3D visual outsole glue spraying workstation and using method thereof

A workstation, 3D technology, applied in applications, spray devices, clothing, etc., can solve the problems of low use efficiency of glue guns, difficult to remove, and troublesome cleaning process, and achieve novel overall structure, reduce spray volume, and increase area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below through specific embodiments.

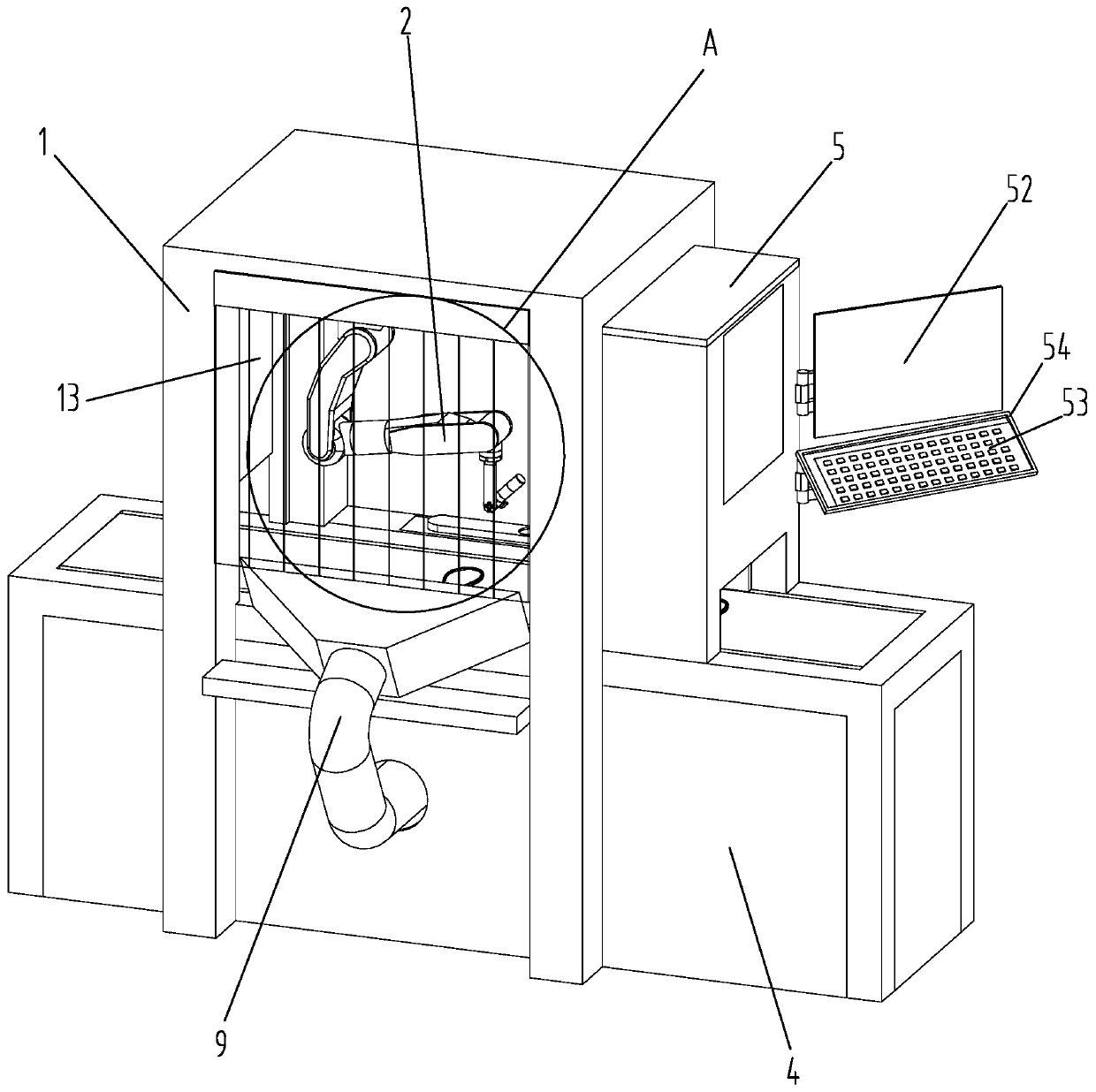

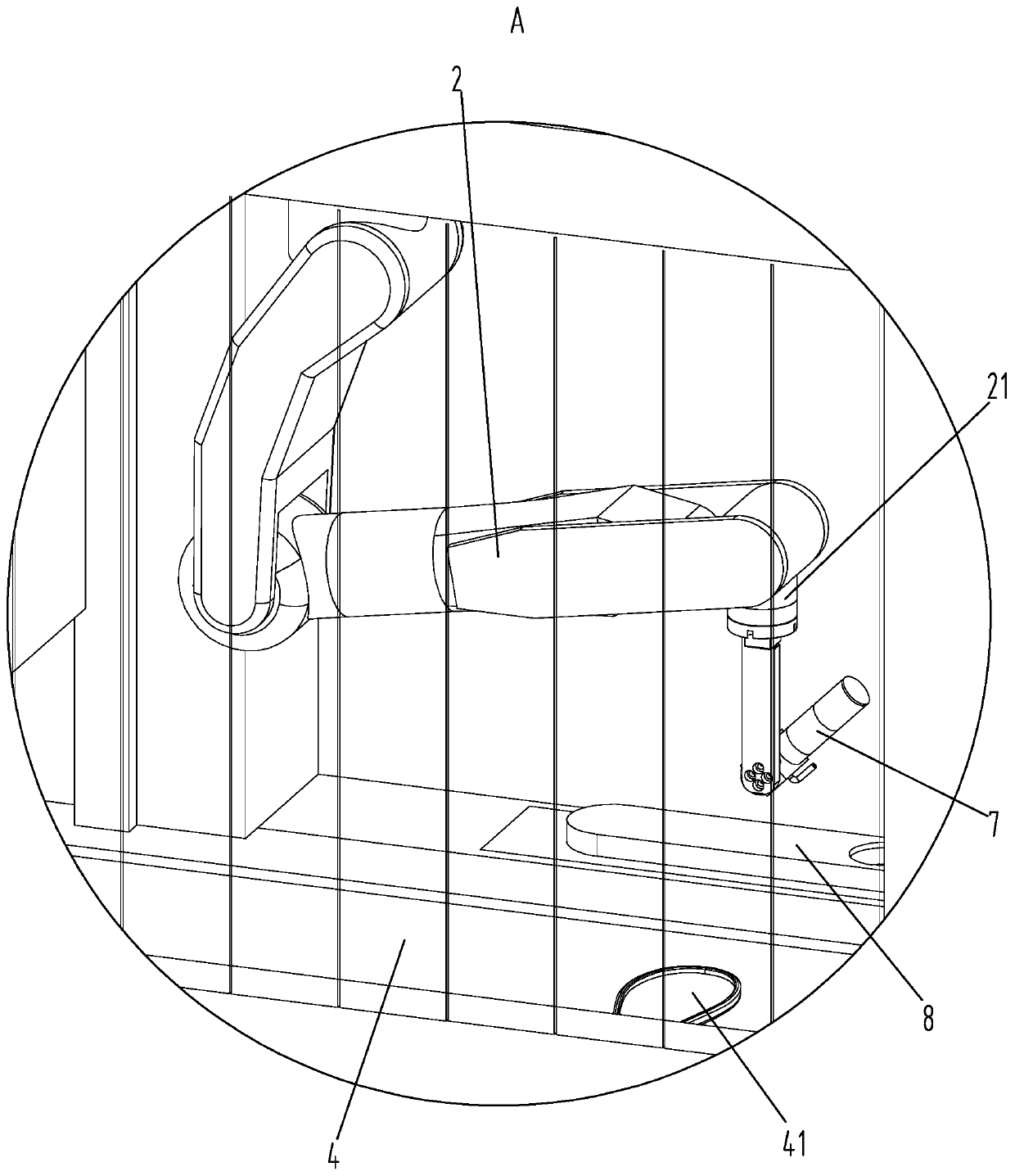

