Intelligent fuse glue sealing machine of environment-friendly firework

An environmentally friendly fireworks, sealing machine technology, applied in the direction of fireworks, devices for coating liquid on the surface, attack equipment, etc., can solve the problems of unstable product quality, inconsistent extrusion force, personal impact, etc., to save labor costs And the production cost, the glue output is uniform and the effect of reducing glue waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be used in various industries that require sealing and gluing. The application of the present invention will be described in detail below using the sealing process of the outer cylinder of fireworks, but it does not mean that the present invention can only be used in the fireworks industry.

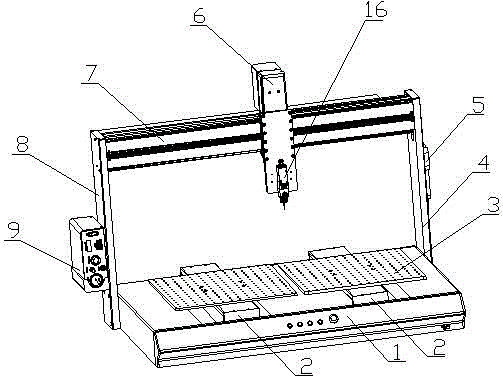

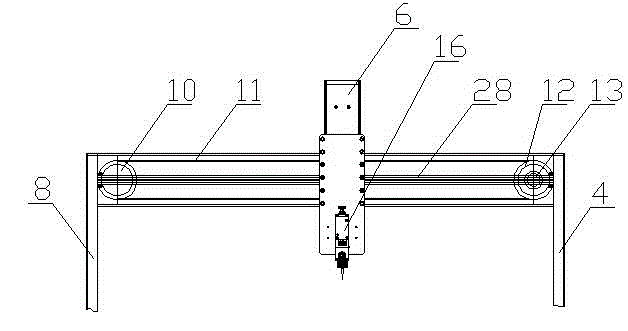

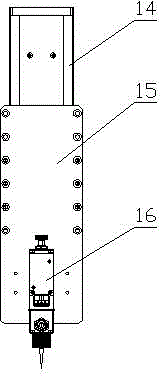

[0019] Such as figure 1 As shown in the figure, an intelligent lead wire sealing machine for environmental protection and environmental protection of firecrackers, including a glue barrel, a dispensing head 16, an X-axis robot arm 7, a Y-axis robot arm 2, a Z-axis robot arm 6, a bottom box 1, a working Platform 3, left column 8, right column 4. The bottom box 1 is made of stainless steel sheet, and the front part of the bottom box 1 is provided with a sealant test switch, a run / pause switch, a stop switch, a reset switch, an emergency stop switch, and 5 communication interfaces for a programmer.

[0020] Bottom box 1 both sides are respectively equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com