Automatic FPC reinforcing board laminating machine

A technology of reinforcing plate and laminating machine, which is applied in the secondary processing of printed circuits, printed circuit parts, electrical components, etc. The steps of strengthening the plate are cumbersome and other problems, so as to achieve the effect of improving the efficiency of the assembly and quickly brushing the glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

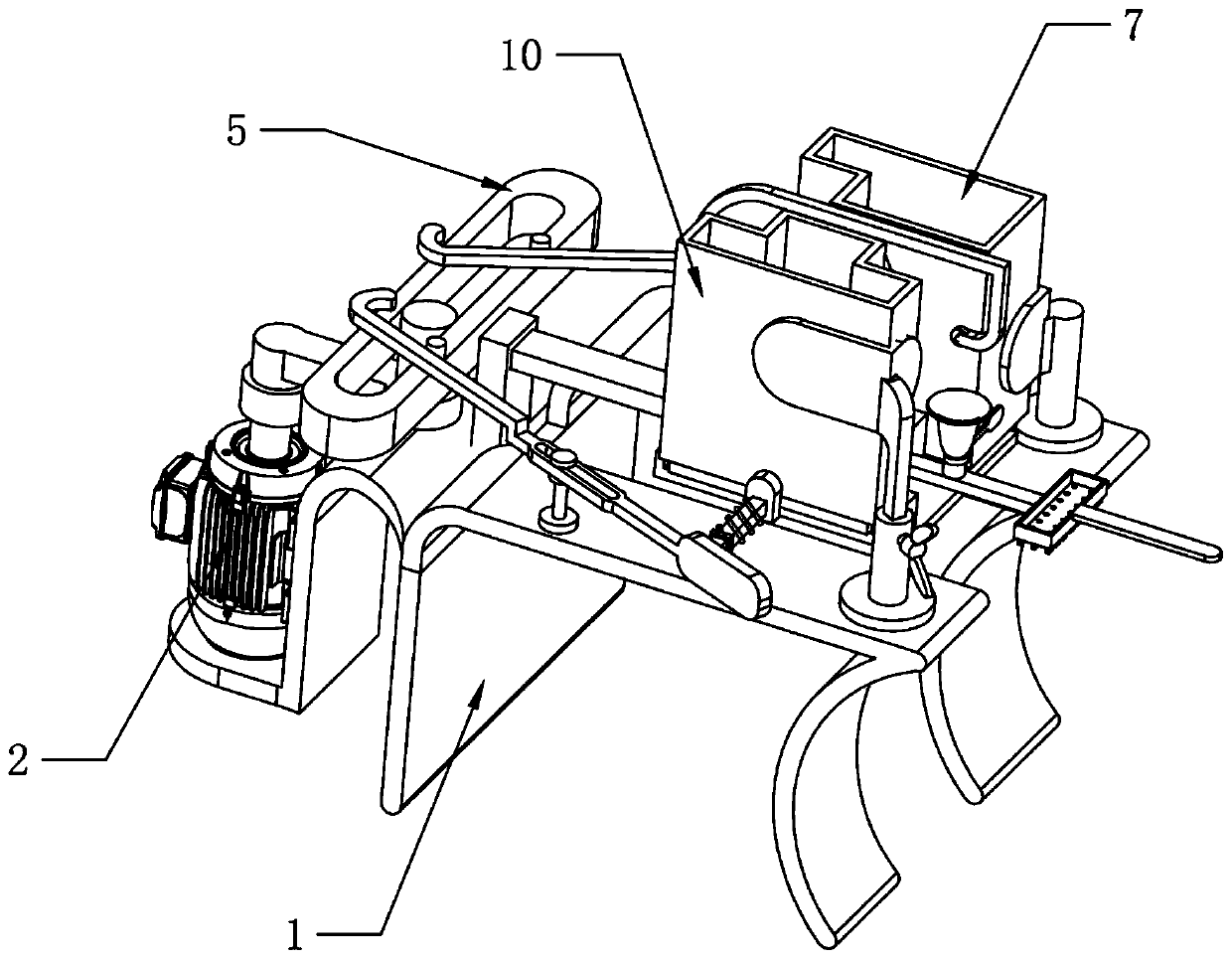

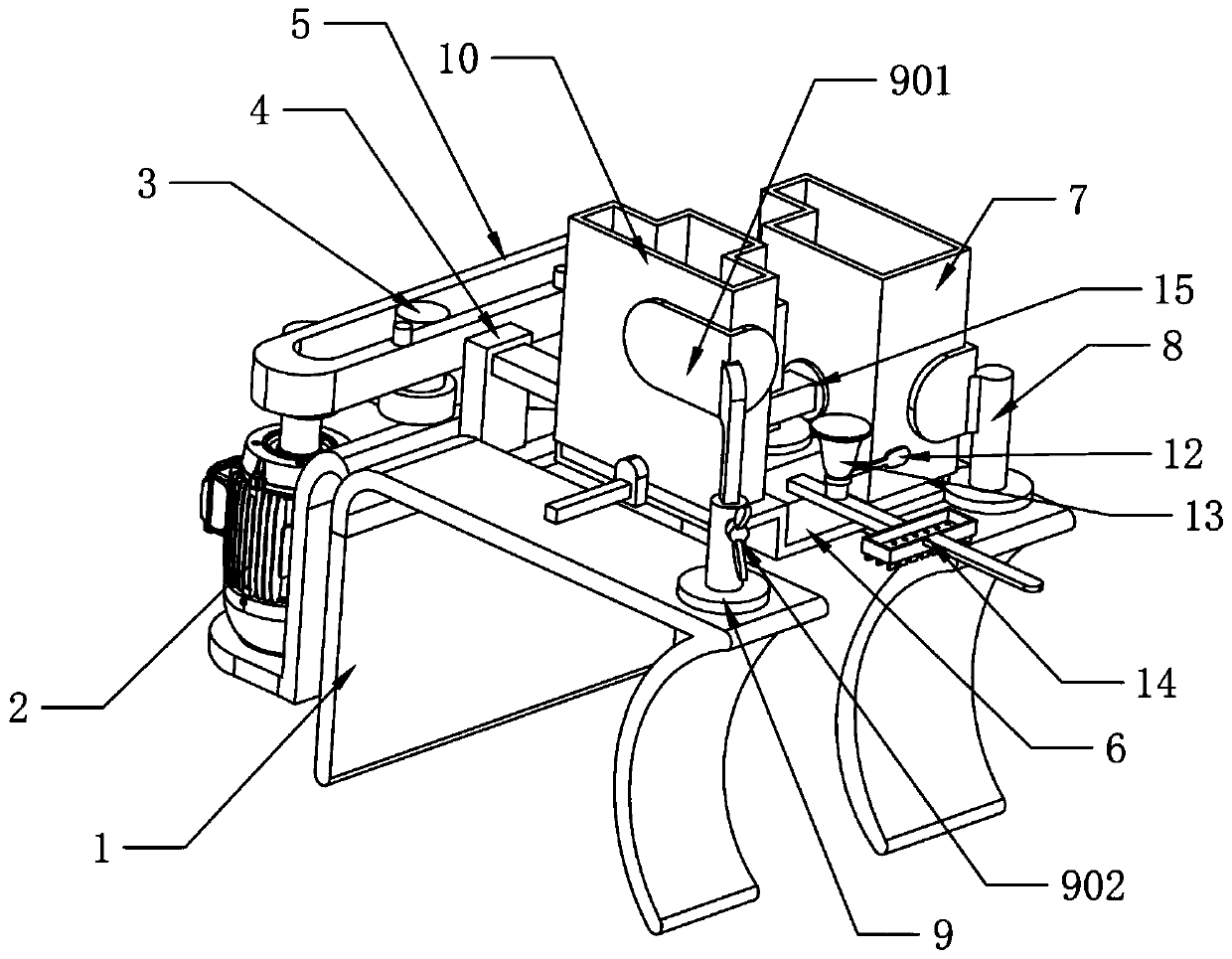

[0024] A kind of automatic FPC reinforcing plate bonding machine, such as Figure 1-2 As shown, it includes a frame, a pushing mechanism, a support frame 8, a reinforcement plate placement box 7, a movable seat mechanism, an FPC board placement box 10, a support plate 6, a pushing mechanism, a mounting block 15, a pressing plate 16 and a brush Adhesive mechanism, the frame 1 is equipped with a push mechanism, a support frame 8, a support plate 6 and a movable seat mechanism, the push mechanism is connected with a glue brushing mechanism, and the reinforcing plate placement box 7 is installed on the top of the frame 1 through the support frame 8 On the rear side, the FPC board placement box 10 is installed on the upper front side of the frame 1 through the movable seat mechanism, the support plate 6 is fixed on the upper middle part of the frame 1, and the support plate 6 is located in the reinforcing plate placement box 7 and the FPC board placement box 10 Right below, the pus...

Embodiment 2

[0027] A kind of automatic FPC reinforcing plate bonding machine, such as figure 2 As shown, the pushing mechanism includes a servo motor 2, a rocker arm 3, a slideway 4 and a moving frame 5. The servo motor 2 is installed on the left side of the frame 1, and the output shaft of the servo motor 2 is connected with a rocker through a coupling. The arm 3 and the slideway 4 are fixed on the upper left middle part of the frame 1, the slideway 4 is located on the left side of the support plate 6, the moving frame 5 is T-shaped, and its T-shaped bar extension part slides with the slideway 4 Its T-shaped bar extends from left to right to the right side of the frame 1, and the lateral part of the moving frame 5 has a chute, and the moving frame 5 is set on the 3 rocker arms through the chute, and the moving frame 5 and the rocker arm 3 pieces of active connections.

