Device and method for automatic circulation material distribution control of furnace top ore bin of vertical furnace ore returning furnace

A technology of automatic circulation and material distribution, applied in furnaces, vertical furnaces, furnace types, etc., can solve problems such as large area, frequent operations by operators, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

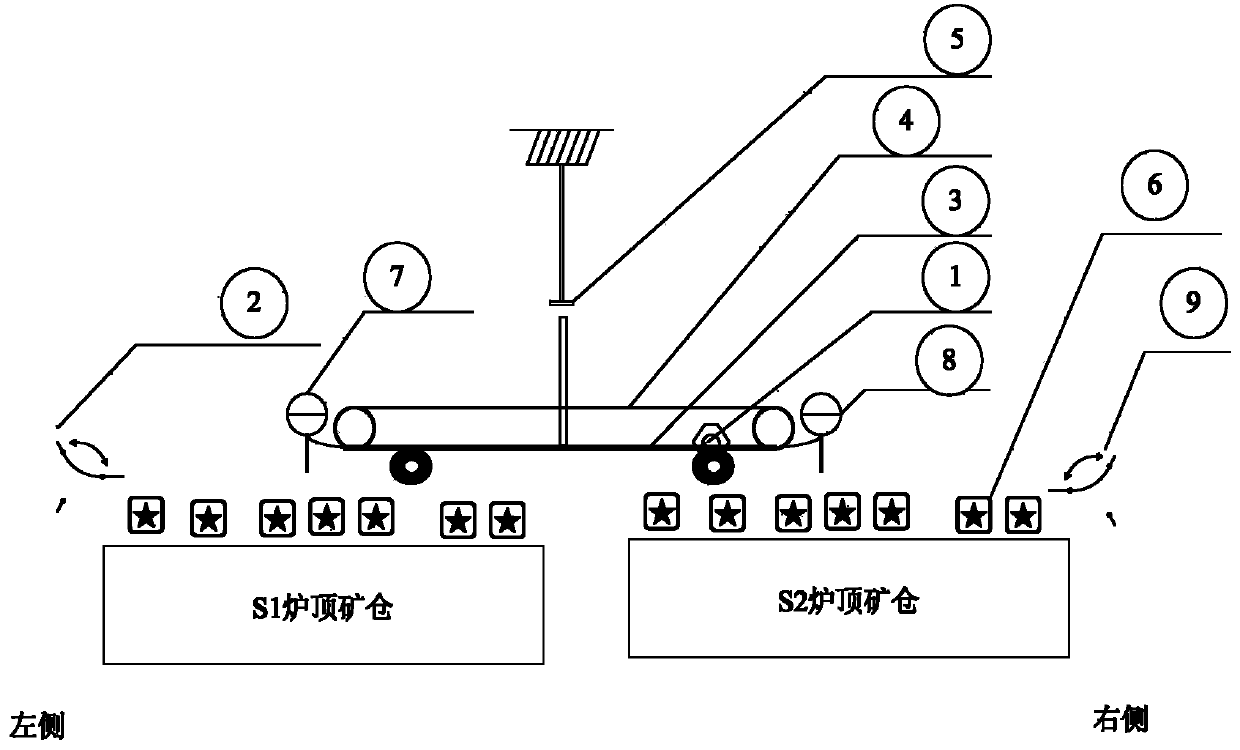

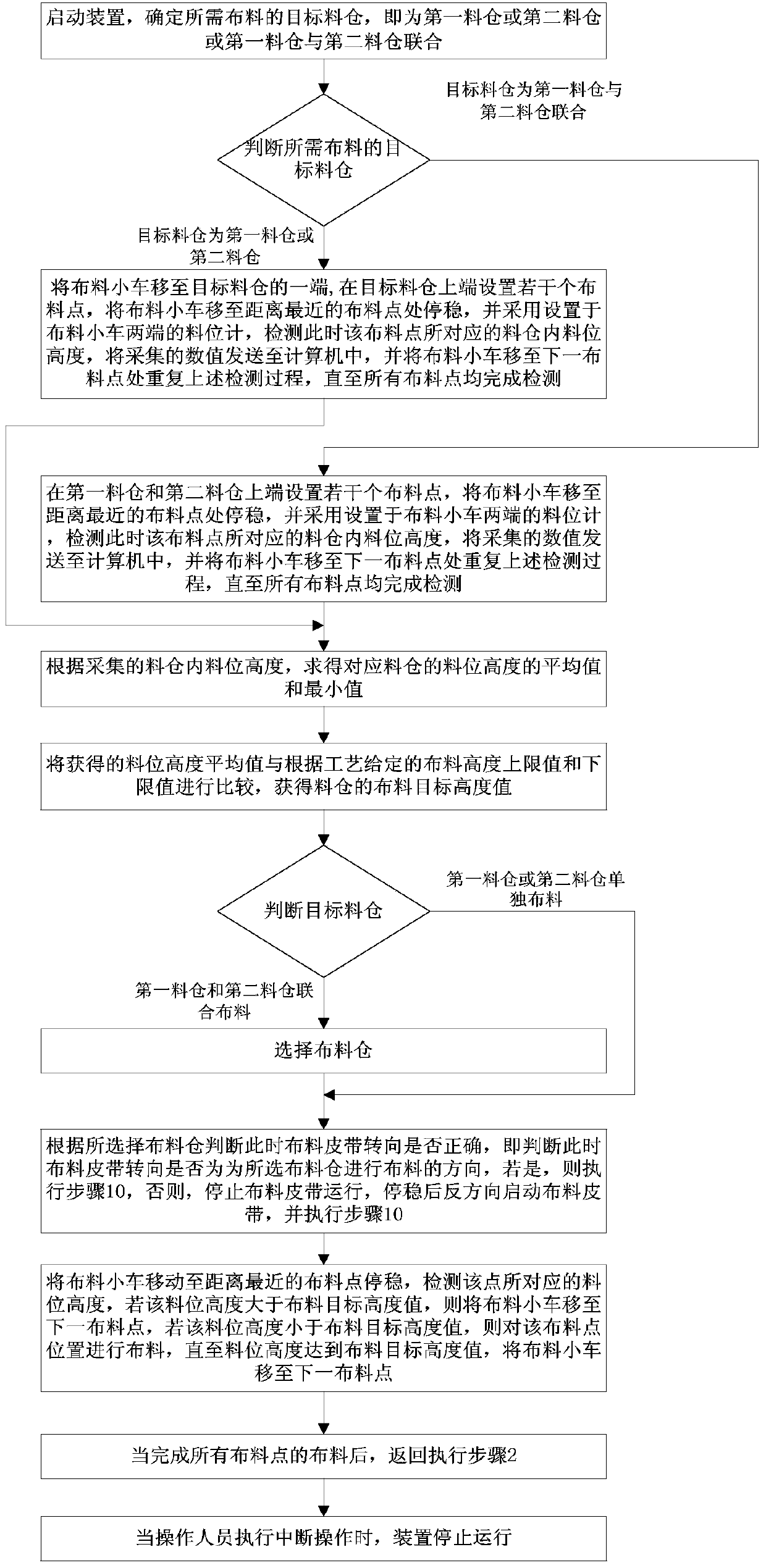