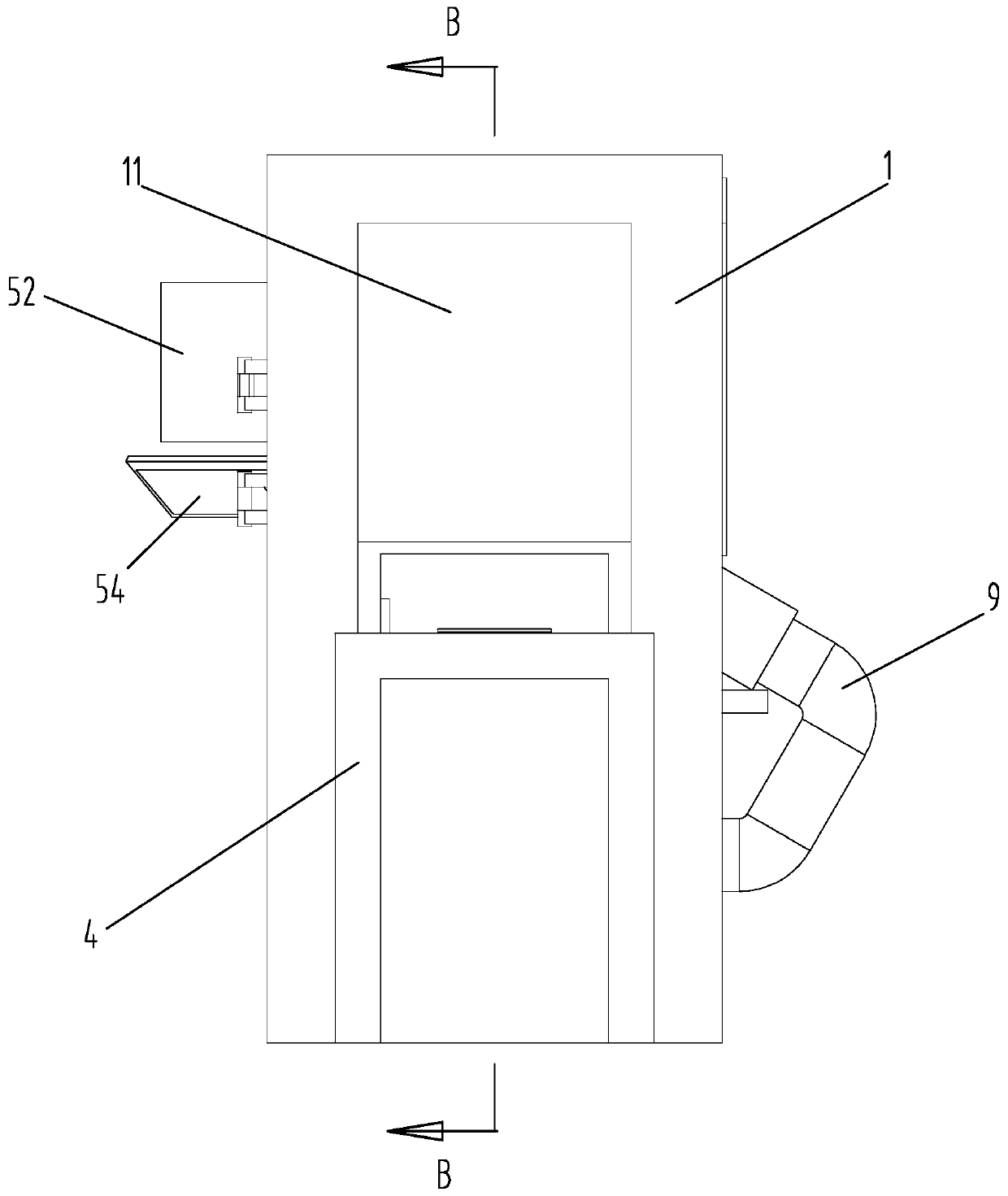

[0042] Such as Figure 1 to Figure 6 As shown, a kind of 3D visual outsole glue spraying workstation according to the present invention is characterized in that it includes a support frame 1, an intelligent manipulator 2, a photoelectric sensor 3, a delivery platform 4, an electric control cabinet 5 and a 3D profile scanner 6, The electric control cabinet 5 is arranged on one side of the support frame 1, and the 3D contour scanner 6 is arranged directly above the feeding end of the conveying platform 4 and installed in the electric control cabinet 5. The electric control cabinet 5. There is a scanning port 51 at the bottom, the photoelectric sensor 3 is fixed on the feeding end of the delivery platform 4, the intelligent manipulator 2 is fixed on the inner top surface of the support frame 1, and the delivery platform 4 is horizontally arranged on the Below the intelligent manipulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com