Easily-recognized and easily-unwound composite expansion adhesive tape and preparation method thereof

An easy-to-identify and tape technology, applied in the direction of film/sheet adhesives, adhesives, adhesive types, etc., can solve the problems of low expansion ratio of intumescent films, difficulty in industrial production, and high unwinding force of tapes, and achieve the same The effect of good capacitance, stable and clear color retention, and easy unwinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

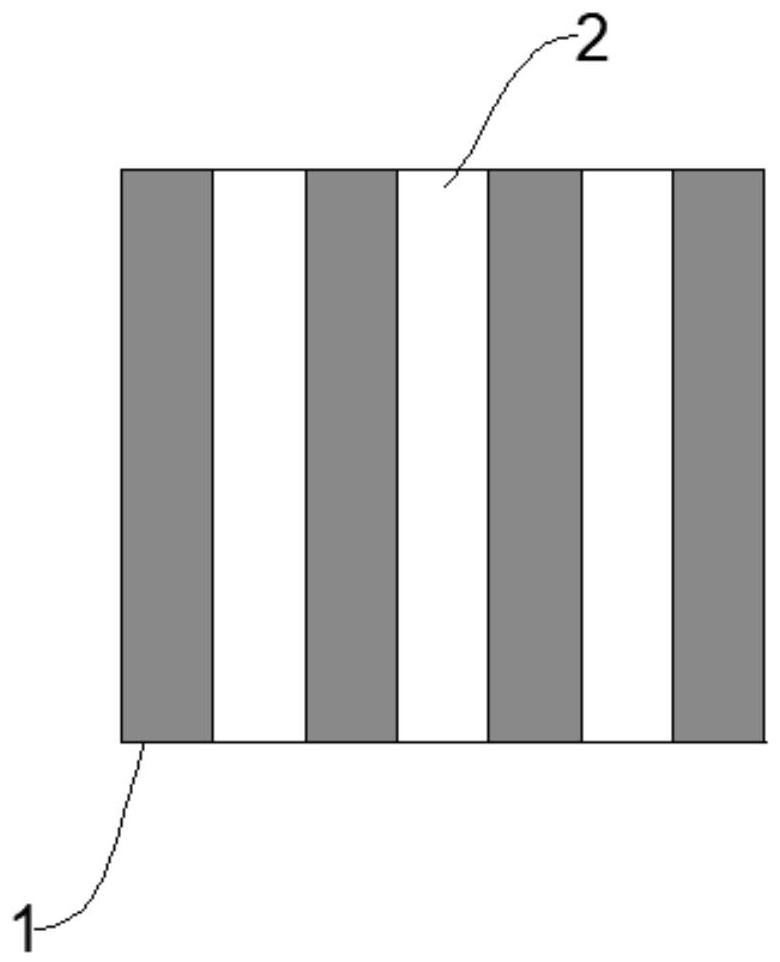

[0040] figure 1 A structural diagram of the second rubber viscosity of the composite expansion tape provided by the present embodiment. 1 is the rubber area, 2 is the detail area.

[0041] A method of preparing a composite expansion tape that is easy to unconflexible, specifically comprising the steps of:

[0042] Step 1: 50μmPET film as a temperature resistant layer, including back pairs of corona surfaces and non-electric disoste, continuously coating transparent polyacrylate glue, forming a first rubber, thickness at 50 μmPET film 10μm;

[0043] Step 2: The 50 μmPET film coated with the first rubber layer is solidified after the oven is solidified with the corona surface of the expanded film (50 μm thickness);

[0044] Step 3: The blue polyacrylate glue is applied in the width direction of the 25 μmPET from the width direction of the 25 μmPET to form a second gel layer, the thickness of 6 μm; the second rubber layer includes along the tape The width direction interval sets the...

Embodiment 2

[0052] A method of preparing a composite expansion tape that is easy to unconflexible, specifically comprising the steps of:

[0053] Step 1: 50μmPET film as a temperature resistant layer, including back pairs of corona surfaces and non-electric disoste, continuously coating transparent polyacrylate glue, forming a first rubber, thickness at 50 μmPET film 8μm;

[0054] Step 2: 50 μmPET membranes coated with the first rubber viscosity were solidified with an electric silica surface of the expansion film (40 μm thick) after the oven;

[0055] Step 3: The blue polyacrylate glue is applied in the width direction of the 25 μmPET from the width direction of the 25 μmPET to form a second rubber viscous layer, and the thickness is 8 μm; the second rubber is included. The width direction interval sets the rubber area and the detail.

[0056] Step 4: 25 μmPET release film coated with a second rubber layer was solidified with a 50 μmPET film.

[0057] Step 5: Target, remove 25 μmPet release ...

Embodiment 3

[0063] A method of preparing a composite expansion tape that is easy to unconflexible, specifically comprising the steps of:

[0064] Step 1: 50μmPET film as a temperature resistant layer, including back pairs of corona surfaces and non-electric disoste, continuously coating transparent polyacrylate glue, forming a first rubber, thickness at 50 μmPET film 6μm;

[0065] Step 2: 50 μmPET membranes coated with the first rubber viscosity were solidified with an electric silica surface of the expansion film (40 μm thick) after the oven;

[0066] Step 3: Blue polyacrylate glue is applied in the width direction of 25 μmPET from the width direction of 25 μmPET, and the thickness is 10 μm, and the second rubber viscosity layer includes along the tape. The width direction interval sets the rubber area and the detail.

[0067] Step 4: 25 μmPET release film coated with a second rubber layer was solidified with a 50 μmPET film.

[0068] Step 5: Target, remove 25 μmPet release film.

[0069] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com