Full-automatic edge painting machine

An oil edge machine, fully automatic technology, applied to the surface coating liquid device, small raw hide/large raw hide/leather/fur treatment, leather surface treatment, etc., can solve the problem of affecting the quality of oil edge, uneven oiling, Low work efficiency and other problems, to achieve the effect of high product quality, improved reliability, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

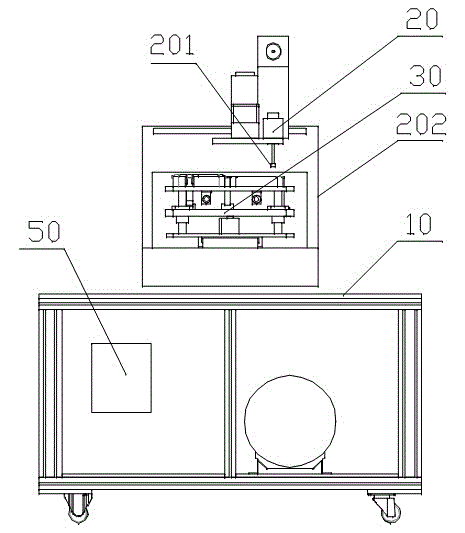

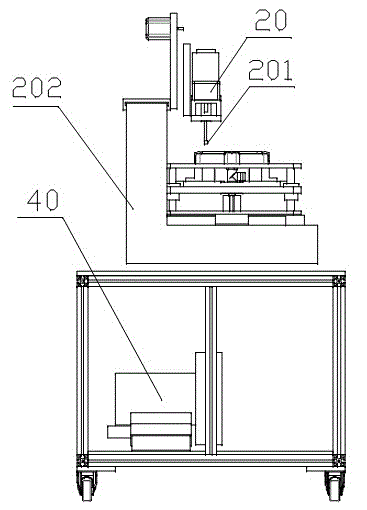

[0028] Such as figure 1 with figure 2 As shown, this example provides a fully automatic oil edge machine, including:

[0029] Rack 10;

[0030] The oil edge head assembly 20 installed on the frame 10, the oil edge head assembly 20 includes the oil nozzle head 201 and the mechanical shaft 202 for realizing the two-dimensional movement of the oil nozzle head 201;

[0031] A workpiece positioning device 30 for realizing oil edge positioning, the workpiece positioning device 30 is arranged on the frame 10, and is arranged below the oil edge head assembly 20;

[0032] A positioning pump 40 arranged in the frame 10, the positioning pump 40 is connected with the workpiece positioning device 30; and,

[0033] The control member 50 is used for controlling the oil edge process of the oil edge head assembly 20 , and controls the workpiece positioning device 30 and the positioning pump 40 to cooperate with the oil edge head assembly 20 respectively.

[0034] Wherein, the frame 10 bel...

Embodiment 2

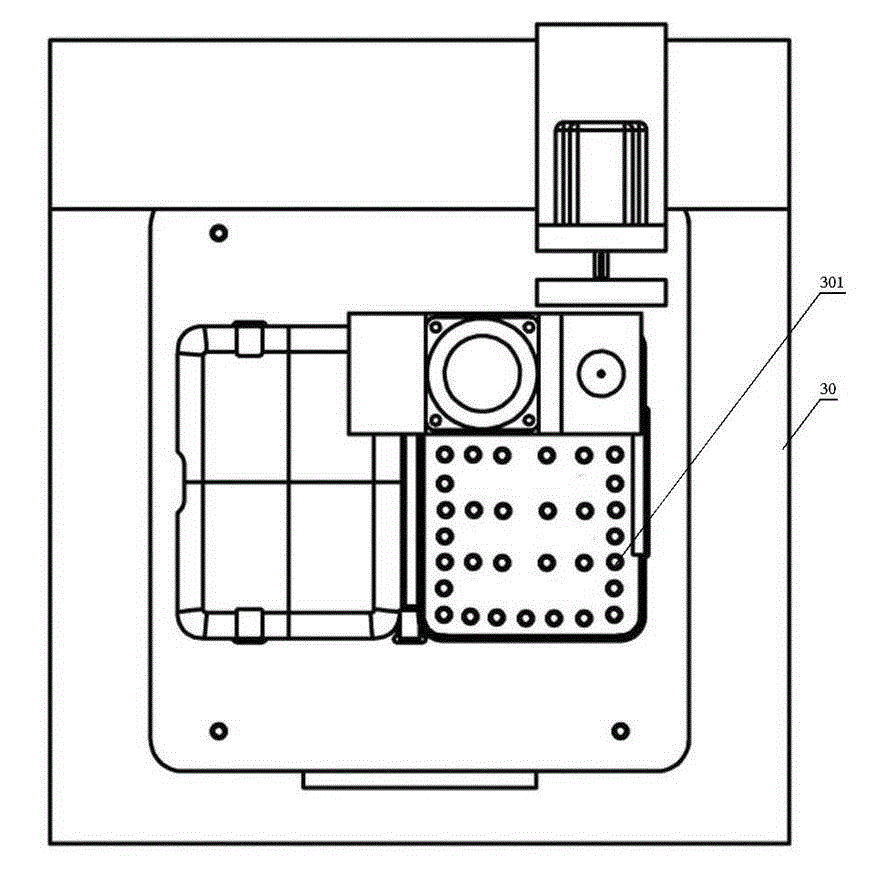

[0038] Such as image 3 As shown, on the basis of Embodiment 1, the further improvement of this example is that the upper surface of the workpiece positioning device 30 is provided with an air hole 301, the positioning pump 40 is an air pump, and the air hole 301 is connected to the air pump. Connection, in the oil edge process, the air hole 301 sucks the workpiece that needs oil edge through the air pump; after the oil edge is completed, the air pump stops working.

[0039] The upper surface of the workpiece positioning device 30 is used to place workpieces that require oil edge, and the upper surface of the workpiece positioning device 30 is provided with an air hole 301. During the oil edge process, the air pump can form a wind suction through the air hole 301, Suction the workpiece on the workpiece positioning device 30, and then on the basis of the positioning column, further realize the oil edge control without misalignment; after the oil edge is completed, the air pump ...

Embodiment 3

[0045] On the basis of Embodiment 1 or Embodiment 2, the oil nozzle head 201 in this example is connected to the control member 50 , and the control member 50 controls the fuel injection speed of the oil nozzle head 201 . Preferably, oil holes are evenly arranged on the circumference of the oil nozzle head 201 , and the oil nozzle head 201 realizes the self-rotation movement with adjustable speed during the oil edge process.

[0046] The control member 50 controls the oil injection speed of the oil nozzle head 201, which is convenient to control the oil injection speed of the oil nozzle head 201 according to different oil edge requirements or workpiece materials, improves the degree of customization, and has a high degree of humanized design. Furthermore, oil holes are uniformly arranged on the circumference of the oil nozzle head 201. During the oil edge process, the oil nozzle head 201 realizes the rotation movement, that is, the oil edge head assembly 20 controls the oil noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com