Wrap around carton packaging machine

a carton and packaging machine technology, applied in the field of packaging machines, can solve the problems of less production of systems, less packaging, and more expensive pre-formed cartons to buy,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

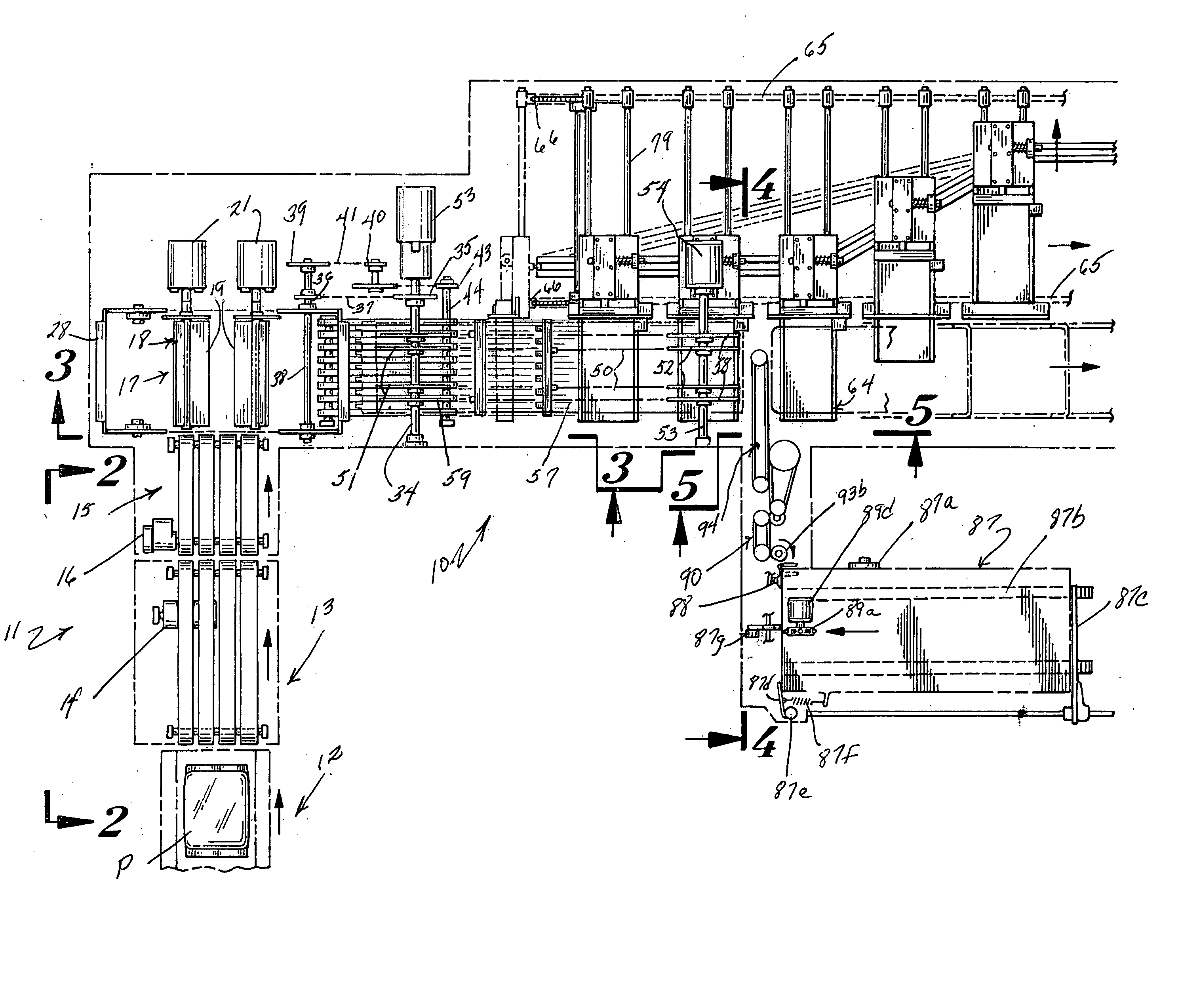

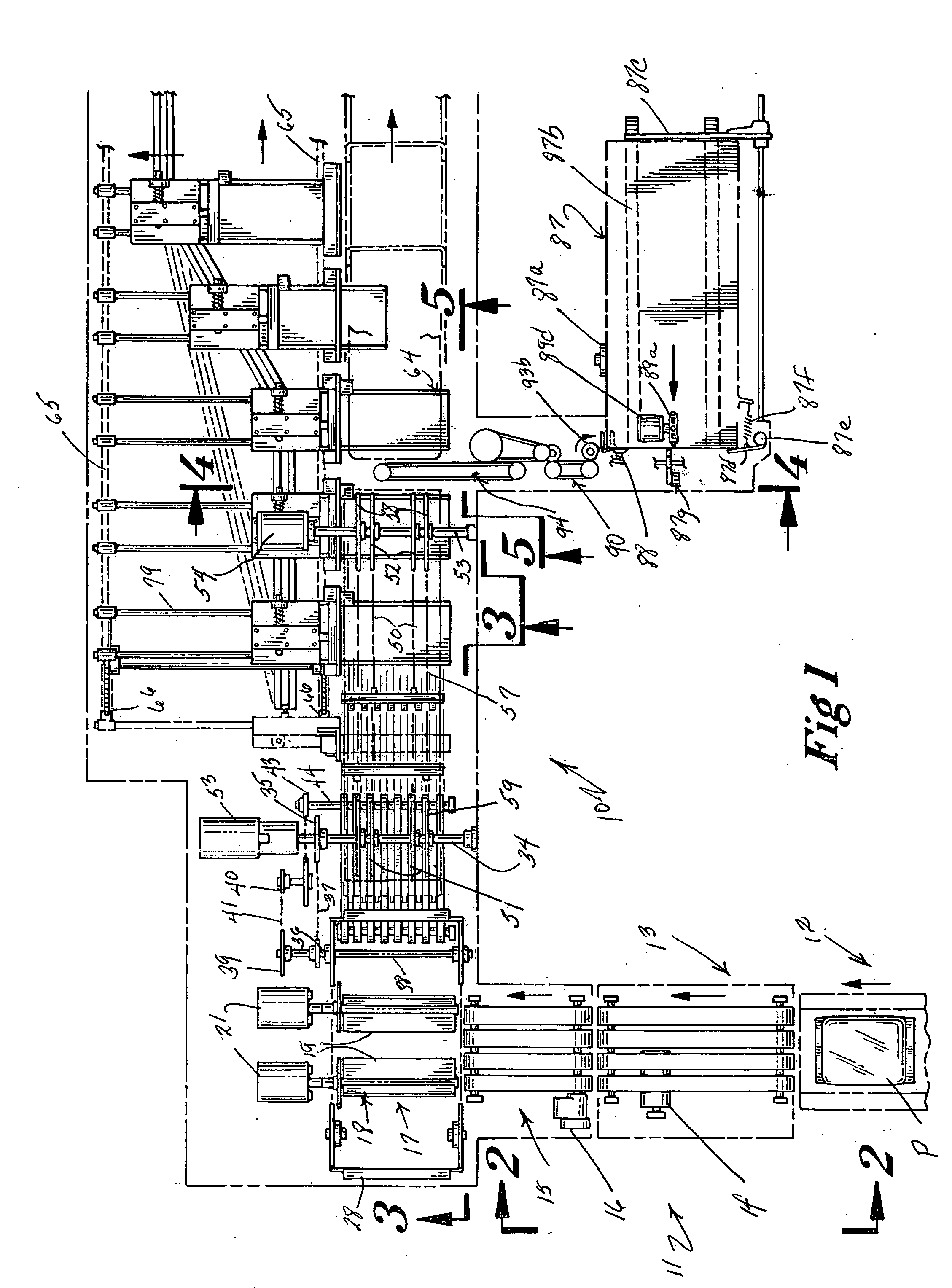

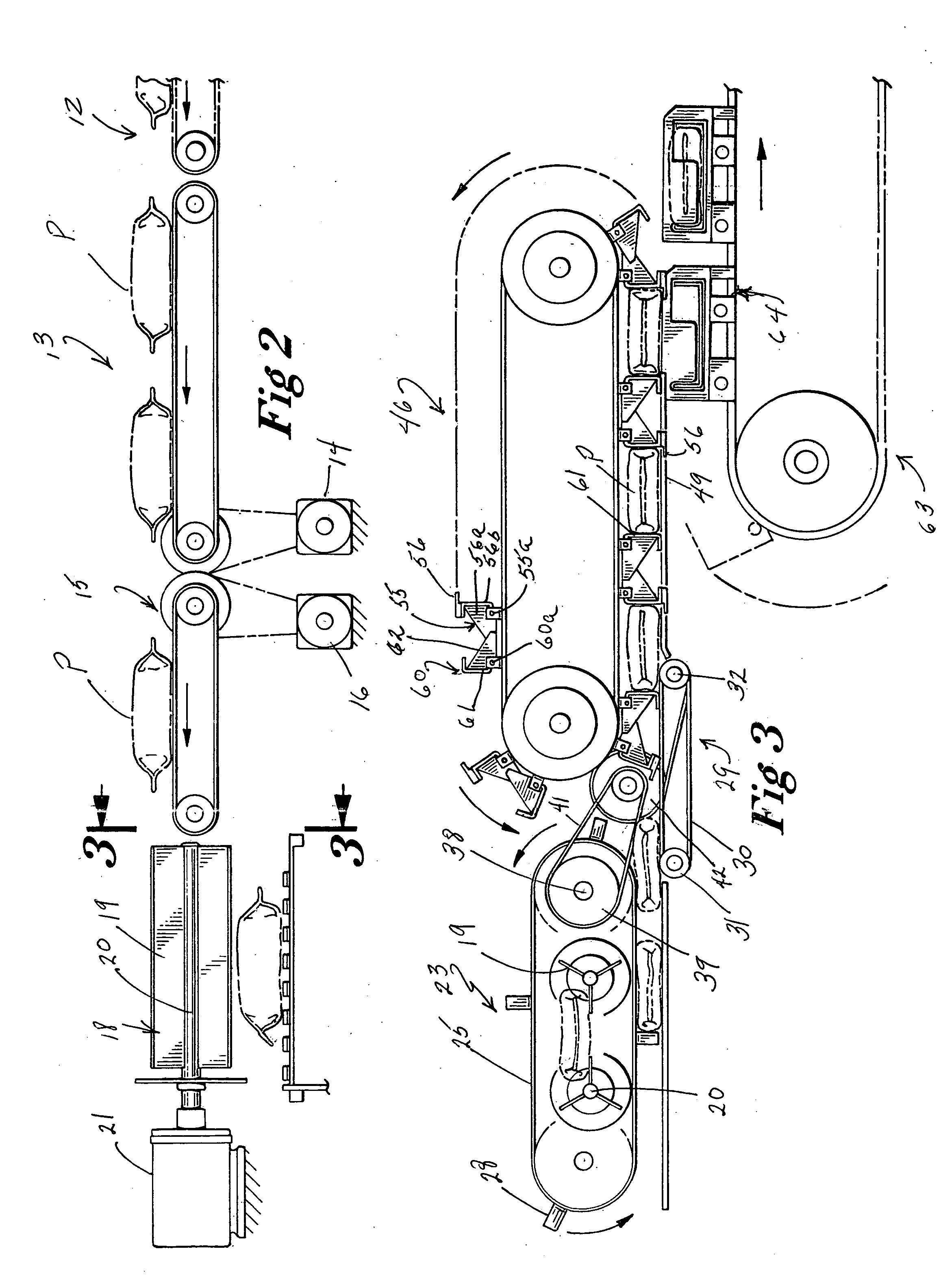

[0033] Referring now to the drawings, and more particularly to FIG. 1, it will be seen that the novel wrap around packaging apparatus or machine 10 is thereshown. The wrap around apparatus wraps the carton blank around a product rather than inserting the product into a preformed carton. In the embodiment shown, the product is cereal although the novel wrap around packaging apparatus may be used to carton other types of product.

[0034] As used herein, the term blank refers to a single piece of packaging material that has been shaped, sized and scored in preparation for use in a packaging process. Various components of the apparatus are driven by precision electrically controlled motion generating devices (PECMGD). Three common types of PECMGD are servomotors, stepper motors, and variable frequency drive motors (VFD). There are also other types of PECMGD but servomotors and VFD motors are preferred in the embodiment shown.

[0035] The term mandrel as used herein comprises a rigid struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com