Hoisting device with self-adaptive supplement structure for metal heat treatment

A metal heat treatment and self-adaptive technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of reduced heat treatment efficiency of iron ingots, affecting the heating efficiency of the bottom of the iron ingot, uneven heating of the bottom of the iron ingot, etc., to achieve The effect of prolonging the service life, avoiding the loosening of the hoisting and clamping, and ensuring the stability and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

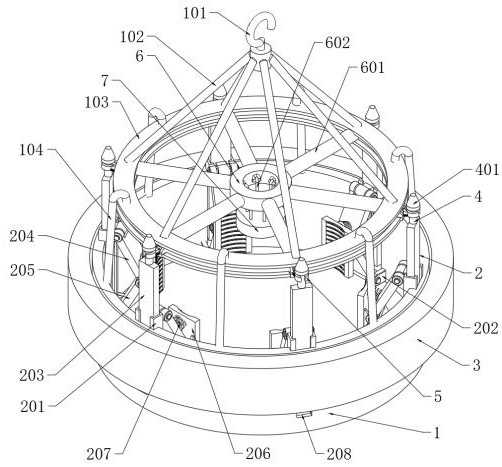

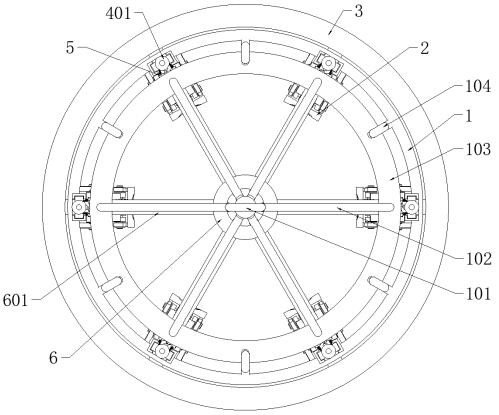

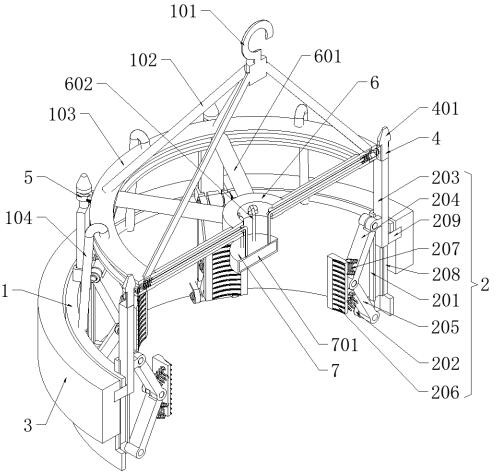

[0046] see Figure 1-2 , a hoisting device for metal heat treatment with self-adaptive supplementary structure, comprising a ring frame 1, a hook 101 is connected to the middle position of the top of the ring frame 1, a plurality of lengths of cables 102 are fixedly connected to the bottom of the hook 101, and a plurality of lengths The bottom of the drag cable 102 is fixedly connected with a connecting frame 103, and a plurality of two-section drag cables 104 are evenly and fixedly connected between the connecting frame 103 and the ring frame 1. The connection and pulling of the cable 102 and the second section of the cable 104 can be guided outwards. By fixing the connecting bracket 103 between the first section of the cable 102 and the second section of the cable 104, the connection between the hook 101 and the ring frame 1 can be connected. The first section of the cable 102 and the second section of the cable 104 are kept supported outwards to prevent the device from bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com