Automatic gluing machine used for automobile luggage rack

A car luggage rack and gluing machine technology, which is applied in the field of automatic gluing of car luggage racks, can solve problems such as inability to achieve uniform gluing of products, affect product processing quality, and fail to be in the center position, so as to increase the stability of gluing , increase the range of gluing, reduce the effect of eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

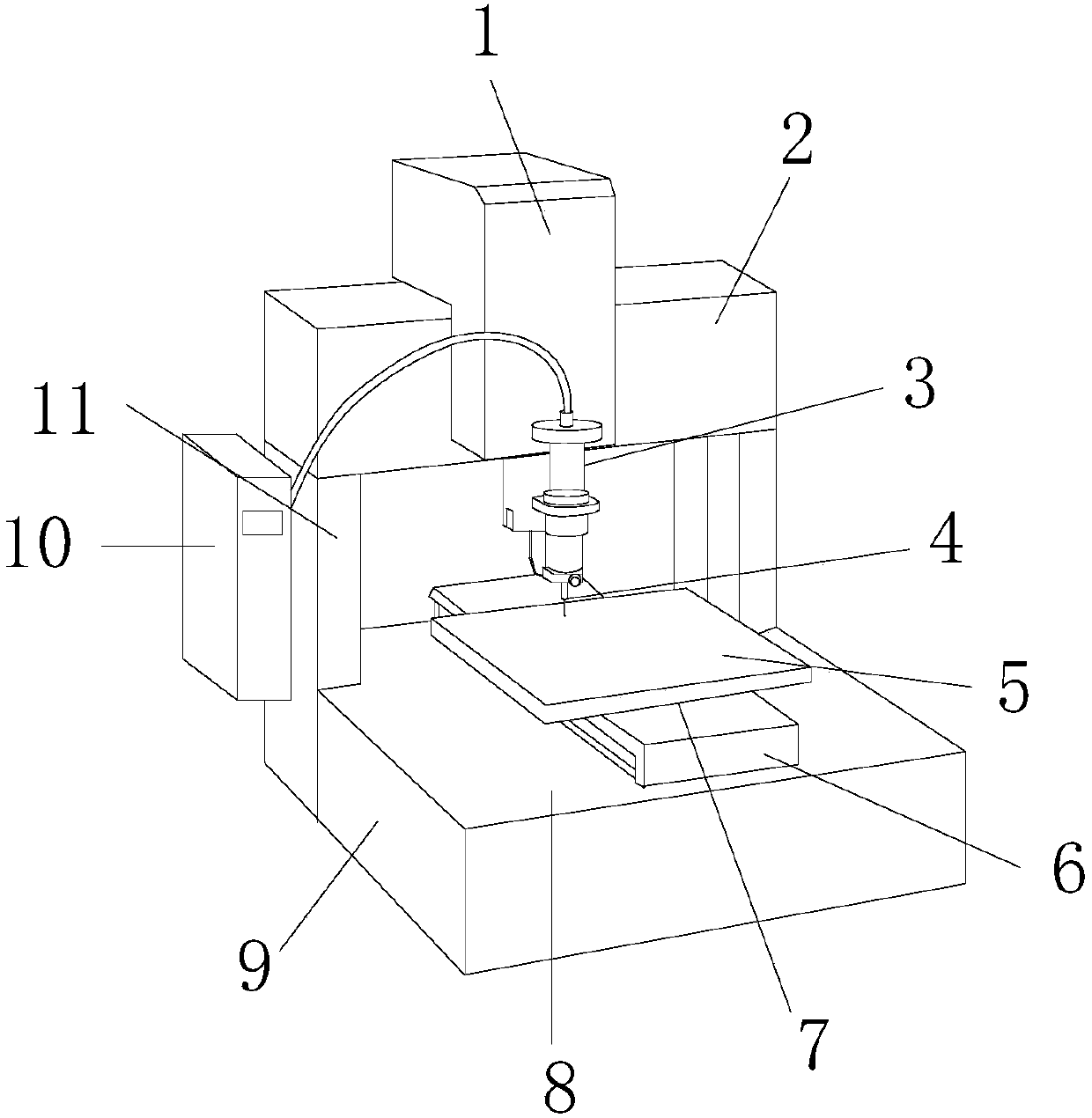

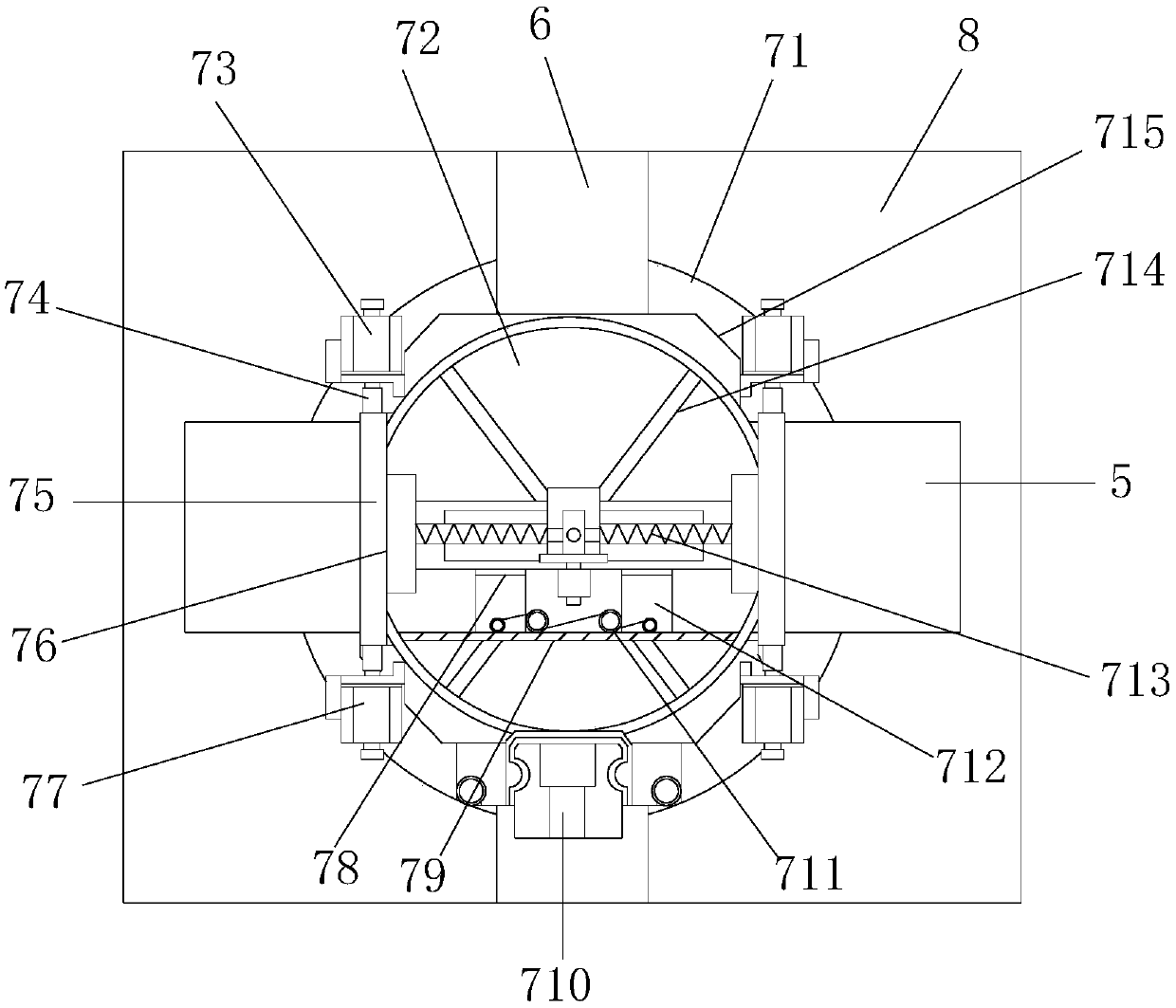

