Electric throttling distributor

An electric throttling and distributor technology, applied in the direction of high-efficiency regulation technology, fluid circulation arrangement, climate sustainability, etc., can solve the problems of stepper motor out-of-step or skipping, complicated pipeline connection and large number of parts, etc. Achieve the effect of low manufacturing cost, uniform flow distribution, and convenient use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

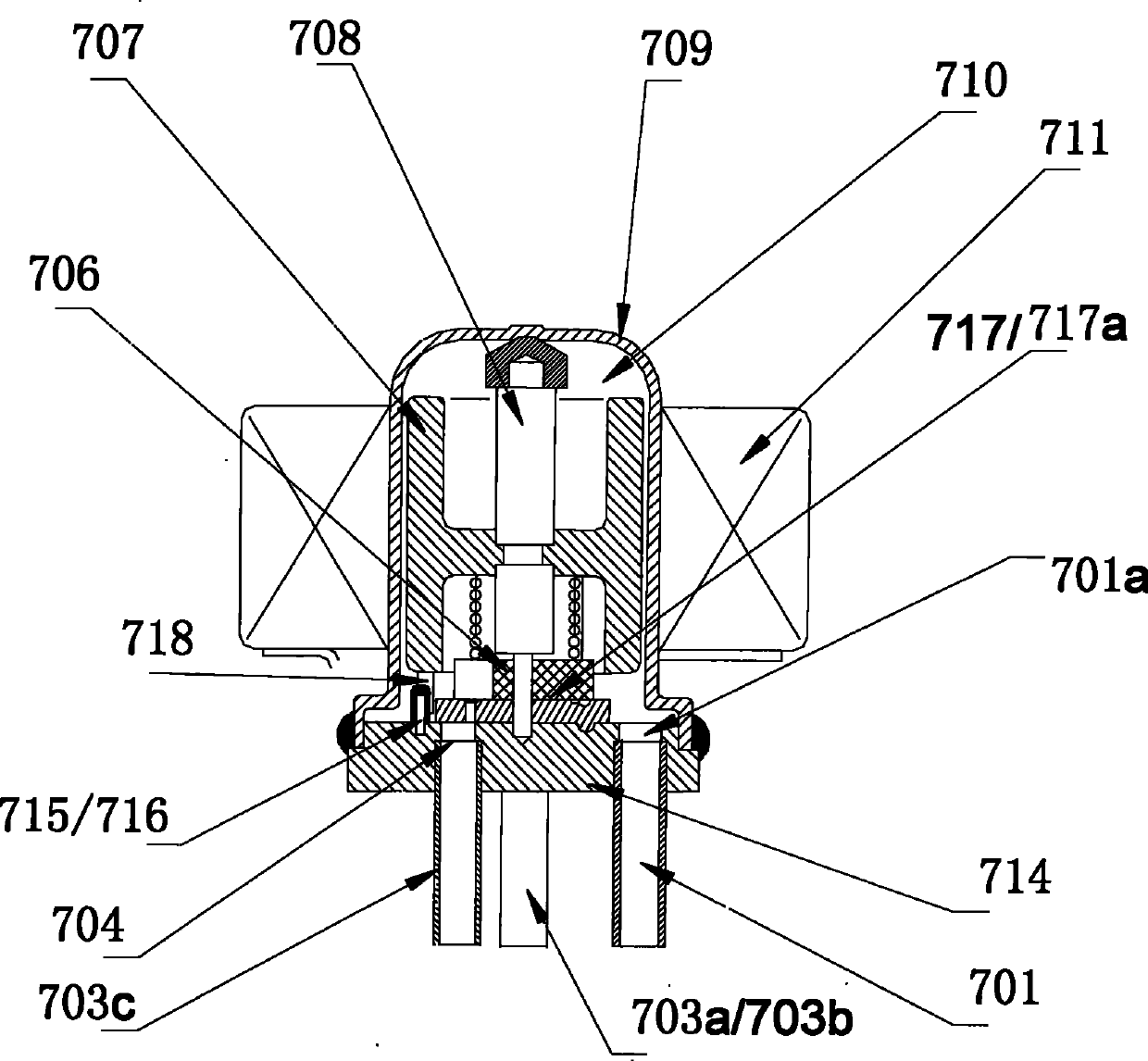

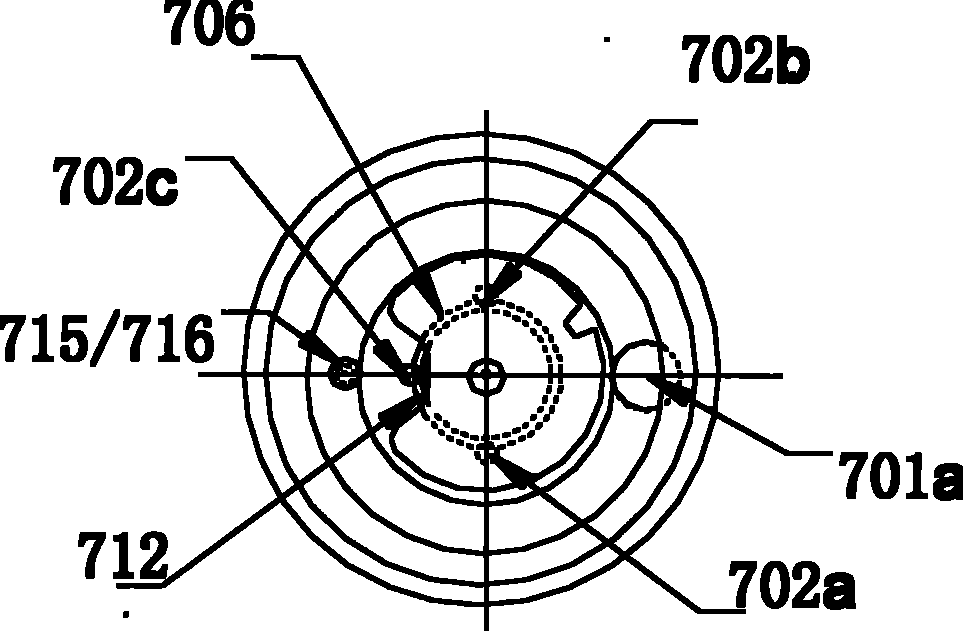

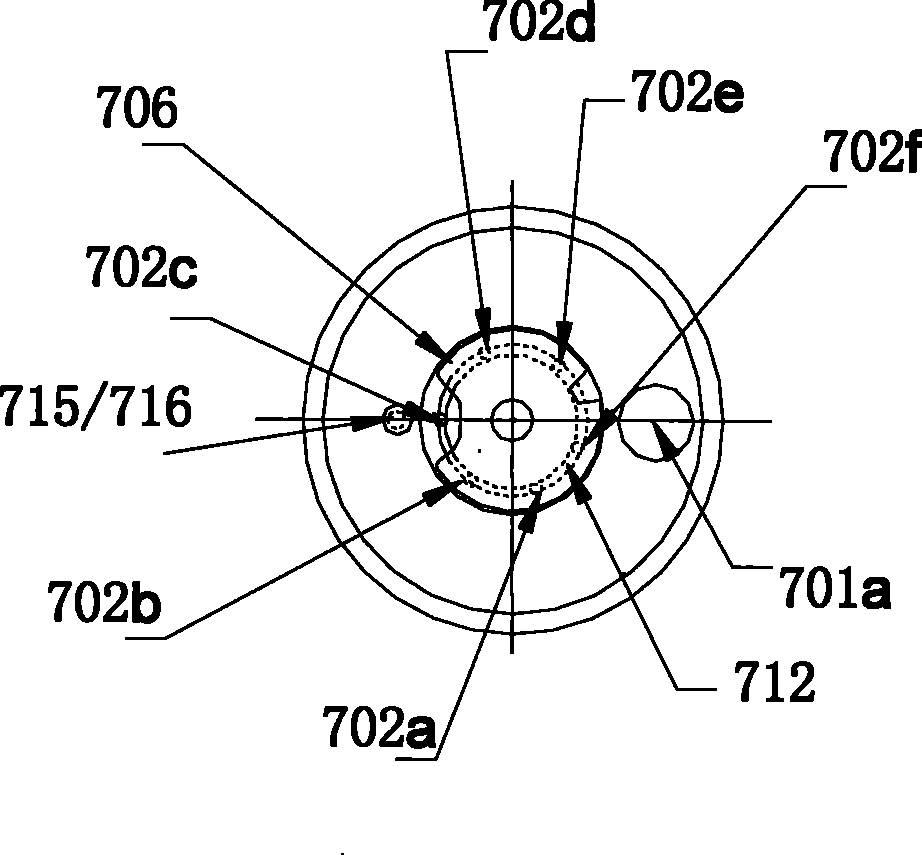

[0035] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the first embodiment of the electric throttling distributor of the present invention, figure 2 for figure 1 The schematic diagram of the local structure of the base part and the slide valve of the electric throttle distributor shown. As shown in the figure, in this embodiment, the electric throttling distributor includes a casing 709, and the fixing part in this embodiment also includes a base part, and the base part includes a base 714 and a bottom plate 717, and the base 714 and the casing 709 are welded and hermetically fixed And jointly form a valve cavity 710, the base 714 is also provided with an inlet 701a and a plurality of outlet through holes and welded and fixed with the inlet connecting pipe 701 communicating with the inlet, and the outlet connecting pipes 703a, 703b, 703c communicating with a plurality of outlet through holes The outer casing 709 is fixed with the coil part 711 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com