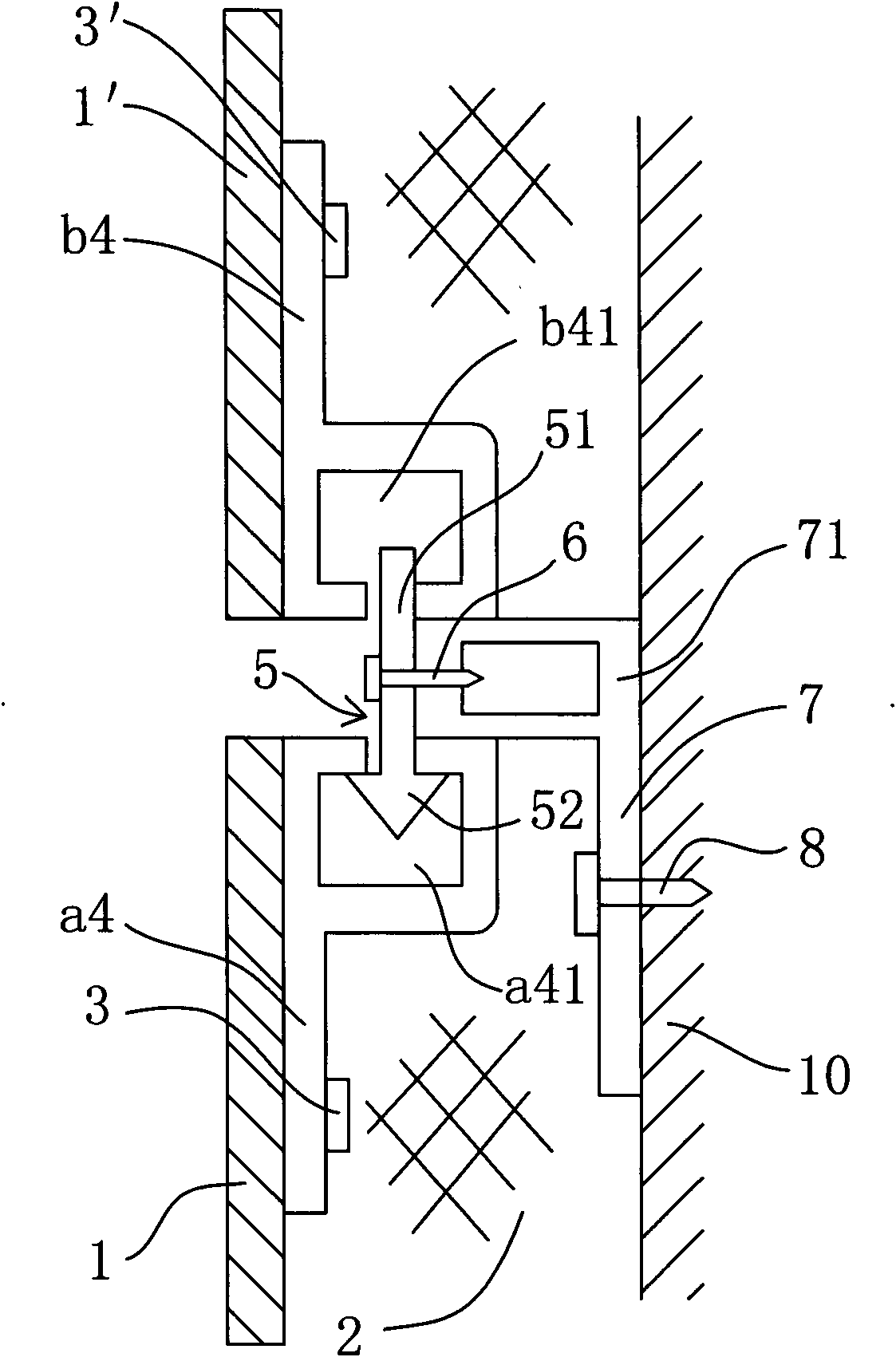

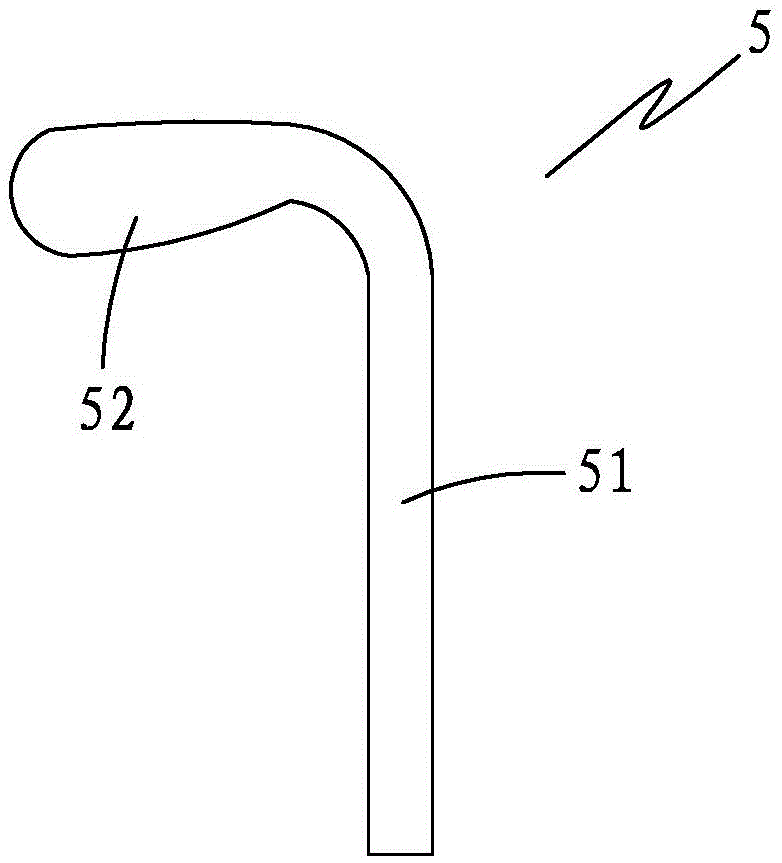

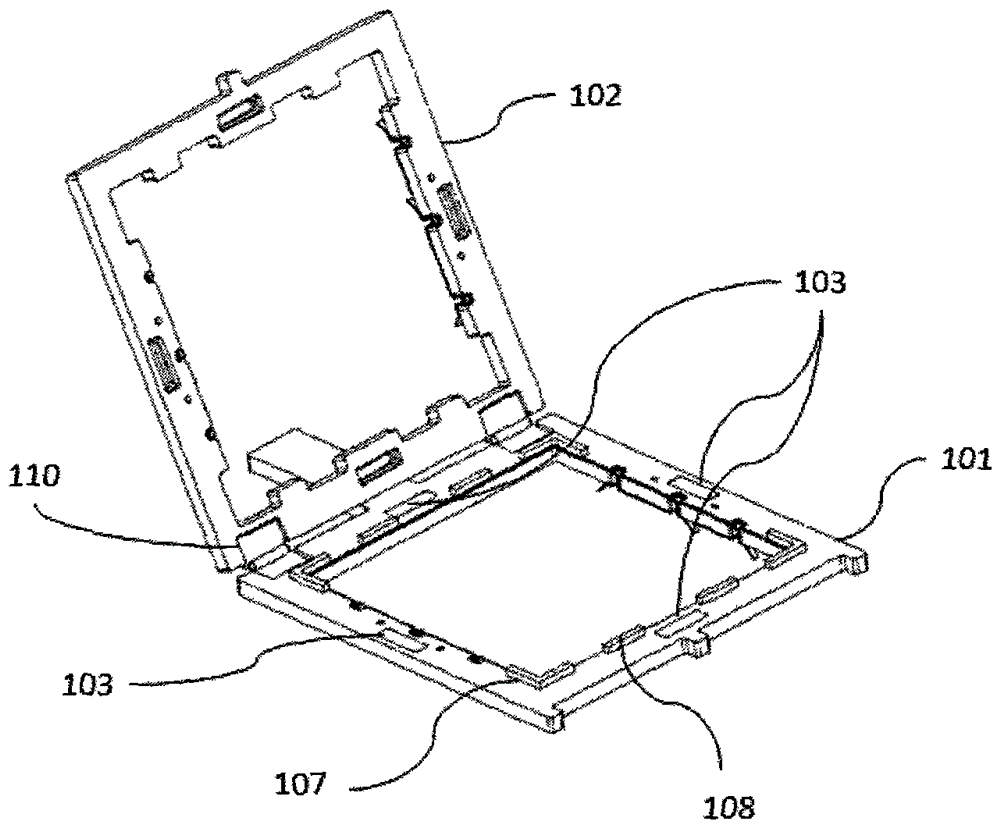

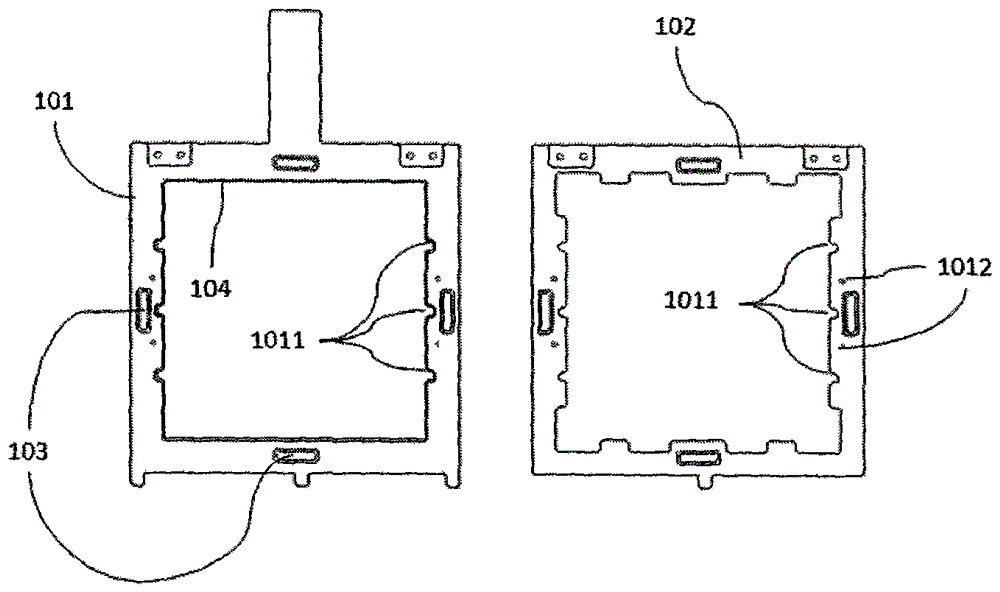

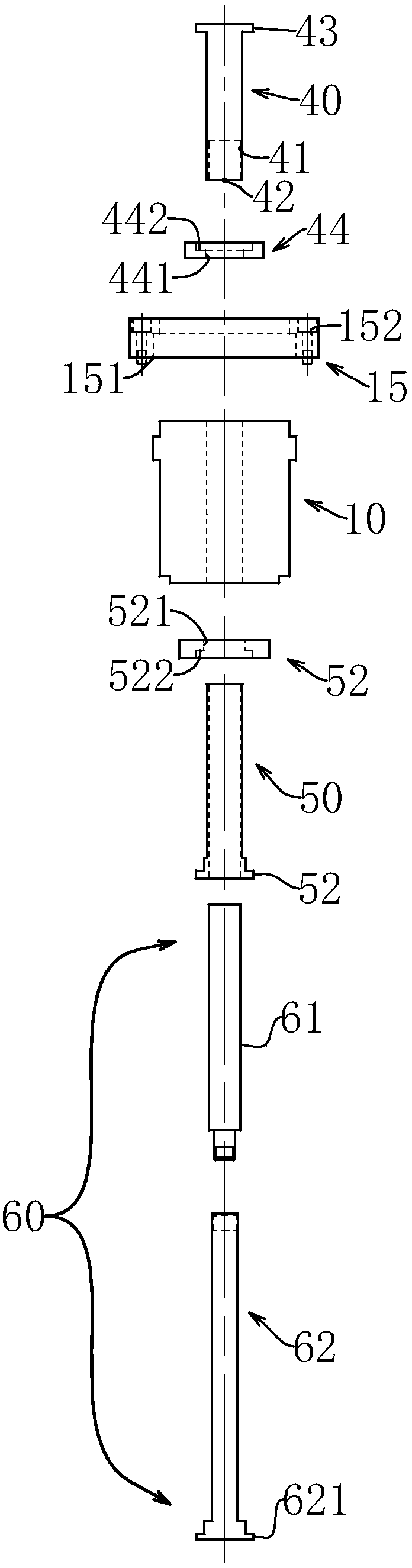

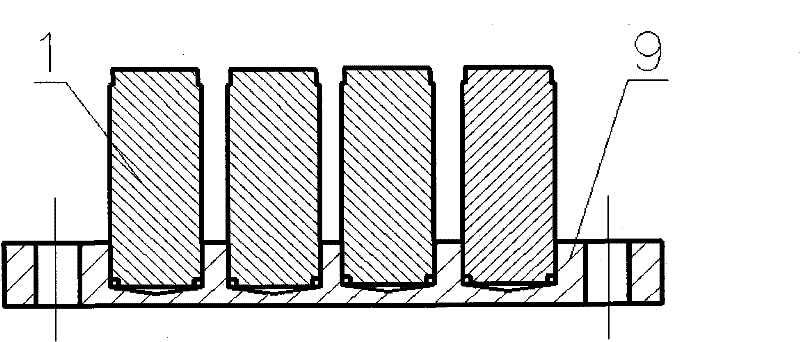

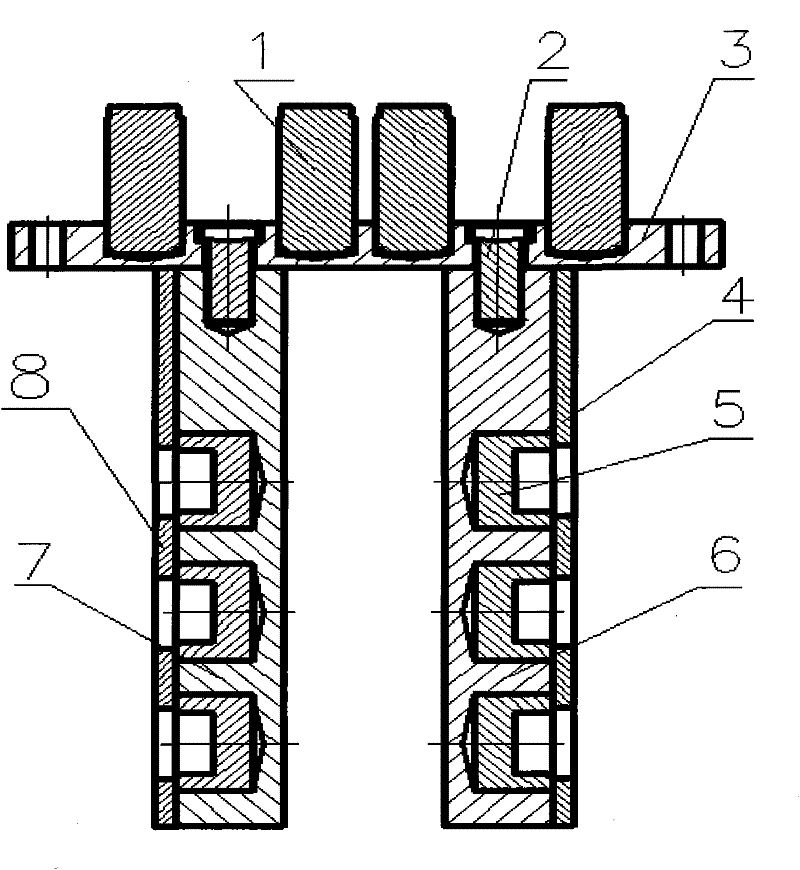

Stone ceramic plate hanging buckle component and mounting process thereof

The invention relates to a stone ceramic plate hanging buckle component which comprises a first pendant and a second pendant respectively mounted at the back part of a stone ceramic plate, a positioning corner fastener with a support part for fixing with the wall surface, and a fastener for respectively limiting the second pendant and the first pendant on the upper side and the lower side of the support part, wherein the fastener comprises a pressure plate and a hanging hook positioned at the lower end of the pressure plate; and the first pendant comprises a T-shaped groove which comprises anupward opening and is matched with the hanging hook, the hanging hook is inserted into the T-shaped groove of the first pendant for lifting the first pendant, the second pendant comprises a groove with a downward opening, and the upper end of the pressure plate is inserted into the groove and leans on the groove wall on one side of the groove, which is near to the wall surface. The stone ceramic plate hanging buckle component has simple structure, a keel framework does not need to be mounted, the dry hanging is not required, the positioning is fast, the stress on all plate blocks is more uniform through hanging (lifting)-supporting-leaning-adhering combination, the seismic performance is better, the detachment, the mounting and the replacement are more convenient, the mutual interference can be avoided, the problem of a cold / thermal bridge of a stone ceramic plate curtain wall can be thoroughly solved, and the stone ceramic plate hanging buckle component has better economic benefits and energy-saving effect.

Owner:王云飞

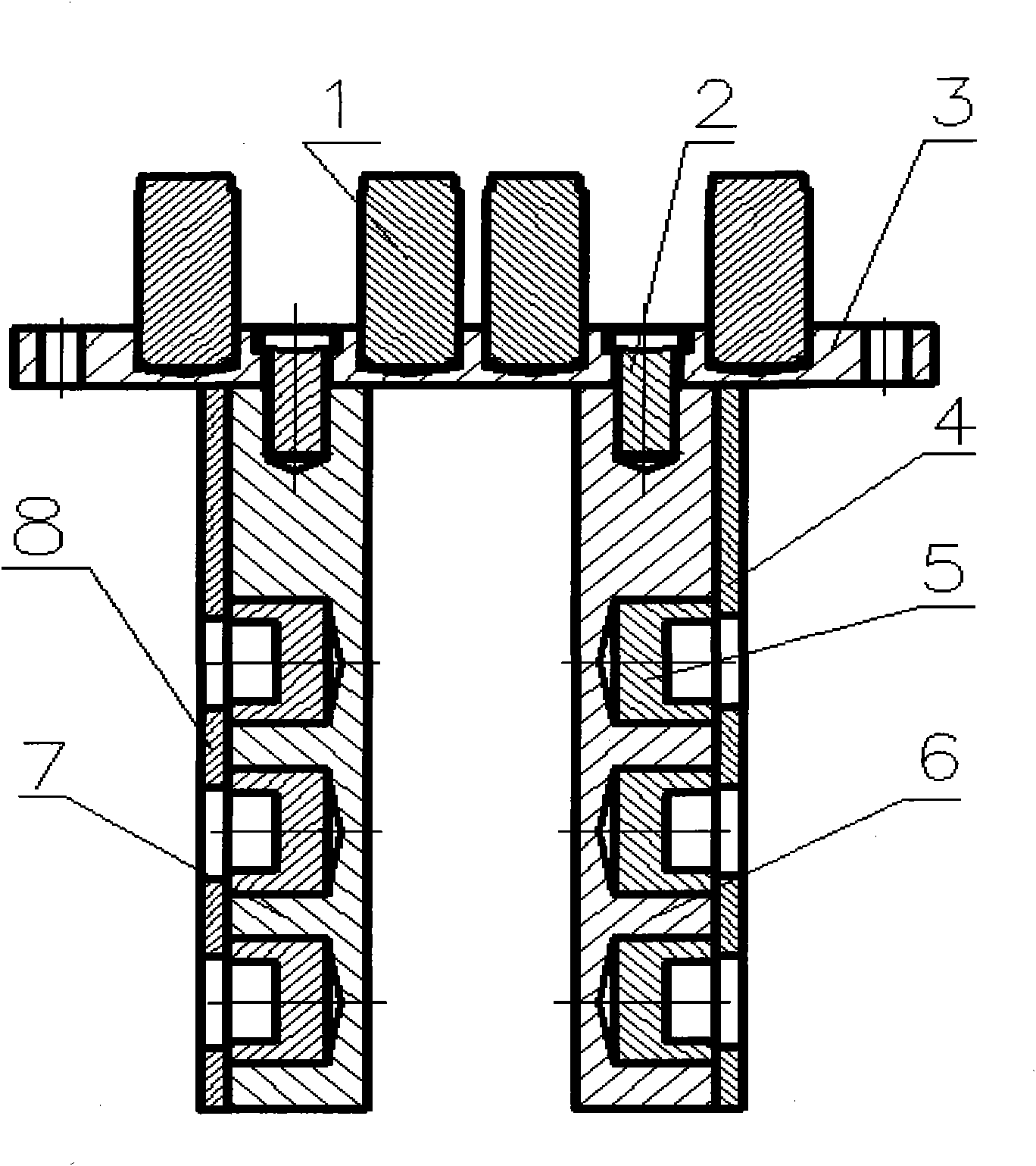

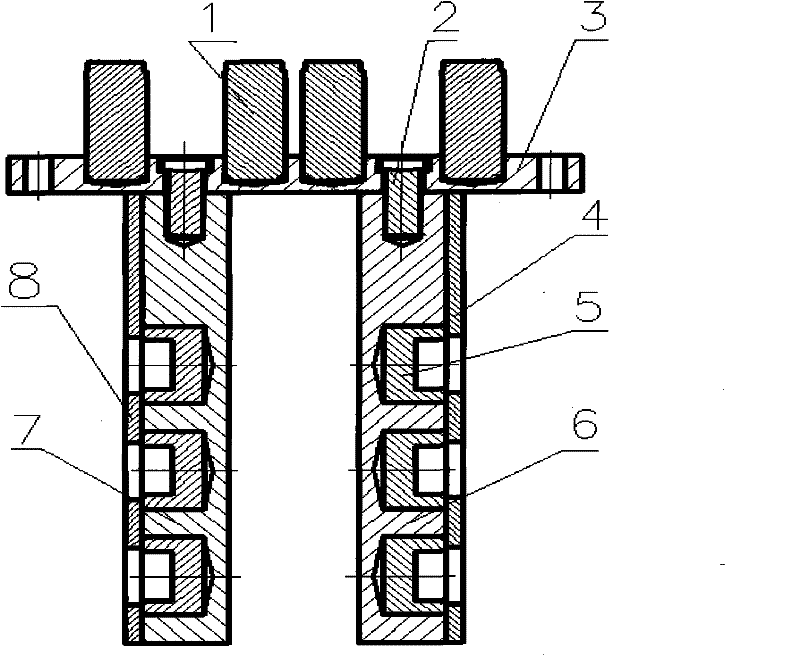

Device and method for implementing local electroplating of parts

The invention discloses a device and a method for implementing local electroplating of parts. The device comprises a copper bottom plate, a copper cover plate, a conductive bar, screws, leads and a metal plate; when a blind hole part is locally electroplated, the non-electroplating part of the part is put into a groove of the copper bottom plate, then the copper cover plate is pressed on the metal plate, and the to-be-electroplated part of the part is naked outside the copper cover plate; when the local surface of a non blind hole part is electroplated, the non-electroplating part of the part is put into the groove of the copper bottom plate, and the to-be-electroplated surface is naked outside. The method comprises the following steps of: processing the copper bottom plate and the copper cover plate, chemically removing oil, coating a layer of vinyl perchloride hydrogen paint on the lower surface of the copper bottom plate and the upper surface of the copper cover plate respectively, airing the paint layers, fixing the part to be electroplated on the copper bottom plate, pressing the copper cover plate as required, then vertically hanging the whole assembly in the center of an electroplating bath, and switching on a power supply. The device has simple structure, is easy to process, accurately positions the plated surface of the part, saves the time and reduces the production cost.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

