Packaging film gluing device

A technology of gluing device and packaging film, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of insufficient uniformity, low degree of automation, and imprecise position of glue applied, and achieve novel structure and precise coating. Glue, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

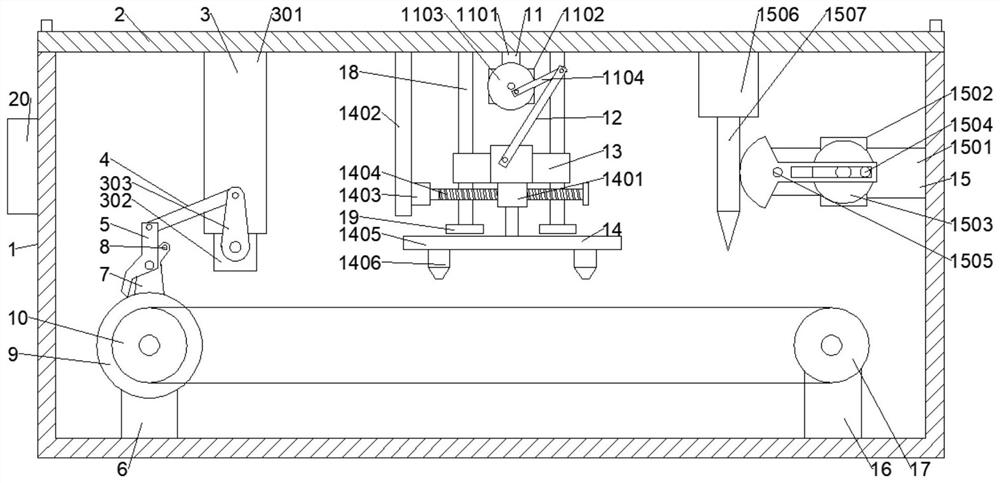

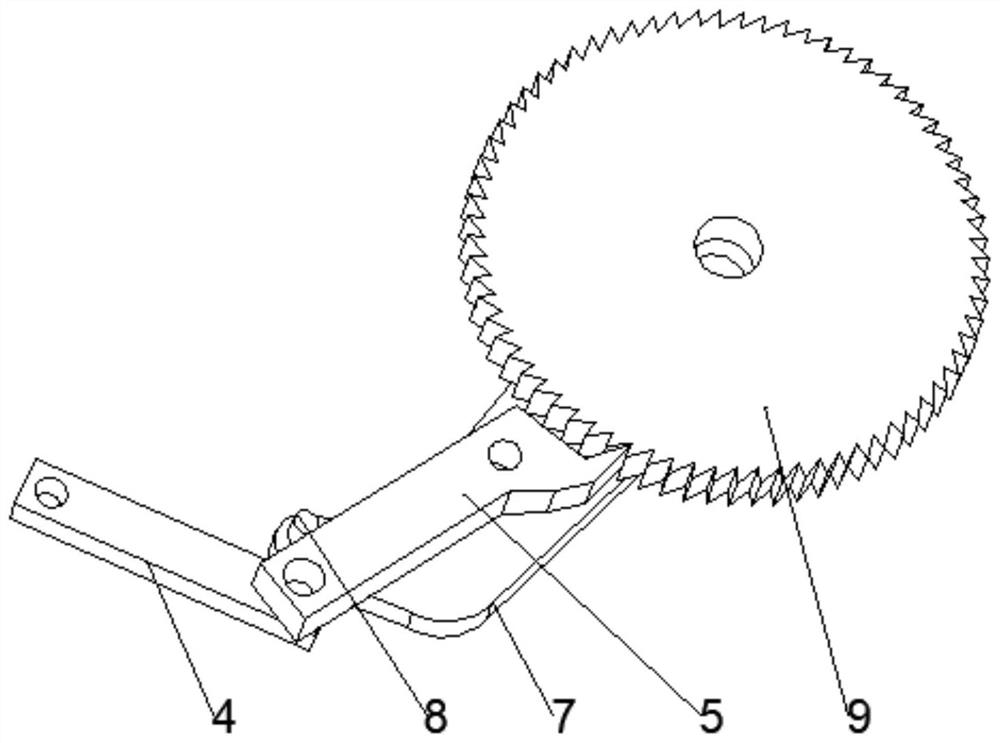

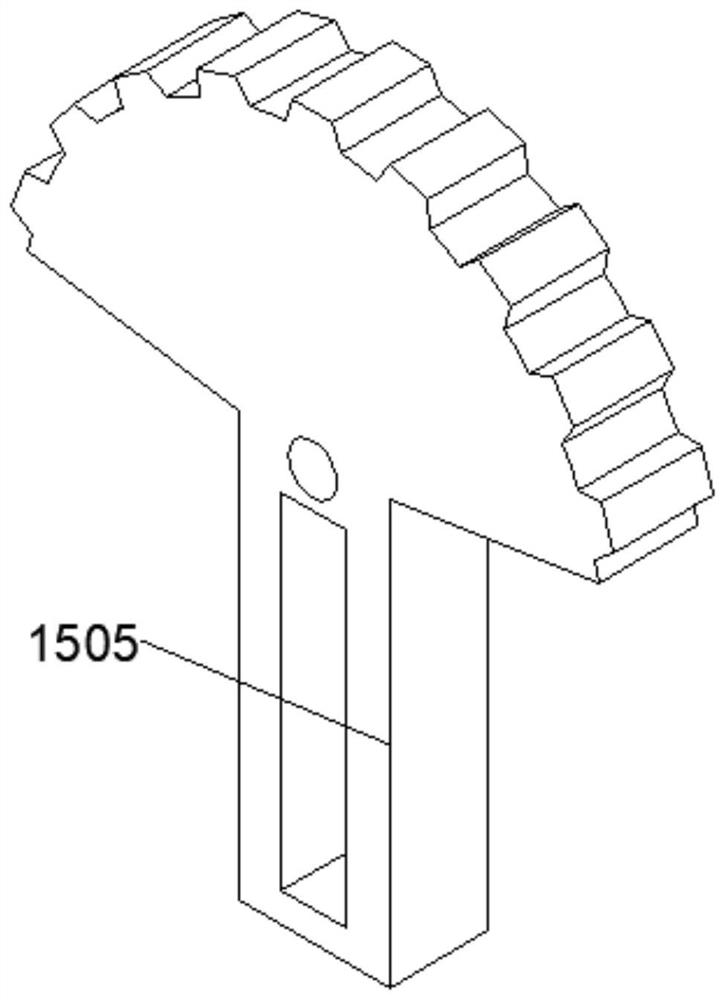

[0024] Example 1: Please refer to Figure 1-4 , a packaging film gluing device, comprising a main box 1, a cover 2, the top of the main box 1 is fixedly connected with a cover 2, and the lower left side of the cover 2 is fixedly connected with a first driving mechanism 3, and the first driving mechanism 3 rotates The first swing rod 4 is connected, the first swing rod 4 is connected with the pawl 5 in rotation, the first vertical plate 6 is fixedly connected with the lower left side of the main box 1, and the first vertical plate 6 is fixedly connected with the middle part of the ratchet 5 to rotate. Connected special-shaped plate 7, the upper right side of the special-shaped plate 7 is fixedly connected with a stop post 8, the middle part of the first vertical plate 6 is rotatably connected with a ratchet 9 cooperating with the ratchet 5, and the front side of the ratchet 9 is fixedly connected with a winding roller 10. The lower part of the cover 2 is fixedly connected with ...

Embodiment 2

[0034] Example 2: Please refer to Figure 1-4 , a packaging film gluing device, comprising a main box 1, a cover 2, the top of the main box 1 is fixedly connected with a cover 2, and the lower left side of the cover 2 is fixedly connected with a first driving mechanism 3, and the