Method for drying tobacco shreds, tobacco shreds, tobacco products and application

A technology for tobacco products and shredded tobacco, which is applied to tobacco products and the application of shredded tobacco, shredded tobacco and dried shredded tobacco, can solve the problems of poor sensory quality and product stability of cigarettes, high shredding rate of shredded tobacco, and low filling value, etc., so as to improve the sensory quality and product stability, reducing the proportion of macular smoke and mildew smoke, and reducing the effect of breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

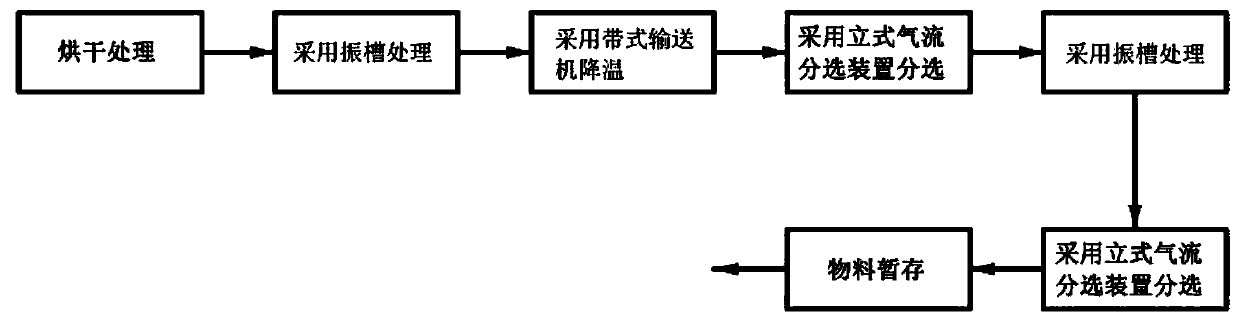

[0048] The ambient temperature is 30.3°C, and the relative humidity of the environment is not higher than 70%. Such as figure 2 Shown, the method for drying flue-cured tobacco cut tobacco comprises:

[0049] (1) Dry flue-cured tobacco shreds with an airflow drying machine, the material flow rate is 4800kg / h, and the dried material with a temperature of 71±3°C and a moisture content of 14.6±0.4% is obtained;

[0050] (2) The drying material is processed through two series vibrating tanks (the size of a single vibrating tank: 6 meters long and 1 meter wide), with a conveying speed of 0.28m / s, a vibration frequency of 4.33Hz, and an amplitude of 25mm. The temperature of the material at the outlet is 55±5°C;

[0051] (3) Cool the processed material through the belt conveyor, the conveying speed is 0.65-0.70m / s, the conveying time is 18-21 seconds, and the temperature of the material at the outlet of the belt conveyor is 49±5°C;

[0052] (4) The material obtained in step (3) is...

Embodiment 2

[0057] The ambient temperature is 30.1°C, and the relative humidity of the environment is not higher than 70%. Such as figure 2 Shown, the method for drying flue-cured tobacco cut tobacco comprises:

[0058] (1) Dry flue-cured tobacco shreds with an airflow drying machine, the material flow rate is 4800kg / h, and the dried material with a temperature of 71±3°C and a moisture content of 13.8±0.5% is obtained;

[0059] (2) The drying material is processed through two vibrating tanks in series (the size of a single vibrating tank: 6 meters long and 1 meter wide), with a conveying speed of 0.28m / s, a vibration frequency of 4.33Hz, and an amplitude of 28mm. The temperature of the material at the outlet is 53±5°C;

[0060] (3) Cool the processed material through the belt conveyor, the conveying speed is 0.67m / s, the conveying time is 18-21 seconds, and the temperature of the material at the outlet of the belt conveyor is 47±5°C;

[0061] (4) The material obtained in step (3) is s...

Embodiment 3

[0066] The ambient temperature is 29.8°C, and the relative humidity of the environment is not higher than 70%. Such as figure 2 Shown, the method for drying flue-cured tobacco cut tobacco comprises:

[0067] (1) Drying the shredded flue-cured tobacco with a drum-type shred dryer, with a material flow rate of 2400kg / h, to obtain a dried material with a temperature of 58±3°C and a moisture content of 13.5±0.4%;

[0068] (2) The drying material is processed through two series vibrating tanks (the size of a single vibrating tank: 5.5 meters long and 0.9 meters wide), with a conveying speed of 0.28m / s, a vibration frequency of 4.33Hz, and an amplitude of 25mm. The temperature of the material at the outlet is 48±5°C;

[0069] (3) Cool the processed material through the belt conveyor, the conveying speed is 0.67m / s, the conveying time is 10-12 seconds, and the temperature of the material at the outlet of the belt conveyor is about 43±3°C;

[0070] (4) Sorting the material obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com