[0028] Wherein, the movable seat mechanism includes a base 9, a connecting plate 901 and a lock nut 902, the base 9 i...

Embodiment 3

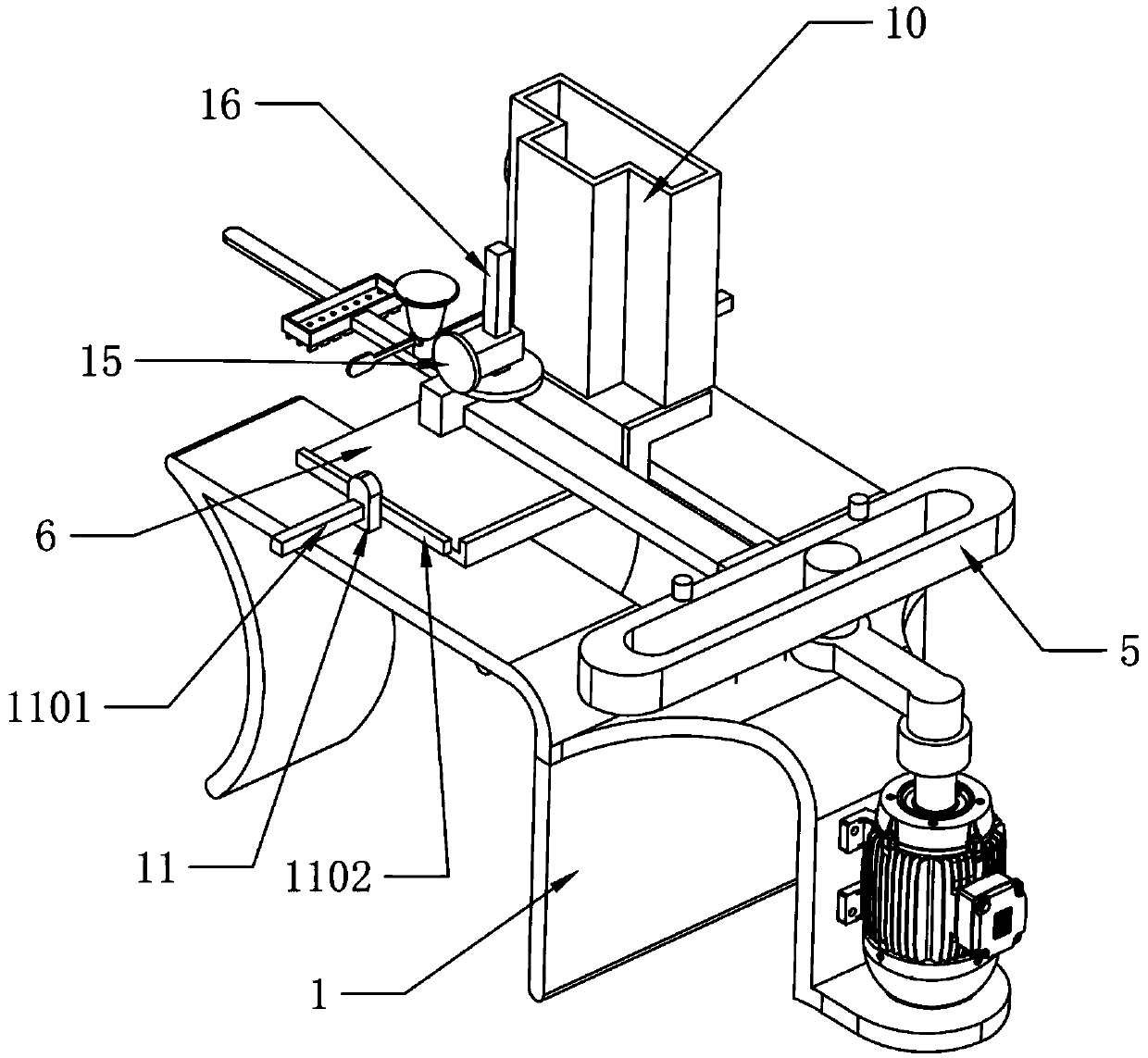

[0036] A kind of automatic FPC reinforcing plate bonding machine, such as Figure 3-5 As shown, a mechanism for pushing the guide rods 1101 on both sides to move is also included.

[0037] Wherein, the mechanism that pushes the guide rods 1101 on both sides to move includes a left rotating seat 17, a left swinging lever 18, a roller 19, a return spring 20, a right rotating seat 21, a right swinging lever 22 and a toggle post 501. Seat 17 is installed on the said frame 1, and left rotating seat 17 is arranged on reinforcing plate placement box 7 rear sides, and left swing bar 18 is provided with chute, and left swing bar 18 is flexibly connected to the left side by the chute on it. Rotating seat 17, wherein both sides guide rod 1101 ends are all equipped with roller 19, all are covered with back-moving spring 20 on its guide rod 1101, and right rotating seat 21 is installed on the said frame 1, and right rotating seat 21 It is arranged on the front side of the FPC board placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com