Fiber-optic head assembly production line

A production line and fiber optic head technology, applied in the field of fiber optic head assembly production line, can solve the problems of low qualified rate of finished products, difficult manual fiber optic head assembly, low efficiency, etc., achieve accurate glue application, improve assembly accuracy and finished product quality, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

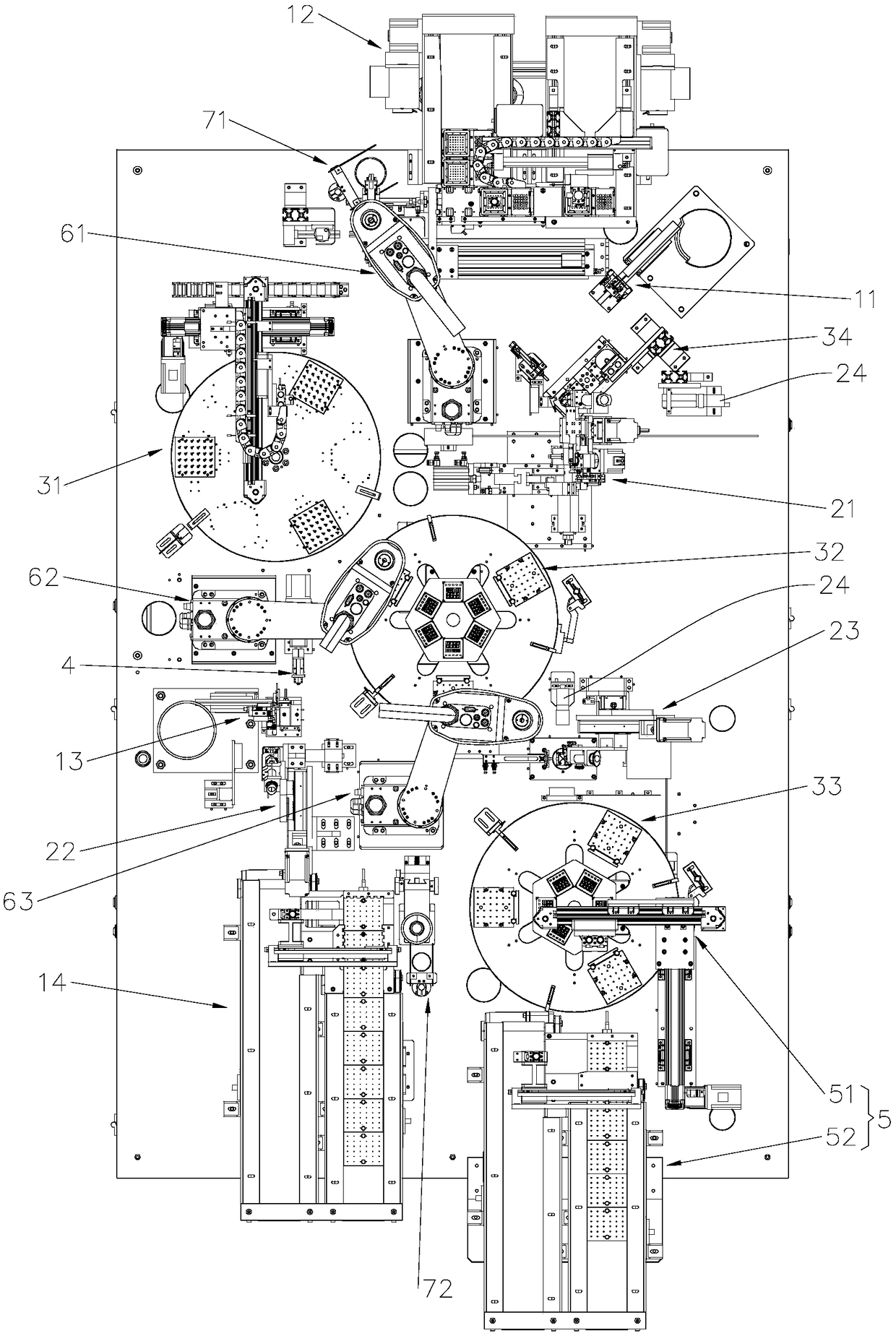

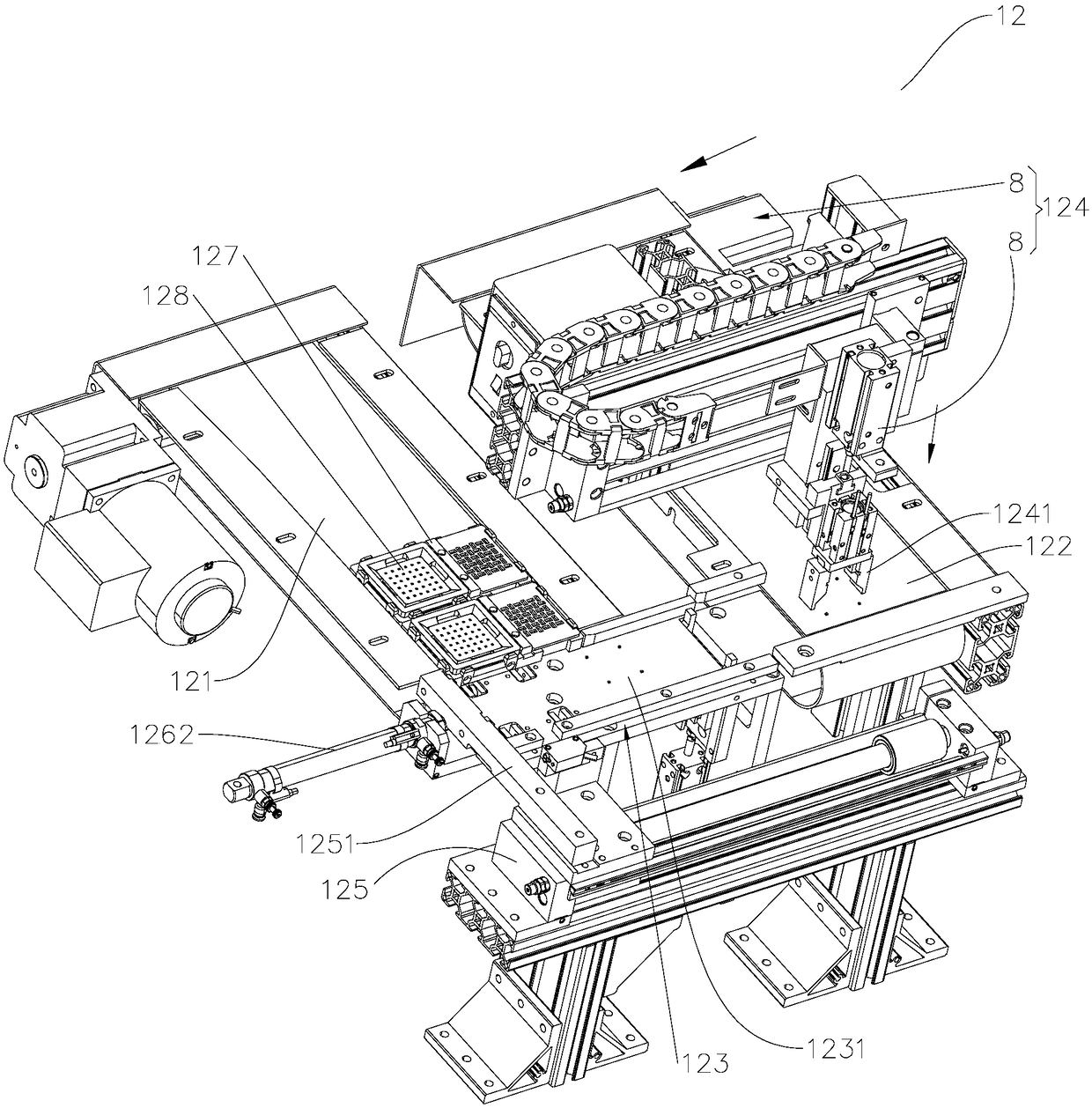

