Decorative plasterboard vibration molding equipment

A vibration molding, gypsum board technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of high labor intensity, inconsistent frame size, uneven thickness, etc., to achieve uniform product quality, accurate thickness, and uniform thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

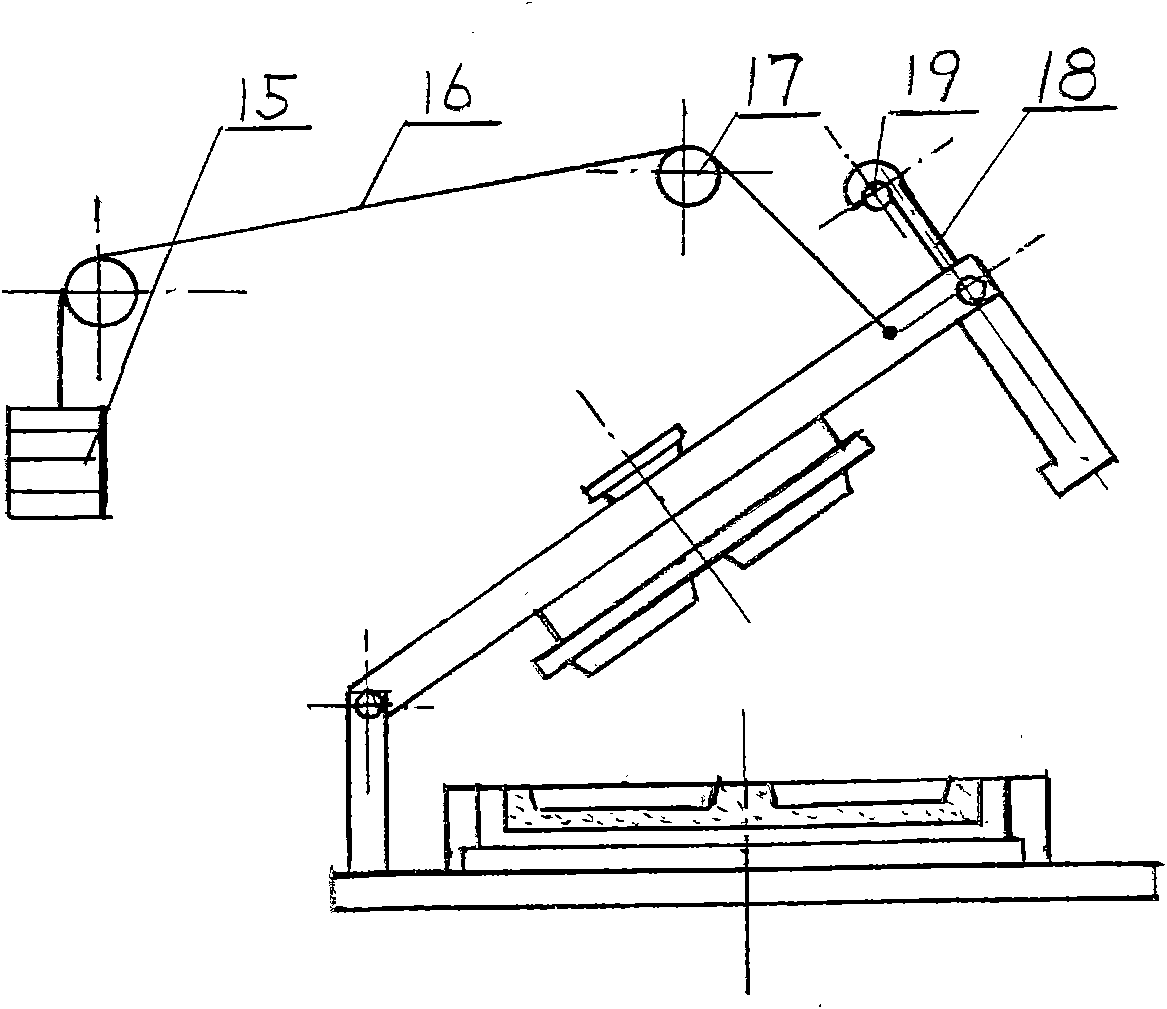

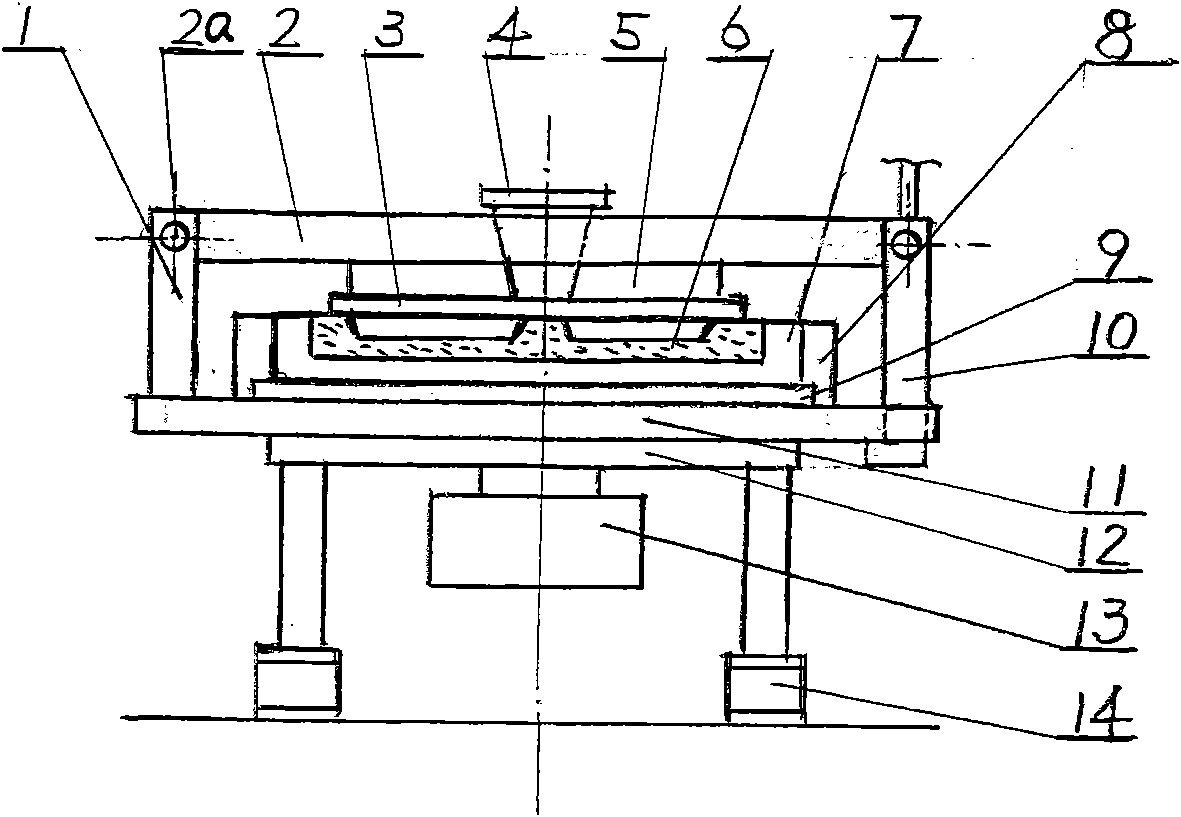

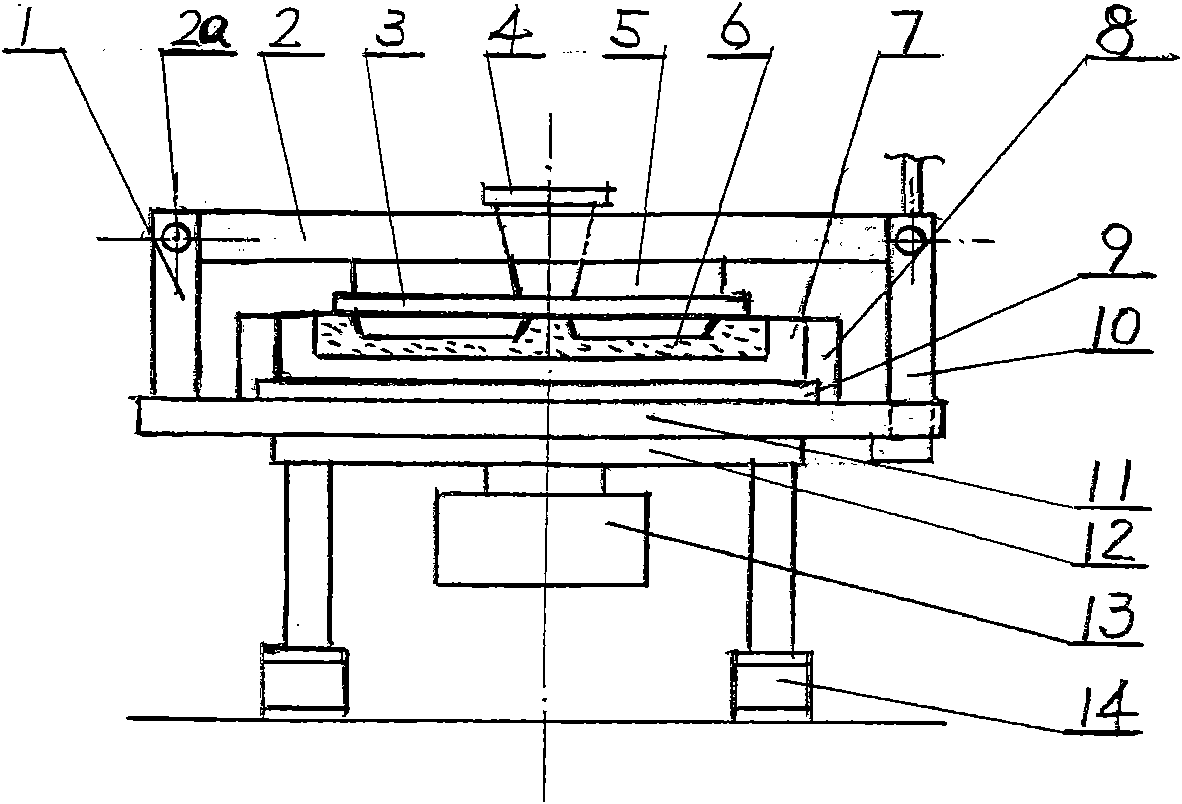

[0015] Such as figure 1 , figure 2 As shown, the present invention comprises a workbench 11 with a vibrating device 13 at the bottom, a bottom mold adjusting device 9 arranged on the workbench, a bottom mold 7 arranged on the bottom mold adjusting device, a support 1 installed on the workbench, an installation The rotatable rotating frame 2 positioned above the workbench on the support, the top cover adjustment device 5 installed on the bottom surface of the rotation frame, the top cover 3 installed on the bottom surface of the top cover adjustment device, and the gate 4 opened on the top cover 3 . The vibration frequency, amplitude and excitation force of the vibrating device 13 can all be adjusted to achieve the best use effect. A support 1 is installed on the workbench, and the other side is locked on the workbench by an openable locking device 10, and the rotating frame is hinged to the top of the support through a hinge shaft 2a. On the top cover, the balance weight de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com