Bonding method

A technology of lamination and sticking area, applied in the direction of adhesive heating, adhesive, etc., can solve the problems of not being able to fully fit large-size products, poor lamination yield, and inability to rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Embodiment: a kind of pasting method

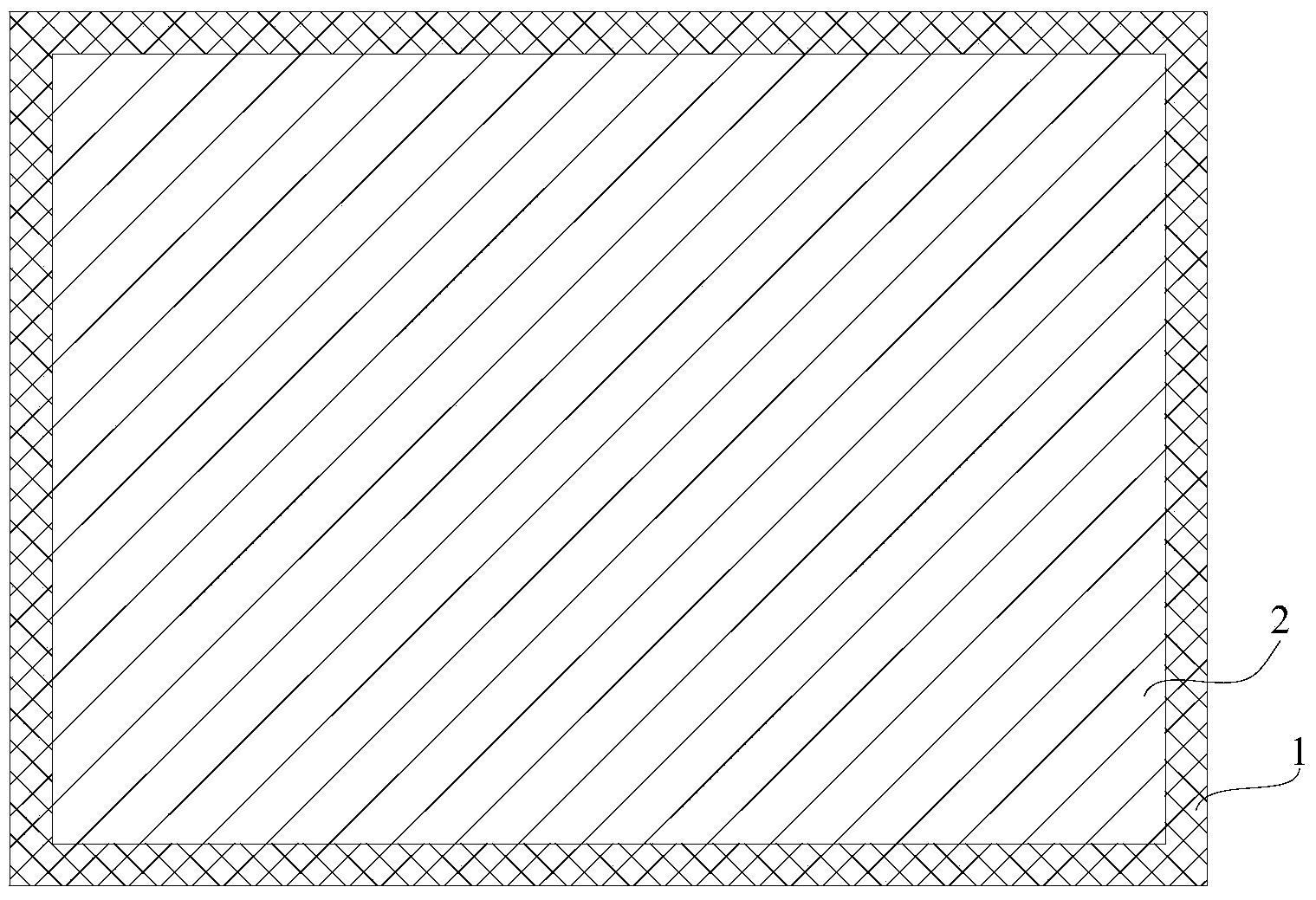

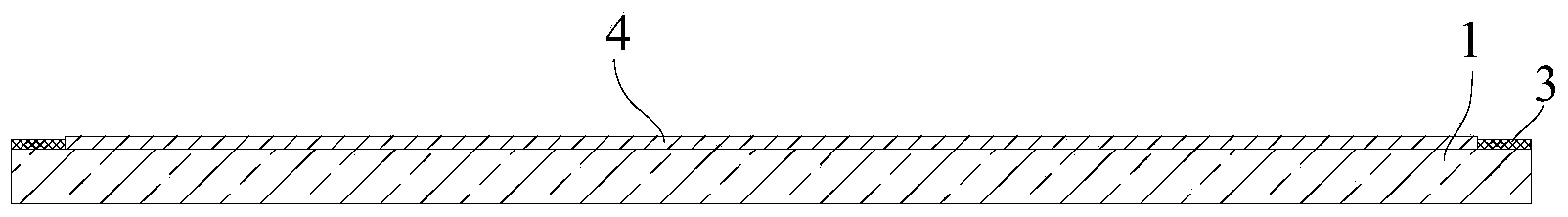

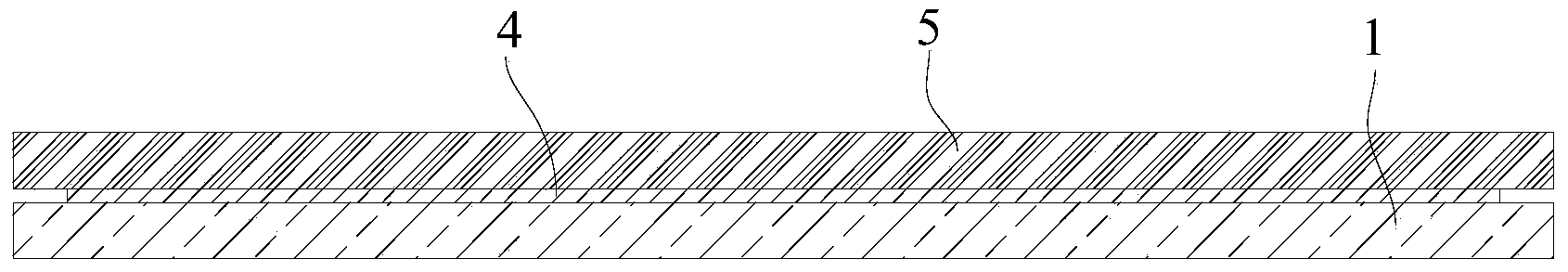

[0067] See attached Figure 1~3 As shown, a bonding method includes the following steps:

[0068] Step 1: Enclose the surface to be glued on the surface of the first component to be bonded 1 (glass cover) with high temperature resistant adhesive tape 3 to form a closed pasting area 2;

[0069] The second step: apply the glue to the sticking area 2 so that in the sticking area 2, the glue is scraped flat, and the excess glue is scraped onto the high temperature resistant adhesive tape, thus forming a A viscose layer 4 with a uniform thickness, and the thickness of the viscose layer 4 is greater than the thickness of the high temperature resistant adhesive tape 3; the glue is made by mixing the A component and the B component according to the mass ratio of 1:1 Obtain; Described A component is made up of the material of blanking weight part:

[0070] Base material 60 parts by weight;

[0071] Catalyst 0.1 part by weight;

[0072]...

Embodiment 2 8

