Positioning gluing device for gluing machine

The technology of a gluing device and a gluing machine, which is applied in the field of gluing, can solve problems such as the inability to move the gluing port to the position to be coated, the lack of a dust removal device and a heating device, and unsatisfactory gluing effects, so as to facilitate long-term use , Guarantee the safety of personnel and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

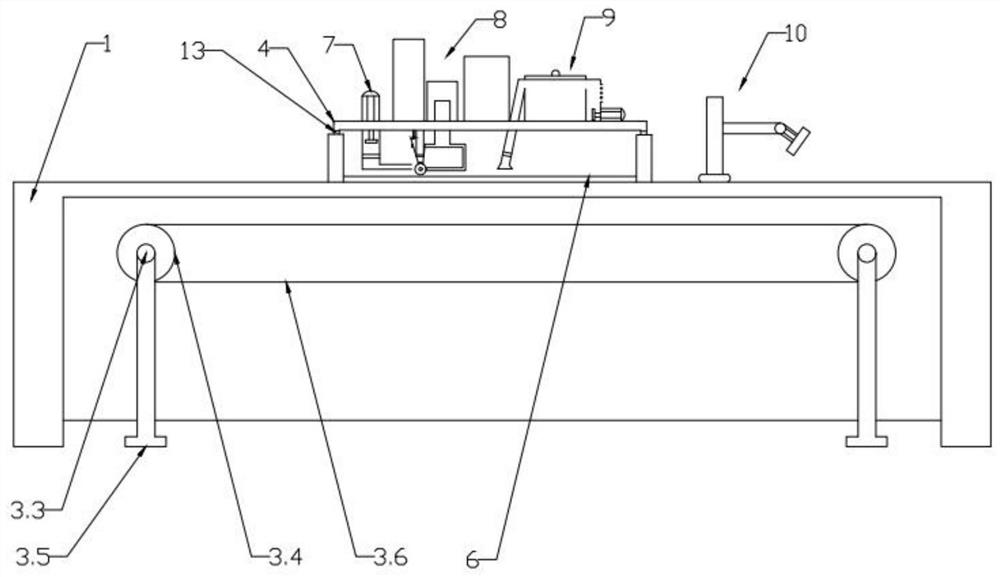

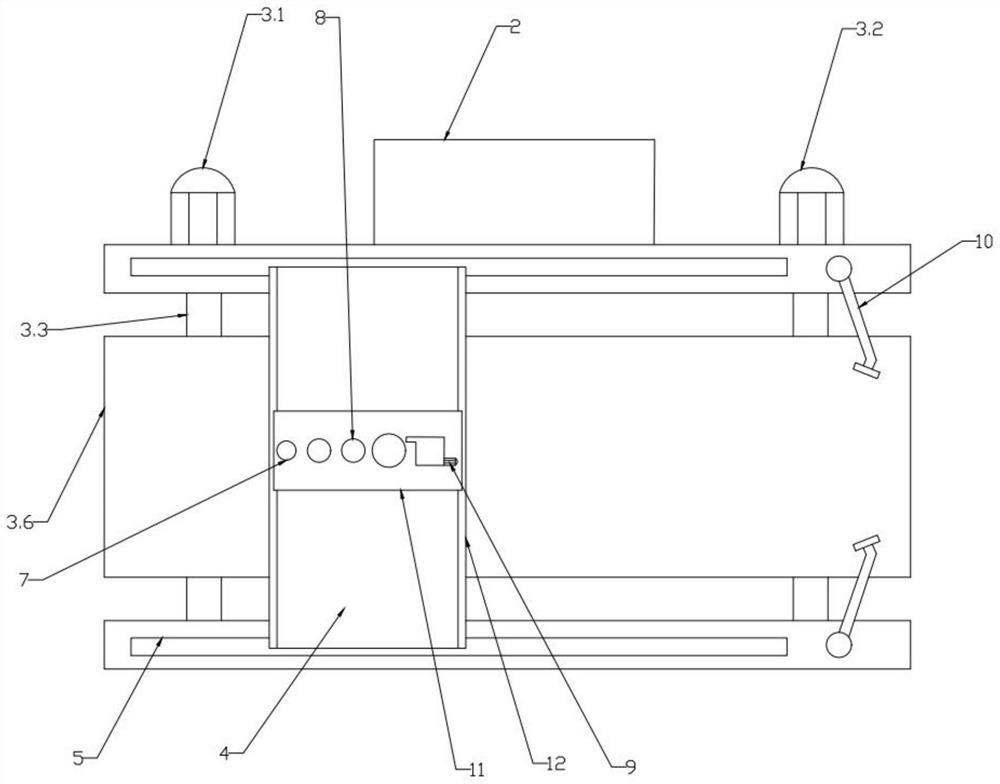

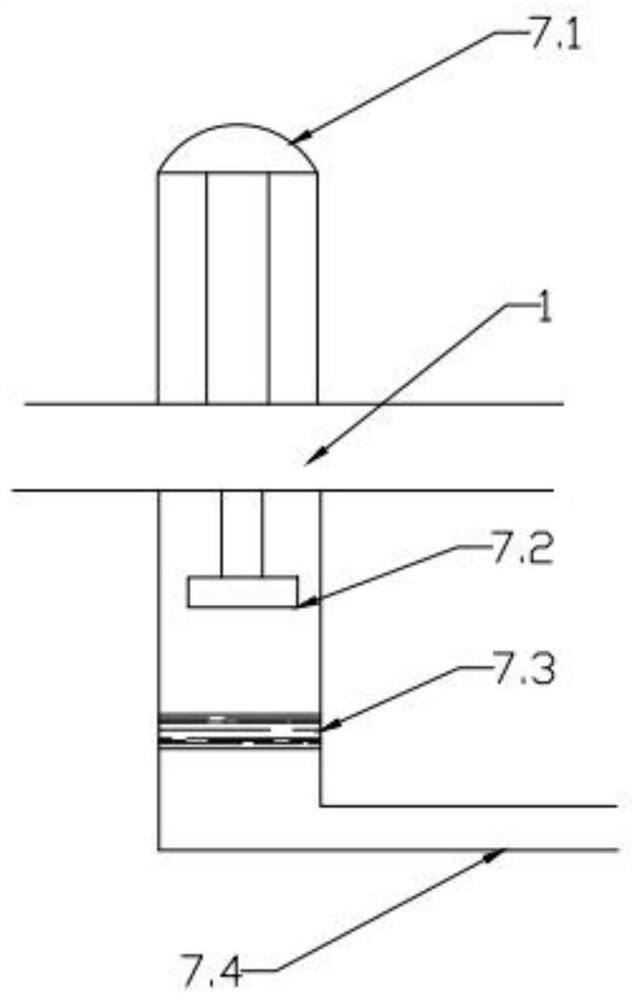

[0023] combined with figure 1 to attach Figure 8 , a positioning gluing device for a gluing machine, comprising a main frame 1, and a transport device 3 is rotated below the main frame 1, and the transport device 3 includes a screw that is fixed on the outer wall of the rear of the main frame 1 by bolts. Motor one 3.1 and motor two 3.2, the extension ends of the motor one 3.1 and motor two 3.2 are welded with a rotating shaft 3.3, the other end of the rotating shaft 3.3 is sleeved with a runner 3.4, and the outside of the runner 3.4 is provided with a conveyor belt 3.6, the other end corresponding to the rotation of the rotating shaft 3.3 is provided with a support leg 3.5, and a chute 5 is provided on the top of the main frame 1 close to the front and rear sides, and a slide plate 4 is provided for sliding on the chute 5, The bottom of the slide plate-4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com