Device and method for implementing local electroplating of parts

A technology for partial electroplating and parts, which is applied in the field of devices that can realize partial electroplating of parts, can solve problems such as affecting the assembly quality and service life of parts, unable to guarantee the uniformity of electroplating, and the coating layer is not bright and smooth enough, and achieves simple structure and good electrical conductivity. The effect of uniformity and current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

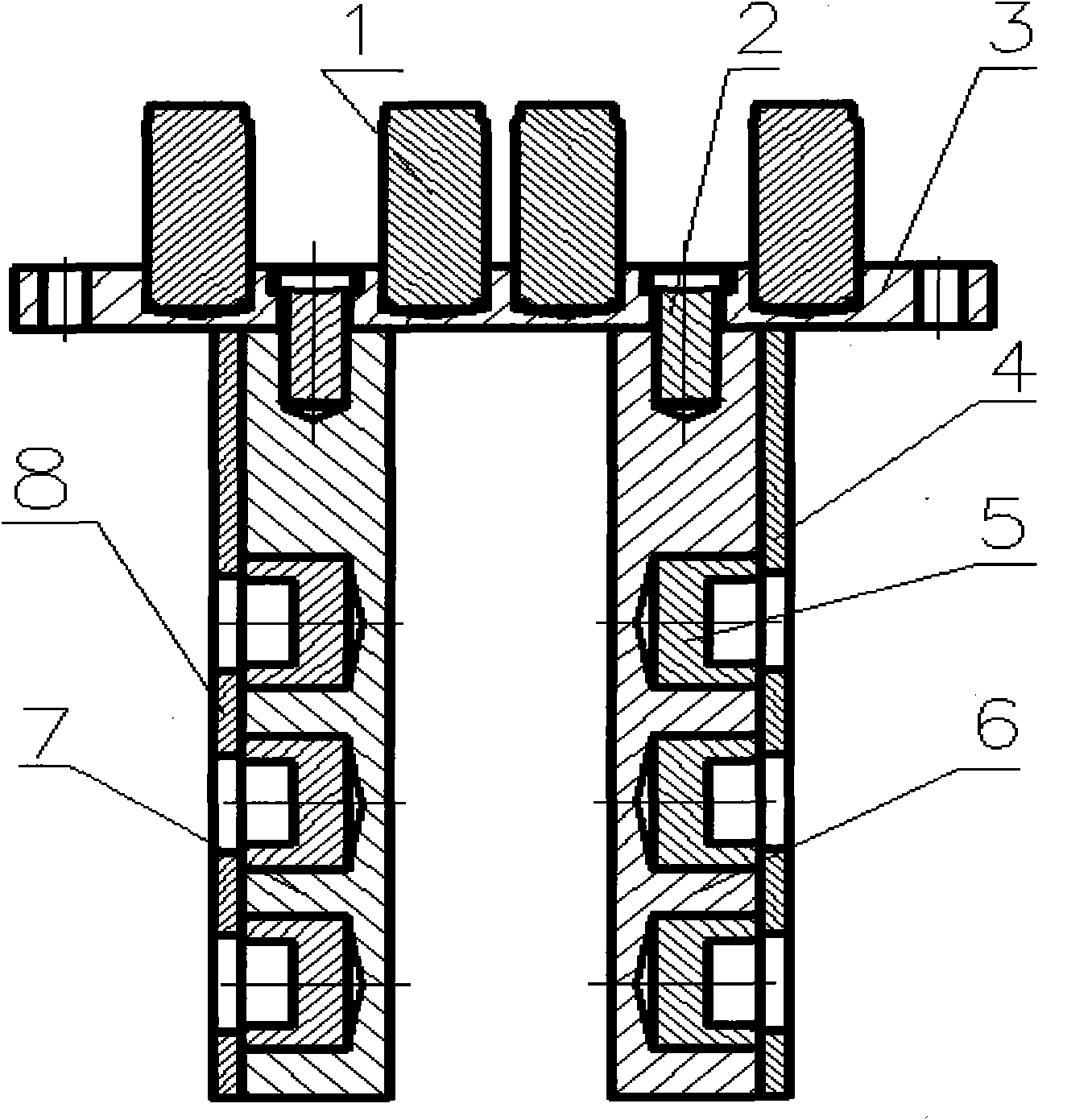

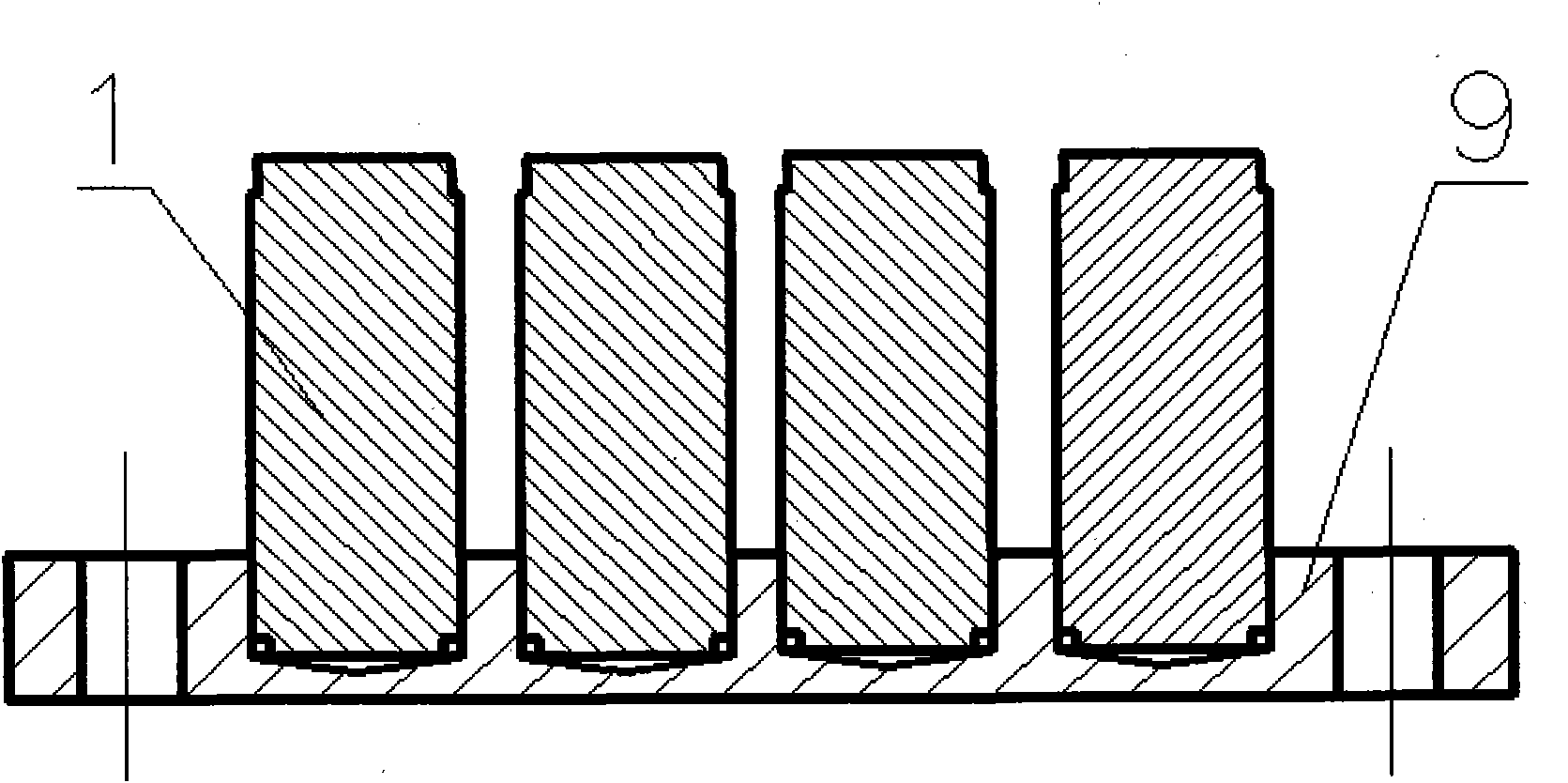

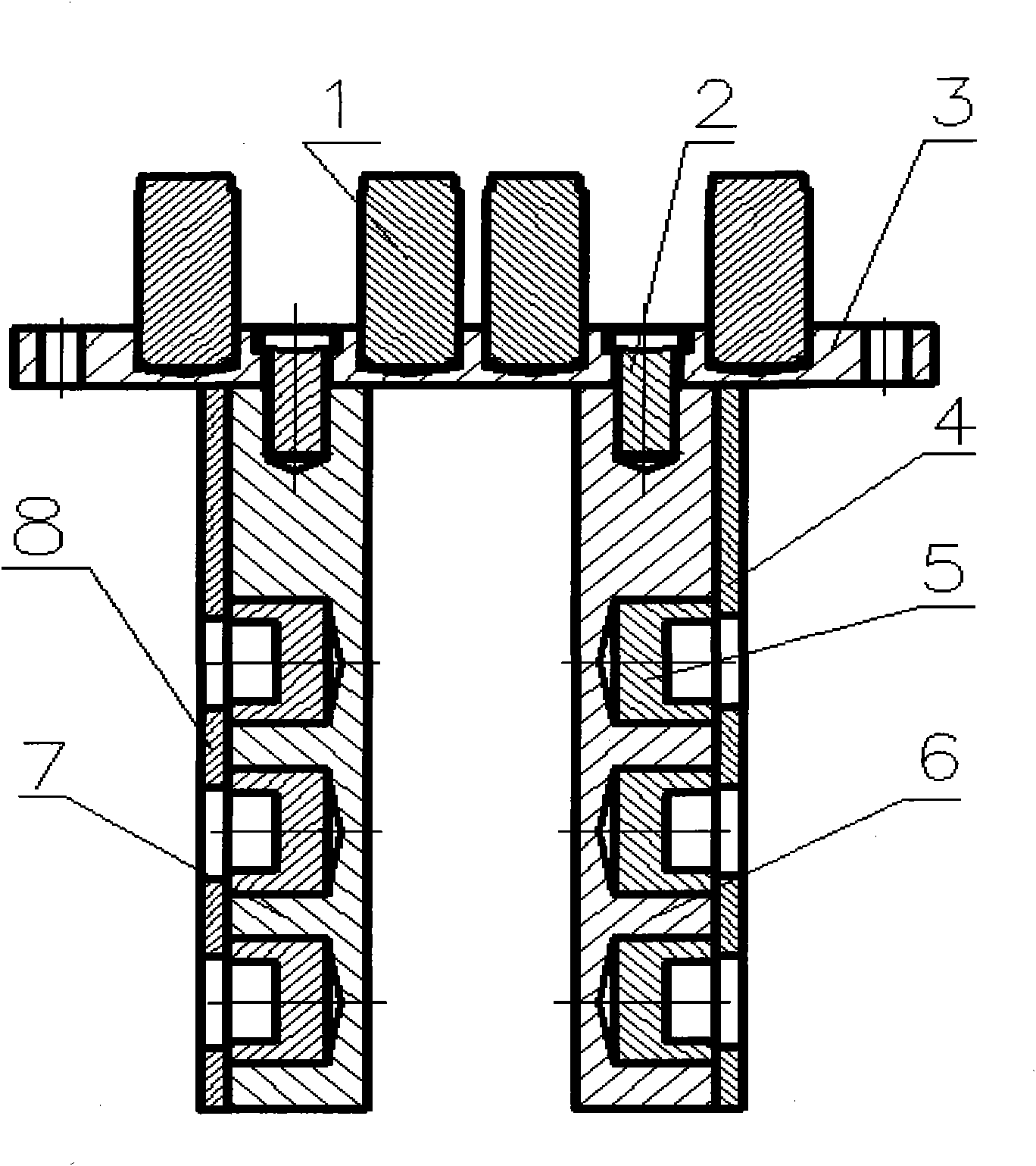

[0037] Such as figure 1 As shown, a partial electroplating device that can realize blind hole parts and non-blind hole parts at the same time, including copper base plates 3, 6, 7, copper cover plates 4, 8, screws 2, conductive rods (not shown), Wire (not shown) and metal plate (not shown), wherein the material of the metal plate is the material to be plated on the part. The copper bottom plates 3, 6, and 7 are circular, and there are grooves for matching parts on the copper bottom plates 3, 6, and 7, and there are a plurality of threaded openings (not shown in the figure) on the surrounding edges. The copper cover plates 4, 8 is also circular, and the through hole (figure not marked) that cooperates with parts is arranged on copper cover plate 4,8 and the threaded mouth that cooperates with the threaded mouth on copper base plate 3,6,7.

[0038] During electroplating, put blind hole parts 5 and non-blind hole parts 1 into the grooves of copper base plates 6, 7 and 3 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com