Oil pan gumming machine

A gluing machine and oil pan technology, which is applied in the direction of coating and liquid coating on the surface, etc. It can solve the problems of gluing accuracy to be improved, low work efficiency, and the inability to realize automatic continuous feeding of the engine oil pan , Precise positioning, precise gluing and automatic discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: a kind of oil sump gluing machine.

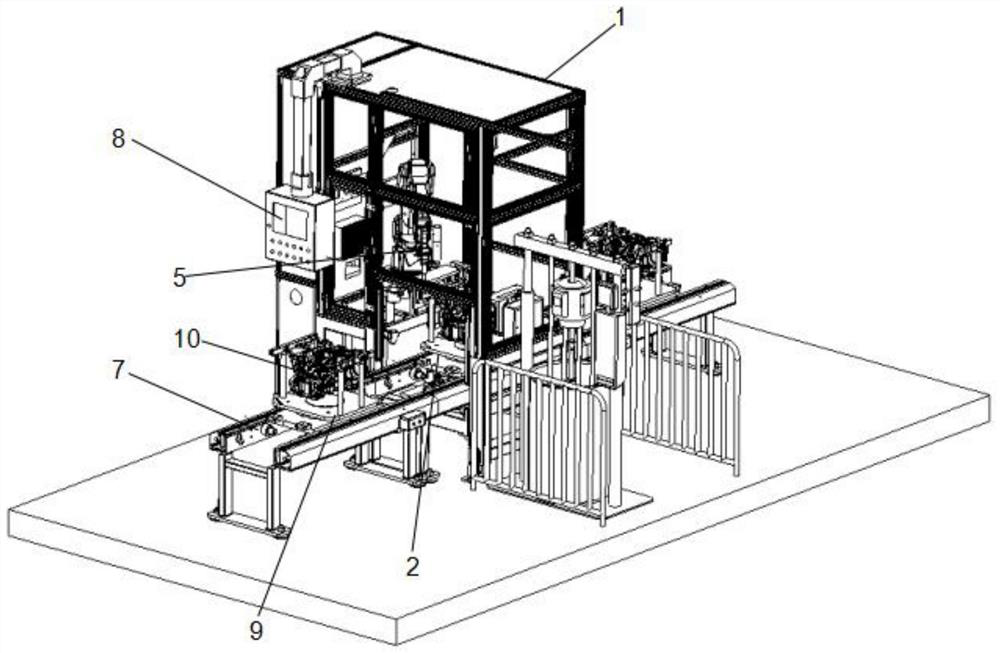

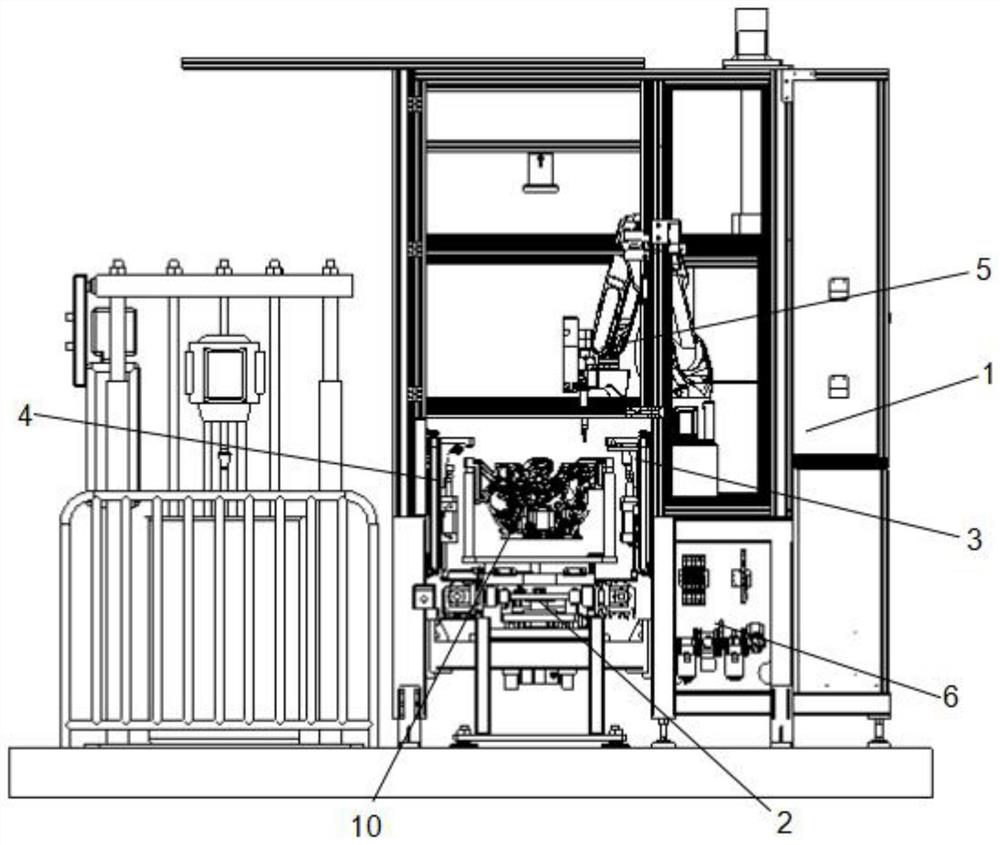

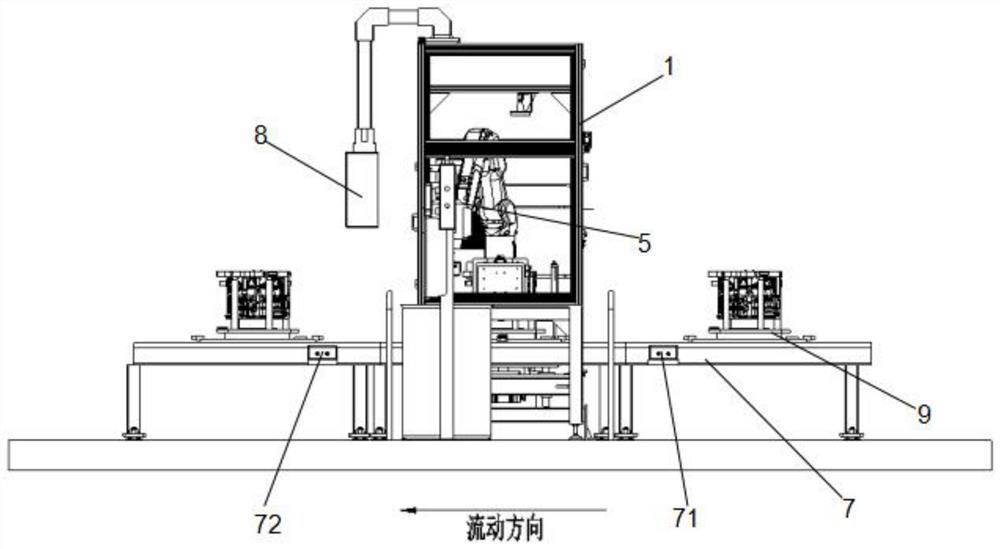

[0033] refer to Figure 1 to Figure 12 As shown, an oil pan glue coating machine includes:

[0034] A protective frame 1, a guide rail 7 is installed on the front side of the protective frame 1, a feed slide 9 is installed on the guide rail 7, and a workpiece 10 is placed on the feed slide 9. In the actual working process, the feed slide 9 fits with the guide rail 7, and the feeding slide 9 can be driven manually or by a driving device to move along the guide rail 7 to drive the workpiece 10 to feed or discharge;

[0035] Lifting and positioning mechanism 2, said lifting and positioning mechanism 2 is installed on the front side of protective frame 1 and located below guide rail 7, said lifting and positioning mechanism 2 includes a lifting base 21, said lifting base 21 is fixed on guide rail 7 Below, the lifting cylinder 22 is installed on the lifting base 21 and arranged vertically upward, the lifting jack shaft 210 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com