first driving mechanism 3 rotates The first swing rod 4 is connected, the first swing rod 4 is connected with the pawl 5 in rotation, the first vertical plate 6 is fixedly connected with the lower left side of the main box 1, and the first vertical plate 6 is fixedly connected with the middle part of the ratchet 5 to rotate. Connected special-shaped plate 7, the upper right side of the special-shaped plate 7 is fixedly connected with a stop post 8, the middle part of the first vertical plate 6 is rotatably connected with a ratchet 9 cooperating with the ratchet 5, and the front side of the ratchet 9 is fixedly connected with a winding roller 10. The lower part of the cover 2 is fixedly connected with ...

Embodiment 3

[0036] Example 3: Please refer to Figure 1-4, a packaging film gluing device, comprising a main box 1, a cover 2, the top of the main box 1 is fixedly connected with a cover 2, and the lower left side of the cover 2 is fixedly connected with a first driving mechanism 3, and the first driving mechanism 3 rotates The first swing rod 4 is connected, the first swing rod 4 is connected with the pawl 5 in rotation, the first vertical plate 6 is fixedly connected with the lower left side of the main box 1, and the first vertical plate 6 is fixedly connected with the middle part of the ratchet 5 to rotate. Connected special-shaped plate 7, the upper right side of the special-shaped plate 7 is fixedly connected with a stop post 8, the middle part of the first vertical plate 6 is rotatably connected with a ratchet 9 cooperating with the ratchet 5, and the front side of the ratchet 9 is fixedly connected with a winding roller 10. The lower part of the cover 2 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com