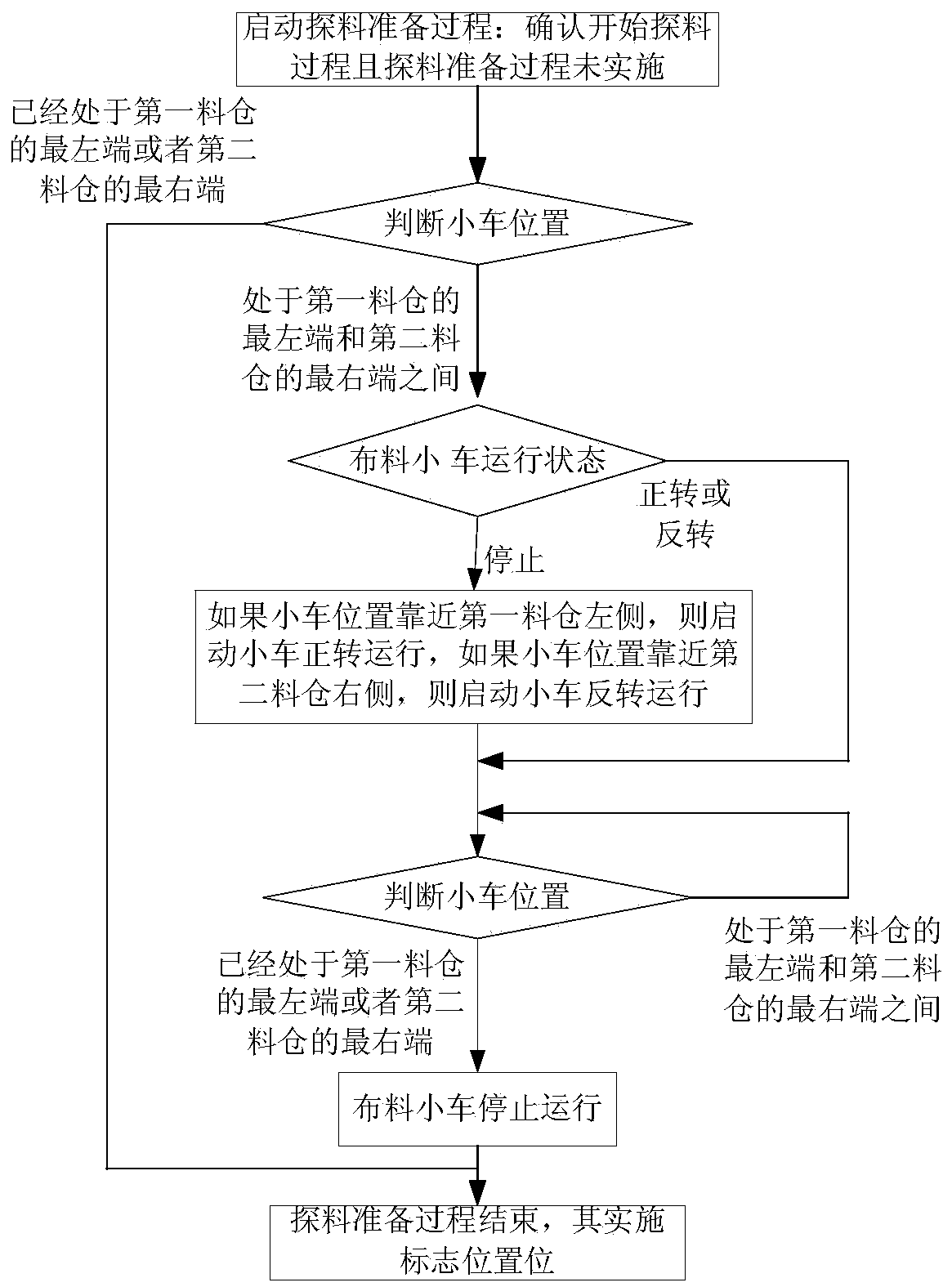

[0049] like figure 1 As shown, in the embodiment of the present invention, taking the process flow of using the reversible material distribution belt 4 and the material distribution trolley 3 as the material for the return ore bin S1 and the return ore bin S2 as an example, the upstream feeding belt is a reversible distribution belt. Material, the reversible warehouse belt conveyor trolley forward turns to S1 mine cloth, the reversible warehouse belt conveyor trolley reverses to S2 mine fabric, the reversible warehouse belt conveyor is fixed on the reversible warehouse belt conveyor On the belt conveyor trolley, it moves with the fabric trolley. The material distributing system composed of the feeding belt, the distributing belt and the distributing trolley, its device part includes: the first material level gauge 7, the second material level gauge 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com