Precise gluing device for corrosive aluminum foil

A technology of gluing device and corroding aluminum foil, which is applied to devices and coatings that apply liquid to the surface. , Improve the efficiency of gluing, improve the effect of the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

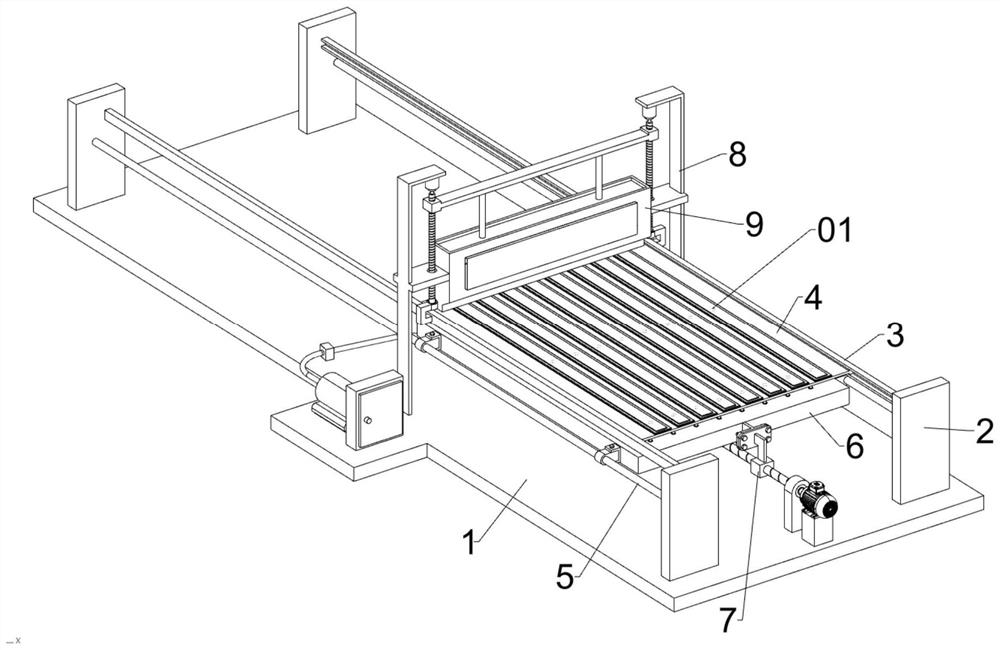

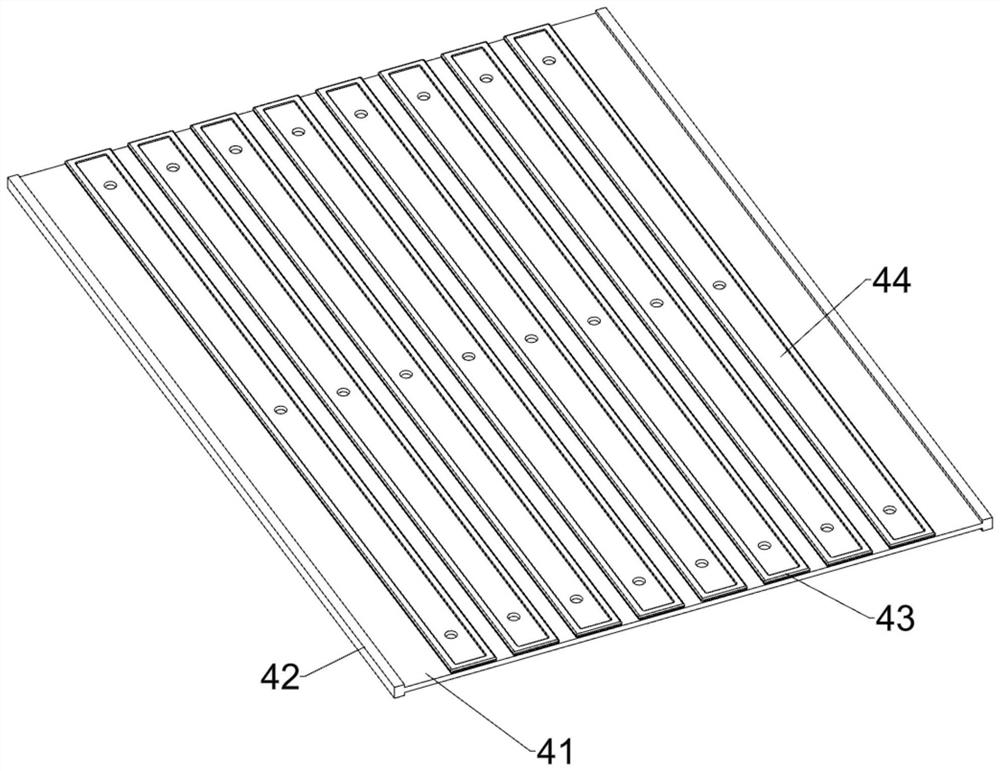

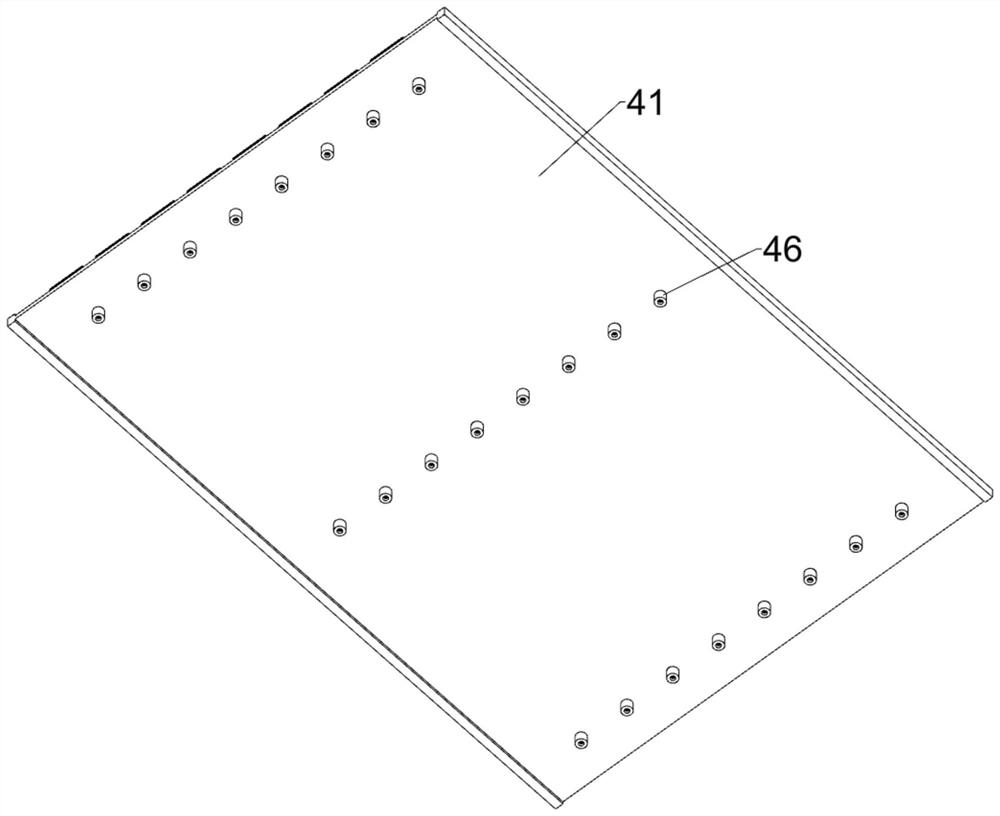

[0037] Such as Figure 1-15 As shown, a precise gluing device for corroded aluminum foil includes a base 1 on which two pairs of support blocks 2 are arranged symmetrically with respect to the direction of its long center line, and guide rails 3 and The guide post 5, the guide post 5 is located obliquely below the guide rail 3, the placement part 4 is slidingly provided between the guide rails 3, the positioning part 6 is slidingly provided between the guide posts 5, and the aluminum foil 01 is placed on the positioning part 6 at even intervals. The part 4 and the positioning part 6 are fixed and communicated with each other through the connecting part. The positioning part 6 is positioned on the aluminum foil 01 on the placement part 4 by means of vacuum adsorption. The pushing part 7 pushes the positioning part 6 and the placing part 4 to slide between the guide post 5 and the guide rail 3 respectively. There is an adjustable glue spraying part 9, the top of the bracket 8 i...

Embodiment 2

[0048] Such as Figure 1-15As shown, on the basis of Embodiment 1, it also includes a temperature sensor 913 for detecting the temperature of the glue in the glue box 91, and a heat shield 13 arranged on the side of the glue box 91 away from the feed port 912. And be arranged in the heating wire 14 that is used for heating the glue in the glue box 91 in the heat shield 13, the heat shield 13 is a vacuum insulation board, the pulse signal sent by the temperature sensor 913 is transmitted to the central control unit 612, and the central control unit 612 controls the heating power of the heating wire 14 .

[0049] When the temperature sensor 913 detects that the temperature of the glue in the glue box 91 is lower than the preset value, the central control unit 612 controls the heating wire 14 to work, so that the heating wire 14 heats the glue in the glue box 91 to make it Always maintain a certain molten state to ensure the fluidity of the glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com