Anisotropic NdFeB magnet compression molding device

An Anisotropic, Oriented Forming Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

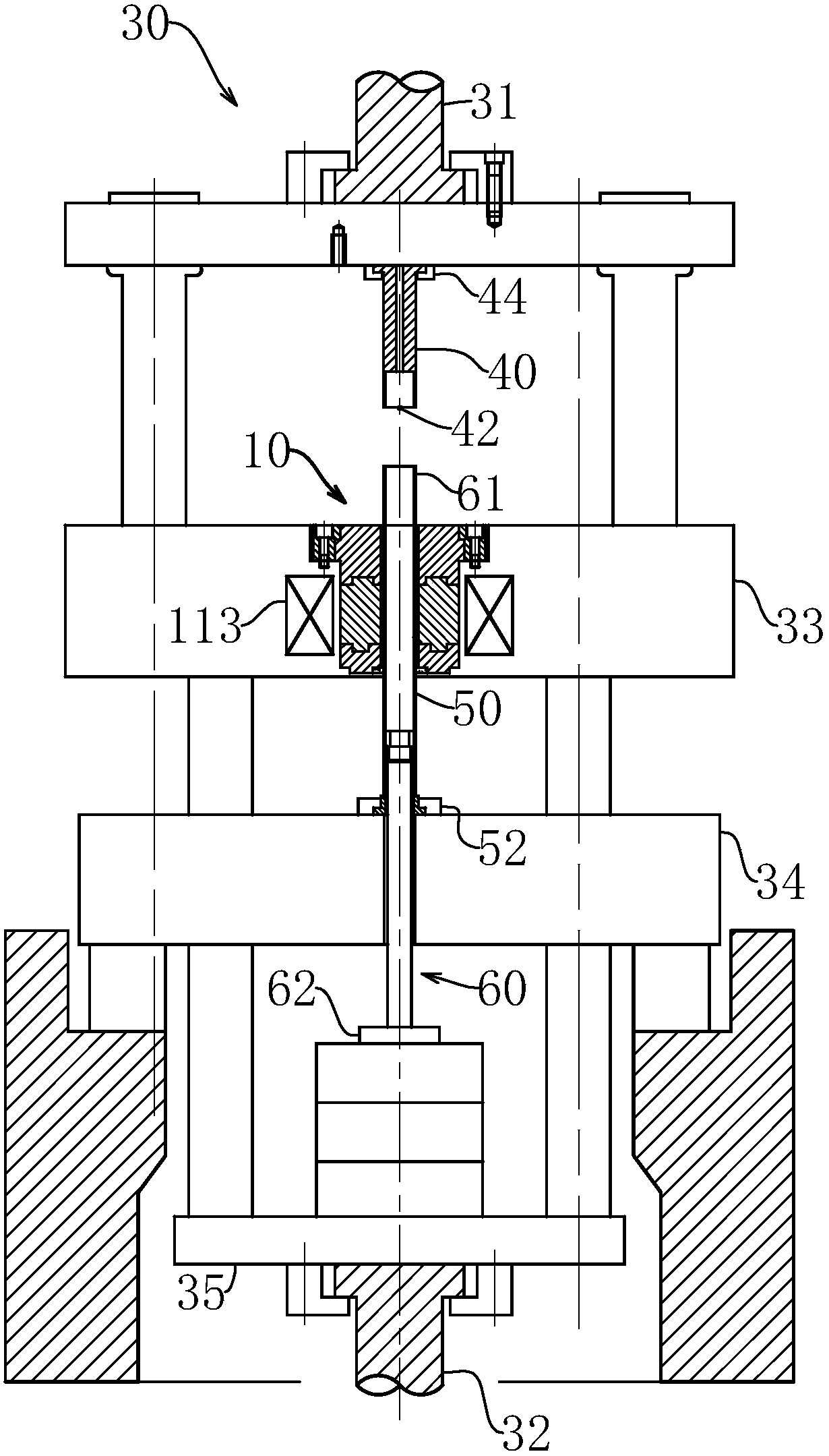

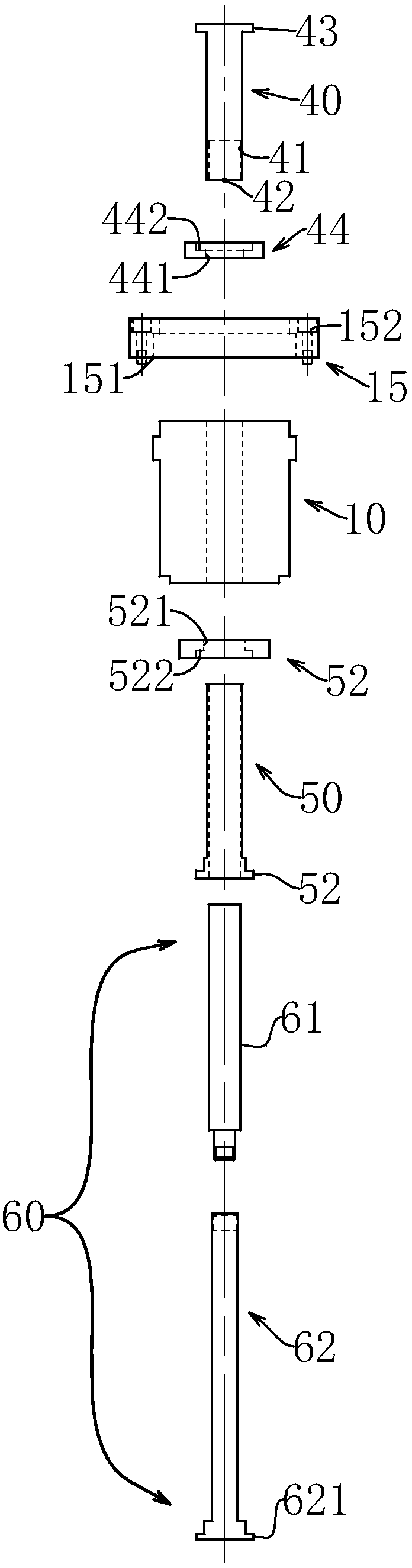

[0031] refer to figure 1 , figure 2 , The anisotropic NdFeB magnet molding orientation molding device of the present invention includes a mold assembly 10 , an upper stamping part 40 , a lower stamping part 50 and a core rod 60 .

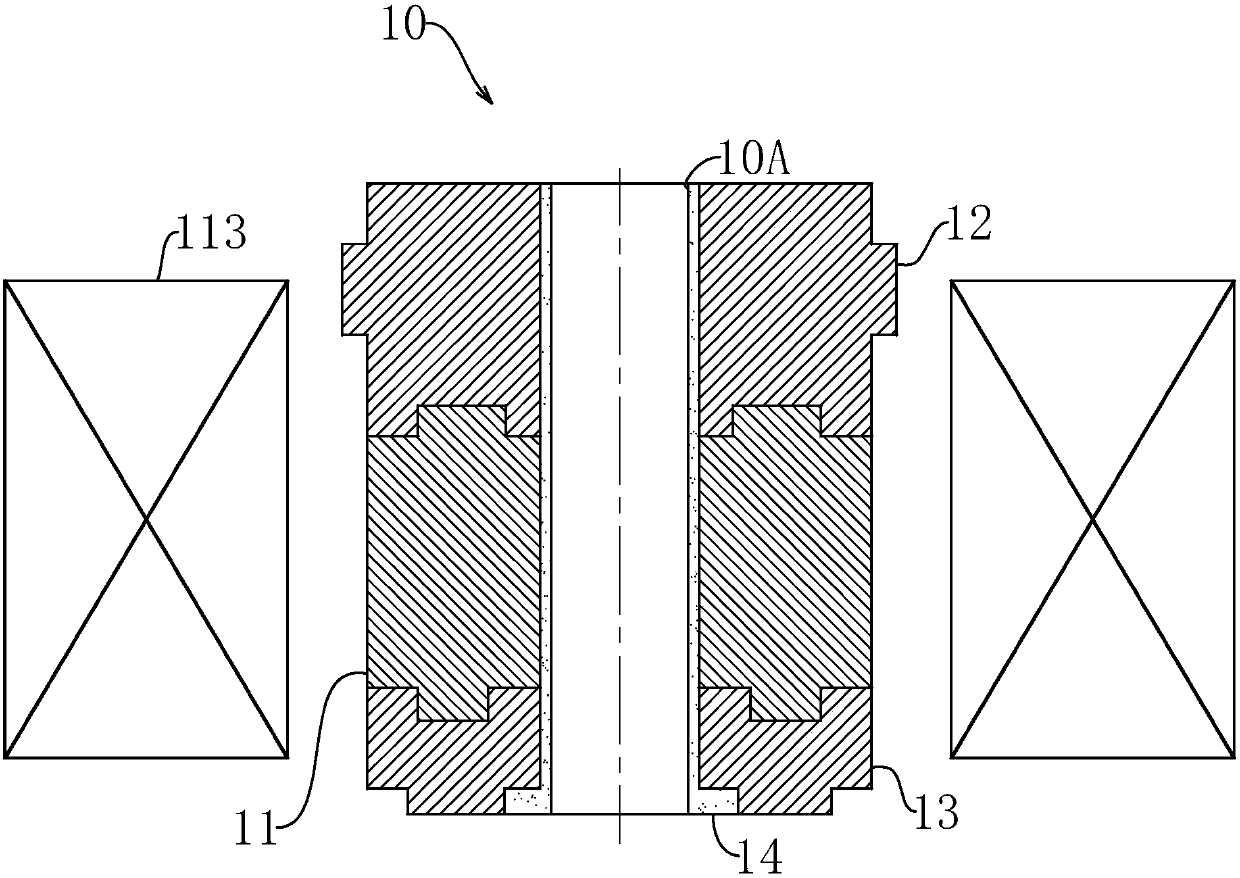

[0032] Such as Figure 1 to Figure 7 As shown, the mold assembly 10 includes a mold body 11, a mold body upper seat 12, a mold body lower seat 13 and an inner sleeve 14, wherein the mold body 11 has a structure such as Figure 4 , Figure 5 As shown, the mold body 11 includes a plurality of sector-shaped magnetic conductors 111 and a plurality of sector-shaped non-magnetic bodies 112. In this embodiment, the magnetic conductors 111 are industrial pure iron DT4, and the non-magnetic bodies are non-magnetic mold steel. HPM75, a plurality of magnetizers 111 and a plurality of non-magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com