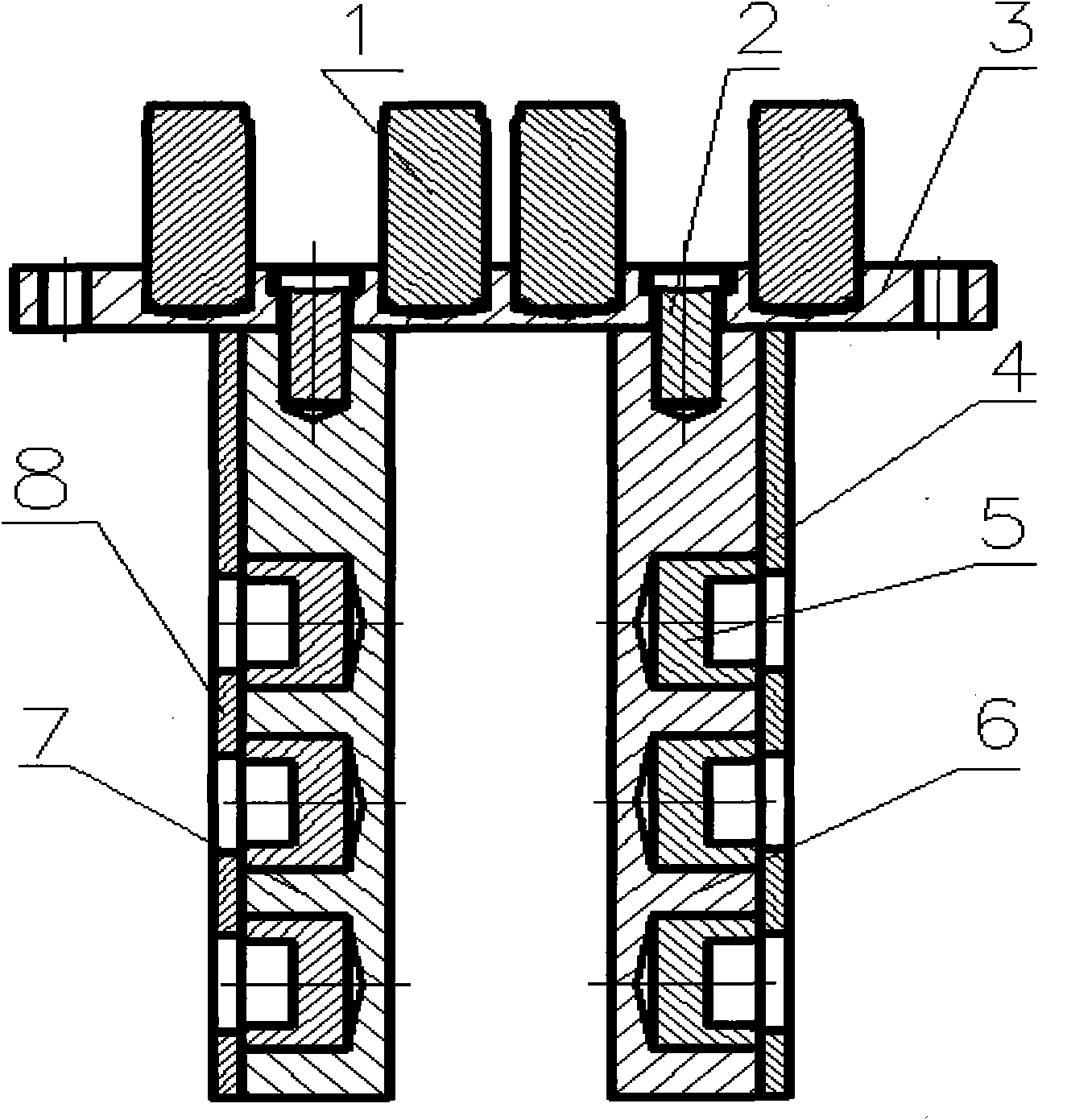

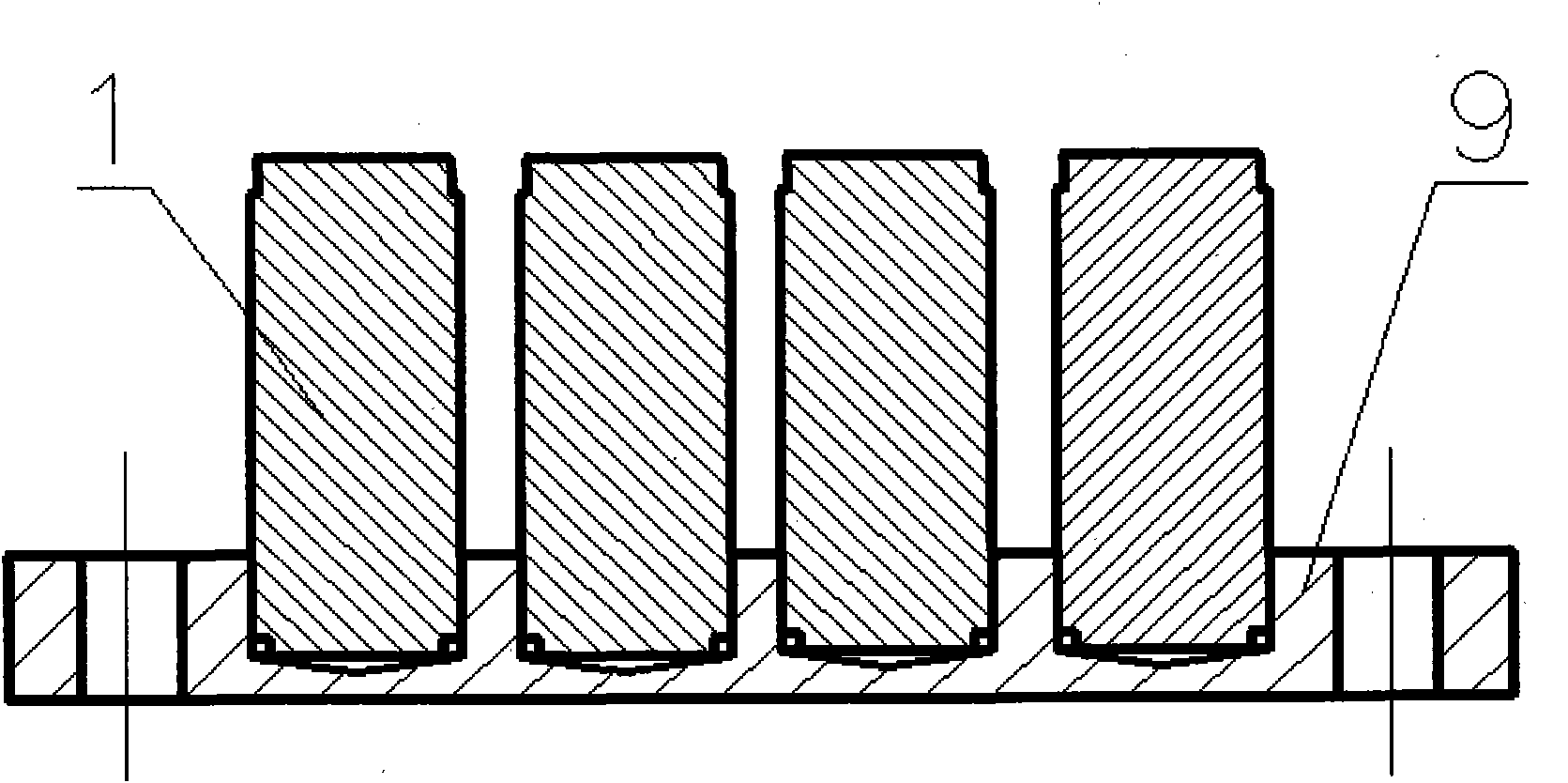

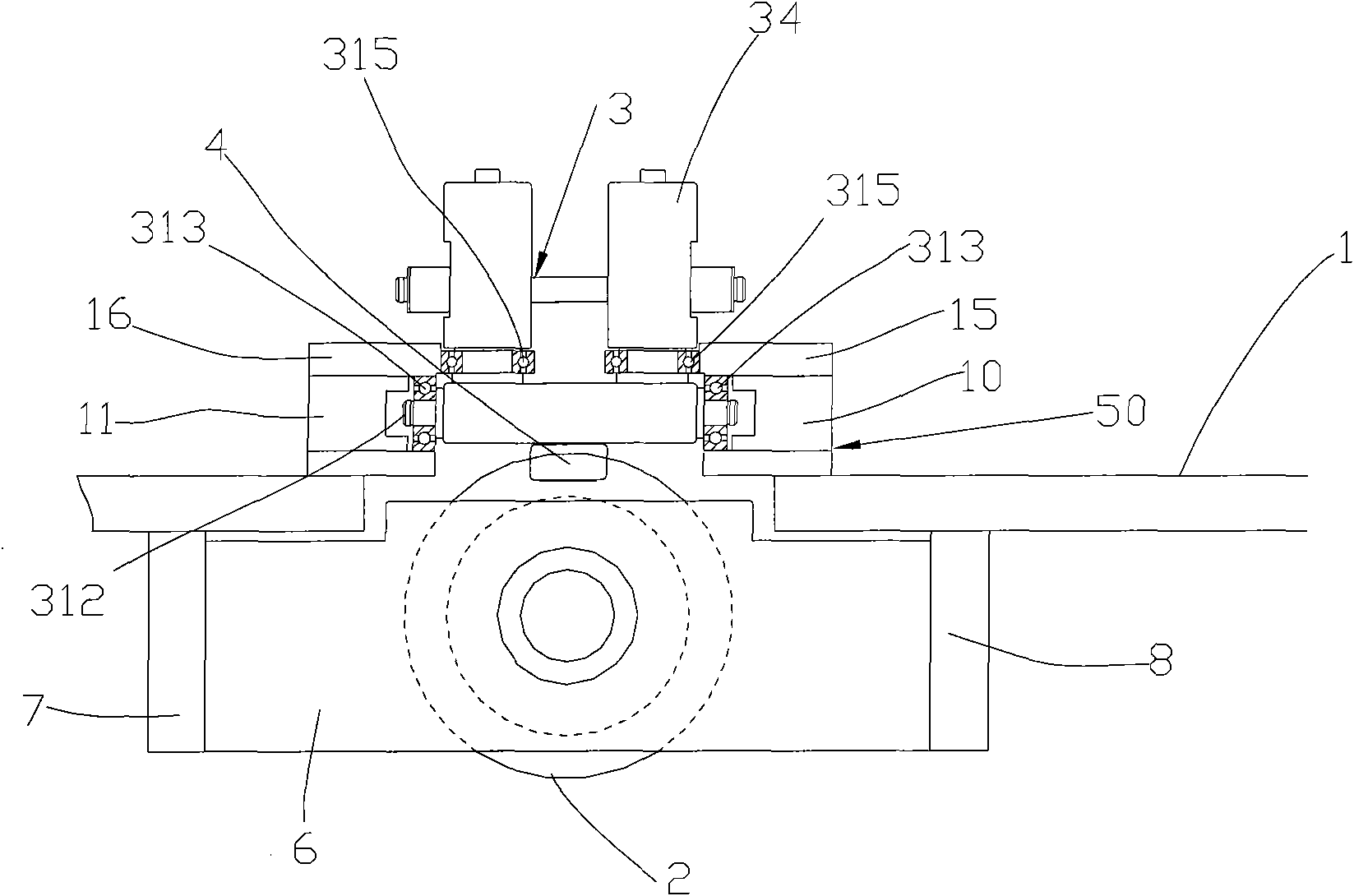

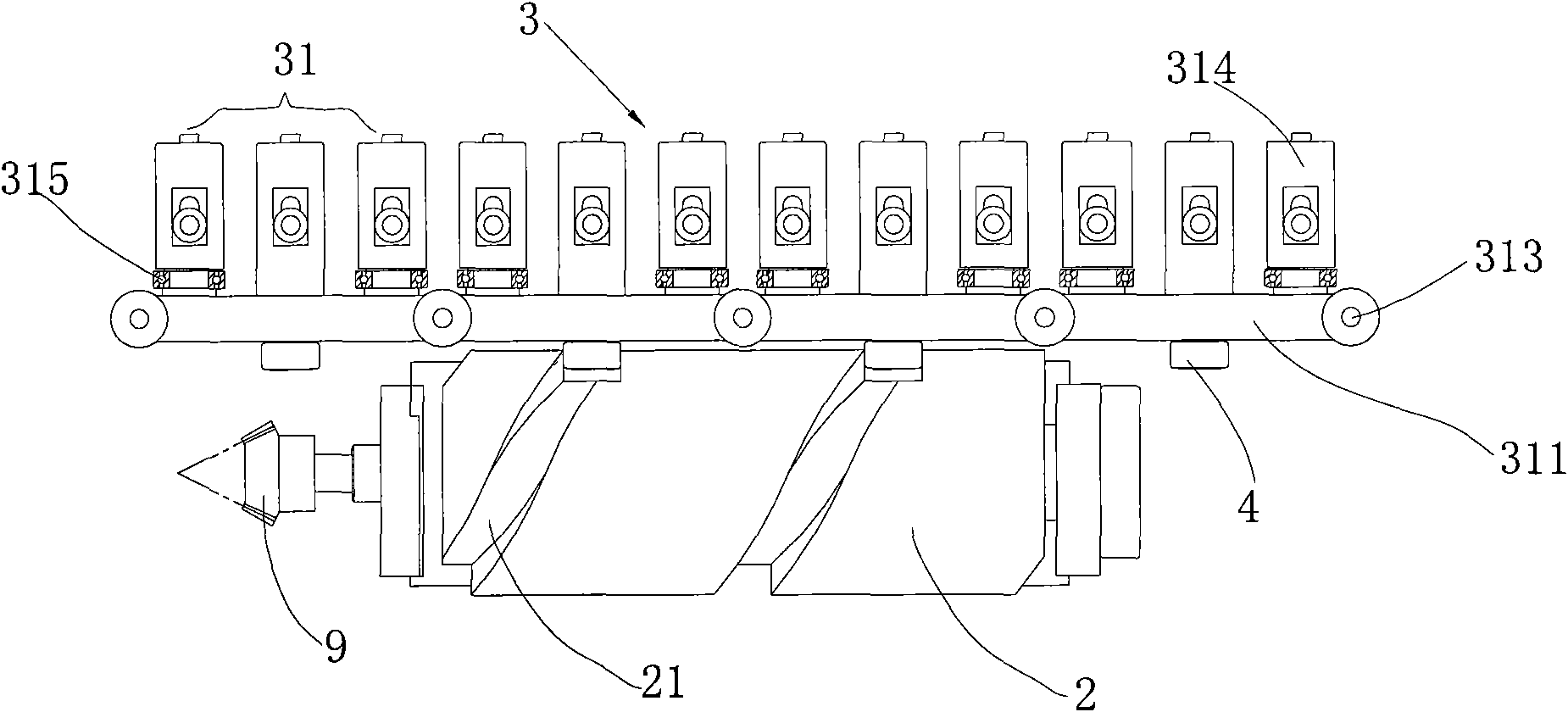

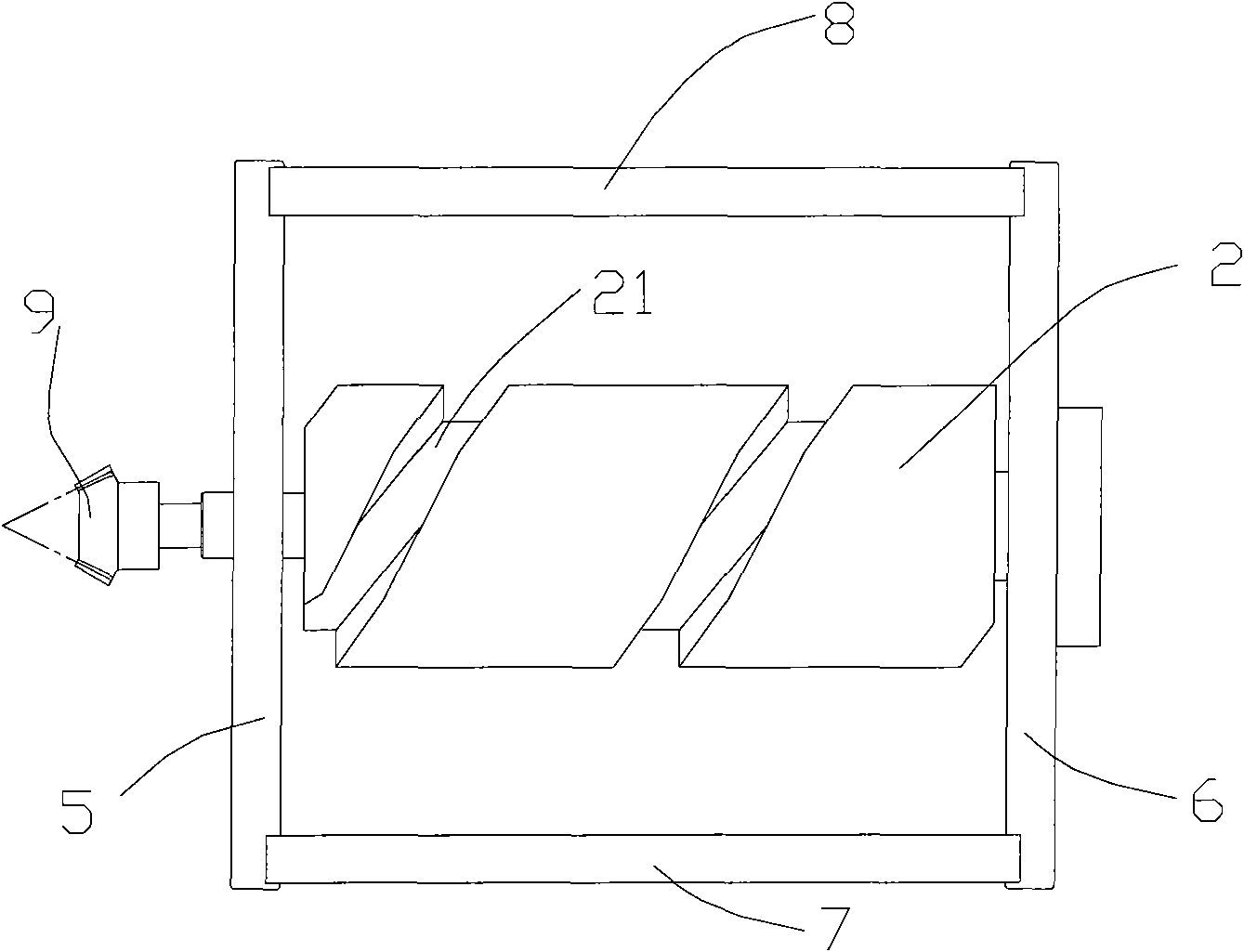

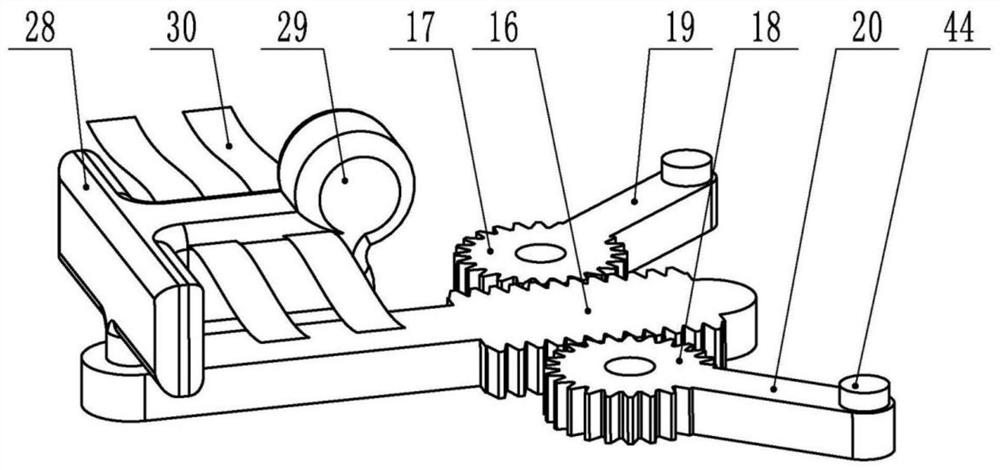

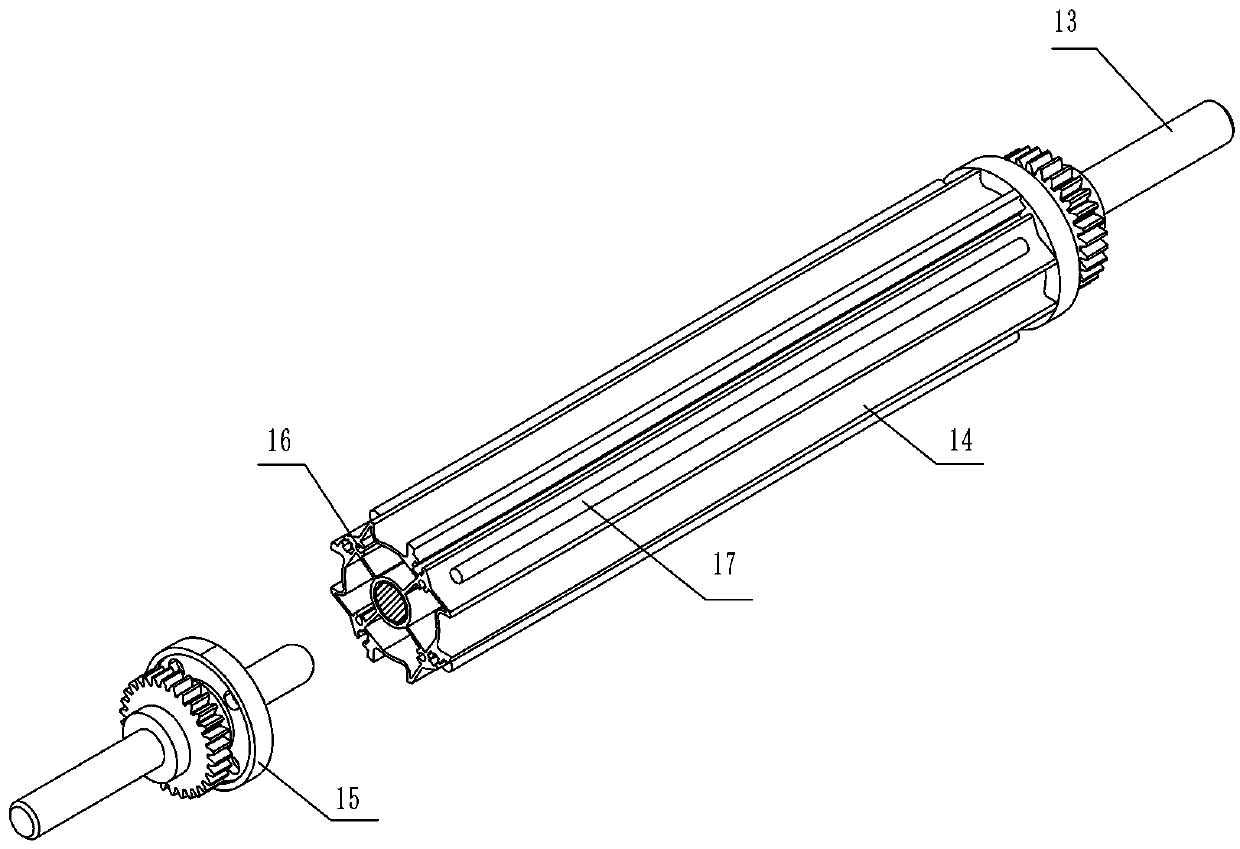

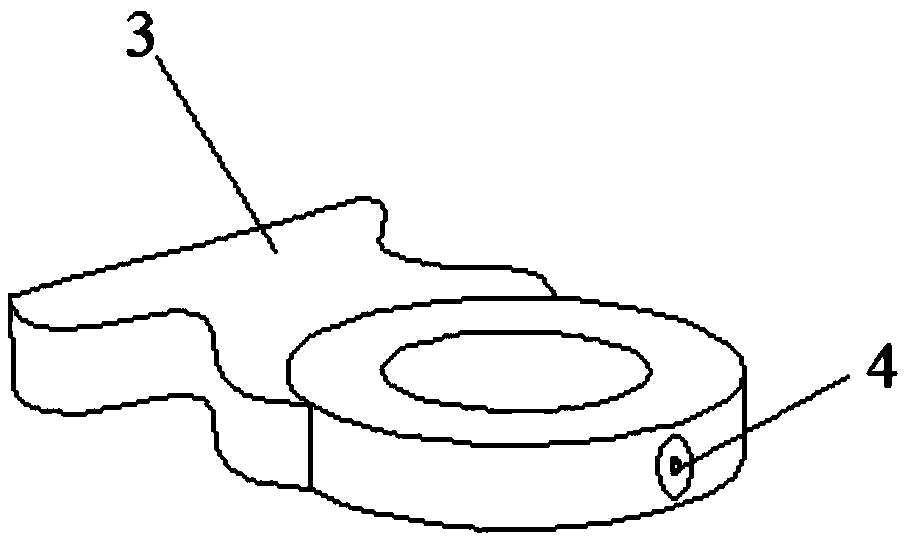

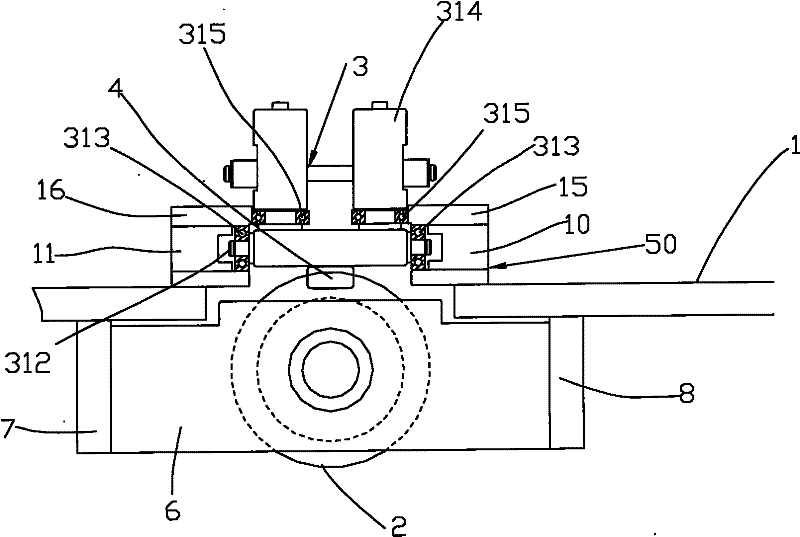

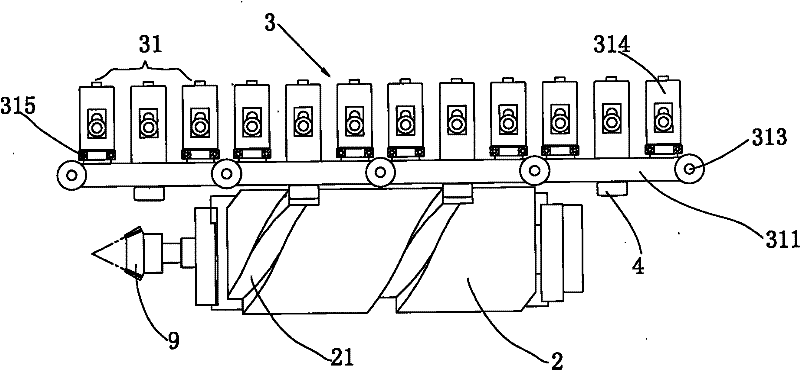

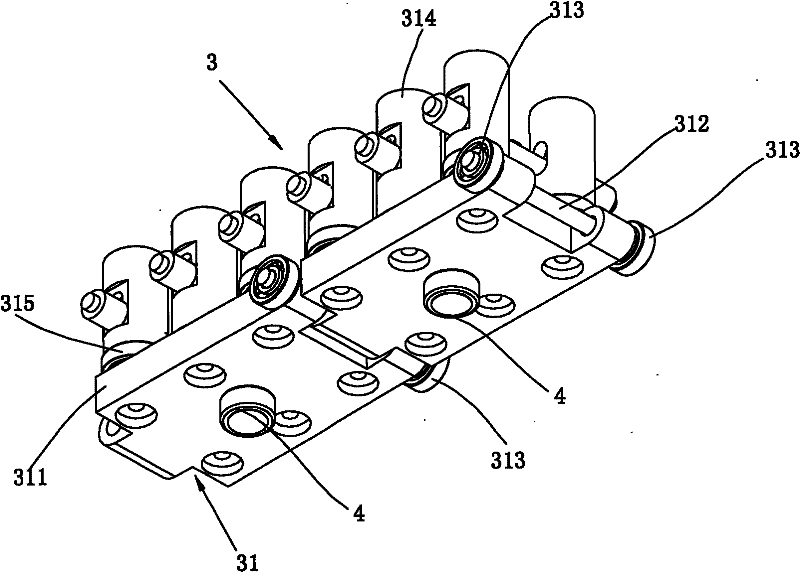

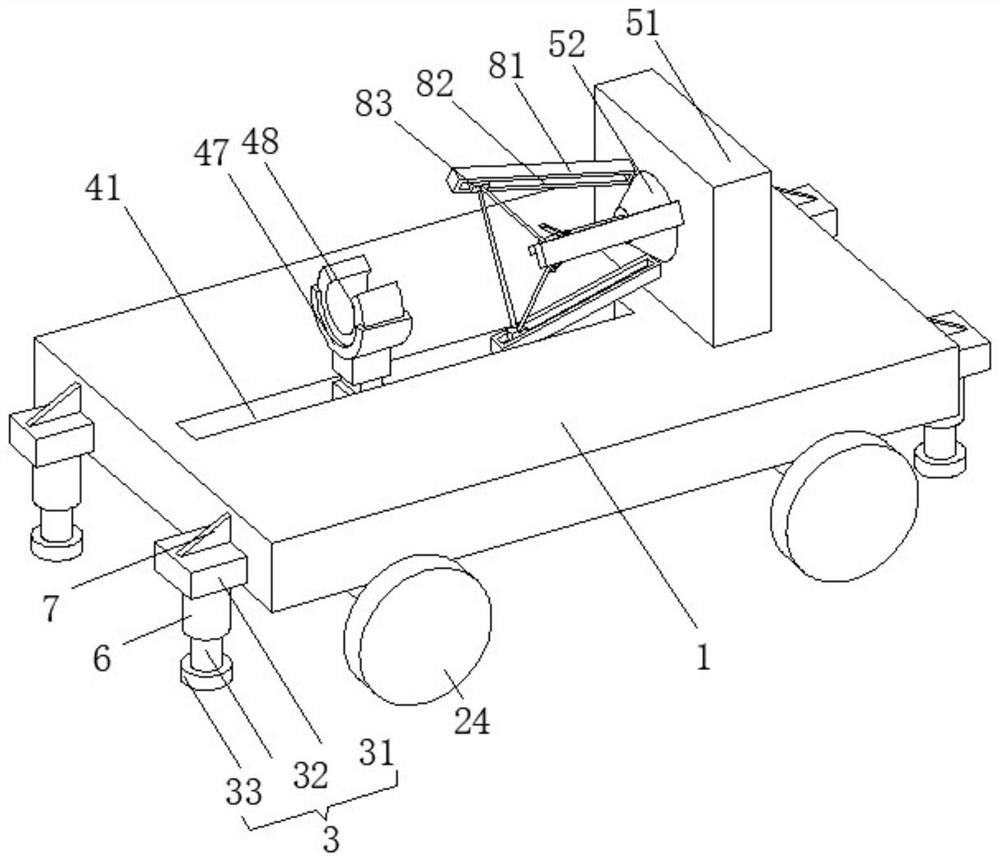

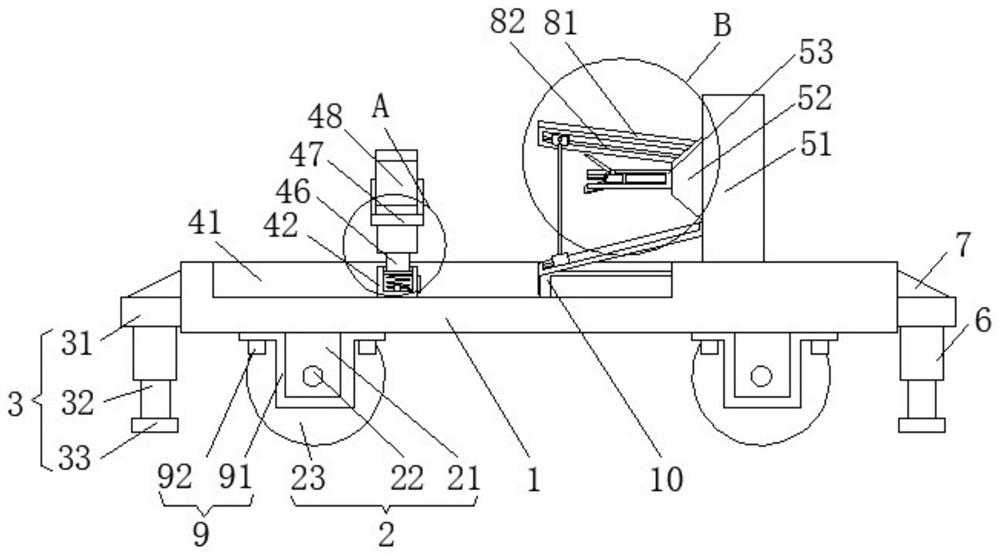

High-speed linear drive mechanism for hectograph

ActiveCN101579962AHigh transmission precisionPrecise positioningRotary pressesHectographLinear drive

The invention discloses a linear drive mechanism for hectograph, comprising a machine frame and a cam arranged under the machine frame, wherein, the front end of the cam is provided with a transmission gear for power transmission, and a cam slot is arranged along the top end and the bottom end of the outer surface of the cam; a moveable cart group is arranged on the machine frame, a sliding track is arranged between the moveable cart group and the machine frame, and a plurality of roller bearings which are kept at intervals and are matched with the cam slot are arranged on the lower bottom surface of the moveable cart group; and when power is transmitted into a transmission gear, the transmission gear drives the cam to rotate, and the cam pushes the roller bearings to run in the sliding track along with the moveable cart group. The mechanism can connect a plurality of cams to simultaneously drive multiple groups of moveable cart group for multiple times of printing, and has the advantages of high transmission accuracy, accurate positioning, high speed, long service life, low noise, simple structure, easy production, low cost, high assembly efficiency, convenient repair, installation and disassembly, safe and reliable installation, reasonable structure, excellent performance, and high convenience and practicability.

