Bridge-crossing conveying vibrating-pressing threshing device of combine harvester

A technology of combine harvester and threshing device, which is applied in the direction of harvesters, threshing equipment, agricultural machinery and implements, etc. It can solve the problems of affecting threshing effect, uneven maturity, and grain damage, so as to reduce the broken rate and ensure the quality of threshing , the effect of high cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

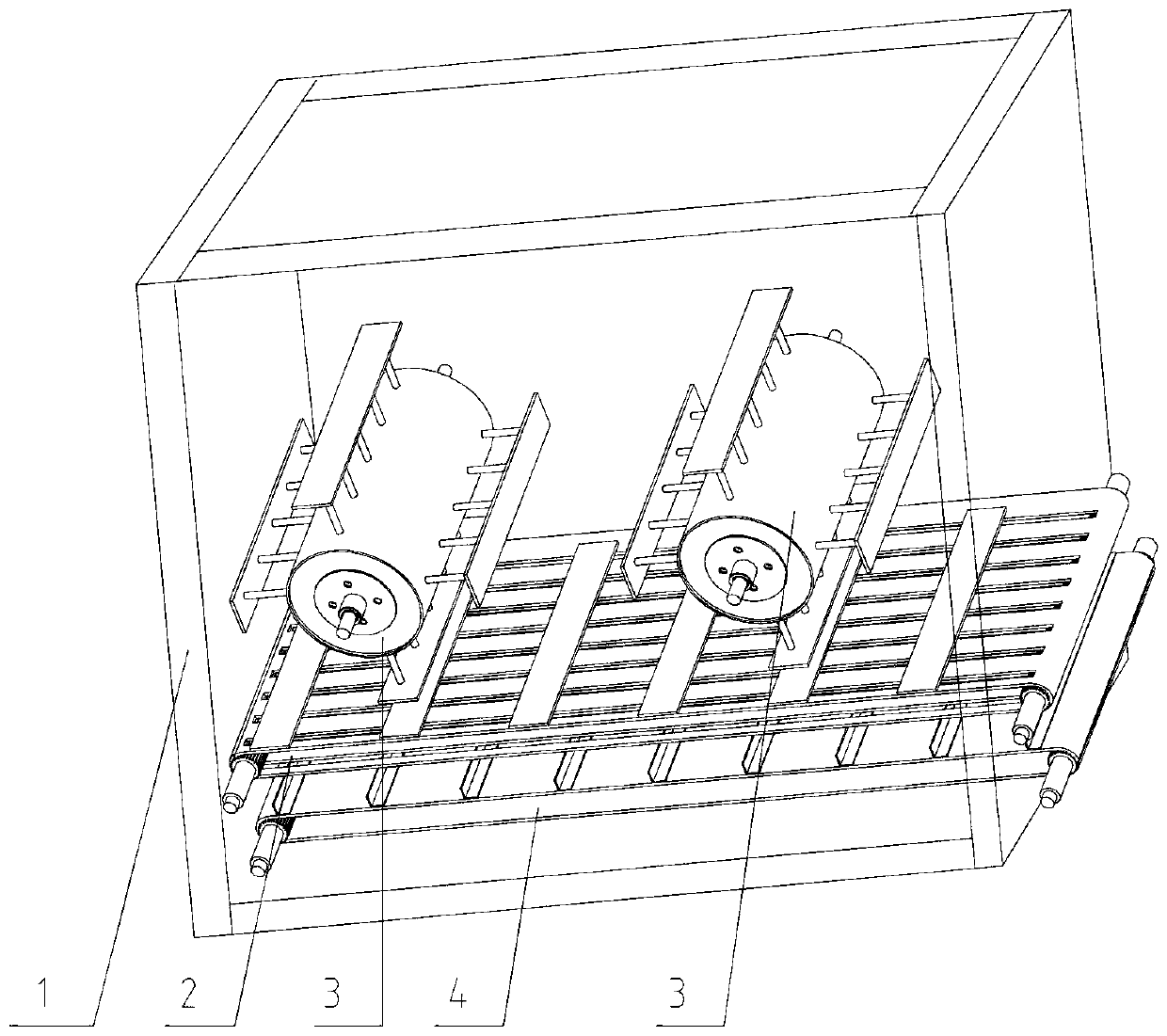

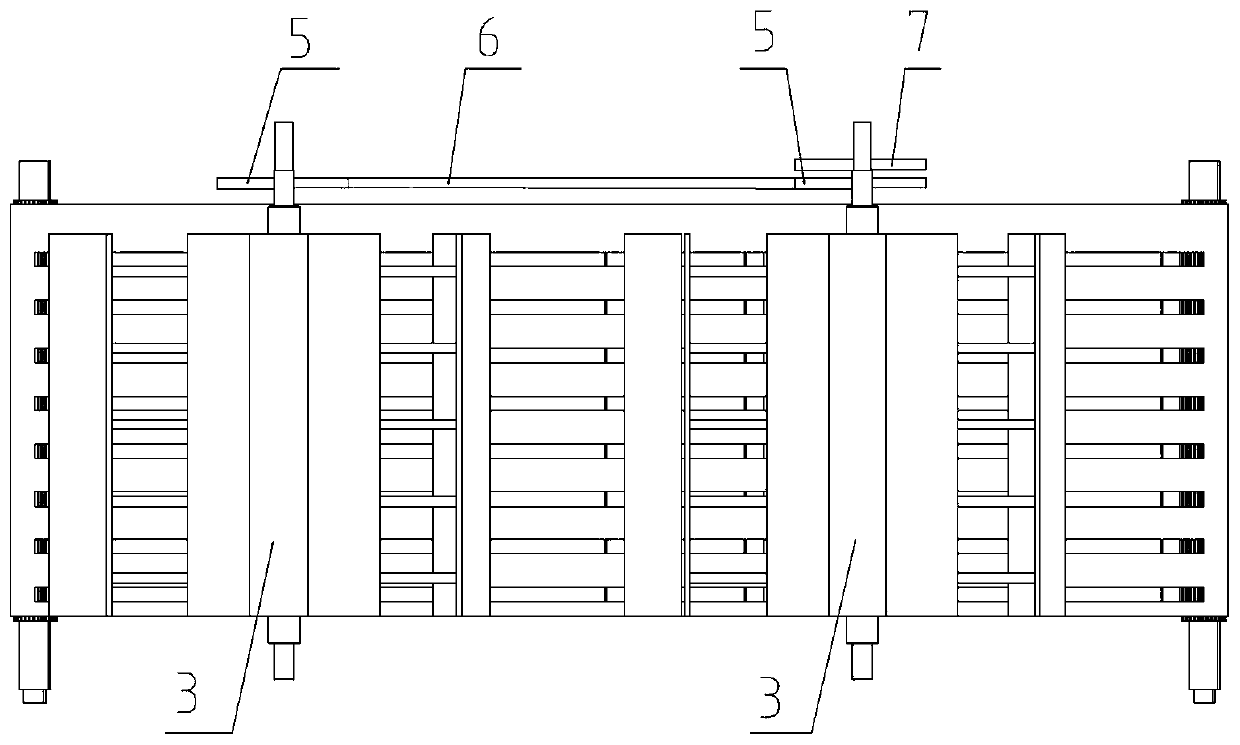

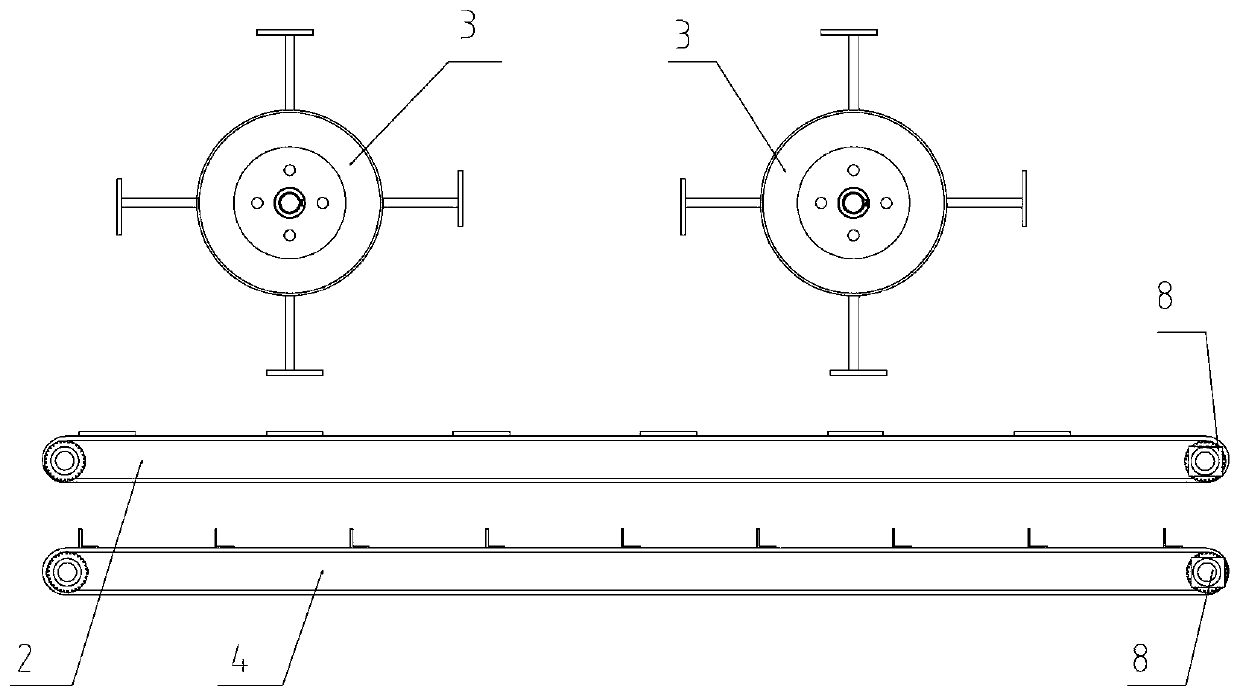

[0024] The combined harvester of the present embodiment bridge-transporting vibration pressure threshing device is as follows: Figures 1 to 6 As shown, it includes a conveying mechanism supported on a frame-type bridge support 1, which is composed of an upper plant conveying vibrating belt 2 and a lower grain conveying belt 4, and two grain conveying belts 4 are installed above the conveying mechanism. Vibration pressure type threshing drums 3 distributed at intervals. Wherein the cylinder shaft of the rear threshing cylinder is fixedly connected with the driving wheel 7 driven by the sprocket wheel 5 and the conveyor belt drive motor 8, and is connected with the chain wheel transmission on the front vibration pressure type threshing cylinder 3 cylinder shaft by the chain 6.

[0025] The plant conveying vibration pressure belt 2 is composed of a vibration pressure belt 2-2 that surrounds the driving roller shaft 2-1 at both ends. Rubber material flexible vibration plate 2-2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com