AC and DC dual-purpose small automatic glue coating machine

An AC-DC dual-purpose, gluing machine technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of slow speed, uneven coating, sticking and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

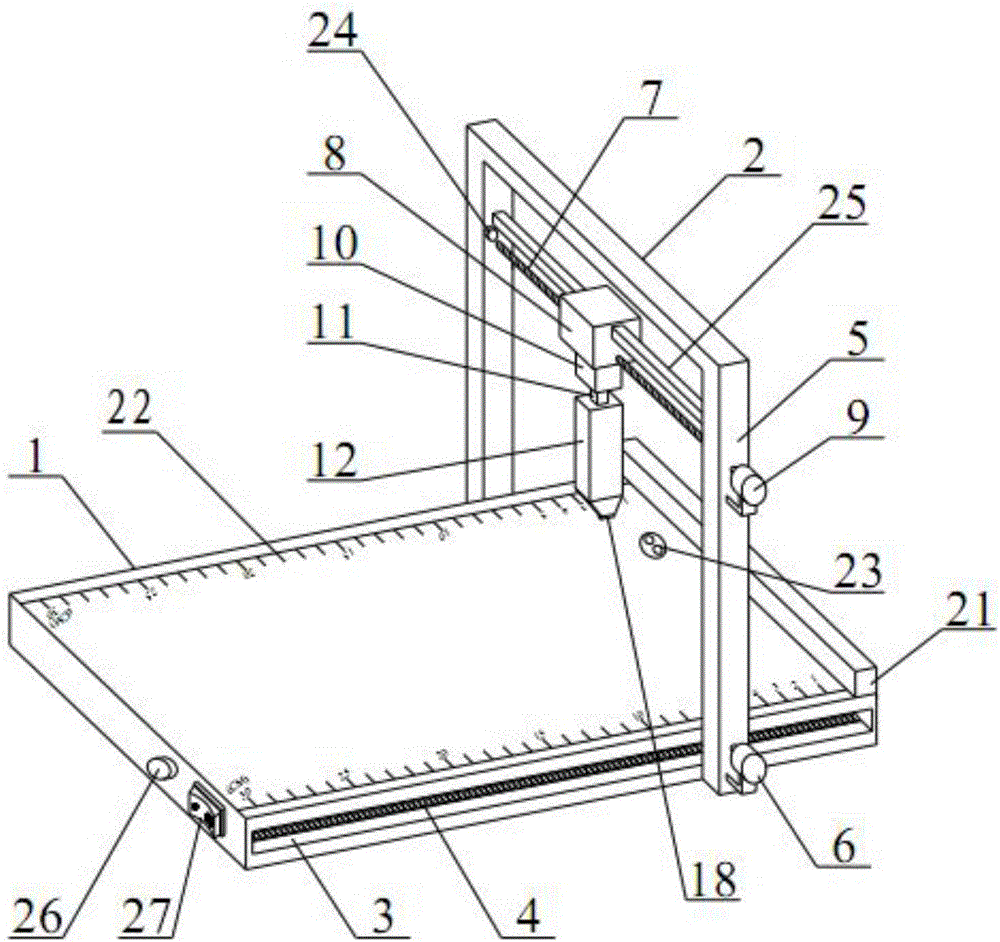

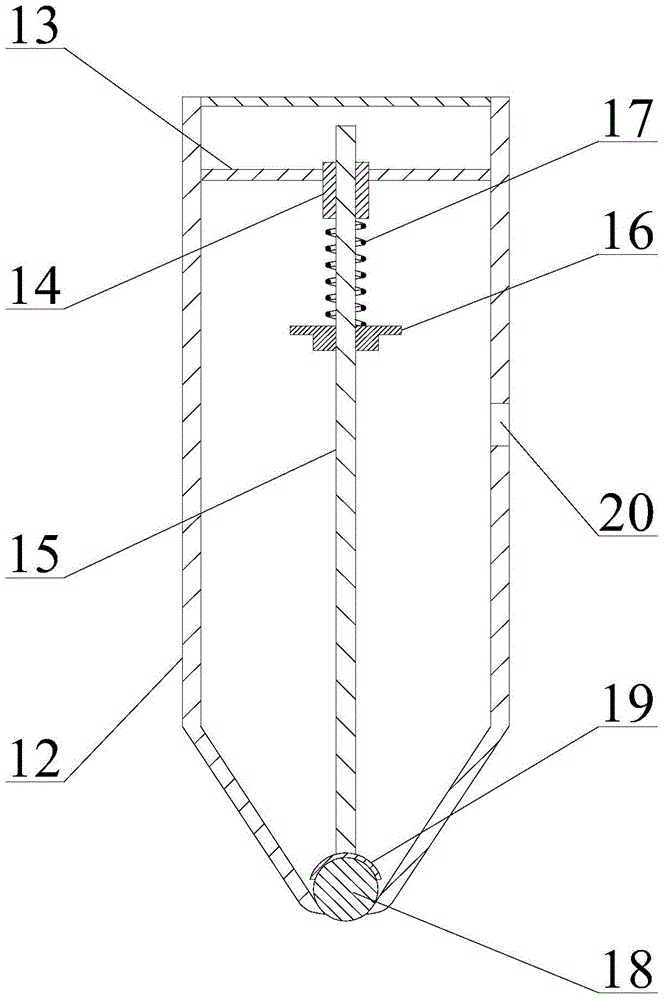

[0015] Combine below figure 1 and figure 2 The present invention is described further:

[0016] The AC / DC dual-purpose small-sized automatic gluing machine includes a base plate 1 and a door frame 2. There is a whole cavity 3 in the base plate 1, and a rack 4 is fixed in the cavity 3 near the openings on both sides. The strips 4 should be parallel to each other and to the long side of the cavity 3 opening. A cross bar is connected between the lower ends of the two columns 5 of the door frame 2, the cross bar is located in the cavity 3, and two gears are fixed on the cross bar, and the two gears mesh with the two racks 4 respectively, The outer side of a column 5 is fixed with a first motor 6, and the output shaft of the first motor 6 passes through the column 5 and is fixed to one end of the cross bar. With the above structure, when the first motor 6 is started, the output shaft of the motor will drive When the cross bar and the gear rotate, the gear will move along the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com