Owner:广州互通气动机器工程有限公司

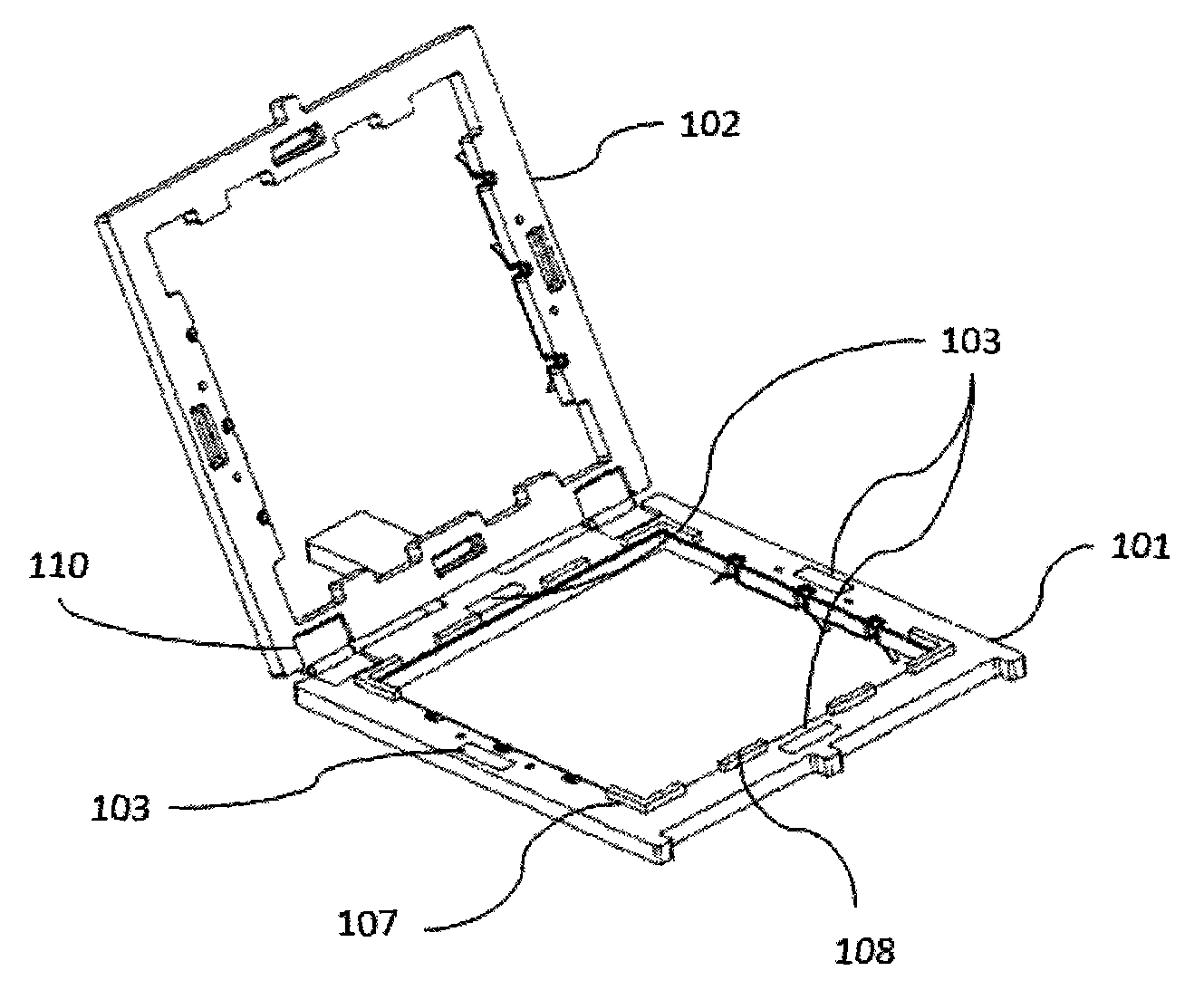

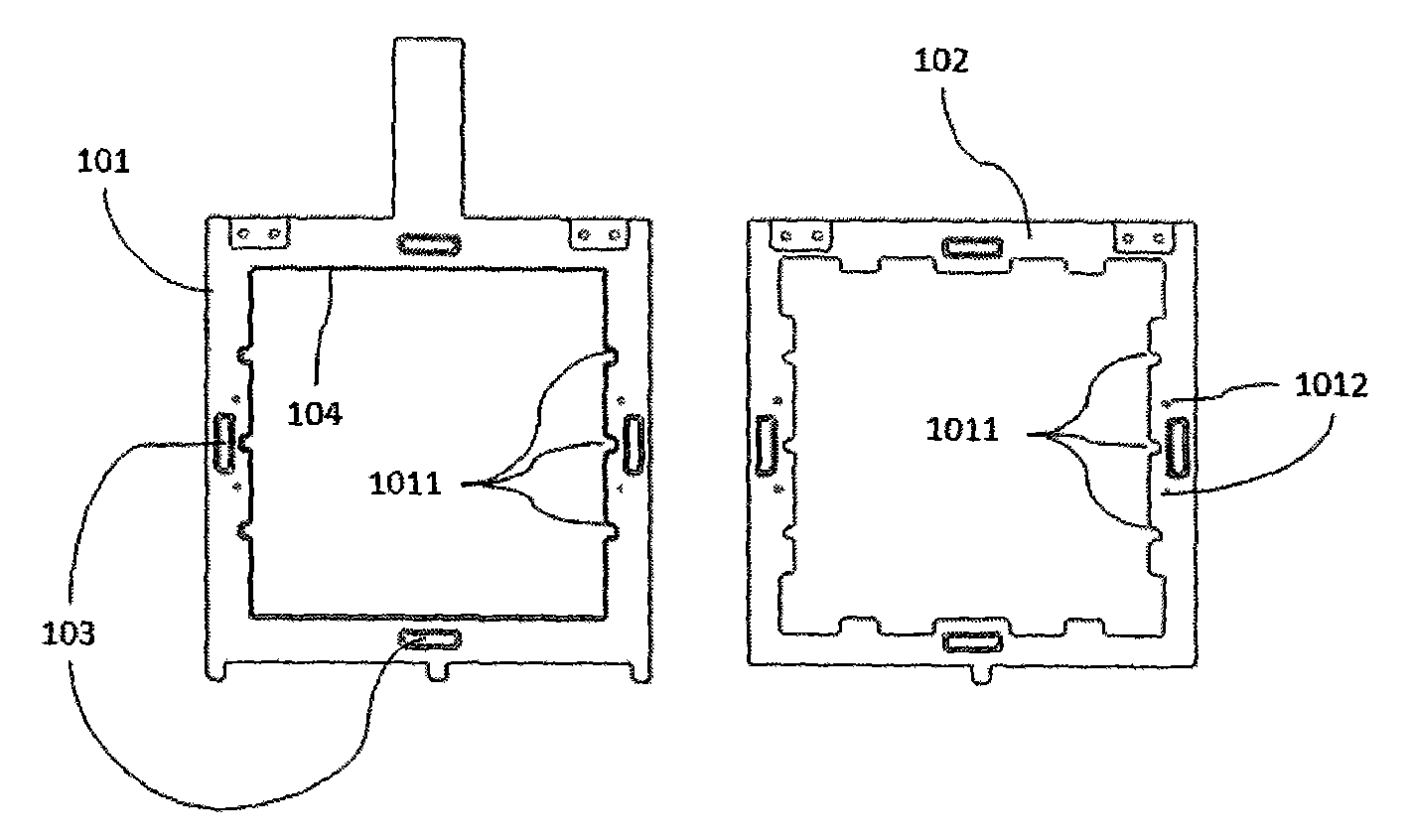

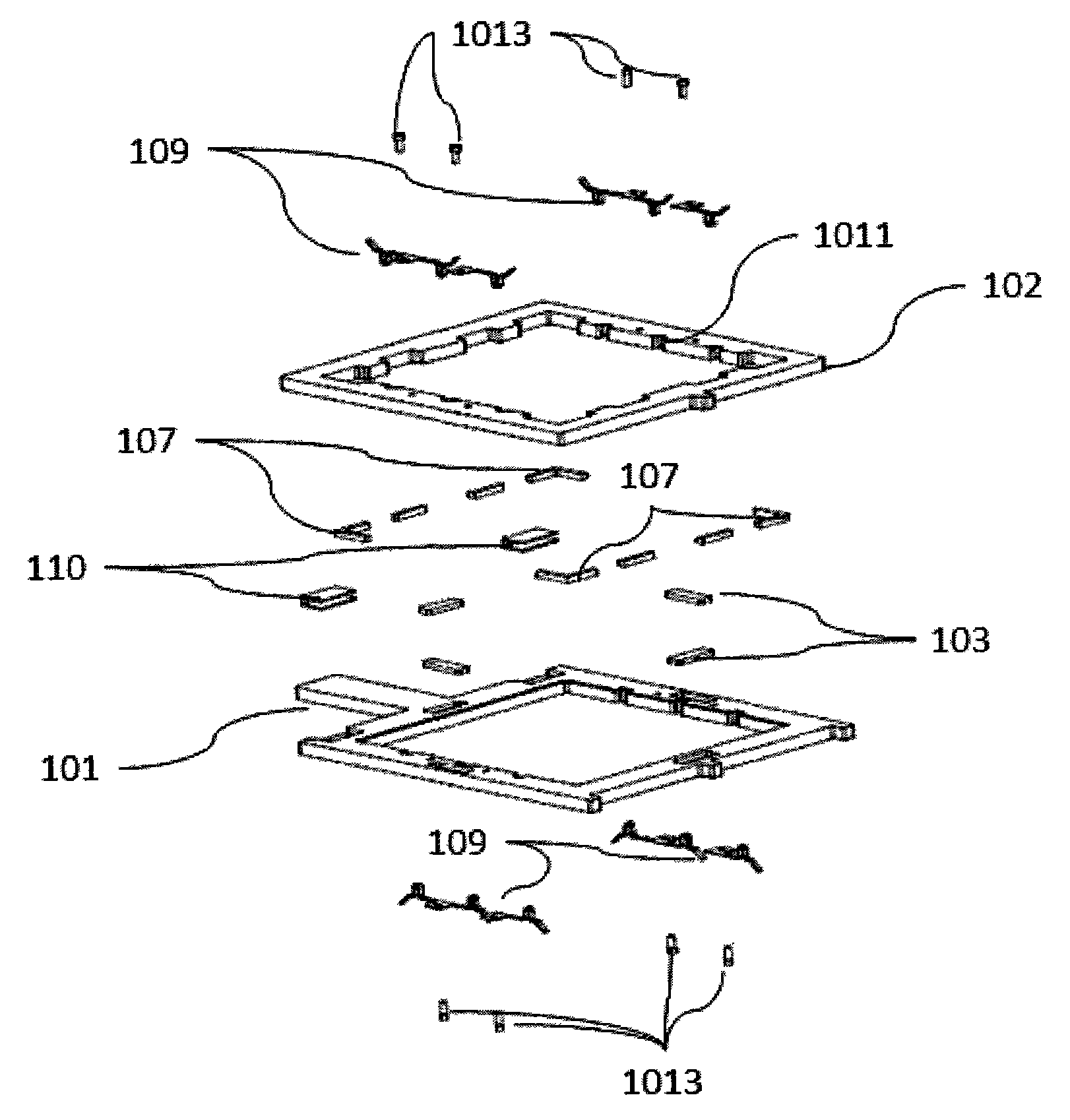

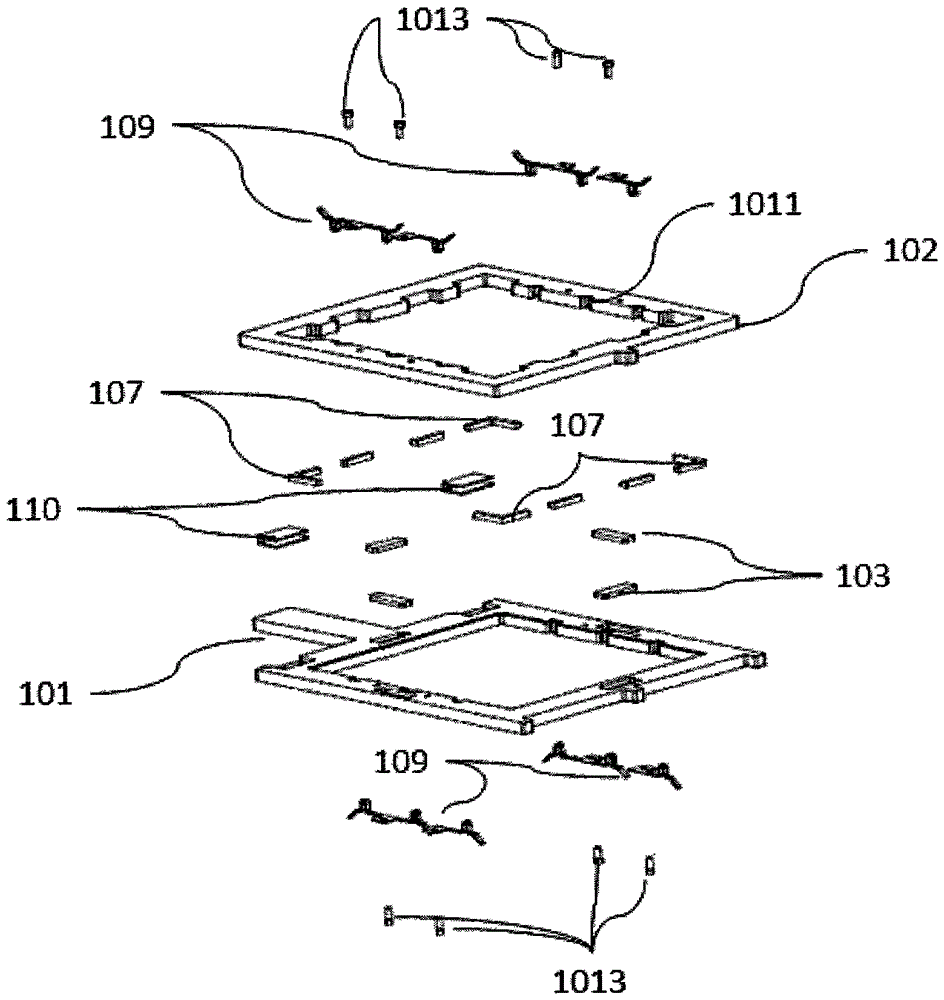

Electroplating clamp of solar cell

ActiveCN104032360AFast positioning and assemblyReduce broken rateElectrolysis componentsSemiconductor devicesMagnetEngineering

The invention provides an electroplating clamp of a solar cell. The electroplating clamp of the solar cell, provided by the invention, comprises a first frame, a second frame and a plurality of magnets, wherein the first frame and the second frame are of a hollow shape, edge parts of the first frame and the second frame are in contact and clamp the cell; and the plurality of magnets are respectively symmetrically fixed on the first frame or second frame, and the first frame and the second frame are jointed by using a magnetic force. The electroplating clamp of the solar cell, provided by the invention, is capable of rapidly locating the cell, quick in assembly, and continuous in production, ensures that the cell is uniformly conducted, and is capable of reducing the breakage rate of the cell.

Owner:平邑经济开发区投资发展有限公司

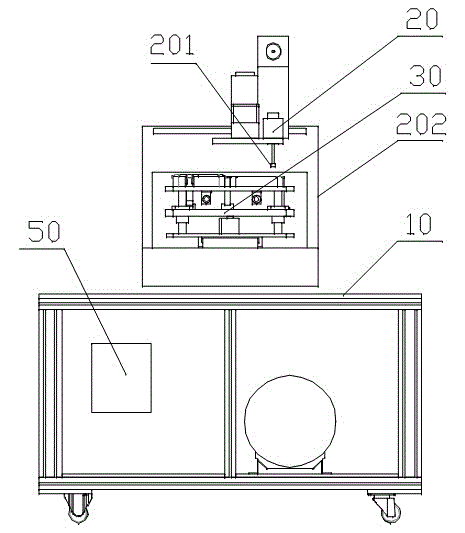

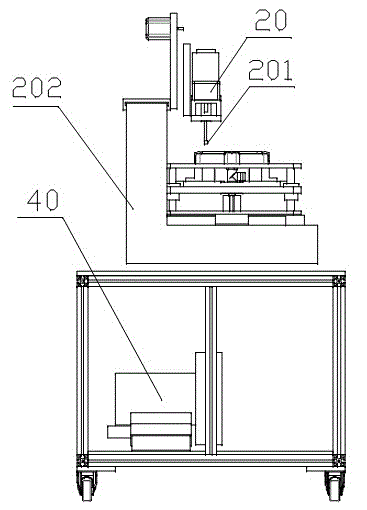

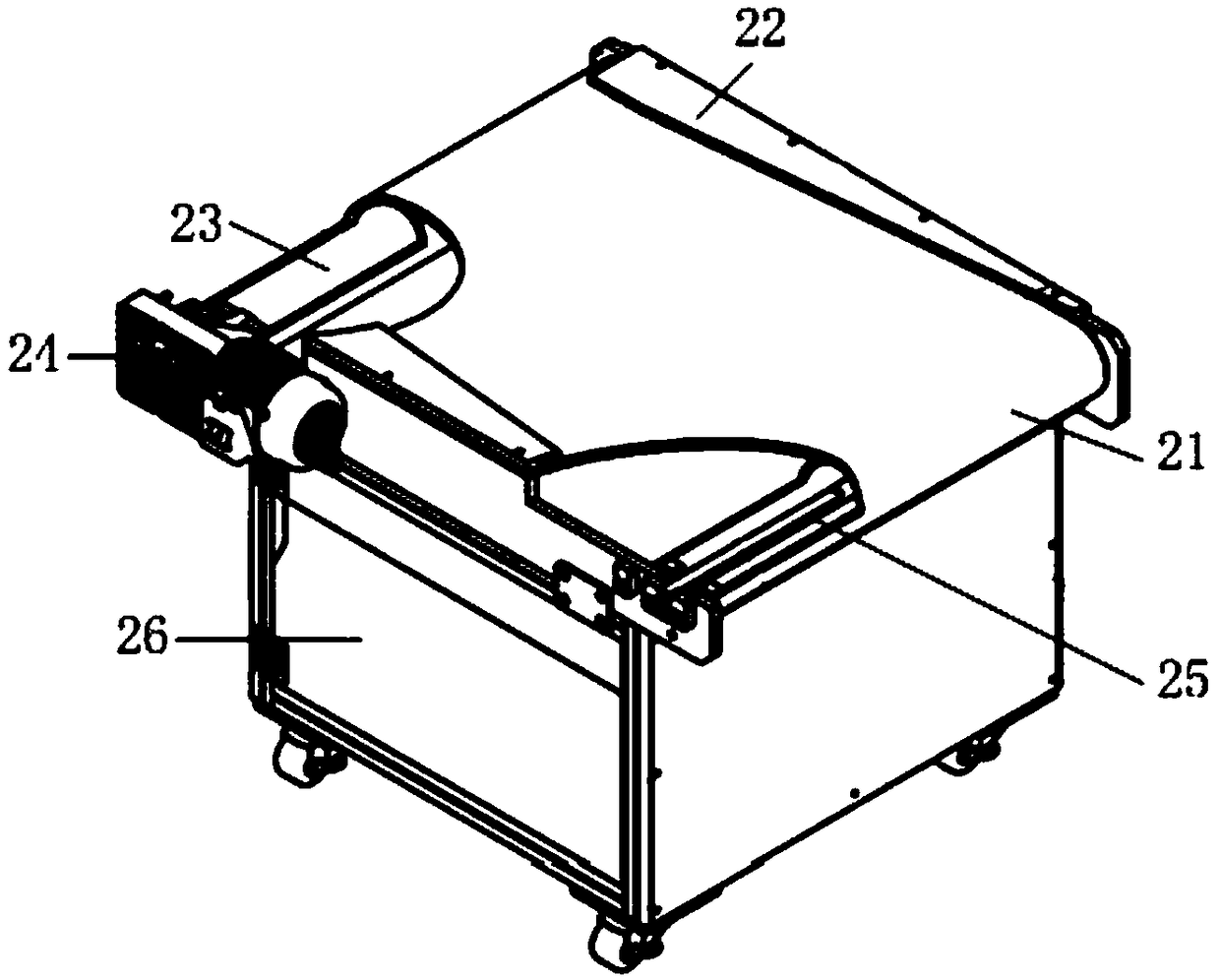

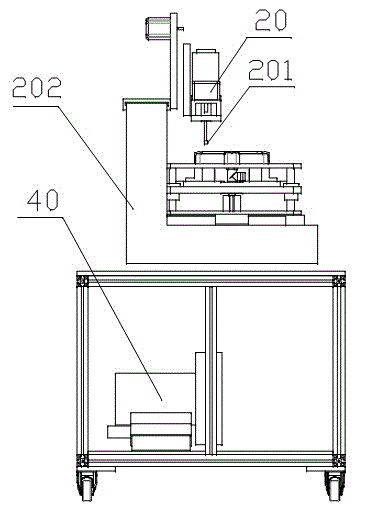

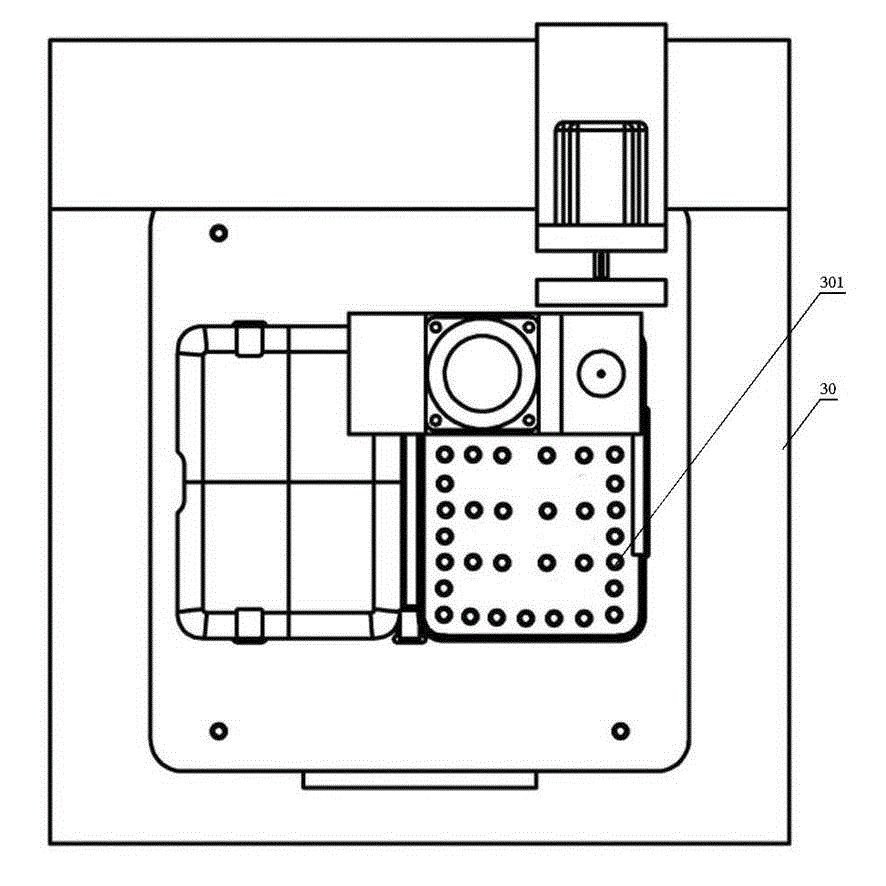

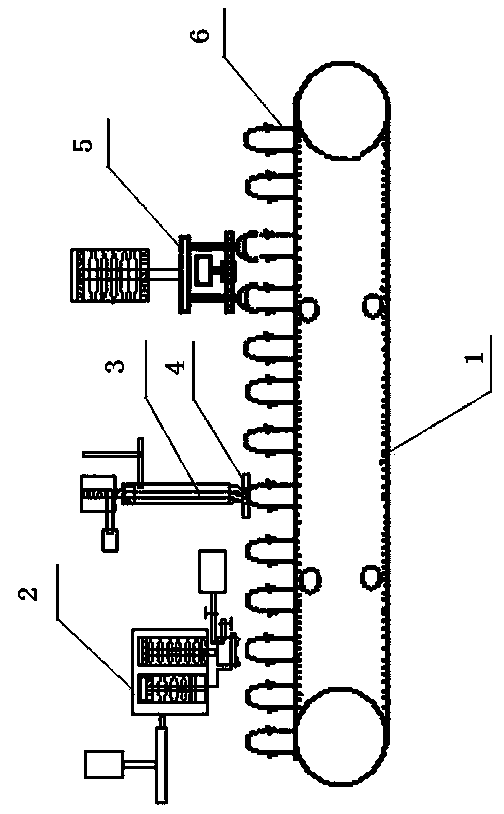

Full-automatic edge painting machine

ActiveCN102716838AImprove product qualityFully automaticLiquid surface applicatorsLeather/skins/hides/pelt chemical treatment apparatusEngineeringFully automatic

The invention provides a full-automatic edge painting machine which comprises a framework, an edge painting head component, a workpiece positioning device, a positioning pump and a control component. The edge painting head component is mounted on the framework and consists of an oil nozzle head and a mechanical shaft, the oil nozzle head moves two-dimensionally by the aid of the mechanical shaft, the workpiece positioning device is used for positioning a painted edge, disposed on the framework and arranged below the edge painting head component, the positioning pump is arranged in the framework and connected with the workpiece positioning device, and the control component is used for controlling an edge painting process of the edge painting head component and controls the workpiece positioning device and the positioning pump to respectively match with the edge painting head component to paint the edge. The edge painting process is fully automatic, the workpiece positioning device and the positioning pump are controlled by the control component on the basis, dislocation in the edge painting process can be prevented, the full-automatic edge painting machine is high in positioning accuracy and can uniformly paint edges of irregular shapes and arc-shaped corners, and the quality of products with painted edges is high.

