Automatic intermittent liquid culture inoculation system for edible mushrooms

A liquid strain, intermittent technology, applied in the fields of application, horticulture, botany equipment and methods, etc., can solve problems such as difficult control of inoculation amount, inconsistent mushrooming and improper operation, etc., to improve labor efficiency and structure The effect of reasonable design and uniform inoculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

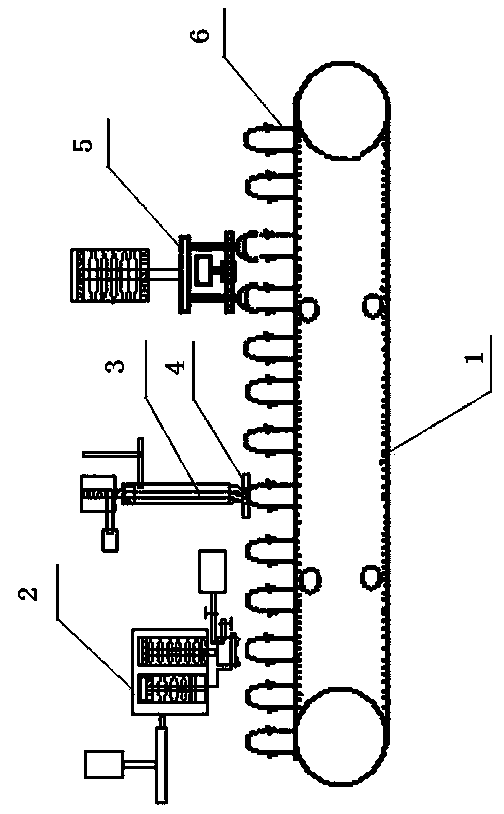

[0041] Embodiment 1, with reference to Figure 1-7 , an automatic intermittent edible fungus liquid strain inoculation system, the system includes a delivery system 1 and an inoculation device 3 located above the delivery system 1, an inoculation device cleaning sterilizer 4, a bacteria bag / bottle cleaning and sterilization assembly 5 and Laminating device 2;

[0042] The conveying system 1 includes a conveyor belt, on which several fixed cards 6 for placing bacteria bottles or bacteria bags arranged in pairs are provided;

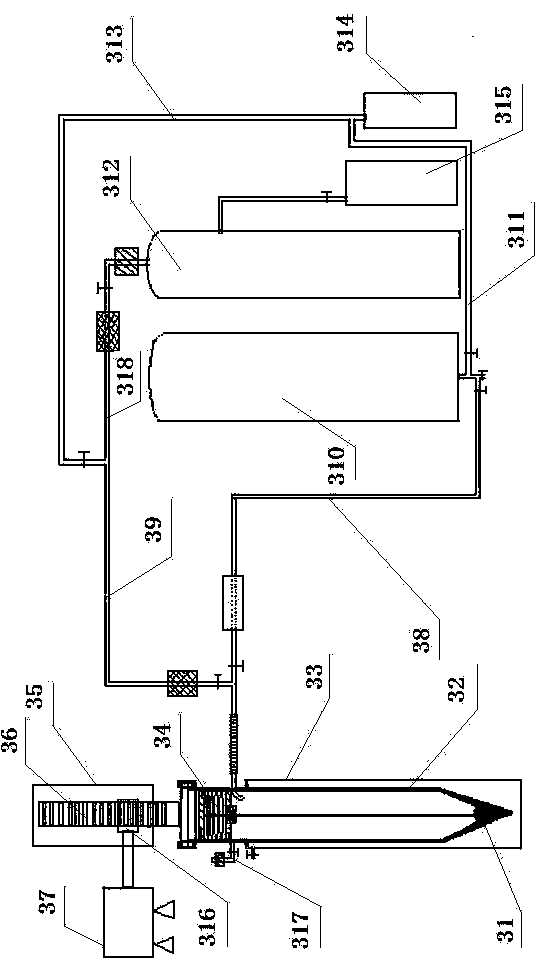

[0043] Described inoculation device 3 comprises inoculation needle 32, and inoculation needle 32 is fixed on the inoculation reciprocating slide bar 36 by connector, and inoculation reciprocating slide bar 36 is located in the chute of inoculation base 35, and inoculation reciprocating slide bar 36 and propulsion gear 316 meshing, the propulsion gear 316 is located at the power output end of the inoculation motor 37; the inoculation needle sleeve 33 with ...

Embodiment 2

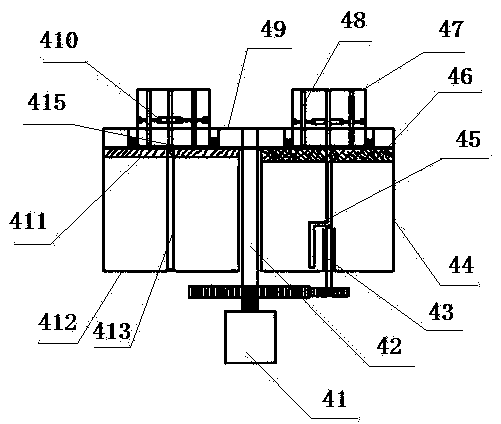

[0047] Embodiment 2, in the automatic intermittent type edible mushroom liquid spawn inoculation system described in Embodiment 1, the first actuator 34, the second actuator 55, the third actuator 27 and the fourth actuator 28 are selected from Solenoids, pneumatic actuators, electric actuators and hydraulic actuators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com