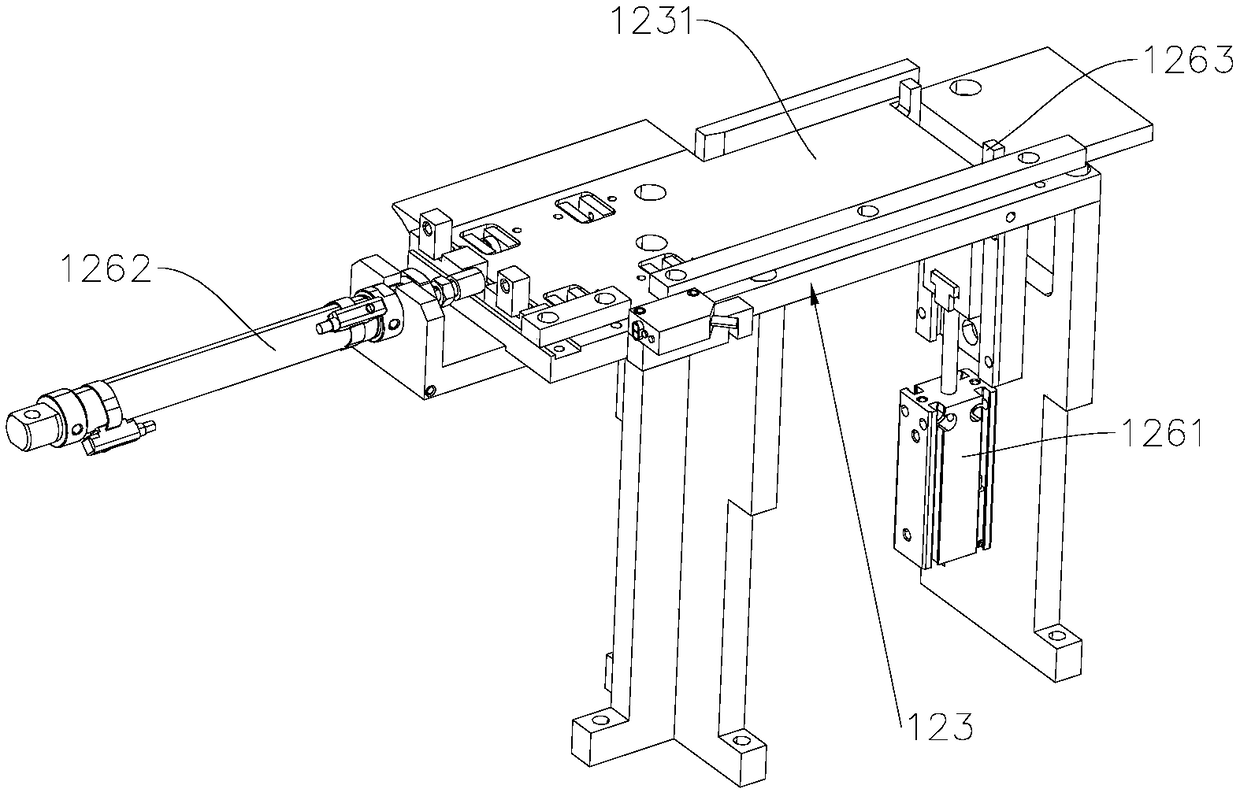

[0074] refer to Figure 1 to Figure 23 , the present invention is an optical fiber head assembly production line, which is used to assemble the light-transmitting sheet 91, the mounting cap 92, the housing 93 and the cylinder 94. The optical fiber head assembly production line includes a mounting cap feeding device 11, a transparent Light sheet feeding device 12, housing feeding device 13, column feeding device, first dispensing device 21, second dispensing device 22, third dispensing device 23, first curing device 31, second curing device Device 32 , third curing device 33 , first displacement device 61 , second displacement device 62 , third displacement device 63 , turning device 4 and unloading device 5 . The mounting cap feeding device 11 , the translucent sheet feeding device 12 , the casing feeding device 13 , and the cylinder feeding device are used to transport the mounting cap 92 , the translucent sheet 91 , the casing 93 and the cylinder 94 respectively.

[0075] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com