Owner:东莞宏川智能科技有限公司

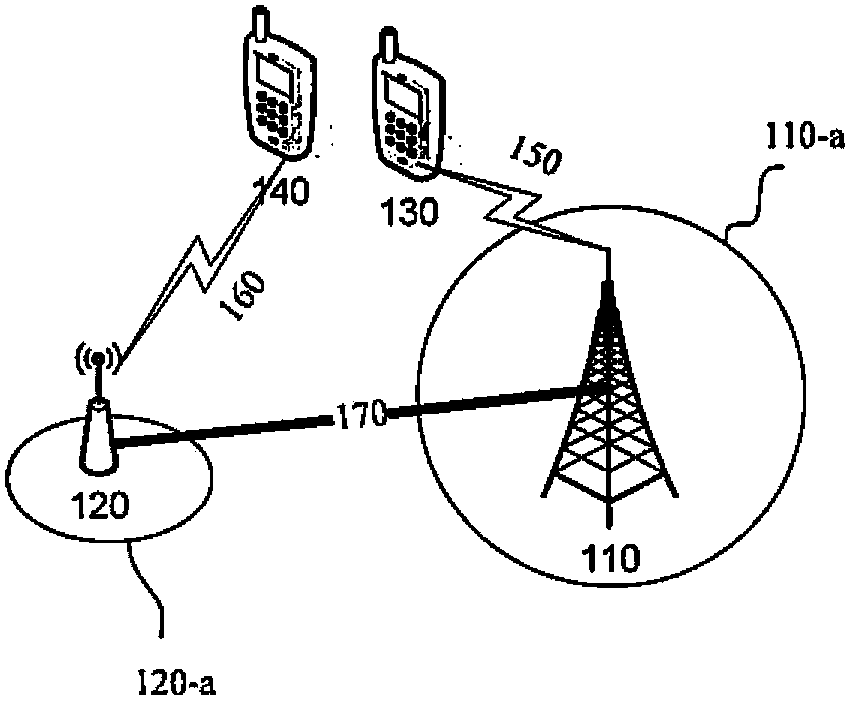

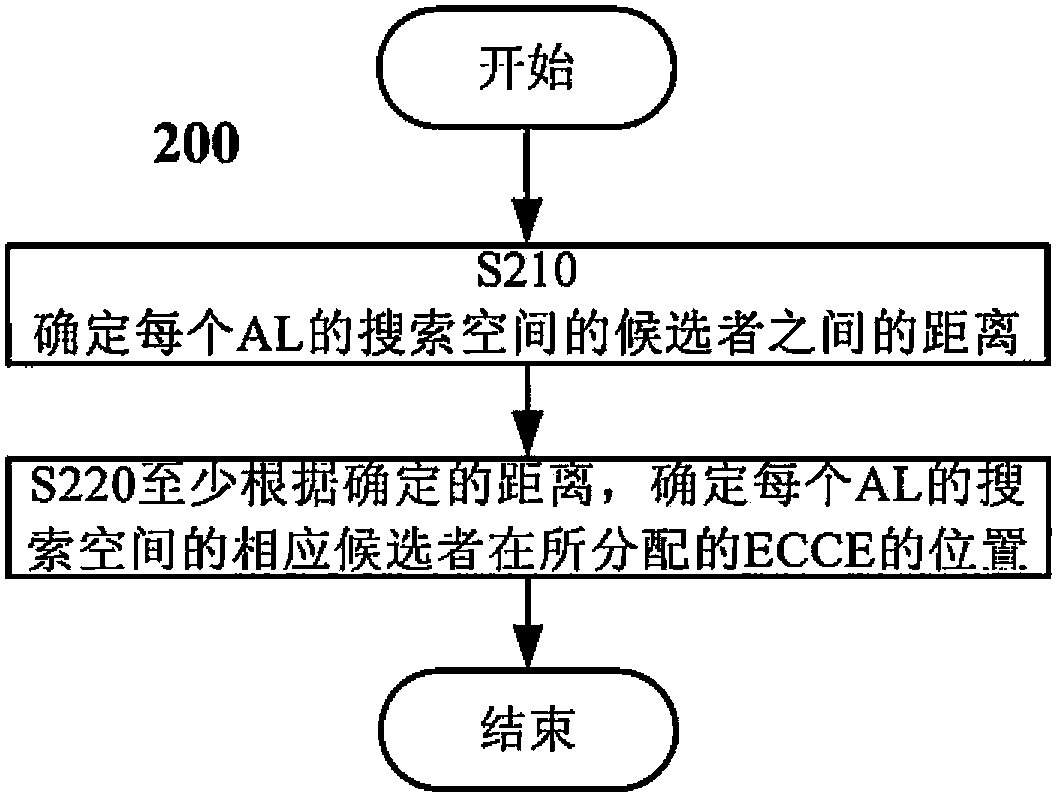

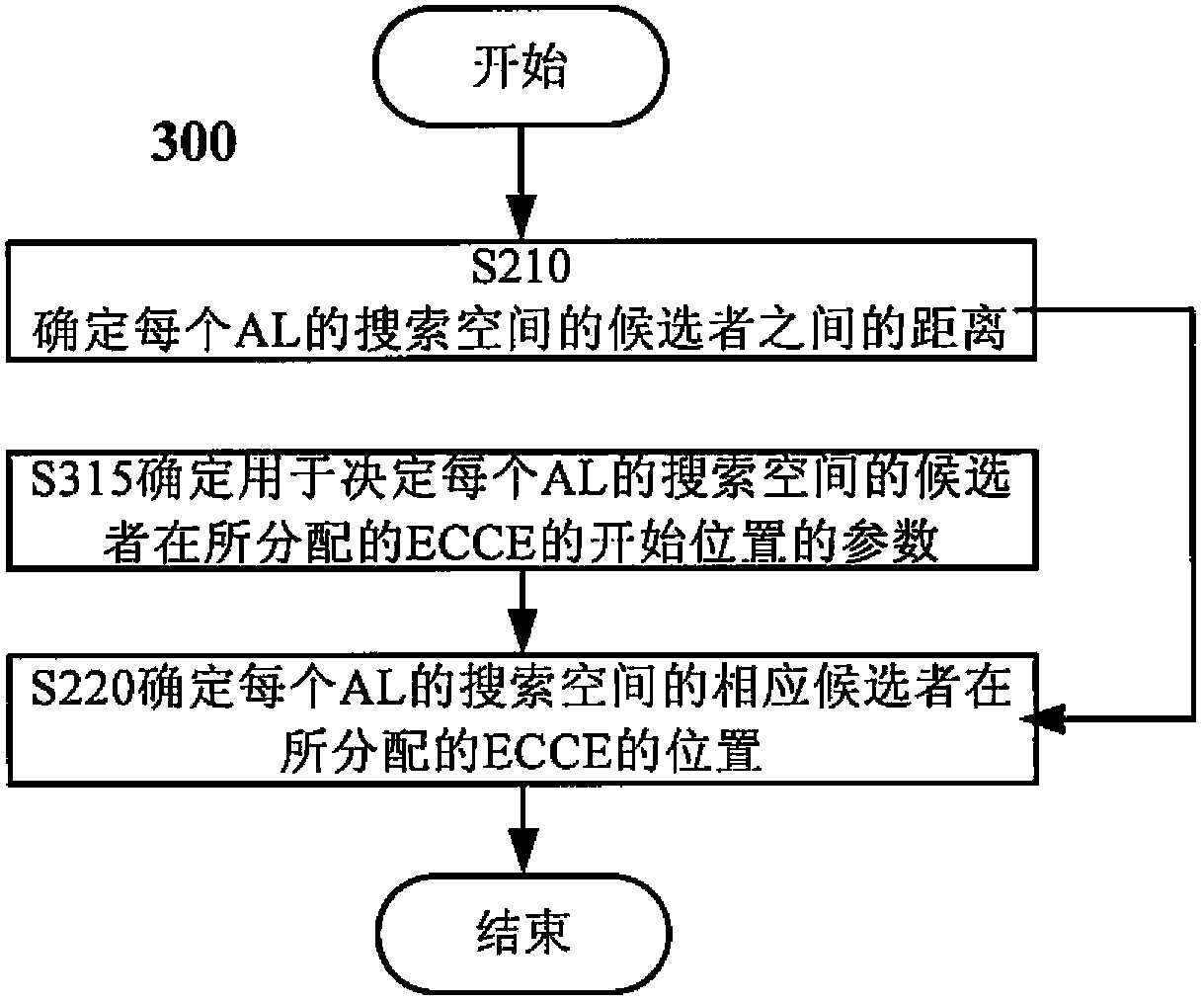

Method and device for determining search space of E-PDCCH (Enhanced Physical Downlink Control Channel) of UE (User Equipment)

InactiveCN103813459APositioning balanceSignal allocationWireless communicationComputer networkControl channel

The invention discloses a method and a device for determining the search space of E-PDCCH (Enhanced Physical Downlink Control Channel) of UE (User Equipment). The method comprises the following steps of: firstly determining the distance among candidates of the search spaces of each aggregation level, and then determining the position of corresponding candidate of the search space of each aggregation level in the allocated ECCE (Enhanced Control Channel Element) at least according to the determined distance. According to the method, the candidates of the search space of each aggregation level can be uniformly positioned on the allocated ECCE.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD +1

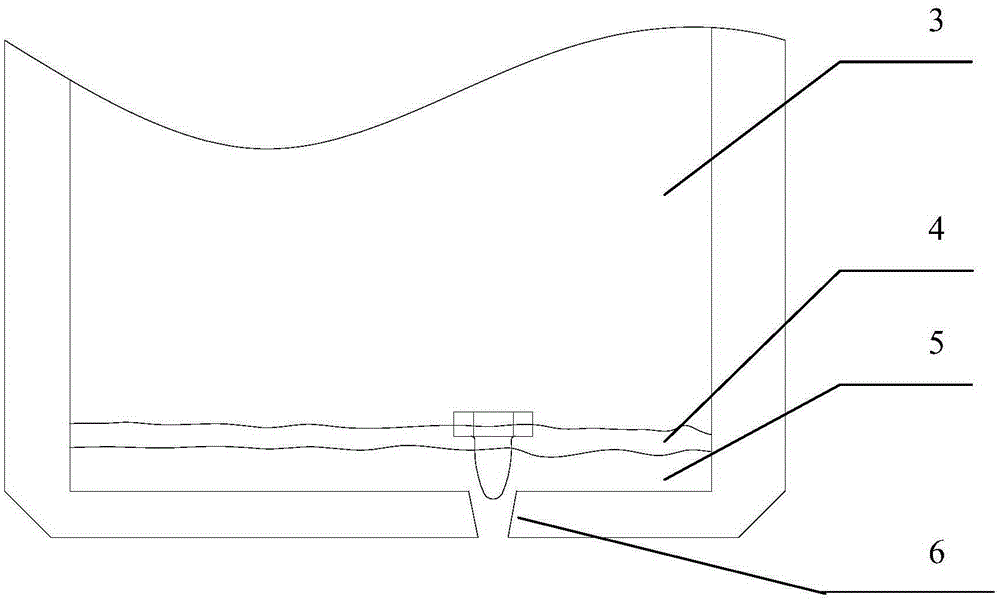

Semi-automatic polarizer stripping device for liquid crystal display panel

ActiveCN104808382AEffective peelingAchieve strippingLamination ancillary operationsLaminationLiquid-crystal displayEngineering

The invention discloses a semi-automatic polarizer stripping device for a liquid crystal display panel. The semi-automatic polarizer stripping device comprises a base, a first conveyor, a stripping platform, a second conveyor, a support plate, a heating plate and a clamping device. According to the semi-automatic polarizer stripping device, as the first conveyor and the second conveyor are arranged, the liquid crystal display panel can be automatically conveyed onto the stripping platform for stripping a polarizer, and the liquid crystal display panel stripped is conveyed out from the stripping platform, so that the processing efficiency is improved, and the labor cost is reduced; as the heating plate is arranged, the polarizer can be heated, and the stripping strength of the polarizer is reduced; a first roll shaft and a second roll shaft are driven by a first motor and a second motor to rotate for realizing the stripping of the polarizer on the liquid crystal display panel, so that the stress on the polarizer is relatively uniform, and the polarizer is unlikely to be fractured. The device can effectively strip the polarizer, and is good in stripping effect, high in work efficiency, low in processing cost and convenient and quick in operation.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

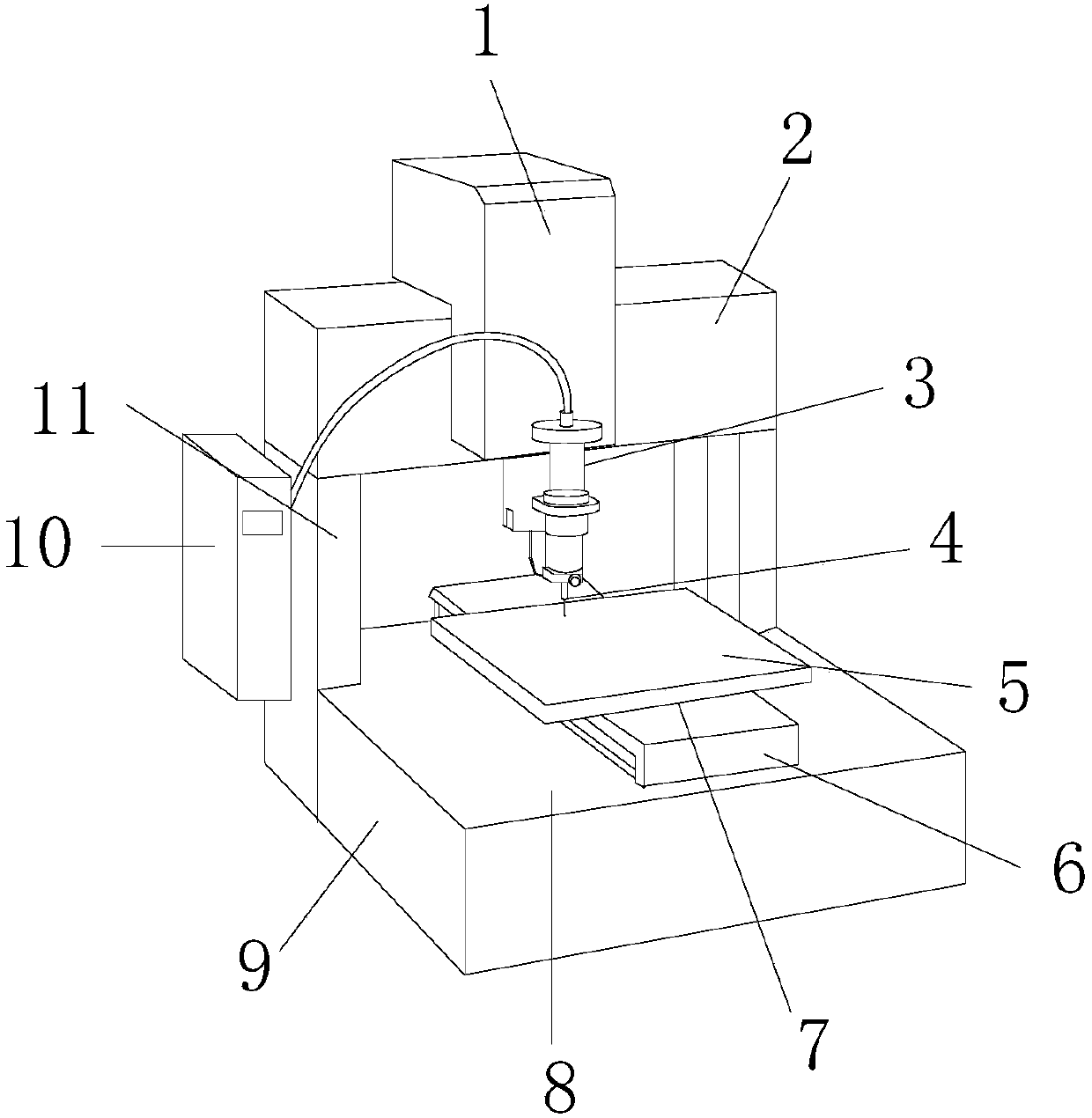

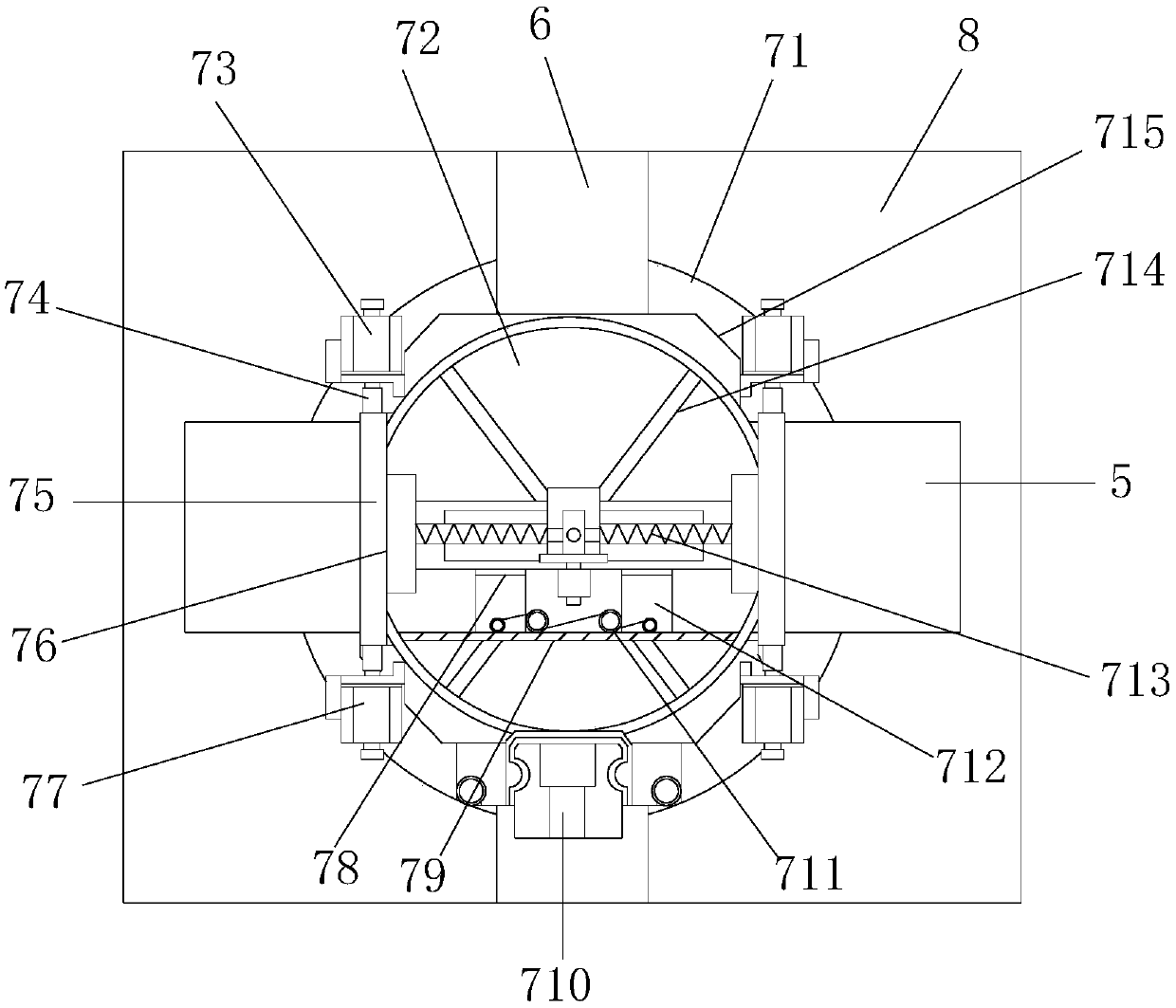

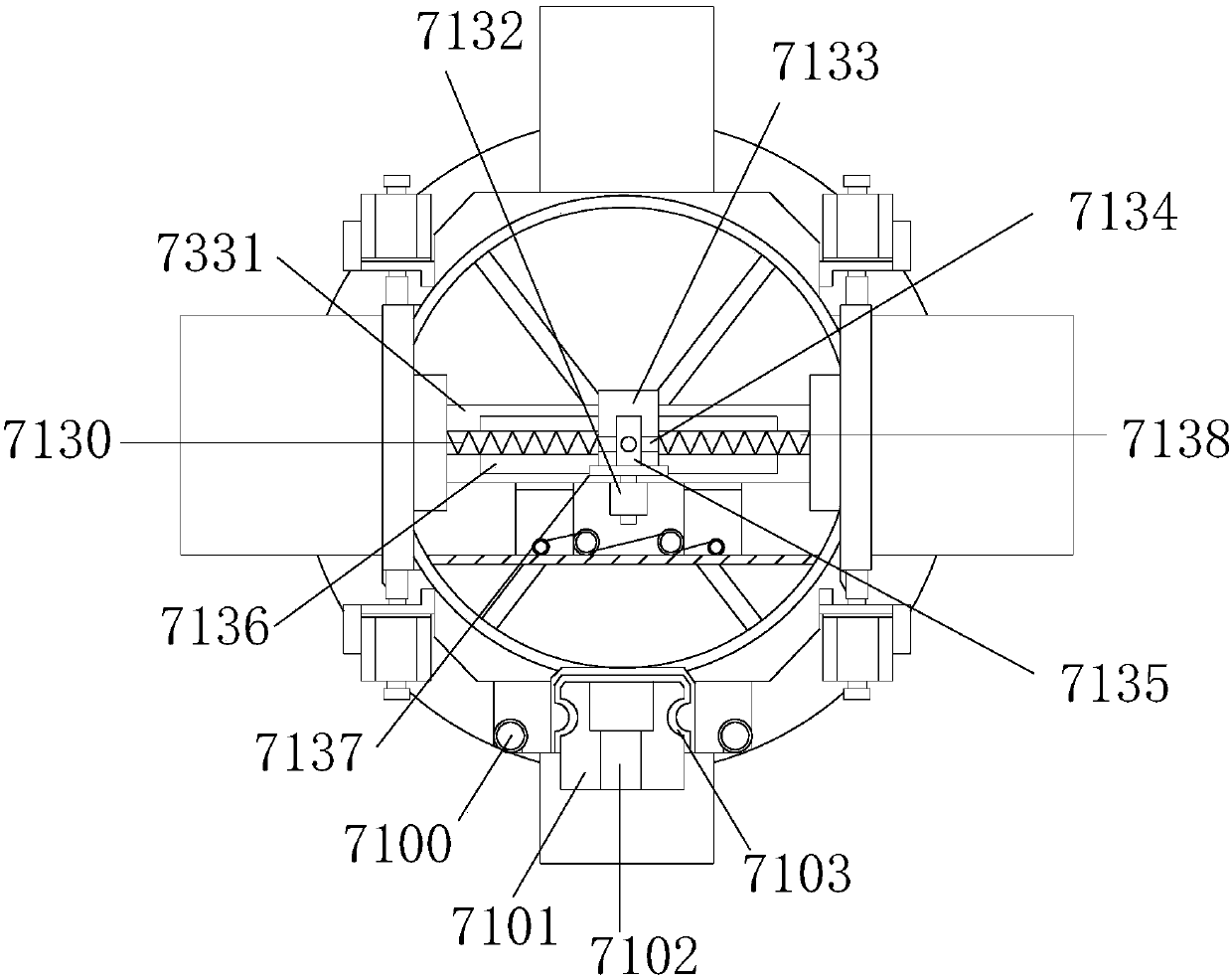

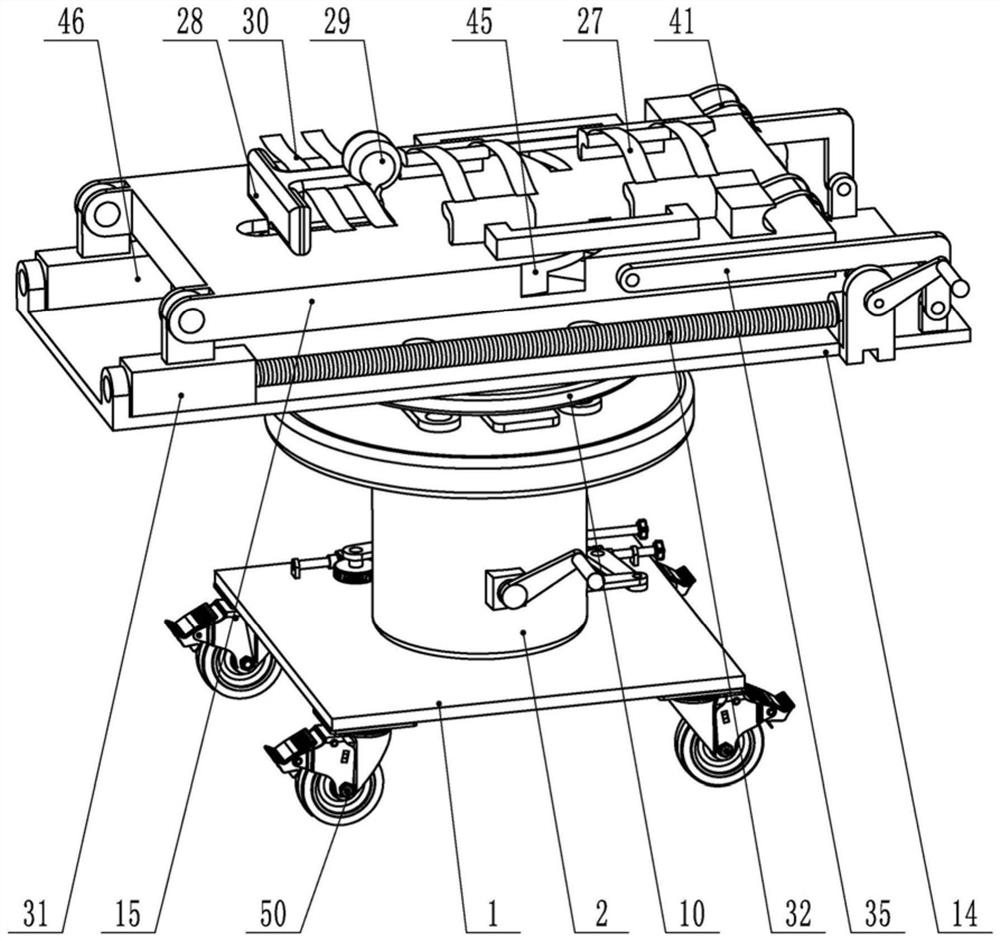

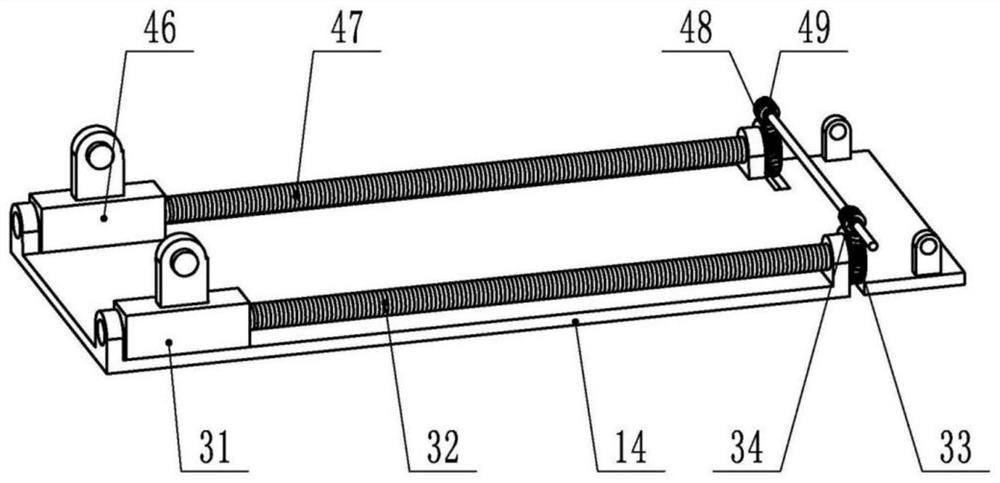

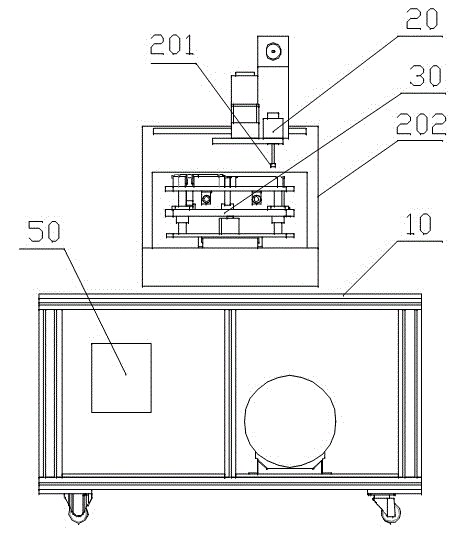

Automatic gluing machine used for automobile luggage rack

InactiveCN107774516APositioning balancePrecise positioningLiquid surface applicatorsCoatingsCircular discElectric machinery

The invention discloses an automatic gluing machine used for an automobile luggage rack. The structure of the automatic gluing machine comprises a gluing stroke moving shaft, a sliding rail rest, a glue storage bottle, a gluing valve head, a workpiece fixing rack, a bottom slide rail, a multi-station rotary positioning mechanism, a working table, a fixed base, a gluing controller and a rack, wherein the fixed base is of a square structure, the top end of the fixed base and the working table are of an integrated structure, and the left and right ends of the rear end of the working table are fixedly connected with and vertical to the rack. According to the invention, a driving motor is used for driving a rotating disk to rotate and driving a workpiece on the workpiece fixing rack to rotate to generate gluing tracks in multiple directions, so as to enlarge the gluing scope, and thus realizing uniform gluing of the product; and under the actions of an offset rod and a magnetic block, the workpiece can be located in a center position more easily and be positioned precisely, and deviation and displacement can be reduced; and an elastic plate can reduce vibration when the workpiece is machined, so as to increase gluing stability, increase the working efficiency and improve the product machining quality.

