High-speed linear drive mechanism for hectograph

A linear drive mechanism and offset printing technology, applied in printing machines, rotary printing machines, printing, etc., can solve problems affecting printing quality and precision, short service life of chains, and cylinder stroke limitations, etc., to achieve uniform speed and excellent performance , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

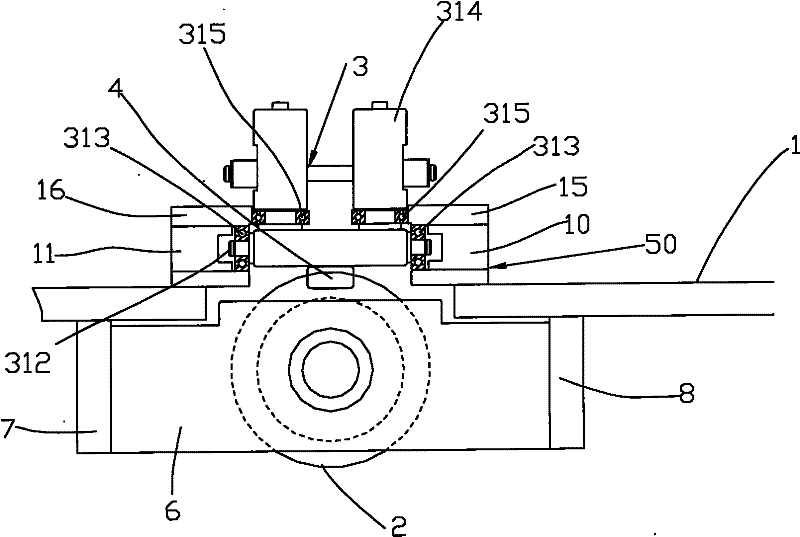

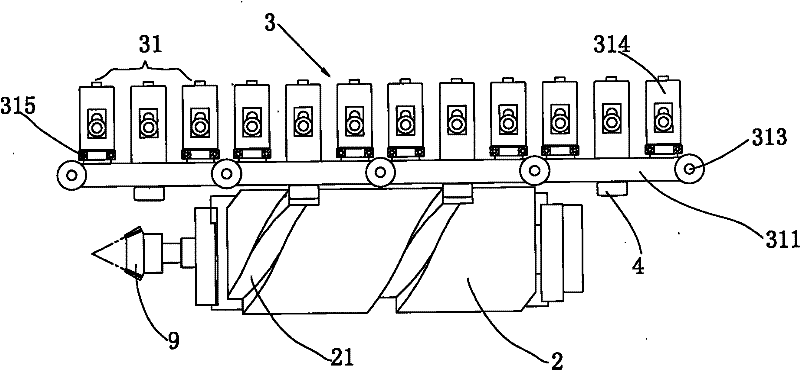

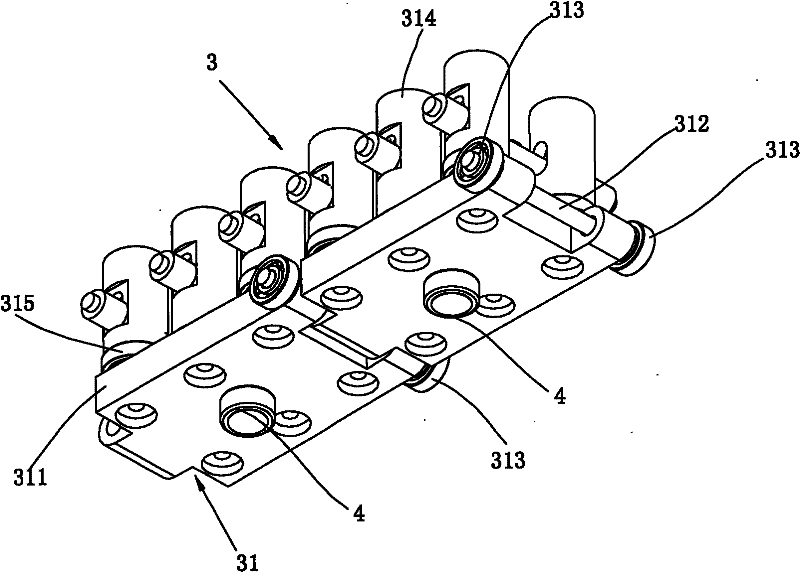

[0026] see Figure 1 to Figure 7 As shown, a linear drive mechanism for offset printing includes a frame 1 and a cam 2 placed below the frame 1. A transmission gear 9 for power transmission is provided at the front end of the cam 2. Along the top of the outer surface of the cam 2 The bottom end is provided with a cam curve groove 21, and a moving trolley group 3 is also arranged on the frame 1. A slide rail 50 is provided between the moving trolley group 3 and the frame 1. There are a plurality of roller bearings 4 that are spaced apart and matched with the cam curve groove 21. When the external power is input to the transmission gear 9, the gear 9 rotates and drives the cam 2 to rotate, and the cam 2 pushes the roller bearing 4 on the cam curve. Sliding in the groove 21, the roller bearing 4 will drive the moving trolley group 3 to run in the slide rail 50 simultaneously, finally forms the high-speed linear movement of the moving trolley group.

[0027] The linear drive mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com