Double-sided adhesive tape applicator for cartons

A technology of glue sticking and double-sided tape, which is applied in the field of carton double-sided tape and glue machine, which can solve the problems of skewed stickers, high product quality, and wrinkling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

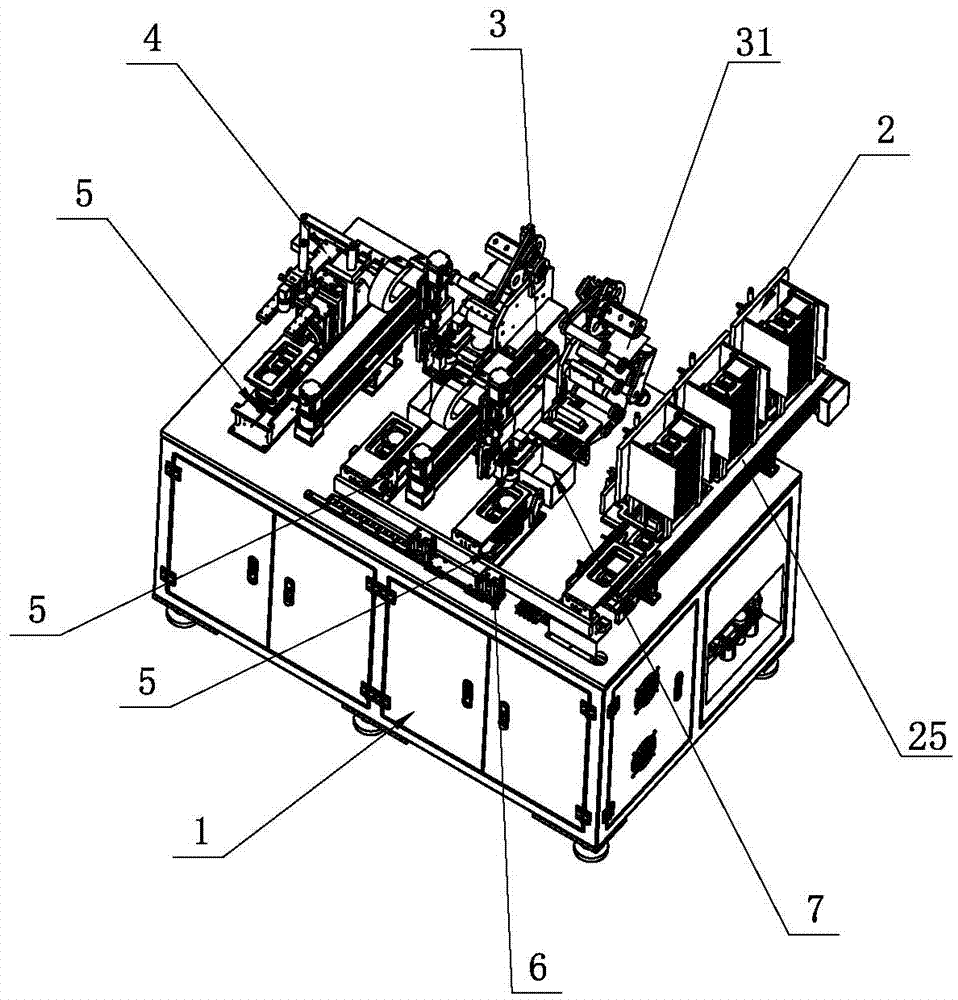

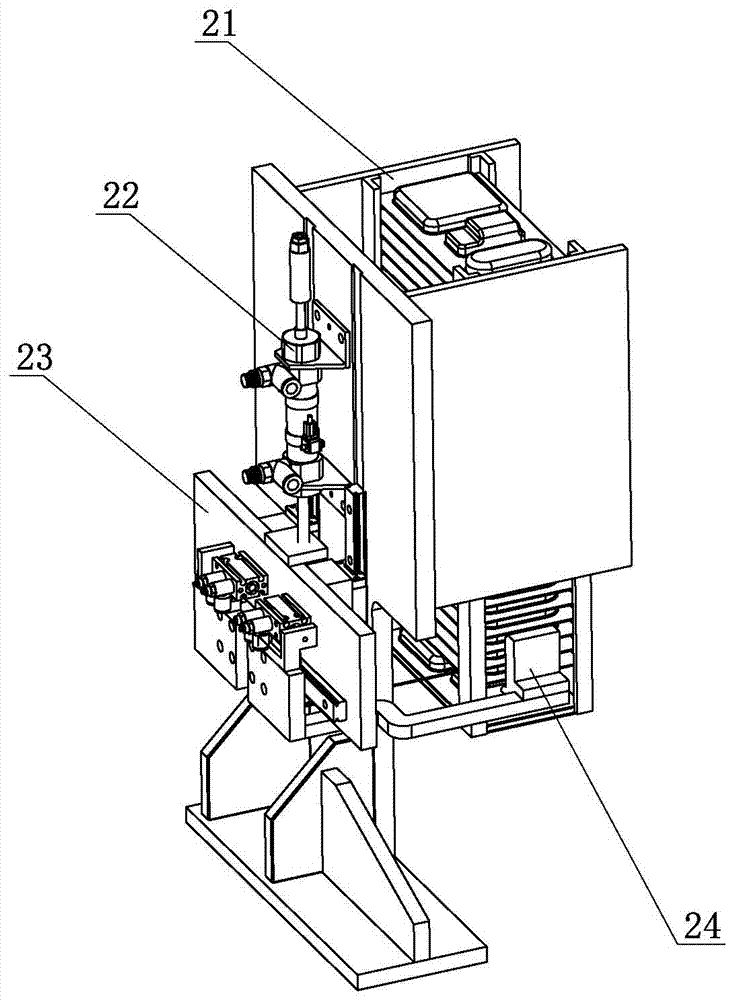

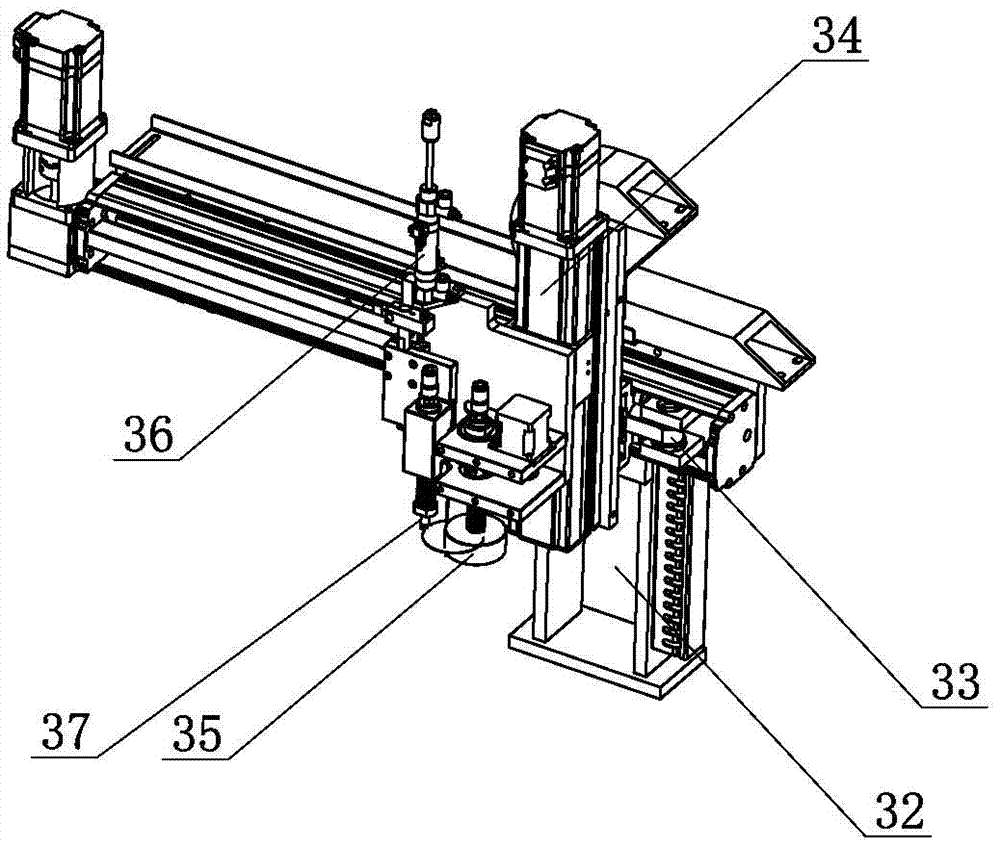

[0025] Such as Figure 1 to Figure 7 As shown, a carton double-sided tape gluing machine of the present invention includes a frame 1, and the frame 1 is sequentially arranged with a carton discharging mechanism 2, a double-sided tape gluing mechanism 3 and a carton turning mechanism 4. Both the front ends of the double-sided tape sticking mechanism 3 and the carton turning mechanism 4 are provided with a carton positioning mechanism 5, and the frame 1 is also provided with a carton for transporting the carton of the carton discharge mechanism 2 to the paper box. The carton transport manipulator 6 on the box positioning mechanism 5. The carton discharge mechanism 2 releases the cartons to be glued one by one, the carton transport manipulator 6 sucks the cartons and places them on the carton positioning mechanism 5 in front of the double-sided adhesive glue sticking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com