Owner:金陈敏

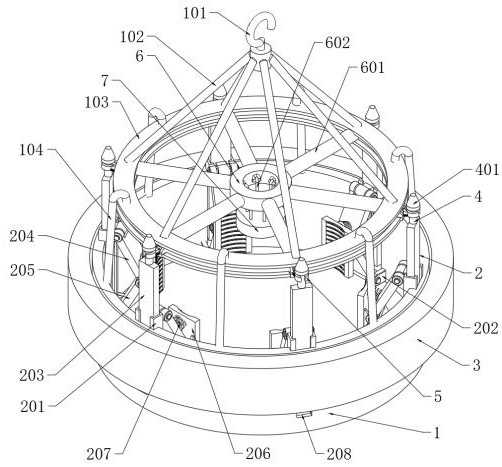

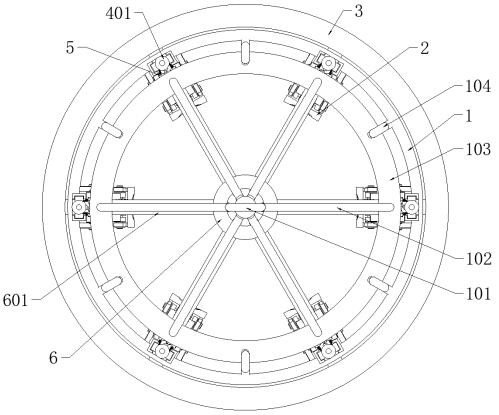

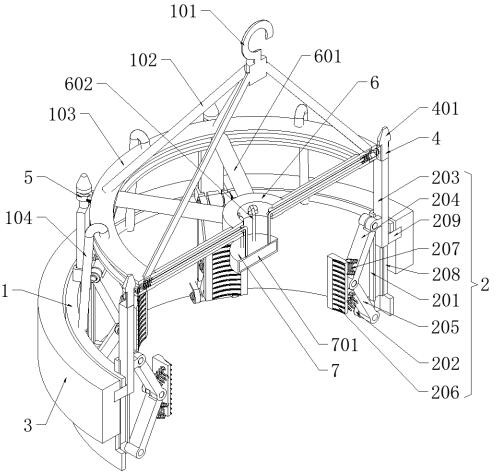

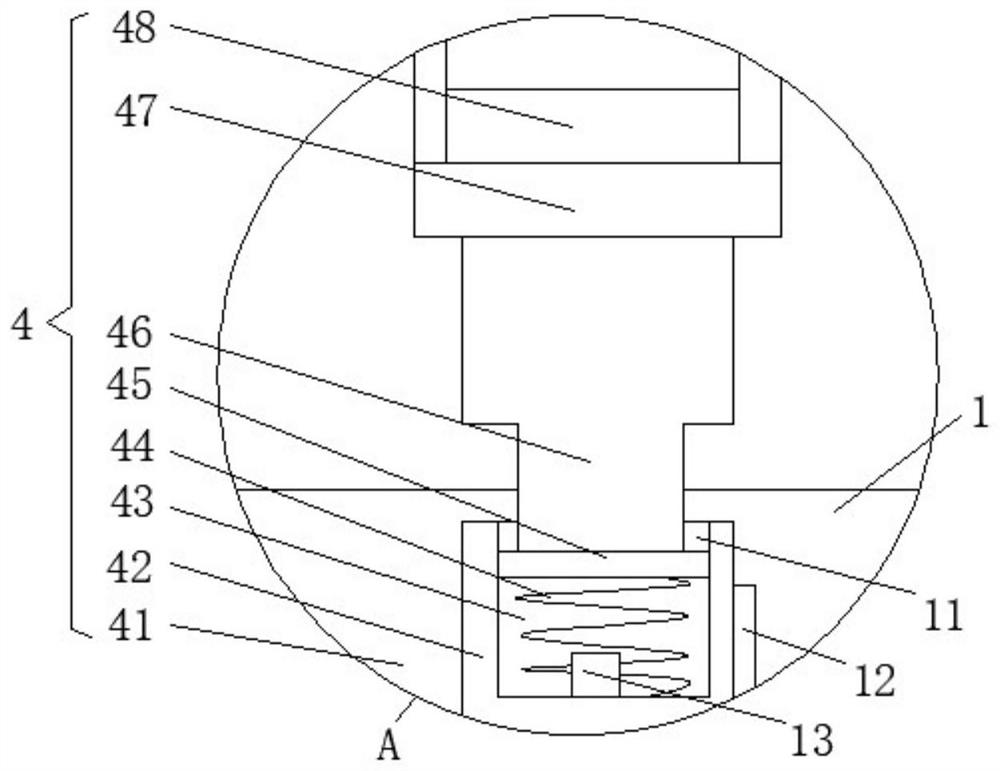

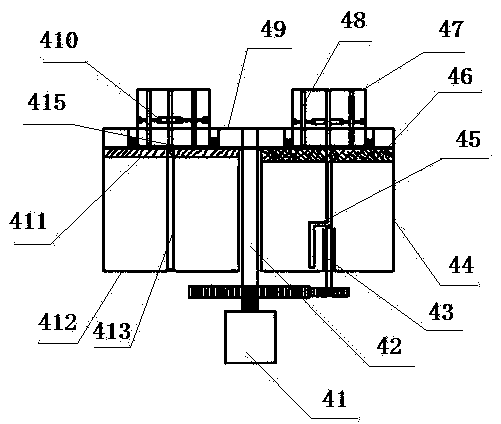

Hoisting device with self-adaptive supplement structure for metal heat treatment

The invention discloses a hoisting device with a self-adaptive supplement structure for metal heat treatment, and belongs to the field of metal heat treatment. According to the hoisting device with the self-adaptive supplement structure for metal heat treatment, a clamping part is installed on the inner wall of an annular frame to clamp the outer wall of a cylindrical iron ingot, so that the covered area during iron ingot fixing is effectively reduced; iron blocks are hoisted through the device instead of being directly stacked for heat treatment, so that the bottom of the iron ingot is effectively prevented from being covered by the contact surface when the iron ingot is placed, and the heating uniformity of the iron ingot during heat treatment is further guaranteed; through fixed connection of a clump weight and a sliding bar, power is provided for movement of the sliding bar by means of the gravity of the clump weight, so that a first clamping arm and a second clamping arm can deform in a self-adaptive manner to keep firm clamping of the iron ingot, the situation that hoisting and clamping of the iron ingot are loosened due to expansion and contraction of the iron ingot is avoided, and the using stability and safety of the device are effectively guaranteed.

Owner:南通江勤美金属制品有限公司

Device and method for rapid calibration of sensitivity of pyranometer

ActiveCN105547468AAchieve regulationPositioning balancePhotometry using reference valuePhotometry for measuring solar lightLaserCamera obscura

The present invention provides a device for rapid calibration of the sensitivity of a pyranometer. The device comprises a light source camera obscura, a taenidium rod, a liftable pedestal, a stepping motor, a test board camera obscura, a laser positioning device, a main control device and a rotating motor. The light source camera obscura and the camera obscura are rapidly aligned and connected to form a large camera obscura which communicates up and down, and a movable hood is arranged in the light source camera obscura and the camera obscura; the taenidium rod penetrates and is arranged in the light source camera obscura, one end of the taenidium rod is connected with a light source, and the other end of the taenidium rod is connected with a stepping motor; the liftable pedestal is arranged in the test board camera obscura, a rotating disk is arranged on the liftable pedestal and is provided with a plurality of screws, the laser positioning device is arranged at the top surface of the liftable pedestal, and the liftable pedestal is provided with a voltage signal acquisition numerical table; and the main control device is arranged at the outer of the test board camera obscura. The device and method for rapid calibration of sensitivity of a pyranometer are able to automatically regulate the irradiance of a light source and rapidly find out an area with uniform irradiance to develop the calibration work of the sensitivity of a pyranometer.

Owner:FUJIAN METROLOGY INST +1

Solar Cell Electroplating Fixture

ActiveCN104032360BRapid positioningQuick assemblyElectrolysis componentsSemiconductor devicesBreakage rateEngineering

Owner:平邑经济开发区投资发展有限公司

Radar tool and radar assembly equipment

PendingCN108581430AGuarantee processing qualitySimple structureMetal working apparatusRadarEngineering

The invention provides a radar tool and radar assembly equipment, and belongs to the technical field of radar processing. The radar tool comprises a first support base, a second support base and an elastic connecting piece; the second support base is connected with the first support base through the elastic connecting piece; the first support base is provided with a first mounting area for bearinga power supply plate; the first mounting plate is provided with at least one projection positioning part for limiting the power supply plate; the second support base is used for bearing a radar shell; the second support base is provided with a groove-shaped second mounting area penetrating through the thickness direction; an insertion piece of the shell is positioned in the second mounting area;and the second support base can drive the shell to move to the power supply plate on the first support base, so that an insertion needle of the insertion piece of the shell can be inserted in an insertion hole of the power supply plate. The radar tool has the characteristics of simple structure, balanced pressure, precise positioning and convenience to assemble; and the radar assembly equipment adopts the radar tool.

Owner:BEIJING AUTOROAD TECH CO LTD

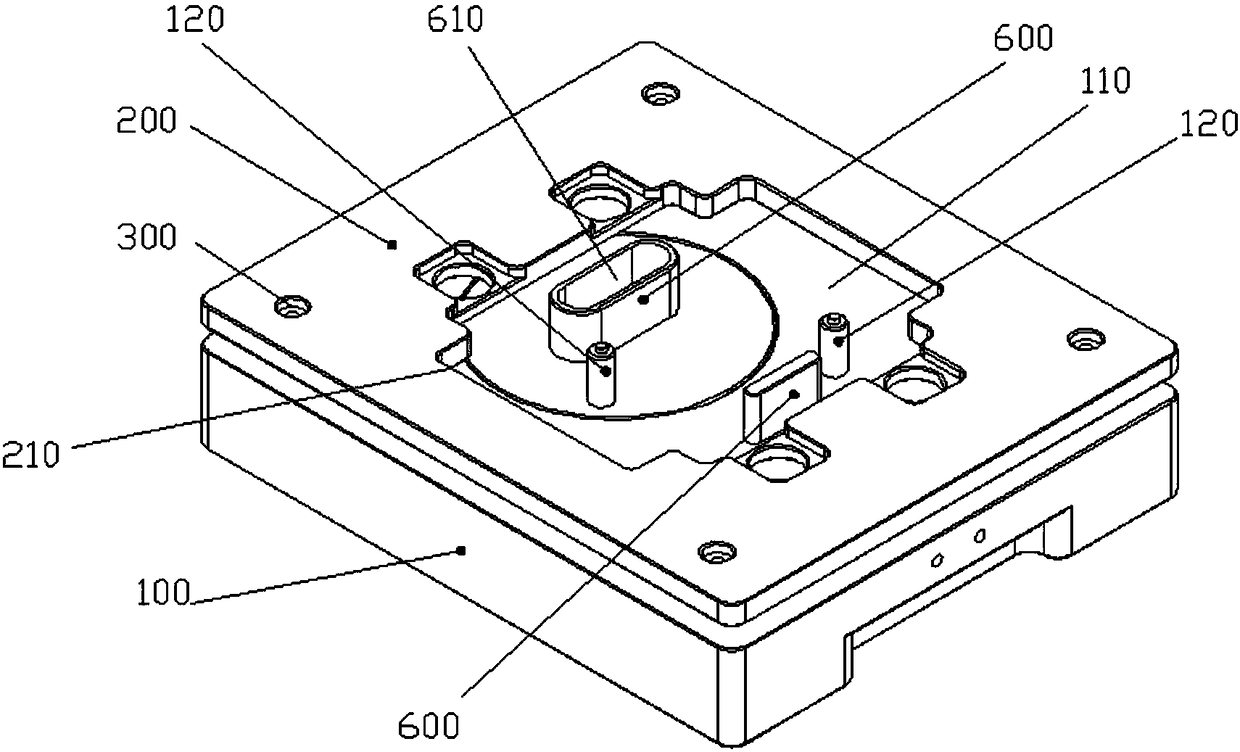

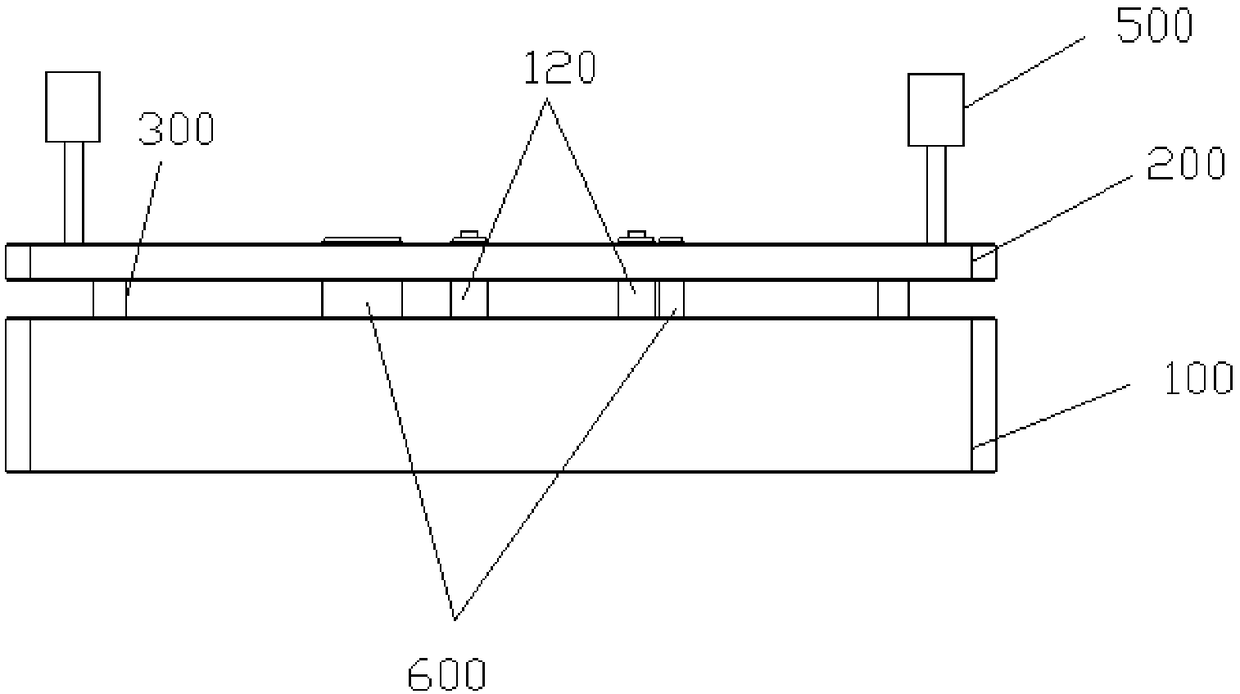

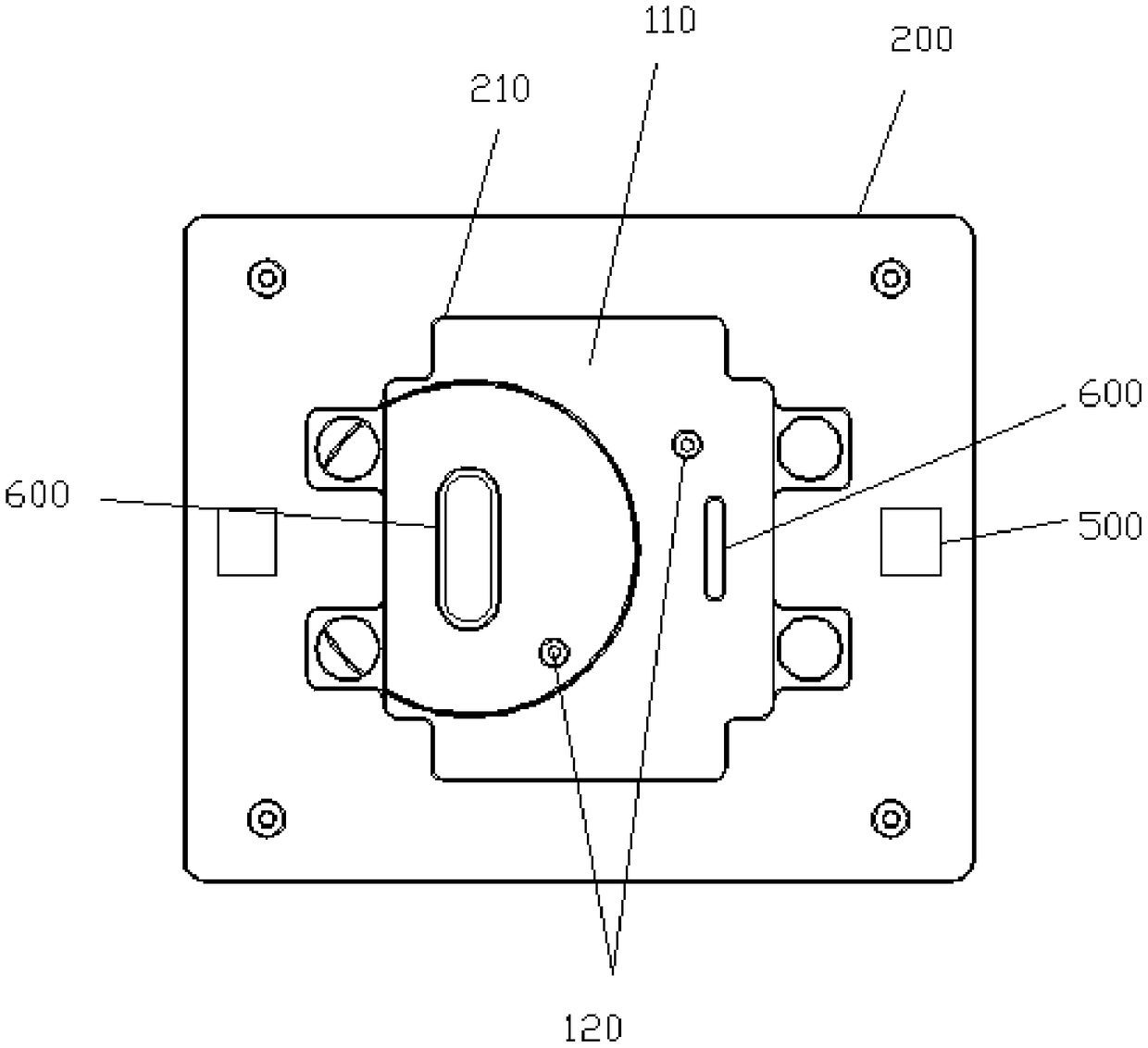

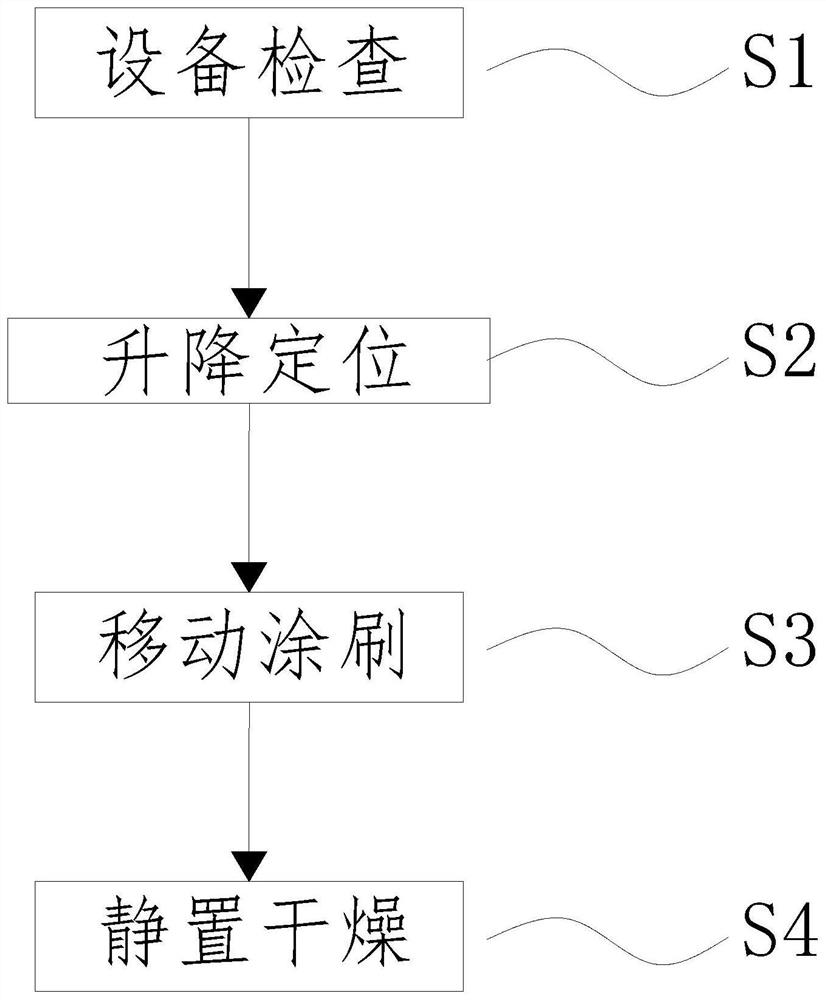

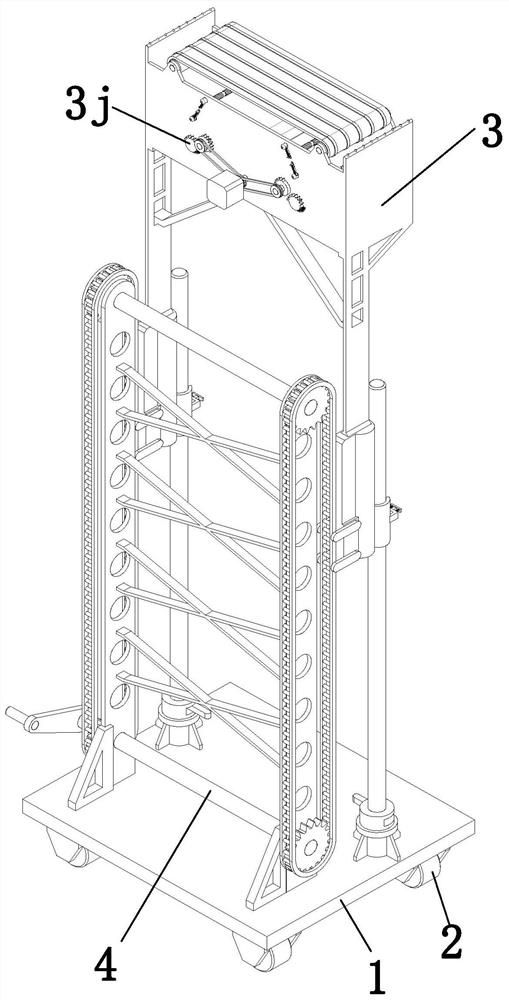

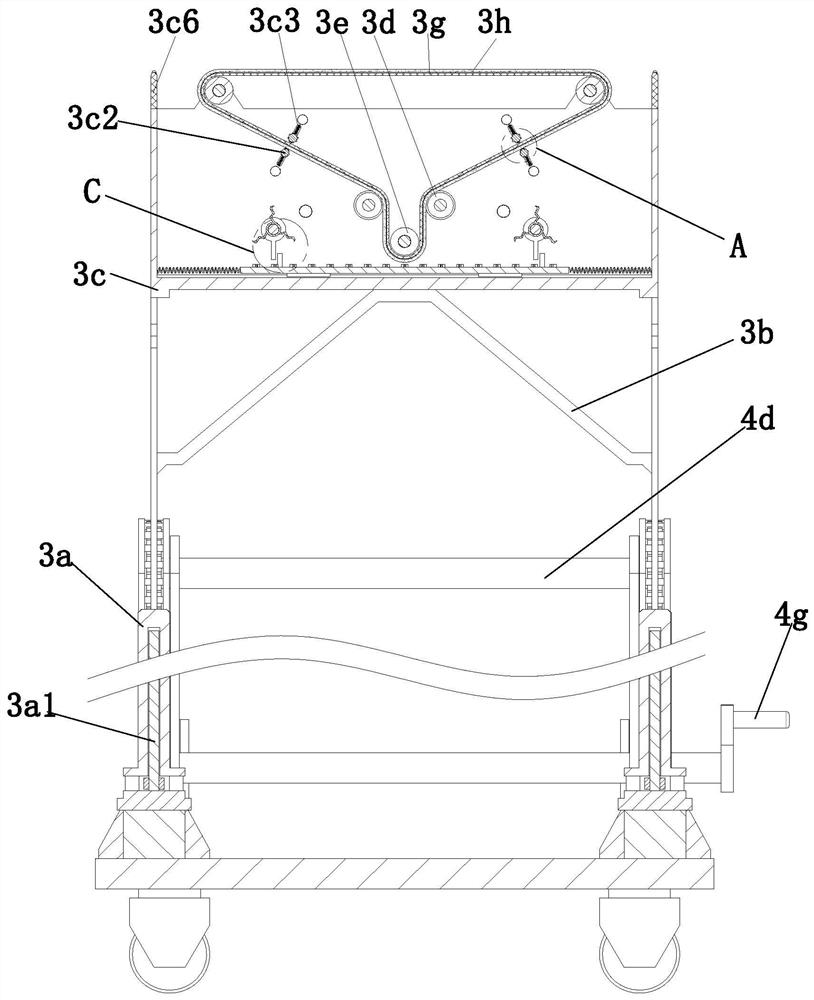

Waterproof coating brushing method for building waterproof construction

InactiveCN113235877AReduce the possibility of shakingReduce workloadRotary stirring mixersTransportation and packagingArchitectural engineeringBrush device

The invention relates to a waterproof coating brushing method for building waterproof construction. A waterproof coating brushing device for low-building waterproof construction is used, and the waterproof coating brushing device for building waterproof construction comprises a mounting bottom plate, universal wheels, a brushing mechanism and a lifting mechanism. The problems that in the waterproof coating brushing process for building waterproof construction, it is difficult to adapt to height changes of walls in different rooms, it is difficult to collect splashed and fallen waterproof coating when wall surfaces are brushed, it is difficult to keep the brushing strength of all areas uniform and consistent, it is difficult to achieve automatic feeding operation of the waterproof coating, and the stacked waterproof coating is more difficult to be continuously stirred in the brushing operation process so as to reduce deposition and condensation of the waterproof coating are solved.