[0107] Embodiments 2-8: a bonding method

[0108] The bonding steps are the same as in Example 1, the difference is the glue: the glue is prepared by mixing component A and component B according to the mass ratio of 1:1.

[0109] The A group batching table of embodiment two~six is as follows:

[0110] Binder catalyst Accessories Embodiment two 85 parts by weight 0.2 parts by weight 25 parts by weight Embodiment Three 95 parts by weight 0.3 parts by weight 15 parts by weight Embodiment Four 90 parts by weight 0.5 parts by weight 20 parts by weight Embodiment five 67 parts by weight 0.1 parts by weight 5 parts by weight Embodiment six 85 parts by weight 0.15 parts by weight 30 parts by weight

[0111] The batching table of B group of embodiment two~six is as follows:

[0112] Binder crosslinking agent Inhibitor Accessories Embodiment two 65 parts by weight 7 parts by weig...

Embodiment 2

[0114] Embodiment 2: The compound conforming to the general formula (1) and the compound conforming to the general formula (2) are mixed according to the mass ratio of 1:1. In general formula (1), R 1 Represents methyl; R 2 , R 3 , R 4 represents a vinyl group; x=20, y=20; the viscosity of the compound conforming to the general formula (1) is 7000 centipoise; in the general formula (2), a is equal to 20, and b is equal to 30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Lap shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com