A slag stopper for ladle pouring slag stopper and its preparation and slag stopper method

A technology of slag blocking plug and plug body, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problem that slag is not easy to control, and achieve the effect of reducing the amount of slag, simple production and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Raw material ratio: 10-30mm grain steel 25.1%, 5-10mm grain steel 25.2%, 3-5mm grain steel 13.8%, 0-3mm grain steel 12.8%, high alumina fine powder 13.5%, calcium aluminate Cement 9.2%, sodium tripolyphosphate 0.4%.

[0056] The preparation method is as follows:

[0057] Put granular steel, steel fine powder and high alumina fine powder of different particle grades into the mixer according to the ratio, and add refractory binder and water reducer at the same time to mix the dry material. The mixing time of the dry material is controlled at 5 to 8 minutes. Then add water to mix the wet material. The amount of water added is controlled between 6.5 and 7.5 wt% of the total weight of the raw materials. Generally, due to the influence of the water absorption of the raw materials in summer and winter, the amount of water added is slightly changed. The mixing time of the wet material is 8 to 10 minutes. After mixing, put the wet material into a special mold, vibrate and form ...

Embodiment 2

[0061] Raw material ratio: 10-30mm grain steel 24.7%, 5-10mm grain steel 25.6%, 3-5mm grain steel 13.5%, 0-3mm grain steel 13.7%, high alumina fine powder 12.6%, calcium aluminate Cement 9.4%, sodium tripolyphosphate 0.5%.

[0062] The preparation method is the same as in Example 1.

[0063] The performance indicators of the slag stopper obtained by adopting the process of this embodiment and the ratio of raw materials are shown in the following table:

[0064]

[0065]

Embodiment 3

[0067] Raw material ratio: 10-30mm grain steel 23.7%; grain steel grain size 5-10mm 27.3%; grain steel grain size 3-5mm 13.1%; grain steel grain size less than 3mm 13.2%; steel fine powder 13.4%; Binder 8.9%; water reducing agent 0.4%.

[0068] The preparation method is the same as in Example 1.

[0069] The performance indicators of the slag stopper obtained by adopting the process of this embodiment and the ratio of raw materials are shown in the following table:

[0070]

[0071] The following introduces the usage method of the slag stopper of the present invention:

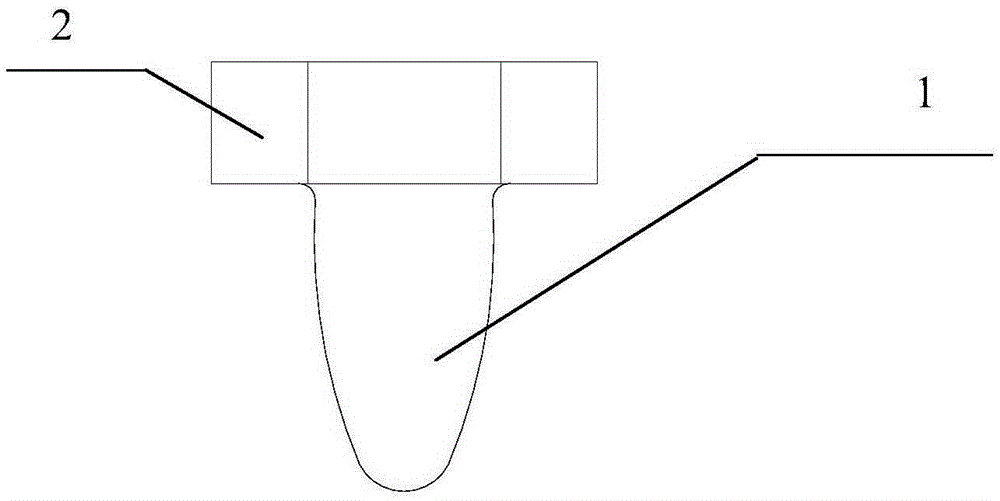

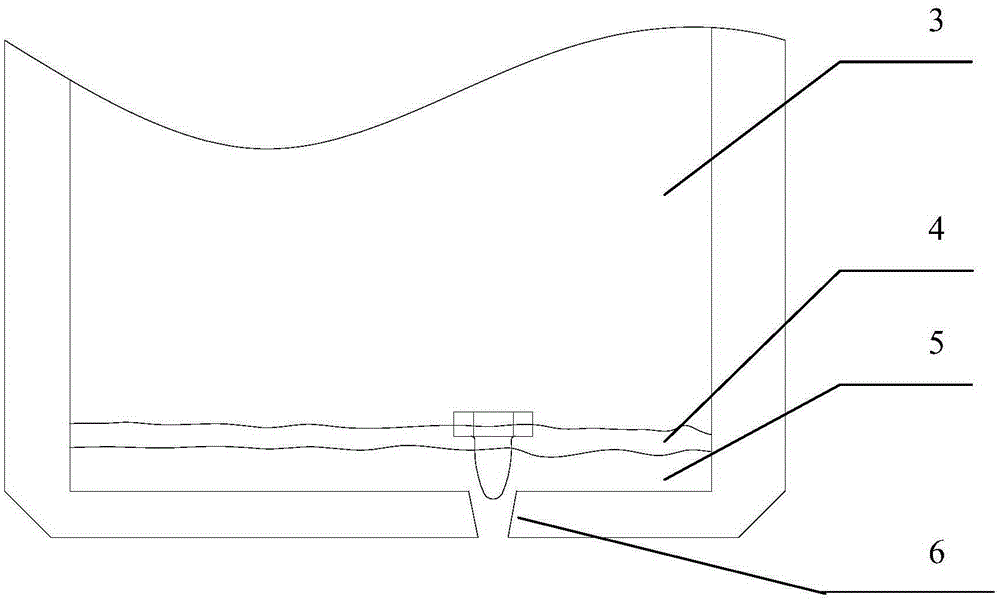

[0072] After the molten steel is refined out of the station and before pouring, the slag stopper is put into the ladle above the ladle nozzle bowl. Since the inside and outside of the slag stopper are homogeneous, the bulk density is 4.0g / cm 3 , the slag stopper falls to the molten steel and slag interface under the action of gravity, and the ladle pouring process produces a vortex flow with the drop of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com