Owner:高杰

Auxiliary examination device for imaging department

InactiveCN111887881APositioning balanceThe angle of the positioning plate can be adjusted evenlyPatient positioningPatient positioning for diagnosticsEngineeringExamination assistance

An auxiliary examination device for the imaging department solves the problems that at present, when a doctor shoots abdominal X-ray radiography on a baby, the baby or a seriously ill patient cannot stand, the radiography quality is affected, and other diversified auxiliary examinations cannot be met for different children patients. The angle of the positioning plate is adjusted through the rotarydisc capable of rotationally adjusting the angle, the first swing rod and the second swing rod which are parallel to each other are rotationally connected to the rotary disc, the connecting block isarranged between the first swing rod and the second swing rod, the sliding groove is formed in the connecting block, and the first positioning column and the second positioning column are slidably connected into the sliding groove; an adjusting disc is fixedly connected to the first positioning column and the second positioning column, a controllable adjusting rod is spherically hinged to the bottom end of the adjusting disc, a positioning plate capable of being turned over upwards is arranged on the rotary disc, and a positioning mechanism is arranged on the positioning plate; the device is novel in structure, ingenious in conception, convenient to adjust, safe and reliable, the irradiation quality is improved, the situation that parents and medical staff cannot be diagnosed due to the fact that the irradiation quality is affected while the bodies of the parents and the medical staff are prevented from being injured is avoided.

Owner:吴永彬

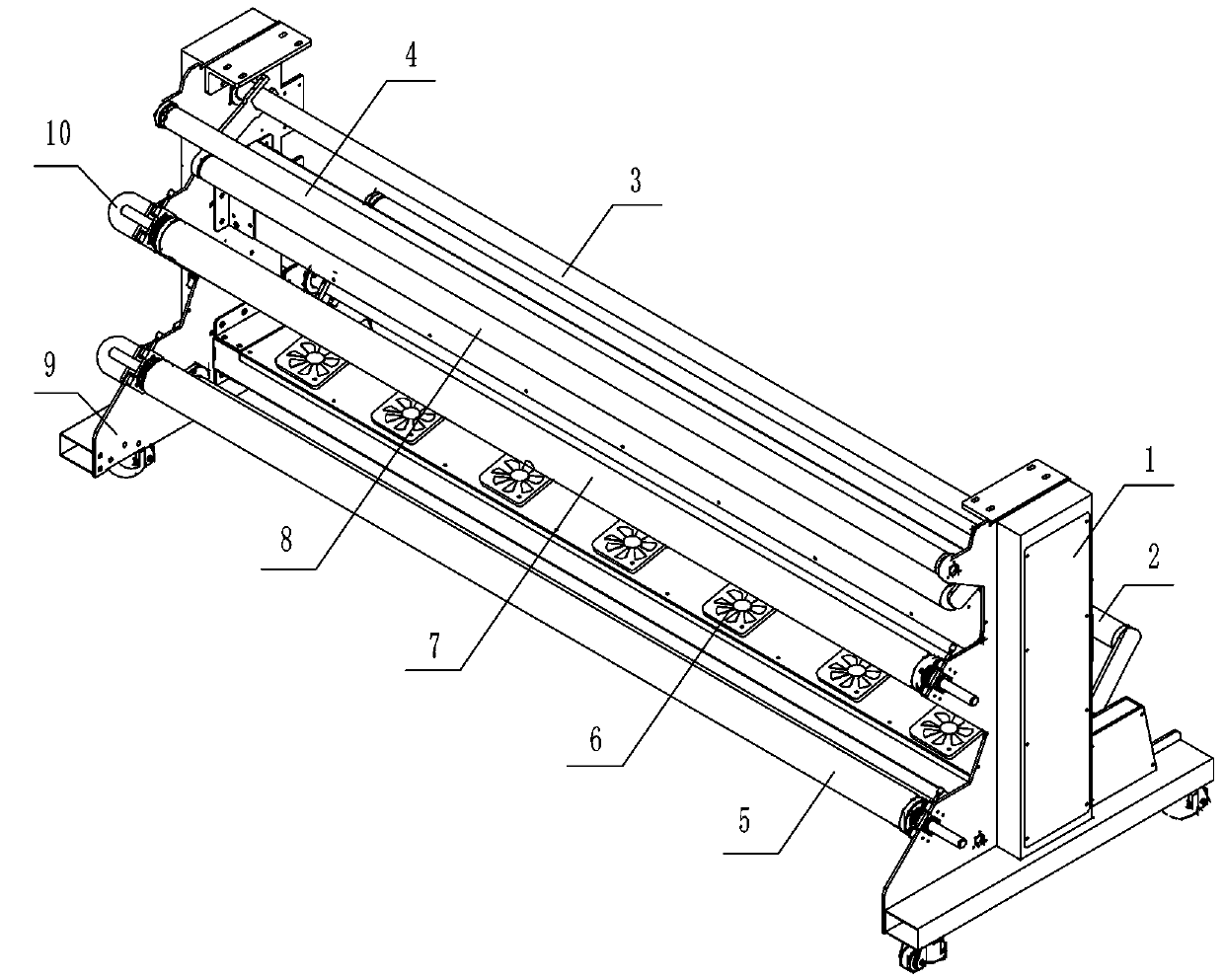

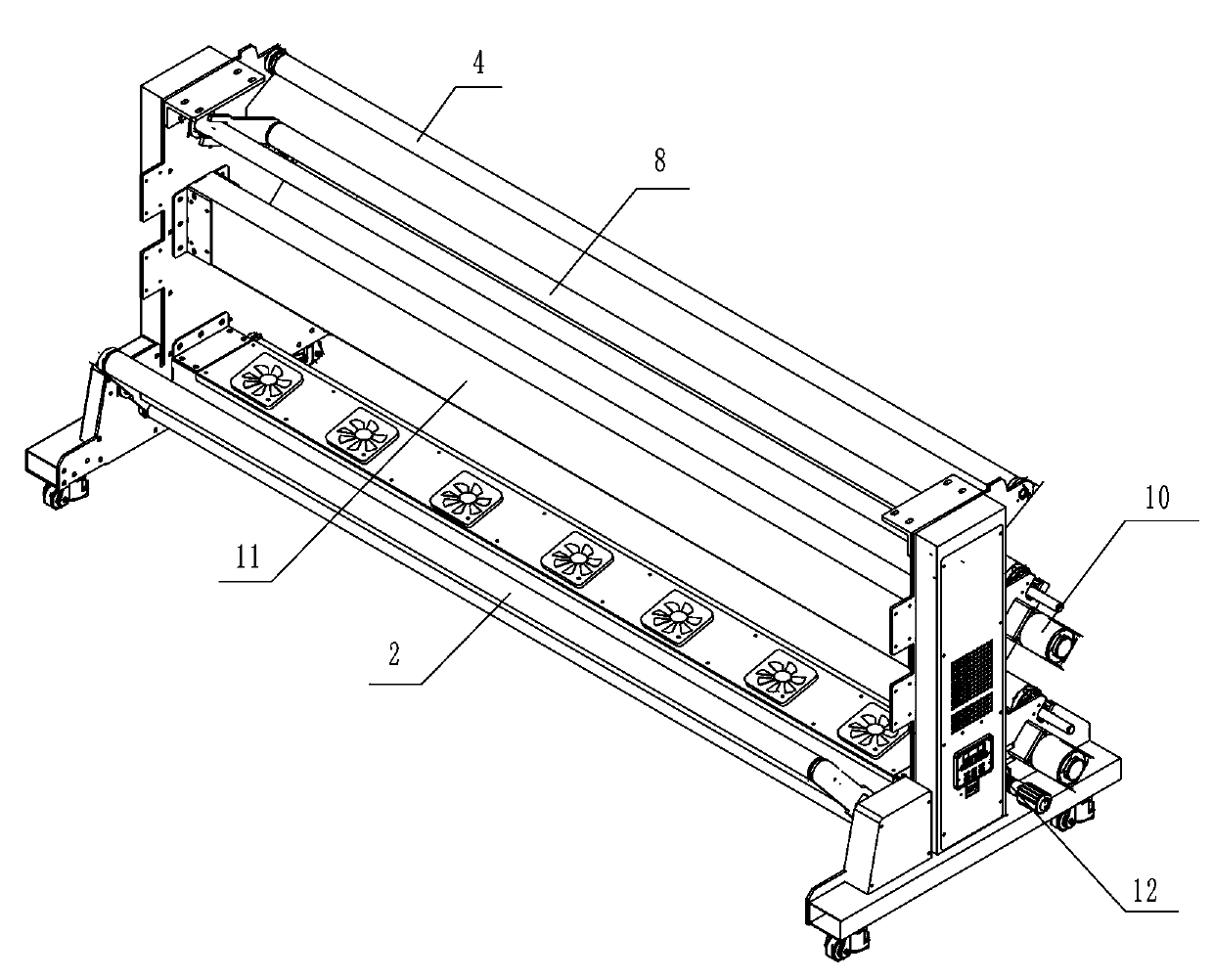

Double-head supporting winding and unwinding system for printing machine

The invention provides a double-head supporting winding and unwinding system for a printing machine. The double-head supporting winding and unwinding system comprises a machine frame, wherein an unwinding roller, a winding roller, a cloth winding roller, a swing rod supporting rod, an unwinding swing rod, a winding swing rod and a damping roller are rotationally arranged on the machine frame through an integral positioning installing plate, and the cloth winding roller, the swing rod supporting rod, the unwinding swing rod, the winding swing rod and the damping roller are used for supporting aprinting medium to achieve winding and unwinding; and the unwinding roller and the winding roller each comprises a rotating shaft and a supporting profile which sleeves the circumferential surface ofthe rotating shaft, a plurality of rubber strips are clamped on the surface of each supporting profile, and each rotating shaft is in transmission connection with a winding and unwinding motor. According to the system, all the rollers are installed on the integral positioning installing plate, and the winding roller and the unwinding roller are designed into a complete rotating shaft, so that thewhole paper tube can be uniformly supported during winding and unwinding, and the phenomena such as staggering, inclining or wrinkling in the winding and unwinding process are effectively avoided.

Owner:NEW CENTURY DIGITAL PRINT TECH

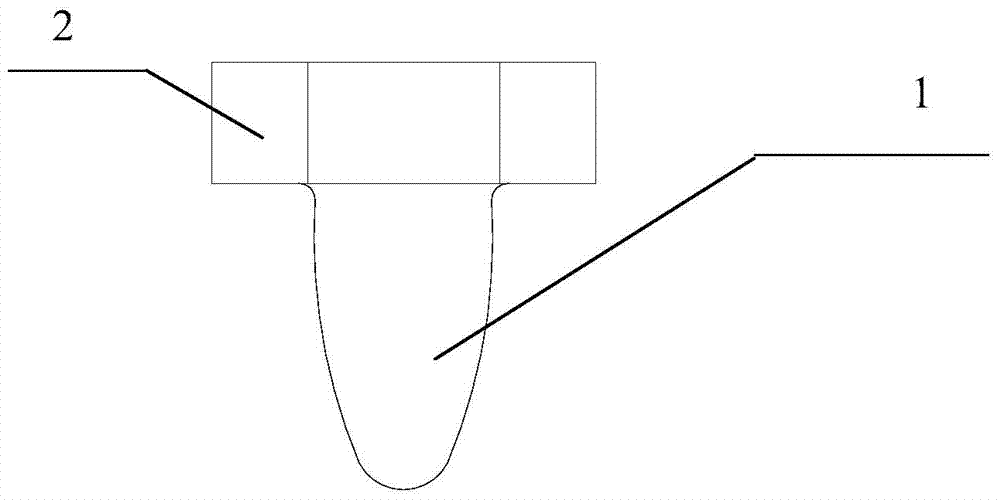

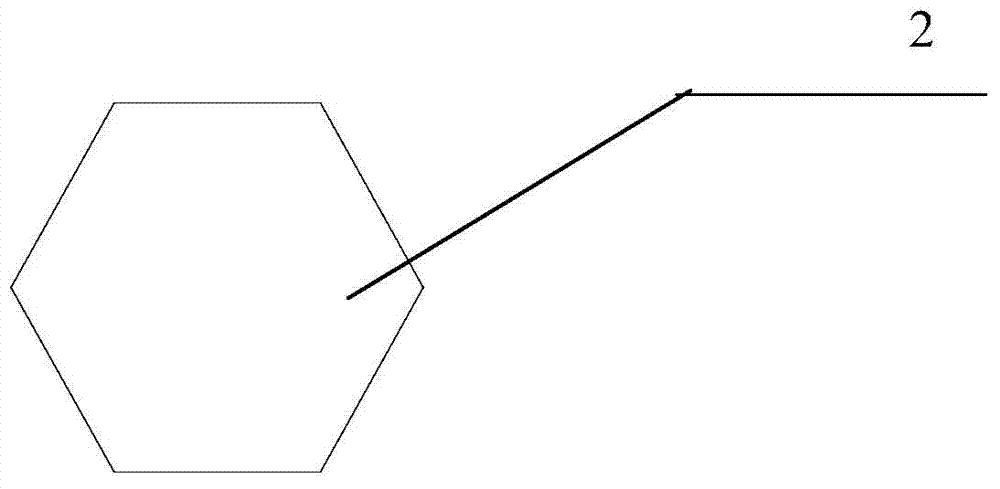

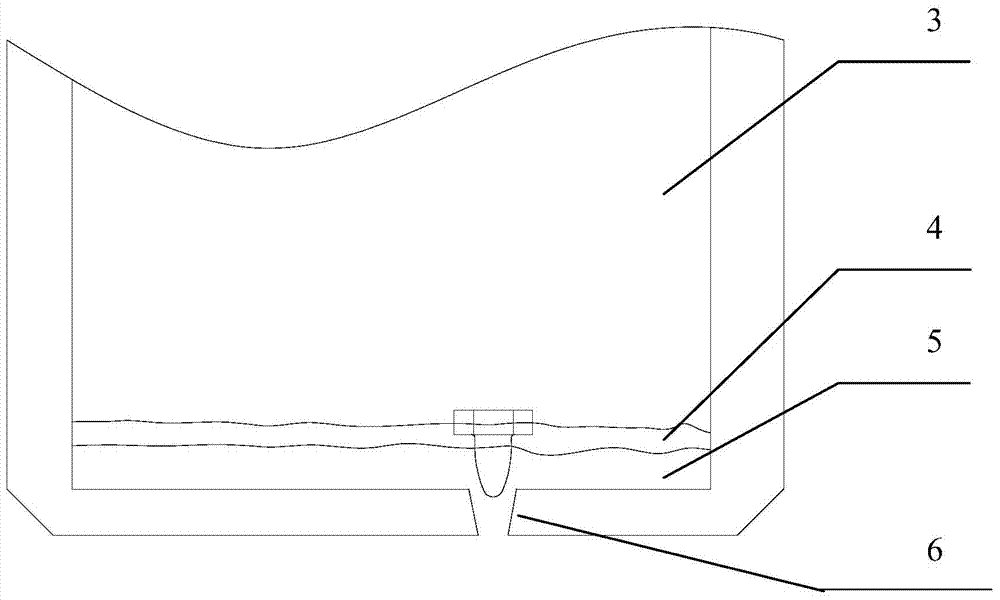

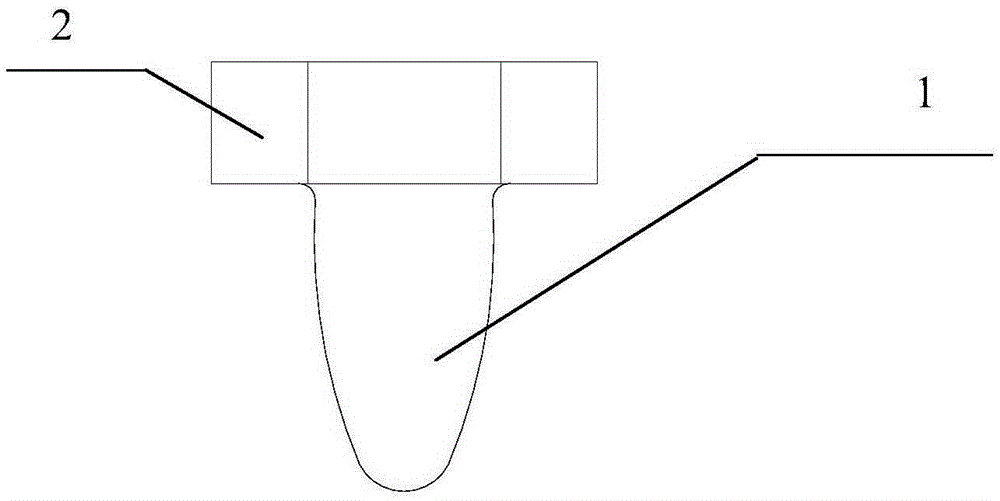

Floating plug for large-ladle pouring slag stopping, preparation method of floating plug for large-ladle pouring slag stopping and slag stopping method

The invention discloses a floating plug for large-ladle pouring slag stopping, a preparation method of the floating plug for large-ladle pouring slag stopping and a slag stopping method. The floating plug is composed of a plug head part and a plug body part and prepared by mixing fireproofing materials, water reducing agents and binding agents. After molten steel is refined and leaves from a station, before pouring is carried out, the floating plug is put into a large ladle, eddy flowing generated by molten steel liquid level drawdown in the large-ladle pouring process is used, the floating plug operates to the position above a water gap bowl of the large ladle and is in point contact with the surface of the water gap bowl of the large ladle, and the slag stopping operation is accordingly completed. The interior and the exterior of the floating plug prepared with the method are homogenous, the density is even, location in the molten steel is accurate, the problem that manual judgment is inaccurate so that slag discharged from the large ladle in continuous casting production enters a middle ladle is solved, the slag stopping effect is remarkable, the slag discharging amount of the molten steel in the large-ladle pouring process is greatly reduced, the purity of the molten steel is improved, the blank casting quality is improved, and the performance of finished products of rolled metal is improved.

Owner:LAIWU IRON & STEEL GRP

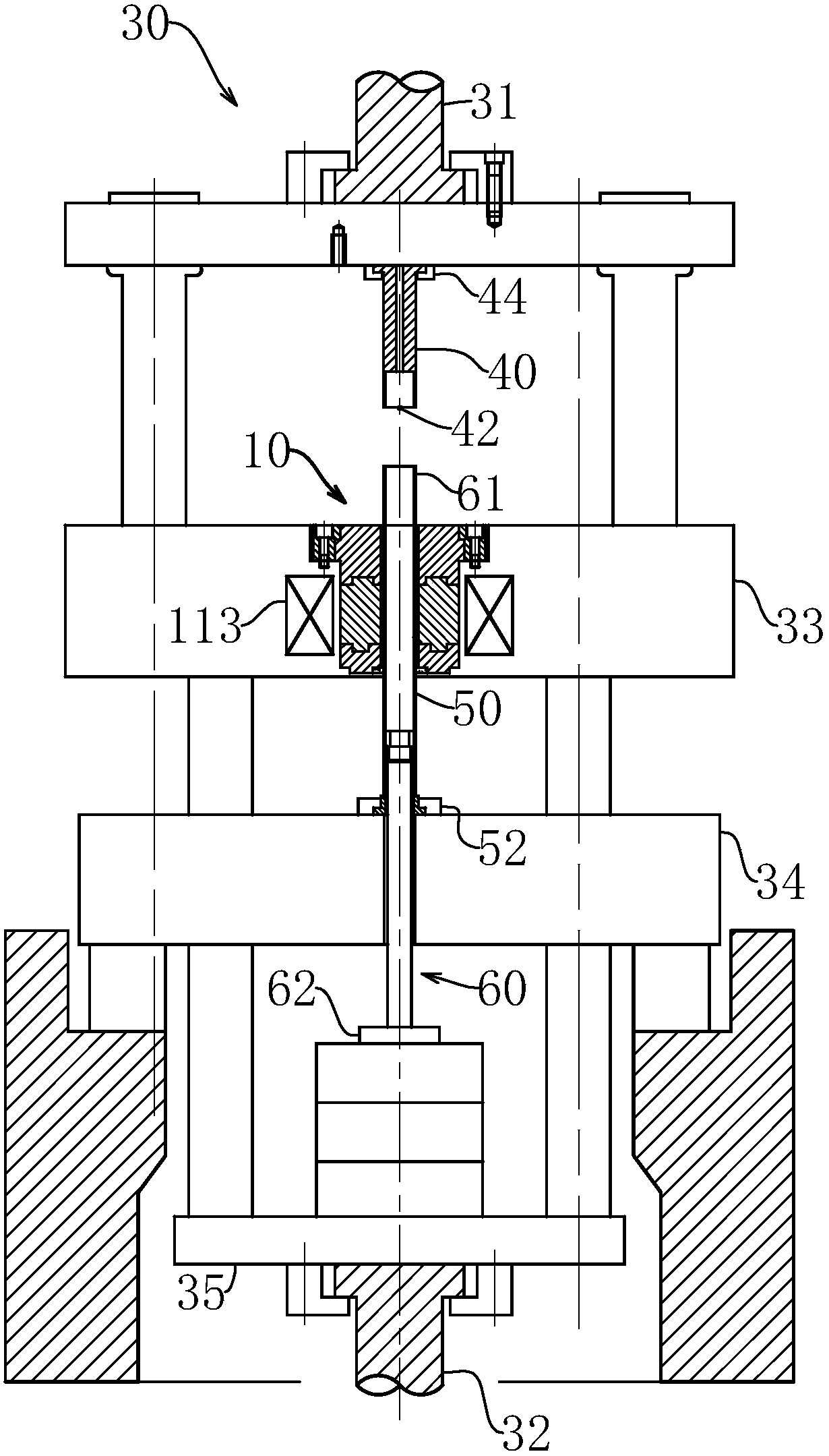

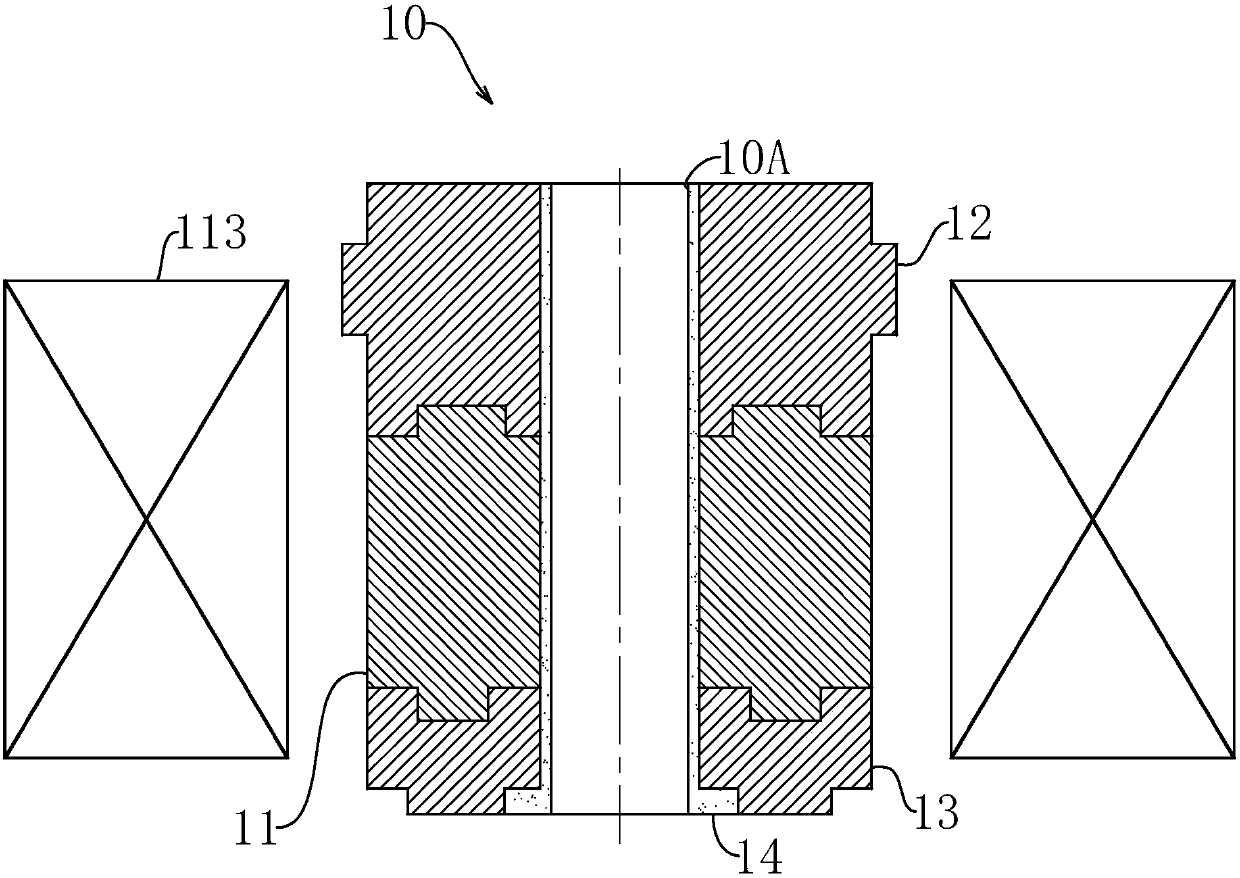

Anisotropic NdFeB magnet compression molding device

ActiveCN106252054BImprove magnetismPositioning balanceInductances/transformers/magnets manufactureMagnetic polesLarge size

Provided is an anisotropic neodymium-iron-boron magnet mold pressing orientation molding device. The device comprises a mold assembly, an upper stamping part, a lower stamping part and a core rod; the mold assembly is formed by connecting a mold main body with a mold main body upper base, a mold main body lower base and an inner sleeve; the upper stamping part can vertically move along with a stamping handpiece; the upper end of the lower stamping part stretches into a mold cavity of a mold main body; the core rod is movably arranged in the lower stamping part in a penetrating mode and can vertically move, and the lower end of the core rod is movably connected with a stamping machine base; an anisotropic neodymium-iron-boron magnet prepressing part is arranged between the mold cavity of the mold main body in a heating state and the core rod and falls to the top of the lower stamping part, the upper stamping part is started to move downwards, when the upper stamping part enters the mold main body, an orientation device is conducted for magnetic-pole orientation, the upper stamping part continues moving downwards, and then the neodymium-iron-boron magnet prepressing part is pressed to be molded. According to the device, multi-magnetic-pole positioning orientation can be achieved, magnetic-pole orientation is uniform, the orientation efficiency is high, the density and the comprehensive performance of a magnet are high, and the device can be used for pressing the magnet with the small wall thickness and the large size in the height direction.

