Production principle and process of special fracturing propping agent with strong anti-pressure ability

A technology of fracturing proppant and compressive capacity, which is applied in the field of fracturing proppant, which can solve the problems of weak compressive capacity of fracturing proppant, unfavorable support and diversion use, high cost, etc., and achieve good fluidity , low breakage rate, good ball forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

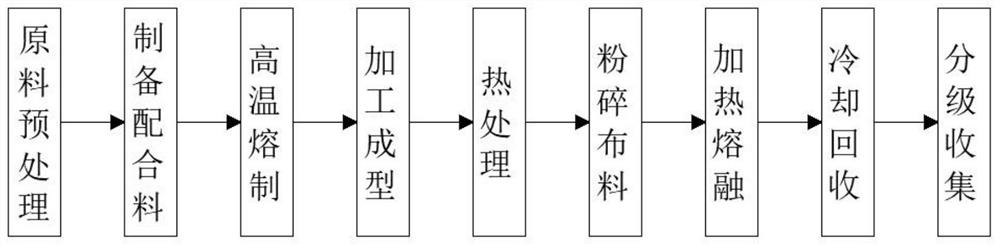

Method used

Image

Examples

Embodiment 1

[0052] After the block is first prepared silica sand, soda ash, limestone, and feldspar raw materials, the grinding process, and to ensure that material is dried, pulverized and the raw material for processing iron treatment to ensure the quality of raw materials, and then taking 45 parts quartz powder, 35 parts of soda ash powder, limestone powder prepared by mixing 14 parts and 34 parts of feldspar raw batch, the batch in crucible furnaces or kilns 1600 ℃ high-temperature heating, so as to form a uniform, bubble-free, and meet the molding requirements The liquid proppant will be formed by high-temperature machining, by annealing, quenching, etc., cleans or produce stress, phase-phase or crystallization of the proppant, and changing the structural state of the proppant, and will be molded The proppant is pulverized to 70 mesh-140 mesh, and the powder is uniformly put into the special bead furnace by the cloth, and heats melt in a high temperature gas stream of 1800 ° C, and a sph...

Embodiment 2

[0055] First prepare raw materials such as stone-shaped sand, pure base, limestone, and lear, comminution, and ensure drying of raw materials, and carry out the iron treatment, to ensure the quality of the raw material, then take 40 parts of the stone powder. 32 copies of pure alkali powder, 37 pieces of limestone powder and 11 parts of longite powder, mixed with a mixture of 1550 ° C in the pool kiln or crucible kiln, so that it is uniform, no bubbles, and conforms to form requirements. The liquid proppant will be formed by high-temperature machining, by annealing, quenching, etc., cleans or produce stress, phase-phase or crystallization of the proppant, and changing the structural state of the proppant, and will be molded The proppant is pulverized to 40 mesh-70 mesh, and the powder is uniformly put into the special bead furnace by the fracture, heating in a high temperature gas stream at 1750 ° C, forming a spherical proppant under the surface tension of the proppant, In order ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com