Bamboo batten hot-pressing extension machine

A technology of lengthening machines and bamboo strips, which is applied in the direction of veneer presses, plywood presses, wood processing equipment, etc., can solve the problems of being unsuitable for processing, and achieve the effects of low production cost, good crimping quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

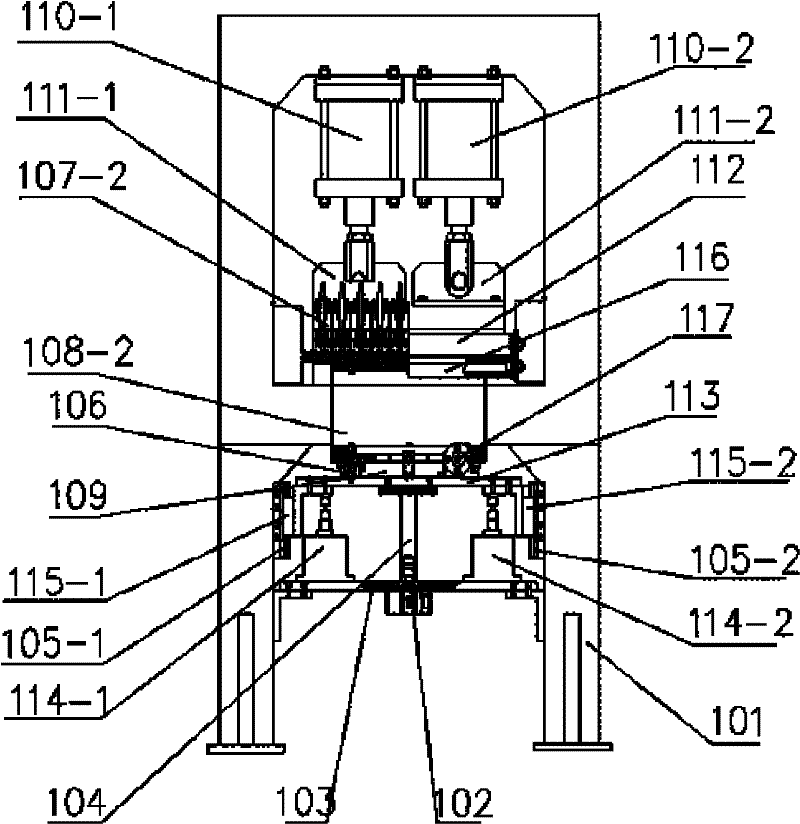

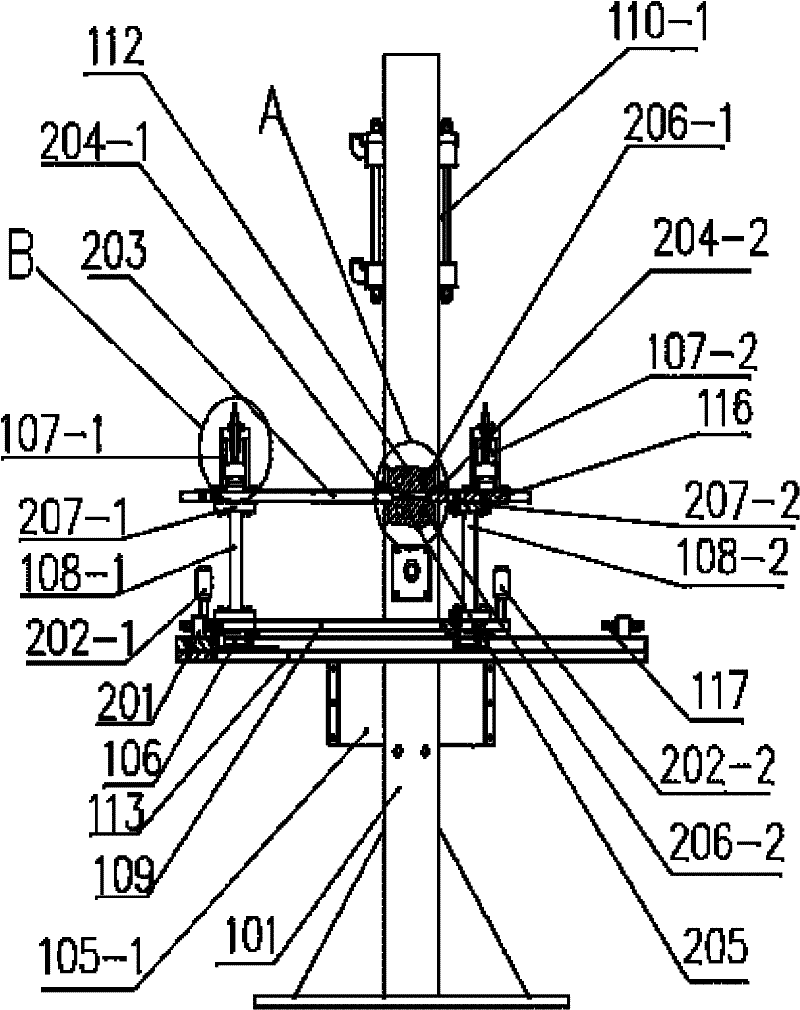

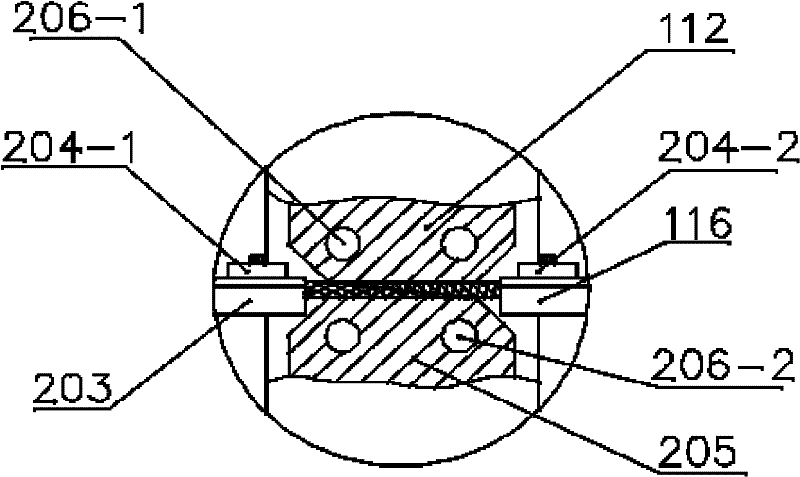

[0015] refer to figure 1 , 2 , 3, the present embodiment comprises frame 101, and frame 101 bottom is equipped with lifting cylinder supporting plate 103, and lifting cylinder supporting plate 103 middle part is equipped with lifting cylinder 102, and lifting cylinder 102 links to each other with push rod 104, and lifting cylinder supporting plate 103 two Bracket buffer I114-1 and bracket buffer II114-2 are respectively installed at the end, and positioning guide rail I105-1, positioning guide rail II105-2, positioning guide rail I105-1, positioning guide rail II105- 2 There are guide rail sliders respectively, and bracket support angle plate I115-1, bracket support angle plate II115-2, bracket support angle plate I115-1, bracket support angle plate II115- are respectively installed on the two guide rail sliders. 2 Connected with the base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com