Owner:安徽粤海磁业有限公司

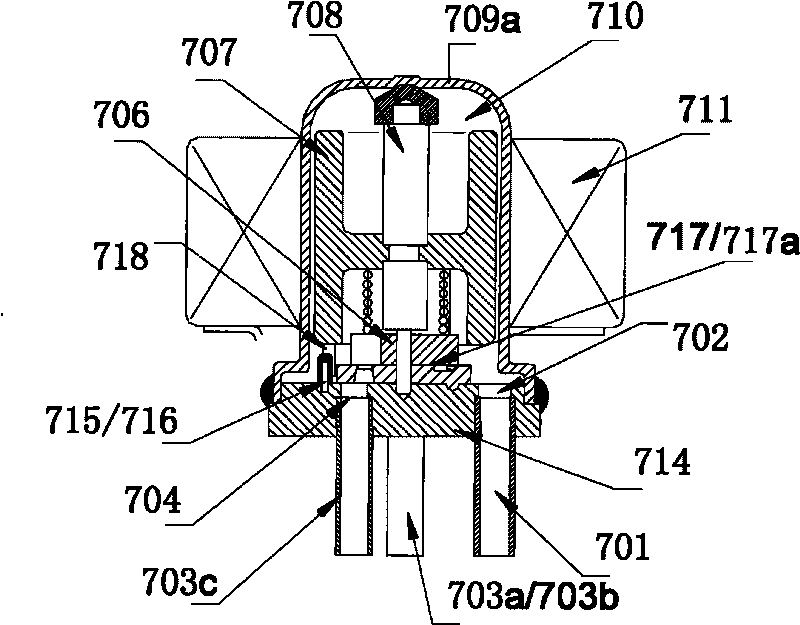

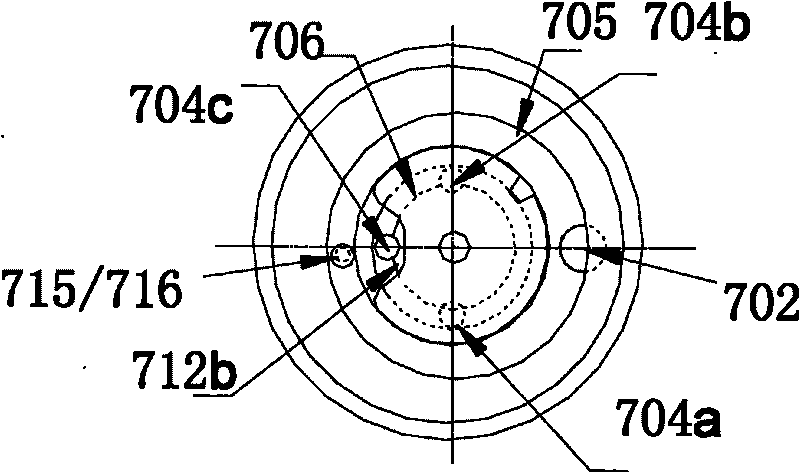

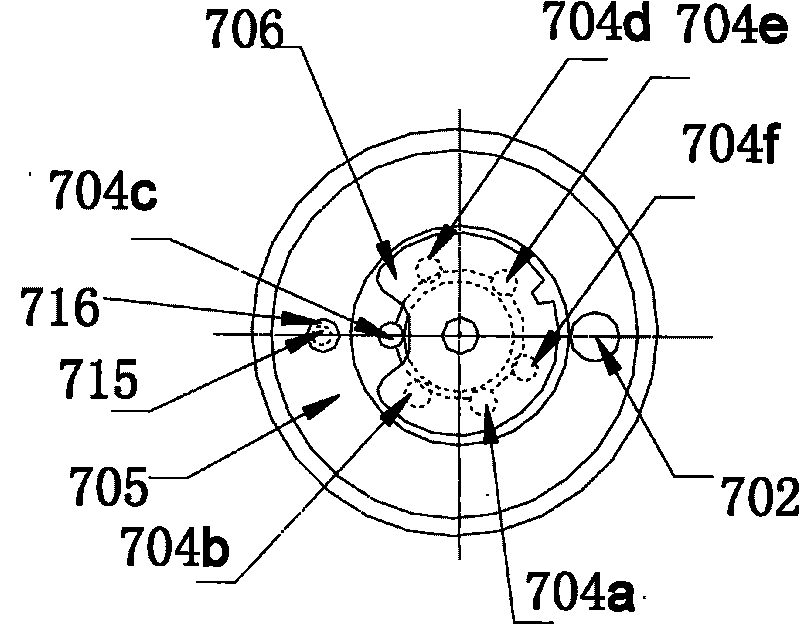

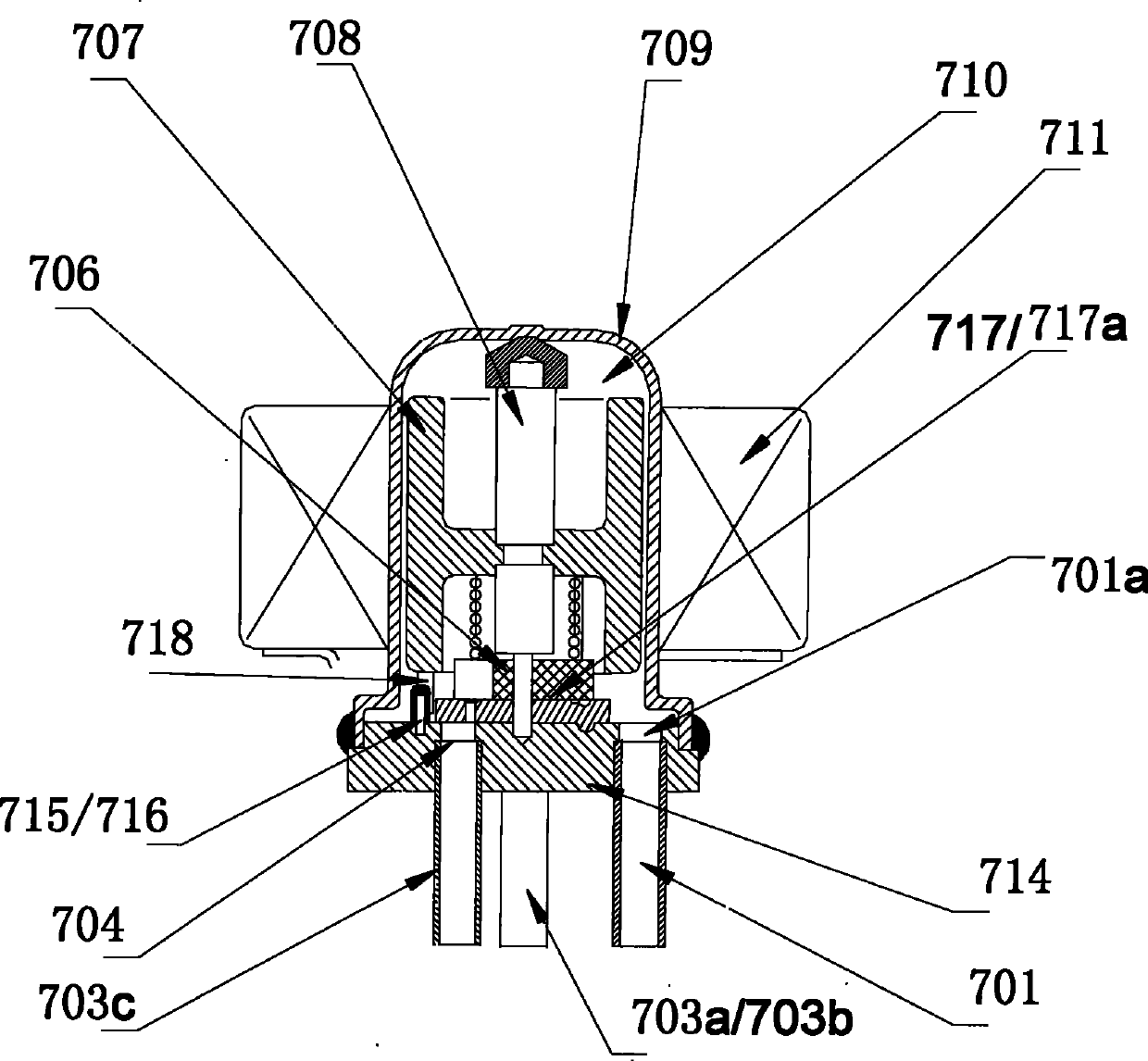

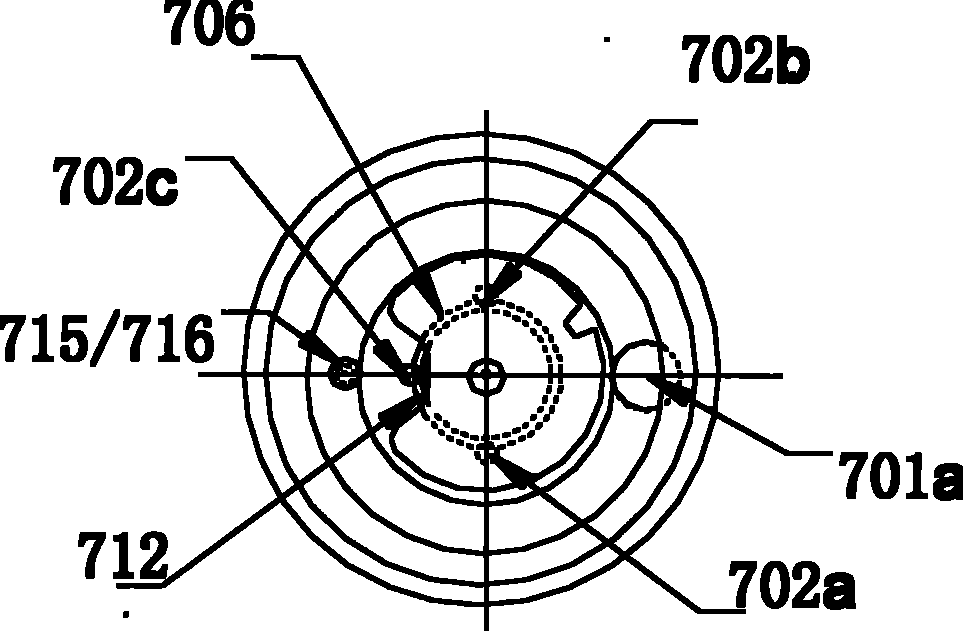

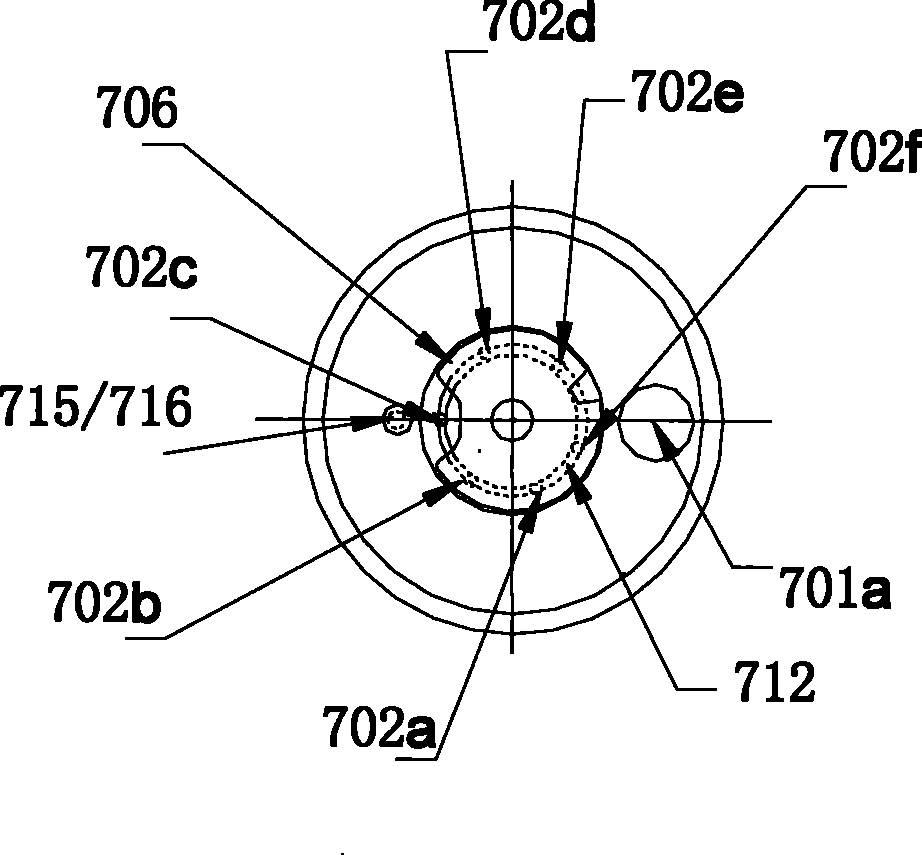

Electric flow distributor

ActiveCN101762120APrecise positioningPositioning balanceFluid circulation arrangementSpool valveDistributor

The invention belongs to an electric flow distributor for a refrigerating system, which comprises a casing, an inlet, an inlet connecting pipe, a plurality of outlets, outlet connecting pipes and a stepping motor for driving, wherein the inlet connecting pipe is communicated with the inlet; the outlet connecting pipes are respectively communicated with the outlets. The interior of a valve cavity in the casing is also provided with a driving rod and a slide valve, wherein the driving rod is driven by a magnetic rotor part; the slide valve is arranged opposite to the outlets. The stepping motordrives the slide valve to rotate to realize the flow distribution between the outlets; and the slide valve is also provided with a positioning mechanism, and the position relationship between the slide valve and the outlet is ensured through the positioning of the positioning mechanism; meanwhile,, the system has the advantages of simple installation and connection, and low manufacturing cost.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

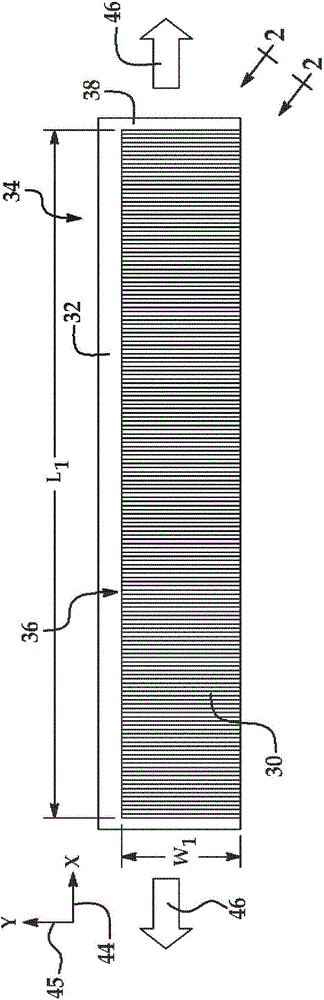

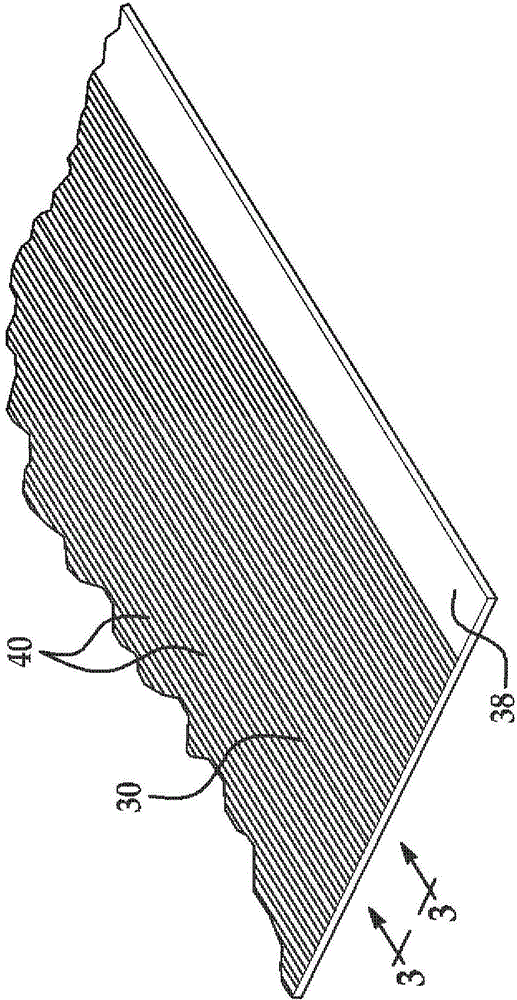

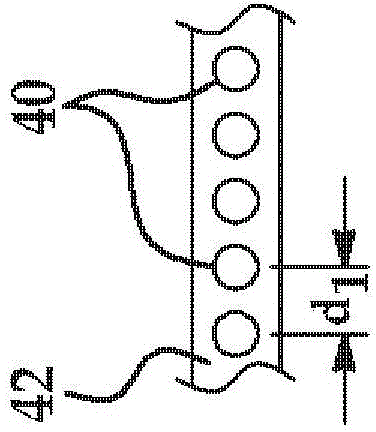

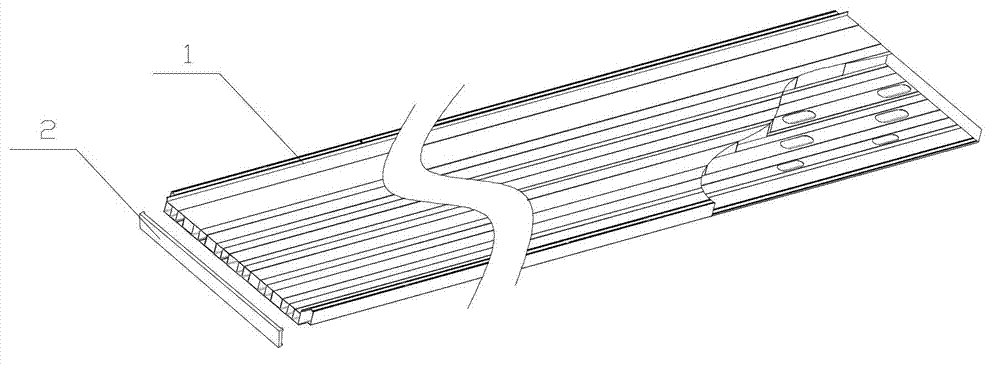

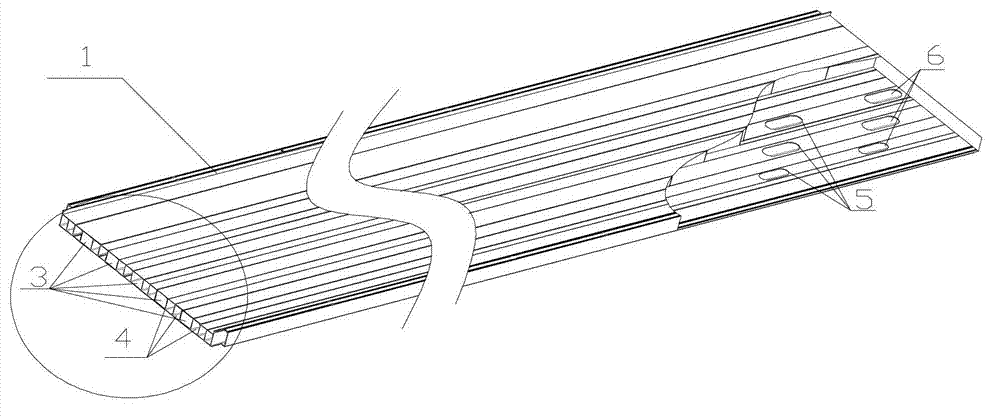

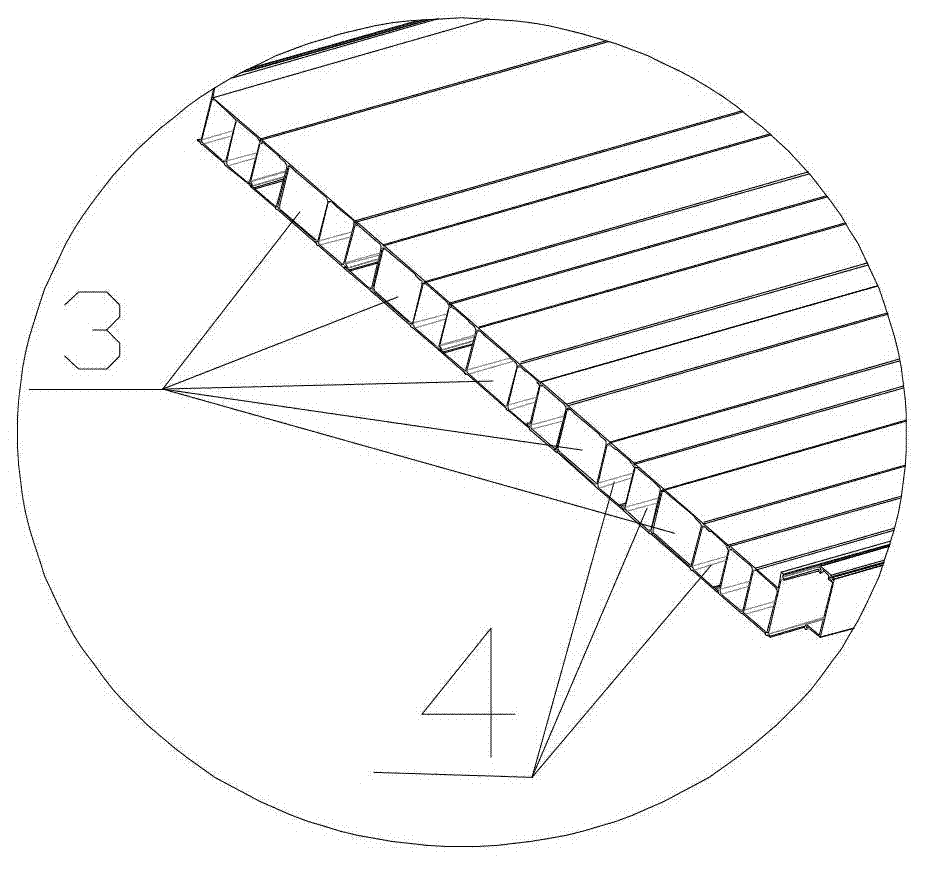

Method of fabricating a curved composite structure using composite prepreg tape

ActiveCN104903081AAvoid wrinklesPrevent/or warpFuselage framesEfficient propulsion technologiesEngineeringFlange

A method is provided of fabricating a composite stiffener having a curved web and at least one curved flange. A substantially straight length of unidirectional prepreg tape (30) is placed on a carrier (32). The at least one curved flange is formed by using the carrier to steer a first portion of the tape onto a first curved tool surface. The curved web is formed by using the carrier to form a second portion of the tape onto a second curved tool surface.

Owner:THE BOEING CO

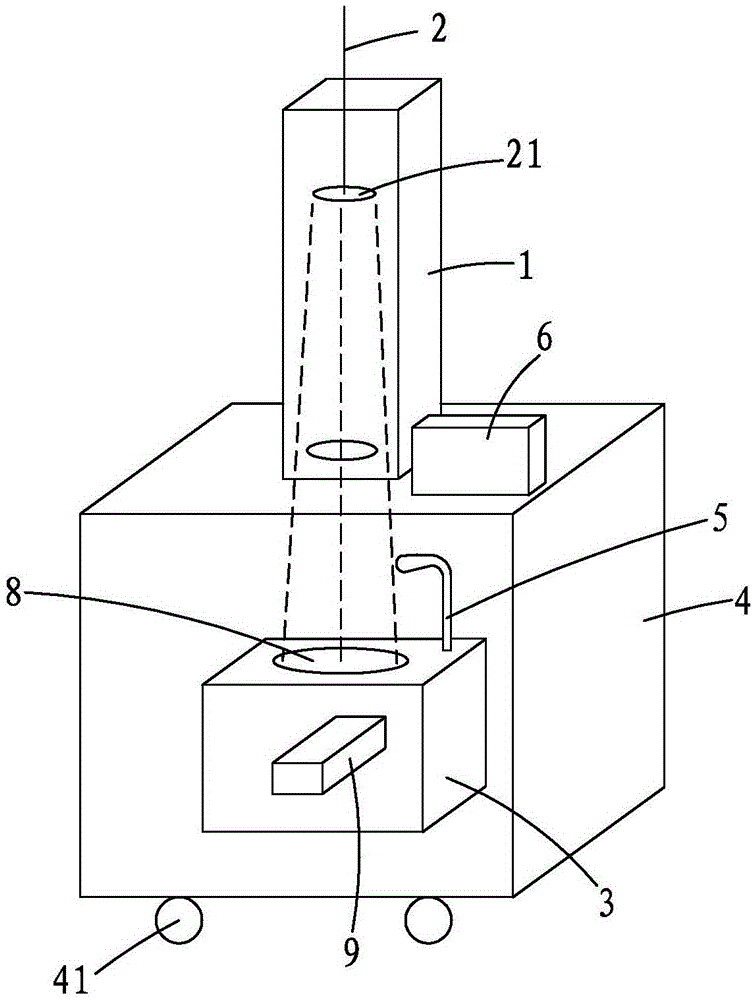

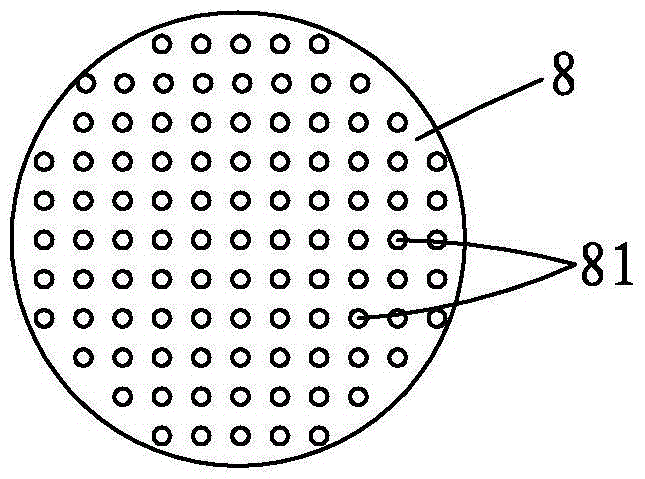

Clamping tooling assembly and machining process method for titanium alloy foil parts

InactiveCN109968053AHigh dimensional accuracyPositioning balanceWork clamping meansTurning machinesPneumatic pressureMachining process

The invention discloses a clamping tooling assembly and a machining process method for titanium alloy foil parts, and belongs to the technical field of machining forming of titanium alloy foils. According to the method, the surface of the titanium alloy foil part is cleaned up, a sucker is aligned, a vacuum drying pump is started, the titanium alloy foil part is rapidly inserted into the sucker, the position of the titanium alloy foil part in the sucker is calibrated, the vacuum pump is started to exhaust air of the interior of the sucker, so that the suction force of the sucker reaches 0.7MPa, a quick coupling is taken down, the sucker is taken down, the sucker is clamped on a lathe, and whether the titanium alloy foil part is loosened or not is checked by using a dial indicator; and a ceramic tool is used for carrying out turning on the appearance of the titanium alloy foil part, and the titanium alloy foil part is turned for two times. According to the method, the pneumatic adsorption positioning and fastening mode is adopted, so that the surface of the foil part is uniformly stressed, accurate positioning is achieved, the ceramic tool is further adopted, so that the surface quality of the small-allowance fine machining process is guaranteed. The method is suitable for machining process for the titanium alloy foil parts.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