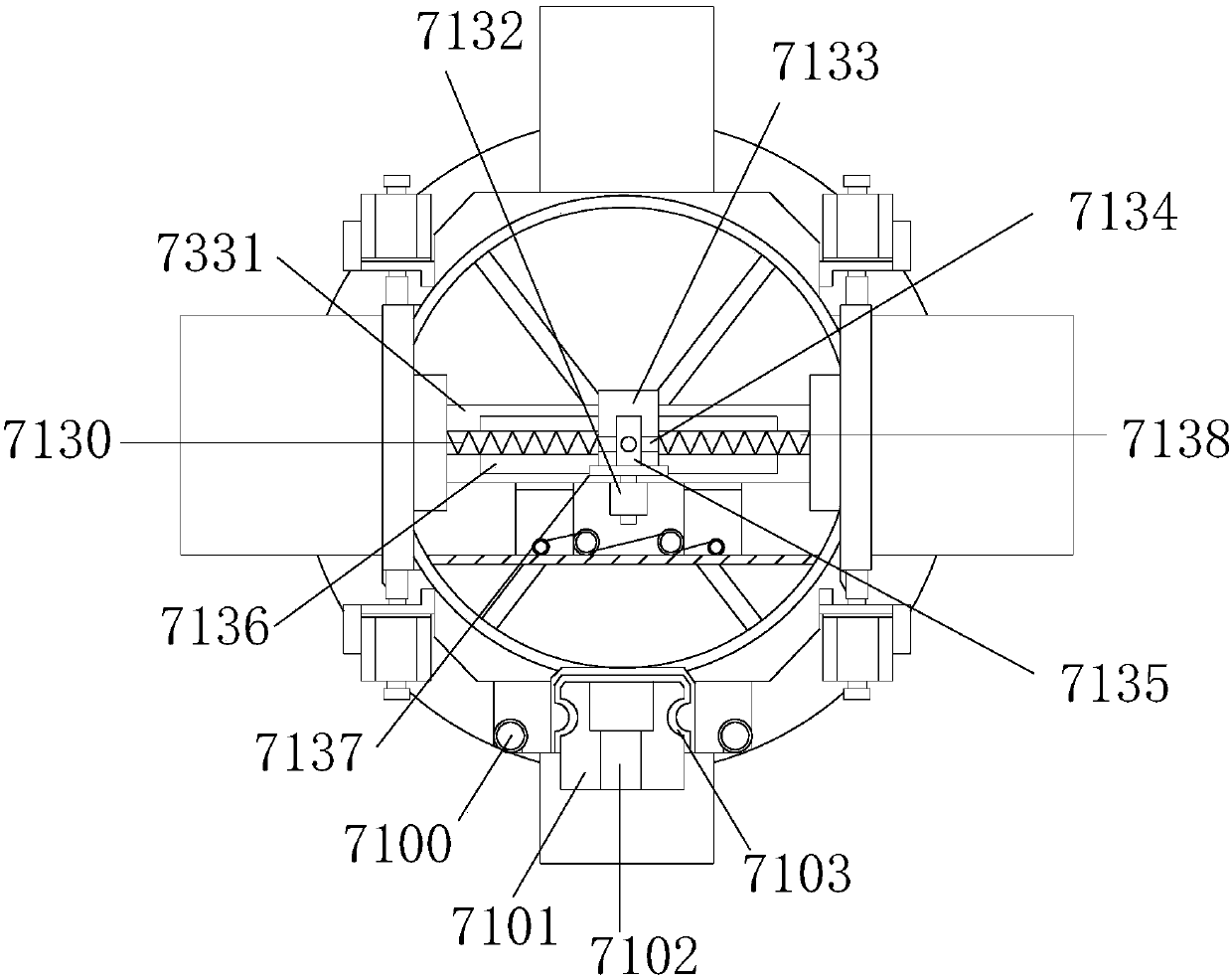

[0023] see Figure 1 to Figure 3, the present invention provides an automatic gluing machine for automobile luggage rack, its structure includes gluing stroke movement shaft 1, sliding rail seat 2, rubber storage bottle 3, gluing valve head 4, workpiece fixing frame 5, bottom sliding Rail 6, multi-station rotary positioning mechanism 7, work surface 8, fixed base 9, gluing controller 10, frame 11, described fixed base 9 is square structure, described fixed base 9 top and work surface 8 is an integrated structure, the left and right ends of the rear end of the worktable 8 are fixedly connected with the frame 11 and are perpendicular to each other, one end of the frame 11 is movable with a glue controller 10, and the top of the frame 11 is connected to the sliding rail Seats 2 are connected and vertical, the sliding rail seat 2 and the working surface 8 are parallel to each other, the movement shaft 1 of the glue-making stroke is installed on the sliding rail seat 2 and is exces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com