Electroplating clamp of solar cell

A technology for solar cells and electroplating fixtures, applied in circuits, electrolytic processes, electrolytic components, etc., can solve the problems affecting the electroplating quality of cells, easy to break the cells, and offset the position of cells, and improve the quality and efficiency of electroplating , reduce the breakage rate and avoid the effect of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Before explaining the technical solutions of the various embodiments of the present invention in detail, the terms and terms involved will be explained. It should be noted that in this specification, components with the same name or the same number represent similar or identical structures, and are for illustrative purposes only.

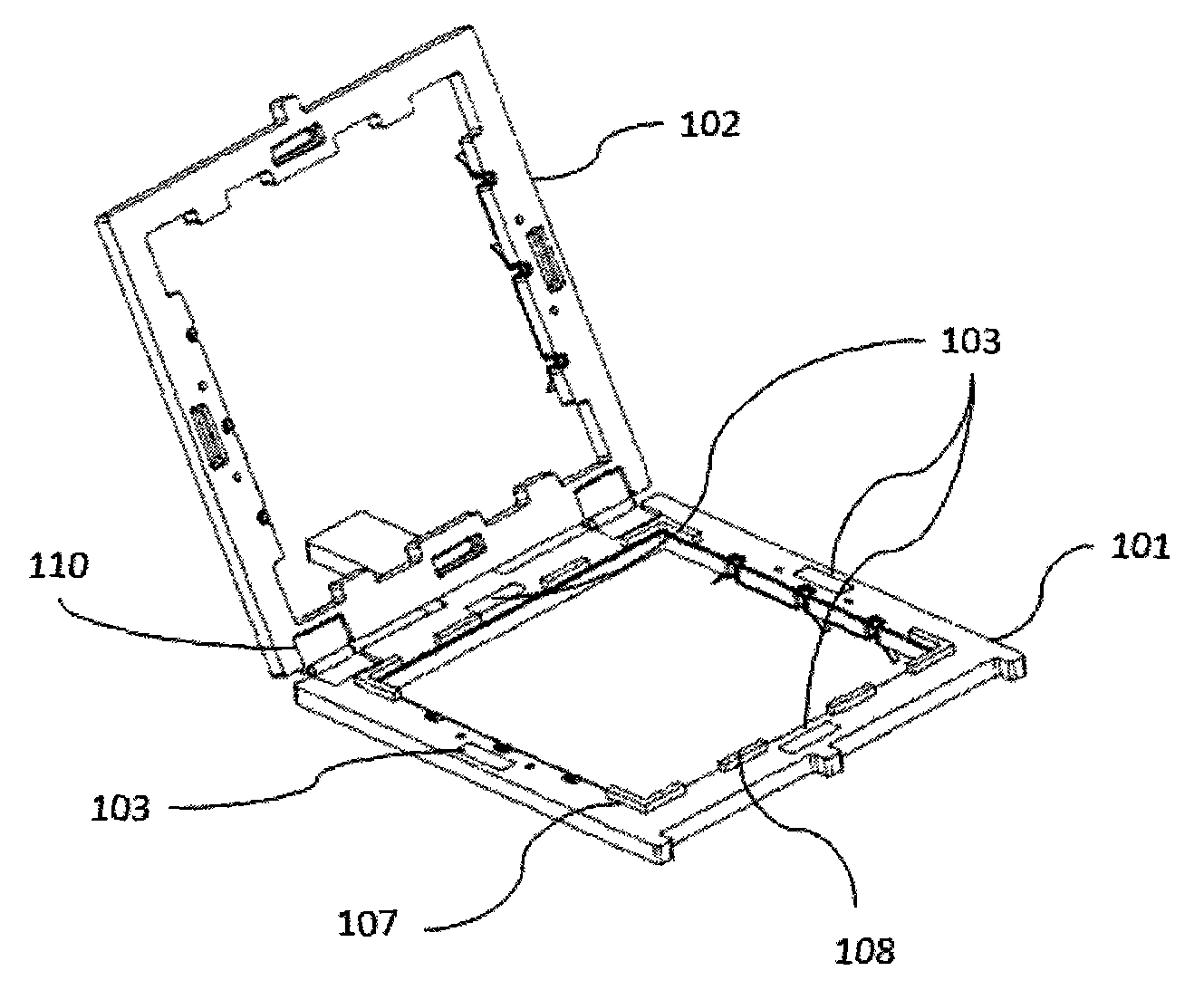

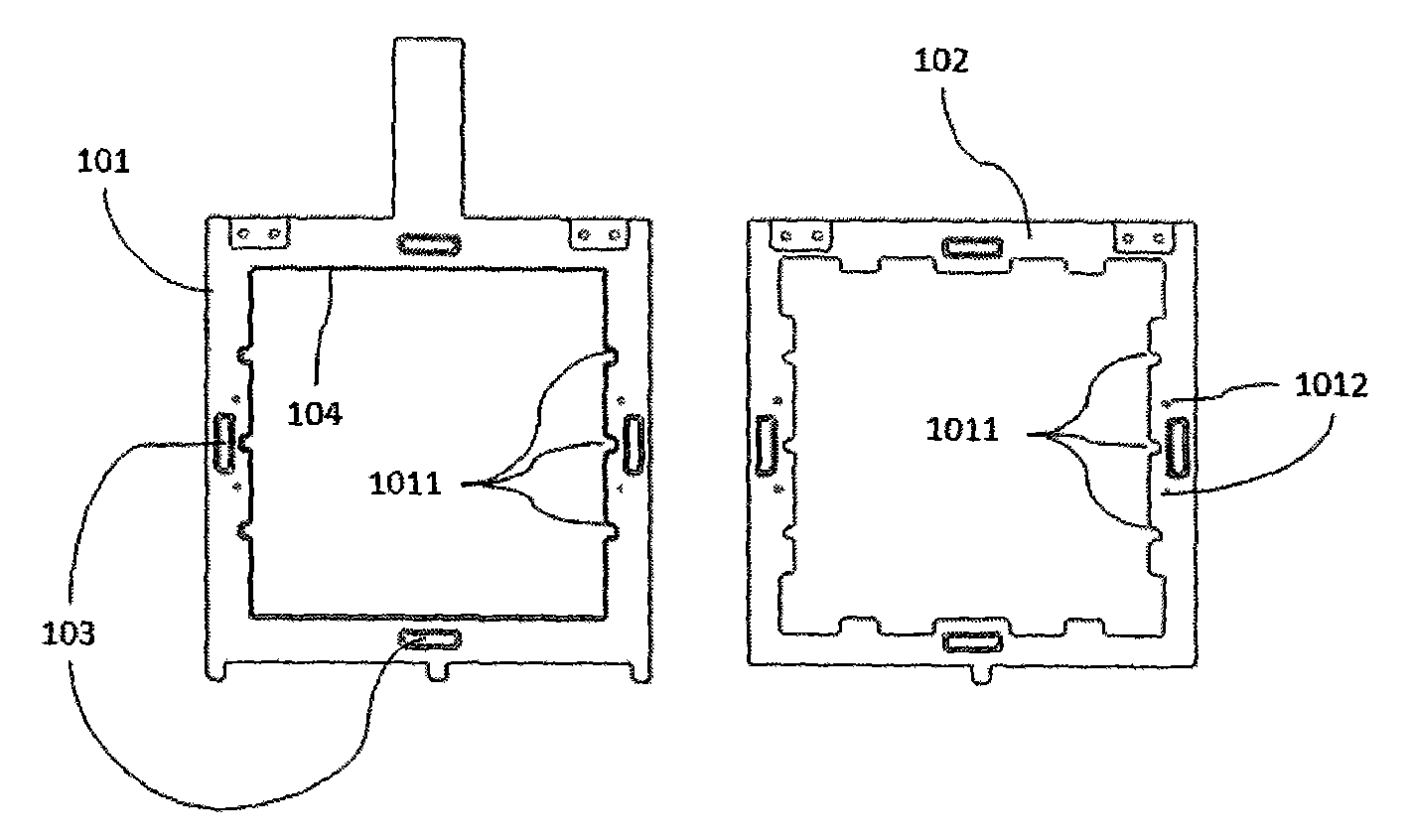

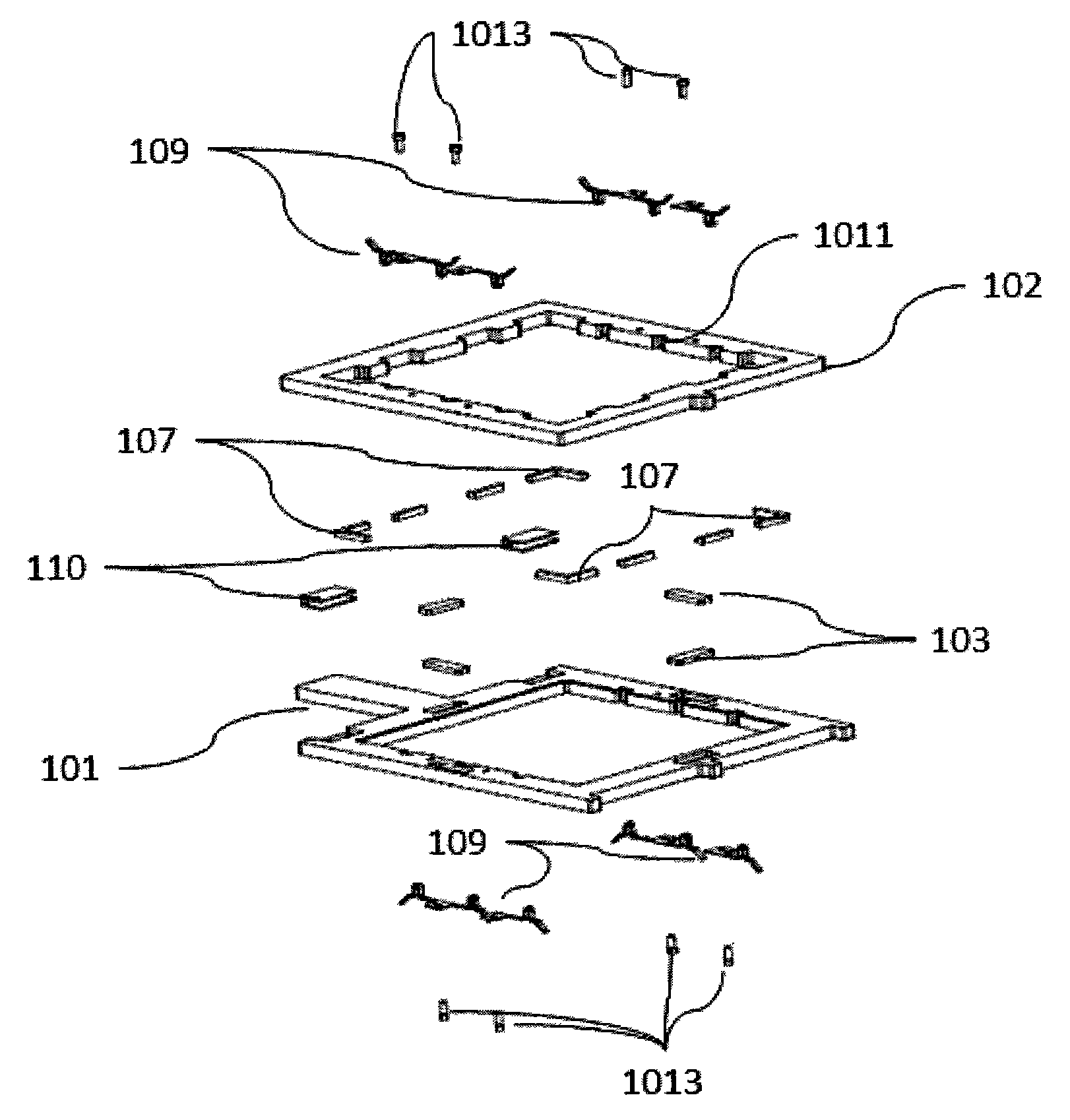

[0036] figure 1 It is a structural schematic diagram of the first embodiment of the solar cell sheet electroplating jig of the present invention. Such as figure 1 As shown, the solar cell sheet electroplating jig of the present invention includes a first frame 101, a second frame 102 and a plurality of magnets 103; the first frame 101 and the second frame 102 are hollow, and the first frame 101 is in contact with the edge portion of the second frame 102 and clamps the battery sheet; the plurality of magnets 103 are symmetrically fixed on the first frame 101 or the second frame 102 respectively, and the first frame is magnetically 101 is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com