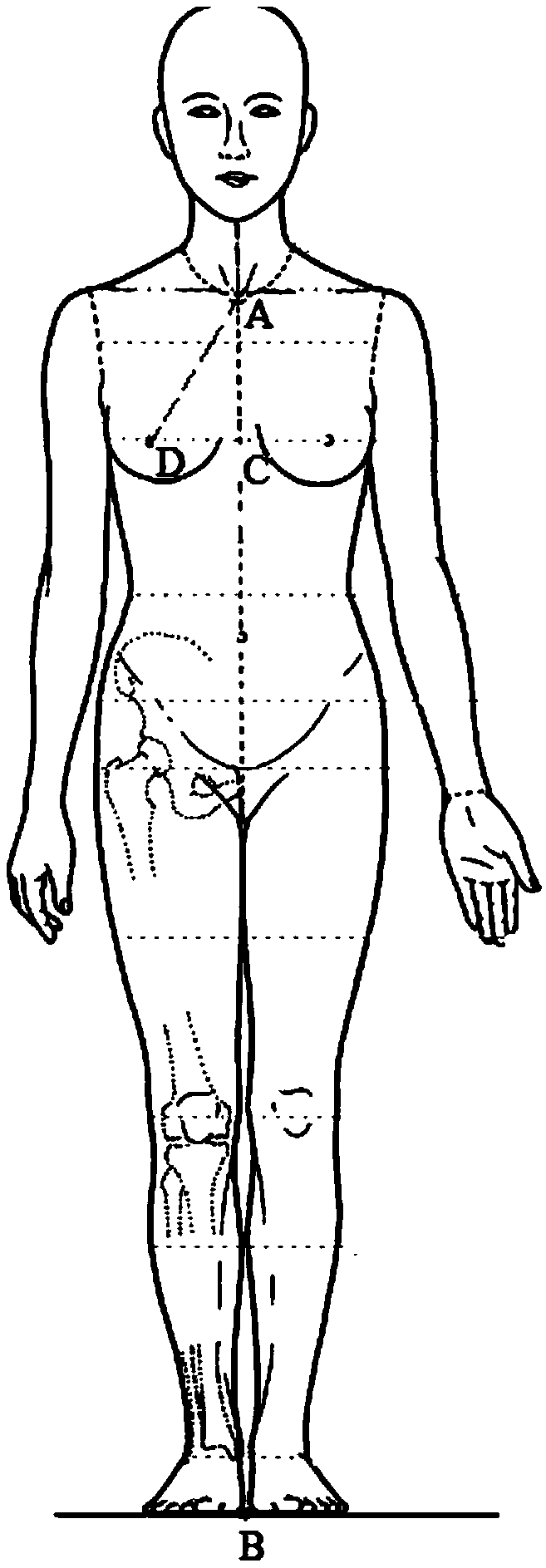

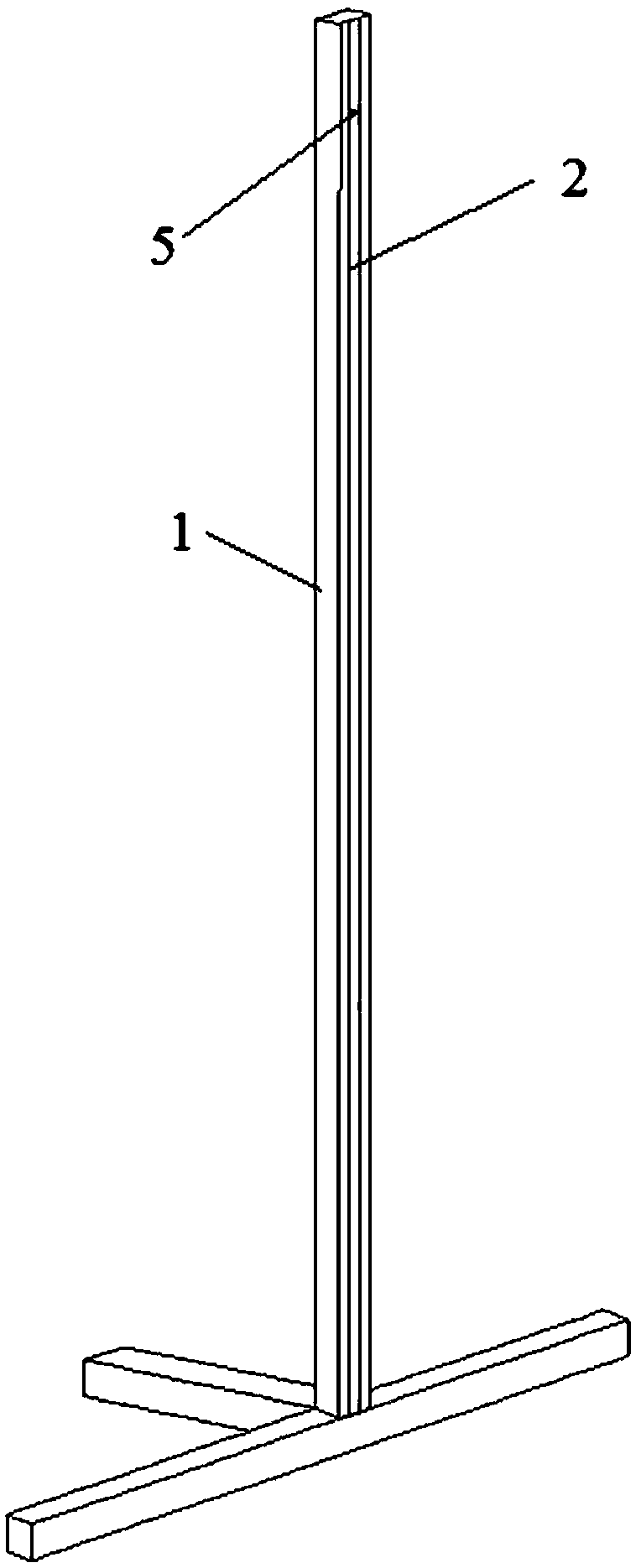

Human body measurement balance locator and method for measuring human body by balance positioning

ActiveCN107019278BPositioning balanceEasy to measureClothes making applicancesMeasurement pointEngineering

The invention relates to a human body measurement balance position finder and a method for measuring a human body in a balance positioning manner. The method is characterized in that the human body is measured by the human body measurement balance position finder and a measurement tool, a plurality of light-emitting sources are arranged on the human body measurement balance position finder, and the light-emitting source in the middle is rotatable; except the rotatable light-emitting source, light paths emitted by the other light-emitting sources are horizontal, and the other light-emitting sources are arranged in an up-and-down movement manner and can be fixed; when a vertical distance is measured, the rotatable light-emitting source and horizontal light emitted by the light-emitting sources arranged at the upper part and the lower part are respectively interacted on two to-be-measured measurement points; when a horizontal girth is measured, the light-emitting sources that are not rotatable move to the position of the girth in measurement of the human body required by cloth and then are fixed, and the to-be-measured girth at a horizontal line is measured; when other distances are measured, the rotatable light-emitting source is rotated to be interacted with light emitted by the parallel light-emitting sources at the two measurement points. According to the method, the human body can be measured conveniently, the position for the measured part of the human body is more balanced, and the measurement accuracy is high.

Owner:HEILAN HOME

High-speed linear drive mechanism for hectograph

The invention discloses a linear drive mechanism for hectograph, comprising a machine frame and a cam arranged under the machine frame, wherein, the front end of the cam is provided with a transmission gear for power transmission, and a cam slot is arranged along the top end and the bottom end of the outer surface of the cam; a moveable cart group is arranged on the machine frame, a sliding trackis arranged between the moveable cart group and the machine frame, and a plurality of roller bearings which are kept at intervals and are matched with the cam slot are arranged on the lower bottom surface of the moveable cart group; and when power is transmitted into a transmission gear, the transmission gear drives the cam to rotate, and the cam pushes the roller bearings to run in the sliding track along with the moveable cart group. The mechanism can connect a plurality of cams to simultaneously drive multiple groups of moveable cart group for multiple times of printing, and has the advantages of high transmission accuracy, accurate positioning, high speed, long service life, low noise, simple structure, easy production, low cost, high assembly efficiency, convenient repair, installation and disassembly, safe and reliable installation, reasonable structure, excellent performance, and high convenience and practicability.

Owner:广州互通气动机器工程有限公司

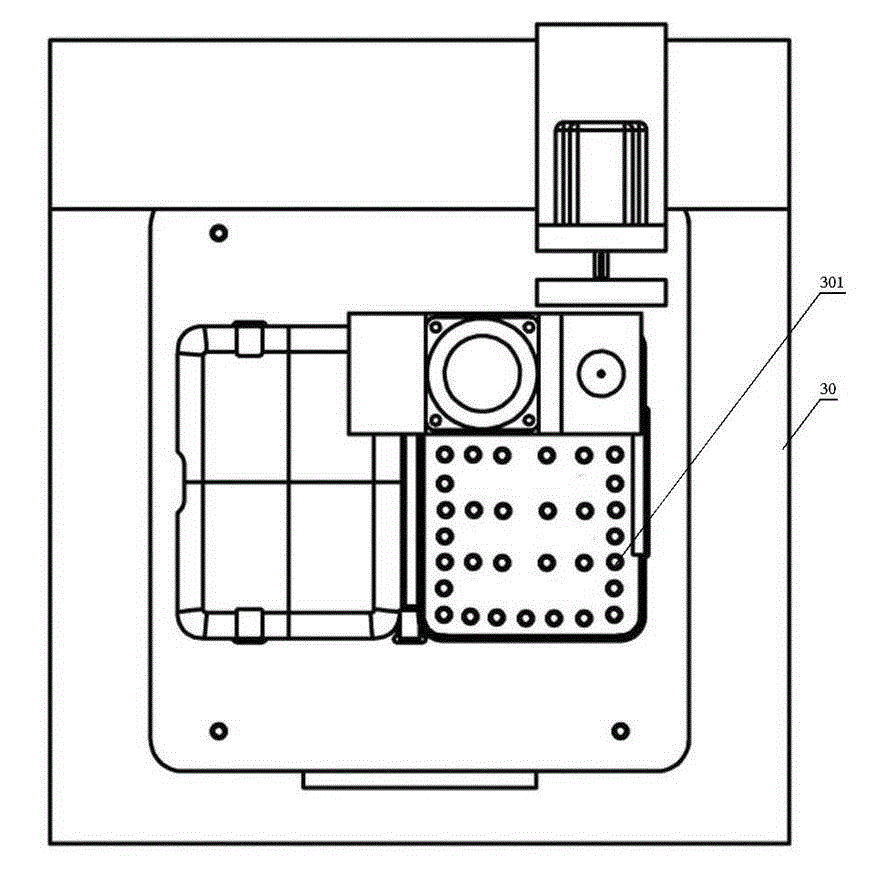

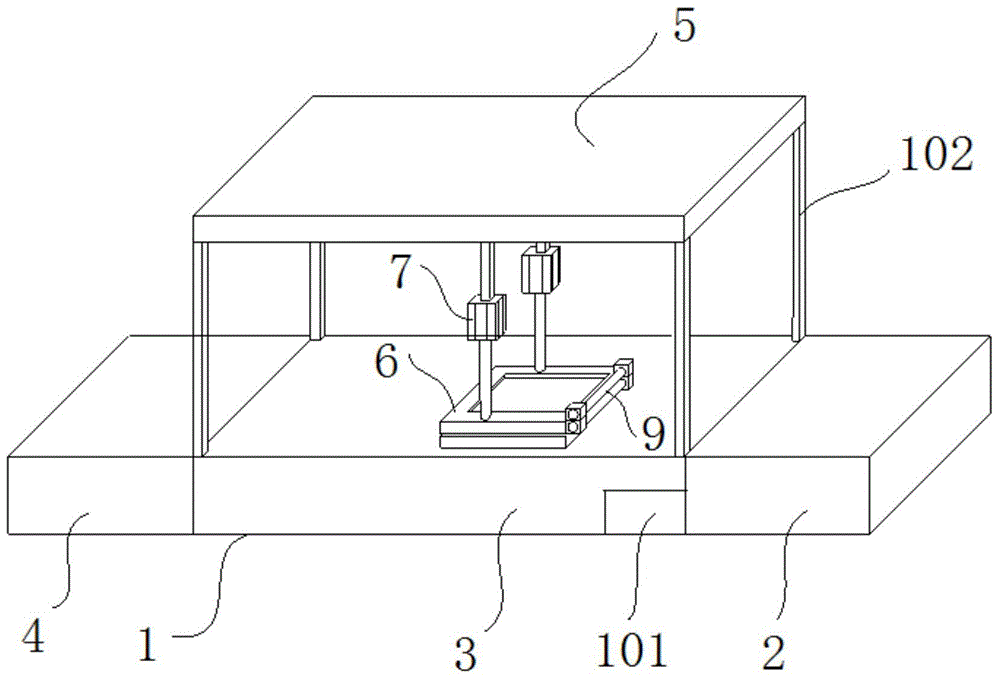

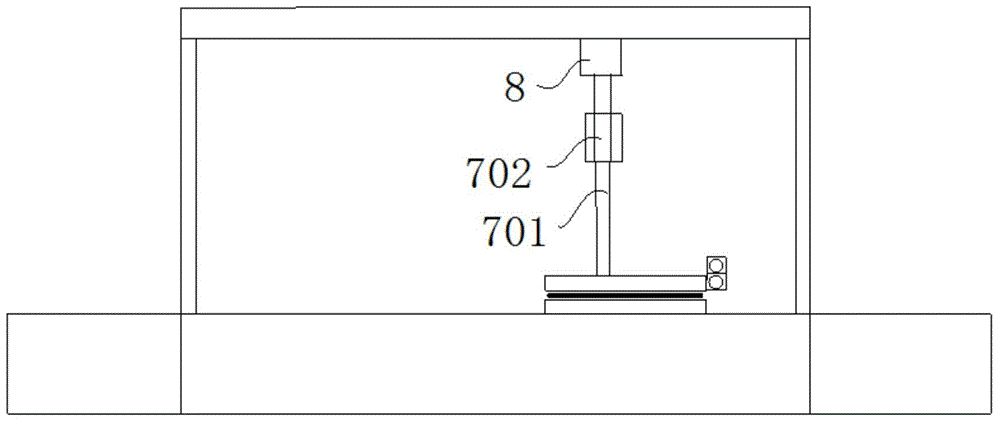

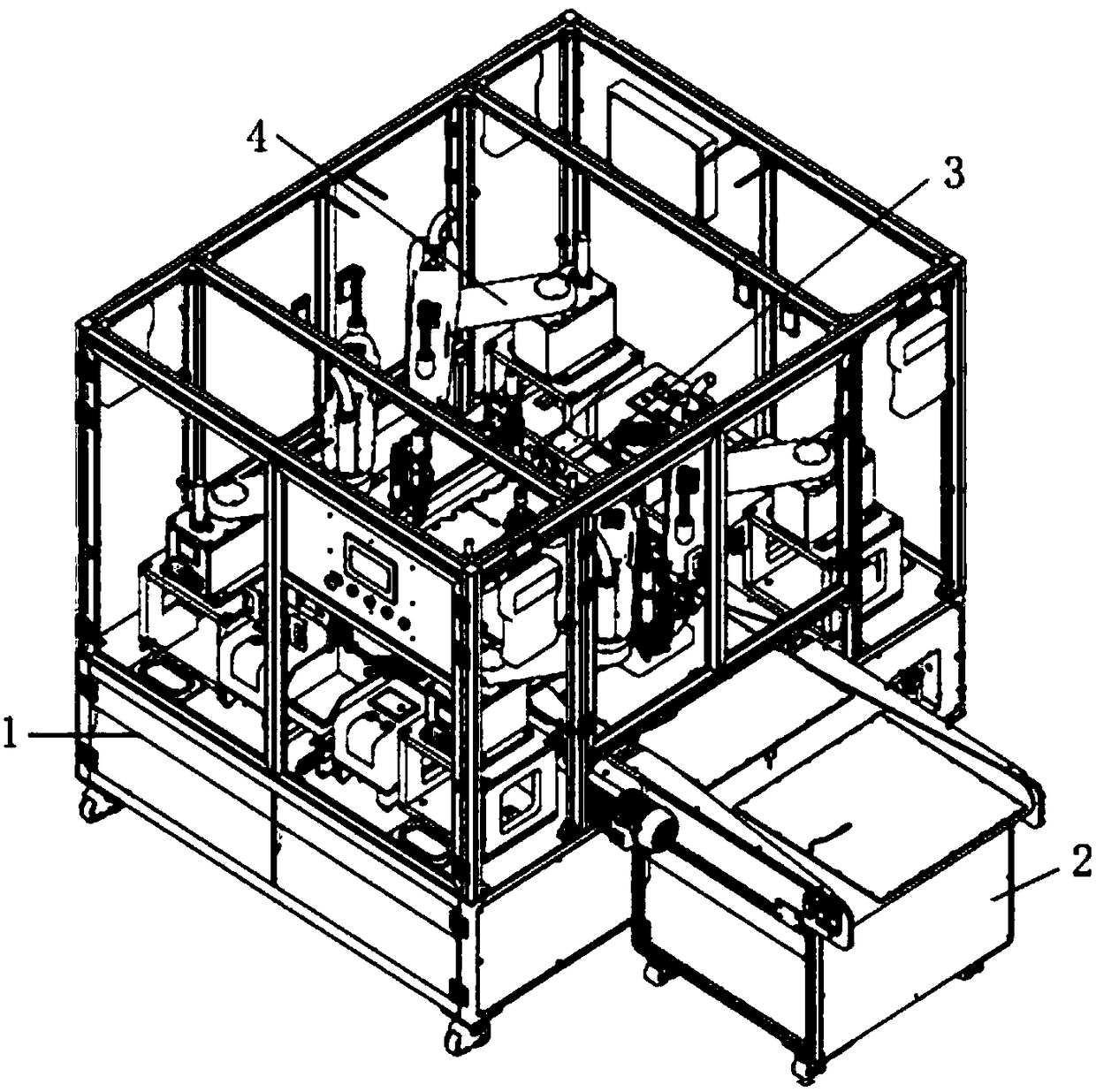

Full automatic LED panel screw locking machine

PendingCN108188718APositioning balanceGuaranteed positioningMetal working apparatusManipulatorEngineering

The invention discloses a full automatic LED panel screw locking machine which comprises a rack, a feeding mechanism, a laminating and locating mechanism and a screw driving mechanism; the laminatingand locating mechanism and the screw driving mechanism are arranged in the rack; the laminating and locating mechanism comprises a downward pushing assembly, a front and rear locating assembly and a side surface locating assembly; and the screw driving mechanism comprises a screw feeder, a manipulator and a screw driving assembly. Through the feeding mechanism, a product to be subjected to screw driving is sent to the laminating and locating mechanism, subsequently, the laminating and locating mechanism uniformly presses the product to be subjected to screw driving and ensures that the productto be subjected to screw driving is located in the front, rear, left and right directions properly, and finally the product to be subjected to screw driving and a frame are locked by the screw driving mechanism, so that the production efficiency is high, the manpower is saved, and the product quality is more stable.

Owner:佛山阿尔法智能控制技术有限公司

A fully automatic oil edge machine

ActiveCN102716838BImprove product qualityFully automaticLiquid surface applicatorsLeather/skins/hides/pelt chemical treatment apparatusEngineeringDislocation

The invention provides a full-automatic edge painting machine which comprises a framework, an edge painting head component, a workpiece positioning device, a positioning pump and a control component. The edge painting head component is mounted on the framework and consists of an oil nozzle head and a mechanical shaft, the oil nozzle head moves two-dimensionally by the aid of the mechanical shaft, the workpiece positioning device is used for positioning a painted edge, disposed on the framework and arranged below the edge painting head component, the positioning pump is arranged in the framework and connected with the workpiece positioning device, and the control component is used for controlling an edge painting process of the edge painting head component and controls the workpiece positioning device and the positioning pump to respectively match with the edge painting head component to paint the edge. The edge painting process is fully automatic, the workpiece positioning device and the positioning pump are controlled by the control component on the basis, dislocation in the edge painting process can be prevented, the full-automatic edge painting machine is high in positioning accuracy and can uniformly paint edges of irregular shapes and arc-shaped corners, and the quality of products with painted edges is high.

Owner:东莞宏川智能科技有限公司

Buffer type glass steel pipe positioning mechanism

The invention discloses a buffer type glass steel pipe positioning mechanism, which includes a bottom plate, a moving mechanism, a supporting mechanism, a placing mechanism and a positioning mechanism; The outer ends of the rotating shafts are all provided with wheels; the support mechanism: it includes four fixed blocks 1, and the bottom ends of the four fixed blocks 1 are fixed with hydraulic columns, and the bottom ends of the hydraulic columns are provided with support seats; the placement mechanism : It comprises a chute one, the inside of the chute one is slidably connected with a slider one, the upper surface of the slider one is provided with a rectangular groove one, and a spring is placed inside the rectangular groove one, and the The top of the spring is provided with a moving block, and the moving block is slidably connected to the inside of the rectangular groove 1. The buffer type glass steel pipe positioning mechanism can support and place the glass steel pipe, which is convenient for users to use and facilitates the positioning of the glass steel pipe. ,Improved work efficiency.

Owner:胜利油田德利实业有限责任公司

A slag stopper for ladle pouring slag stopper and its preparation and slag stopper method

The invention discloses a floating plug for large-ladle pouring slag stopping, a preparation method of the floating plug for large-ladle pouring slag stopping and a slag stopping method. The floating plug is composed of a plug head part and a plug body part and prepared by mixing fireproofing materials, water reducing agents and binding agents. After molten steel is refined and leaves from a station, before pouring is carried out, the floating plug is put into a large ladle, eddy flowing generated by molten steel liquid level drawdown in the large-ladle pouring process is used, the floating plug operates to the position above a water gap bowl of the large ladle and is in point contact with the surface of the water gap bowl of the large ladle, and the slag stopping operation is accordingly completed. The interior and the exterior of the floating plug prepared with the method are homogenous, the density is even, location in the molten steel is accurate, the problem that manual judgment is inaccurate so that slag discharged from the large ladle in continuous casting production enters a middle ladle is solved, the slag stopping effect is remarkable, the slag discharging amount of the molten steel in the large-ladle pouring process is greatly reduced, the purity of the molten steel is improved, the blank casting quality is improved, and the performance of finished products of rolled metal is improved.

Owner:LAIWU IRON & STEEL GRP

Electric throttling distributor

ActiveCN101762126BReduce in quantityPrecise positioningEfficient regulation technologiesFluid circulation arrangementEngineeringDistributor

The invention belongs to an electric throttling distributor for a refrigerating system, which comprises a casing, an inlet, an inlet connecting pipe, a plurality of throttling holes, outlet connecting pipes and a stepping motor for driving, wherein the inlet connecting pipe is communicated with the inlet; the outlet connecting pipes are respectively communicated with the throttling holes. The interior of a valve cavity in the casing is also provided with an actuating part which is driven by a magnetic rotor part; the actuating part comprises a driving rod and a slide valve, wherein the slide valve is arranged opposite to the throttling holes. The stepping motor drives the slide valve to rotate to realize flow distribution between the throttling holes and a positioning mechanism is arranged between a rotatable rotating part and a fixing part in the valve cavity. The position relationship between the slide valve and the throttling holes is ensured by the positioning of the positioning mechanism; meanwhile, the system has the advantages of simple installation and connection, and low manufacturing cost.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Device and method for implementing local electroplating of parts

The invention discloses a device and a method for implementing local electroplating of parts. The device comprises a copper bottom plate, a copper cover plate, a conductive bar, screws, leads and a metal plate; when a blind hole part is locally electroplated, the non-electroplating part of the part is put into a groove of the copper bottom plate, then the copper cover plate is pressed on the metal plate, and the to-be-electroplated part of the part is naked outside the copper cover plate; when the local surface of a non blind hole part is electroplated, the non-electroplating part of the part is put into the groove of the copper bottom plate, and the to-be-electroplated surface is naked outside. The method comprises the following steps of: processing the copper bottom plate and the copper cover plate, chemically removing oil, coating a layer of vinyl perchloride varnish on the lower surface of the copper bottom plate and the upper surface of the copper cover plate respectively, airing the paint layers, fixing the part to be electroplated on the copper bottom plate, pressing the copper cover plate as required, then vertically hanging the whole assembly in the center of an electroplating bath, and switching on a power supply. The device has simple structure, is easy to process, accurately positions the plated surface of the part, saves the time and reduces the production cost.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

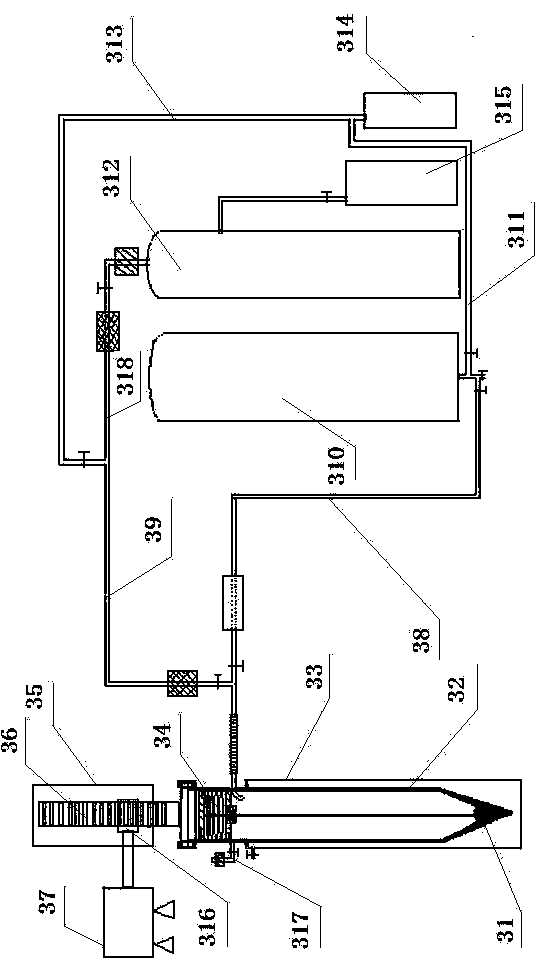

Automatic intermittent liquid culture inoculation system for edible mushrooms

The invention relates to an automatic intermittent liquid culture inoculation system for edible mushrooms. The automatic intermittent liquid culture inoculation system comprises a conveying system, and an inoculation device, an inoculation device cleaning sterilizer, a mushroom bag / bottle cleaning sterilizing assembly and a laminating device which are arranged above the conveying system, wherein the conveying system comprises a conveying belt; a plurality of paired fixed cards for placing mushroom bottles or mushroom bags are arranged on the conveying belt; the inoculation device is used for inoculation operation; the inoculation device cleaning sterilizer can perform sterilizing on the inoculation device; the mushroom bag / bottle cleaning sterilizing assembly is used for sterilizing the mushroom bags / bottles; and the laminating device is used for laminating holes formed by inoculation of the mushroom bags / bottles. The system can achieve continuous, rapid, positioning, quantitative and uniform inoculation of an inoculation needle; the inoculation device cleaning sterilizer can clean and sterilize the surface of the inoculation needle back and forth, so that cross contamination between the mushroom bags is avoided; the surfaces of the mushroom bags are cleaned and sterilized, so that a requirement on an inoculation environment is reduced; open inoculation can be performed; and the system is suitable for large-scale production of the bagged edible mushrooms.

Owner:百仑生物科技(江苏)有限公司

Automobile water storage tank, cooling system with the same and automobile with cooling system

The invention belongs to the automobile field and particularly relates to an automobile water storage tank, a cooling system with the automobile water storage tank and an automobile with the cooling system. The purpose is to provide a scheme of reducing the stress generated on the contact portion of the water tank and a girder. To solve the problem, the technical scheme is that the water storage tank used for the automobile cooling system comprises a water storage tank body, and the water storage tank body is an automobile body base plate or one part of the automobile body base plate. The automobile water storage tank has the advantages that the water storage tank serves as one part of the automobile body base plate or as the automobile body base plate, avoids that the water storage tank acts on the girder, particularly on a certain point of the girder and thus prevents fatigue stress from being generated. A closed cavity is distributed in an axisymmetric mode, so that the position of the water storage tank relative to the girder can be better balanced, and the fatigue stress can be prevented from being generated more effectively.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com